4/3, 4/2 and 3/2 directional valve with wet-pin DC solenoids

4/3, 4/2 and 3/2 directional valve with wet-pin DC solenoids

4/3, 4/2 and 3/2 directional valve with wet-pin DC solenoids

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

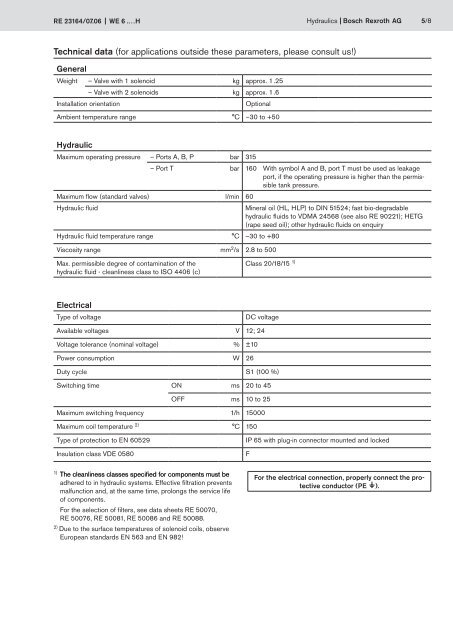

RE 23164/07.06 WE 6 .…H Hydraulics Bosch Rexroth AG 5/8<br />

Technical data (for applications outside these parameters, please consult us!)<br />

General<br />

Weight – Valve <strong>with</strong> solenoid kg approx. .25<br />

– Valve <strong>with</strong> 2 <strong>solenoids</strong> kg approx. .6<br />

Installation orientation Optional<br />

Ambient temperature range °C –30 to +50<br />

Hydraulic<br />

Maximum operating pressure – Ports A, B, P bar 3 5<br />

– Port T bar 60 With symbol A <strong>and</strong> B, port T must be used as leakage<br />

port, if the operating pressure is higher than the permissible<br />

tank pressure.<br />

Maximum flow (st<strong>and</strong>ard <strong>valve</strong>s) l/min 60<br />

Hydraulic fluid Mineral oil (HL, HLP) to DIN 5 524; fast bio-degradable<br />

hydraulic fluids to VDMA 24568 (see also RE 9022 ); HETG<br />

(rape seed oil); other hydraulic fluids on enquiry<br />

Hydraulic fluid temperature range °C –30 to +80<br />

Viscosity range mm 2 /s 2.8 to 500<br />

Max. permissible degree of contamination of the<br />

hydraulic fluid - cleanliness class to ISO 4406 (c)<br />

Electrical<br />

Class 20/ 8/ 5 )<br />

Type of voltage <strong>DC</strong> voltage<br />

Available voltages V 2; 24<br />

Voltage tolerance (nominal voltage) % ± 0<br />

Power consumption W 26<br />

Duty cycle S ( 00 %)<br />

Switching time ON ms 20 to 45<br />

OFF ms 0 to 25<br />

Maximum switching frequency /h 5000<br />

Maximum coil temperature 2) °C 50<br />

Type of protection to EN 60529 IP 65 <strong>with</strong> plug-in connector mounted <strong>and</strong> locked<br />

Insulation class VDE 0580 F<br />

) The cleanliness classes specified for components must be<br />

adhered to in hydraulic systems. Effective filtration prevents<br />

malfunction <strong>and</strong>, at the same time, prolongs the service life<br />

of components.<br />

For the selection of filters, see data sheets RE 50070,<br />

RE 50076, RE 5008 , RE 50086 <strong>and</strong> RE 50088.<br />

2) Due to the surface temperatures of solenoid coils, observe<br />

European st<strong>and</strong>ards EN 563 <strong>and</strong> EN 982!<br />

For the electrical connection, properly connect the protective<br />

conductor (PE ).