Mathcad - LAPD condenser heat transfer area. rev ... - LArTPC DocDB

Mathcad - LAPD condenser heat transfer area. rev ... - LArTPC DocDB

Mathcad - LAPD condenser heat transfer area. rev ... - LArTPC DocDB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

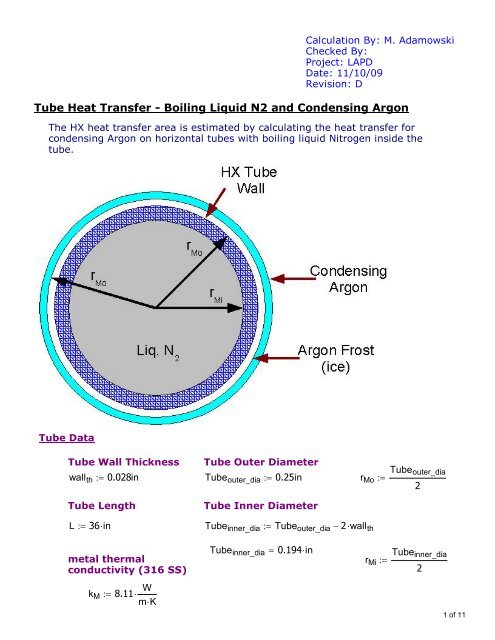

Calculation By: M. Adamowski<br />

Checked By:<br />

Project: <strong>LAPD</strong><br />

Date: 11/10/09<br />

Revision: D<br />

Tube Heat Transfer - Boiling Liquid N2 and Condensing Argon<br />

The HX <strong>heat</strong> <strong>transfer</strong> <strong>area</strong> is estimated by calculating the <strong>heat</strong> <strong>transfer</strong> for<br />

condensing Argon on horizontal tubes with boiling liquid Nitrogen inside the<br />

tube.<br />

Tube Data<br />

Tube Wall Thickness Tube Outer Diameter<br />

Tube outer_dia<br />

wall th 0.028in<br />

Tube outer_dia 0.25in<br />

r Mo <br />

2<br />

Tube Length<br />

Tube Inner Diameter<br />

L 36in<br />

Tube inner_dia Tube outer_dia 2wall th<br />

metal thermal<br />

conductivity (316 SS)<br />

Tube inner_dia<br />

<br />

0.194in<br />

r Mi<br />

<br />

Tube inner_dia<br />

2<br />

k M 8.11<br />

W<br />

mK<br />

1 of 11

Argon Data<br />

Argon physical properties from NIST REPROP<br />

argon liquid density argon vapor density argon liquid visc<br />

ρ Ar_l 1396<br />

kg<br />

ρ Ar_v 0.4<br />

lb<br />

µ Ar_l .261cP<br />

m 3<br />

ft 3<br />

argon liq thermal conductivity<br />

argon ice thermal conductivity<br />

k Ar.liq<br />

128.5<br />

mW<br />

k ice 133<br />

mW<br />

mK<br />

mK<br />

argon condensing<br />

argon <strong>heat</strong> of vaporization<br />

temperature<br />

T Ar 87.8K<br />

h Ar_fg 161<br />

kJ h Ar_fg 69.21754<br />

BTU<br />

kg<br />

lbm<br />

argon freezing temperature<br />

T Ar_freeze<br />

83.8K<br />

T ice T Ar_freeze<br />

2 of 11

Nitrogen Data<br />

Nitrogen physical properties from NIST REPROP<br />

Nitrogen boiling temperature<br />

Nitrogen liquid thermal cond.<br />

T N2<br />

77.3K<br />

k N2_liq 144<br />

mW<br />

mK<br />

Nitrogen liquid density<br />

Nitrogen Heat of<br />

Vaporization<br />

ρ N2_liq 807<br />

kg<br />

Hvap N2 199<br />

kJ<br />

m 3<br />

kg<br />

Nitrogen Vapor<br />

Density<br />

ρ N2_gas 4.5<br />

kg<br />

m 3<br />

Nitrogen Liquid<br />

Viscosity<br />

µ N2_l .162cP<br />

Nitrogen Liquid specific<br />

<strong>heat</strong><br />

Cp N2_l 0.77<br />

kJ<br />

kgK<br />

Mass flow of N2 based on<br />

70% outlet vapor quality<br />

Massflow N2 <br />

240<br />

lb hr<br />

3 of 11

Heat Load<br />

The <strong>heat</strong> load on the HX is taken as twice the <strong>heat</strong> absorbed by the <strong>LAPD</strong> tank<br />

from the environment. Using twice the tank <strong>heat</strong> provides a design margin.<br />

Tank <strong>heat</strong><br />

2106W<br />

Q req 2Tank <strong>heat</strong><br />

Q req 4212W<br />

Boiling Nitrogen Heat Transfer Coefficient<br />

Excess Nitrogen is used to keep the tube side wetted. Under these conditions<br />

the Nitrogen boiling <strong>heat</strong> <strong>transfer</strong> coefficient will be uniform for the whole<br />

tube length.<br />

h N2_boil 1500<br />

kW<br />

m 2 K<br />

this N2 boiling <strong>heat</strong> <strong>transfer</strong> coefficient is<br />

at a a minimum N2 mass flux.<br />

N2 massflux_for_h 70<br />

kg<br />

m 2 s<br />

ref: "Flow boiling <strong>heat</strong> <strong>transfer</strong> characteristics of<br />

nitrogen in plain and wire coil inserted tubes", International Journal of<br />

Heat and Mass Transfer 50 (2007)<br />

4 of 11

Tube <strong>heat</strong> <strong>transfer</strong><br />

The tube <strong>heat</strong> <strong>transfer</strong> is calculated as concentric rings of <strong>heat</strong> <strong>transfer</strong>. The<br />

rings are inner tube metal surface, tube metal wall, Argon ice layer and outer<br />

ice surface. The calculations are arranged starting inside the tube at liquid N2<br />

temperature and then proceeds through the concentric rings to the tube<br />

outside at condensing Argon temperature.<br />

To start the calculation, initial guesses are made for the tube inside metal<br />

temperature and the <strong>heat</strong> flux, q.<br />

Initial Guesses<br />

h Mi<br />

q 200W<br />

h N2_boil<br />

The <strong>heat</strong> <strong>transfer</strong> calculations are define with a <strong>Mathcad</strong> GIVEN block to allow<br />

use of <strong>Mathcad</strong>'s equation solving ability.<br />

Given<br />

q<br />

T Mi T N2 <br />

2π<br />

L<br />

r Mi<br />

h Mi<br />

inner surface formula arranged to solve<br />

for inside tube metal temperature<br />

T Mo T Mi q<br />

<br />

<br />

<br />

<br />

ln r Mo<br />

2π<br />

r Mi<br />

k M<br />

<br />

<br />

<br />

L<br />

<br />

metal tube wall formula arranged to solve<br />

for outside tube metal temperature<br />

<br />

<br />

r ice r Mo exp T Mo T ice<br />

2π<br />

q<br />

k ice<br />

L<br />

<br />

<br />

<br />

Argon ice layer formula arranged to<br />

solve for the radius of the outside<br />

ice surface.<br />

wall ice r ice r Mo<br />

Given block continues on next page >>><br />

5 of 11

Given block continues from p<strong>rev</strong>ious page<br />

The ice outside <strong>heat</strong> <strong>transfer</strong> coefficent is for condensing Argon. This<br />

coefficient is estimated as condenstion on a horizontal tube.<br />

h Ar_condi<br />

<br />

<br />

<br />

<br />

<br />

0.728 g ρ 3<br />

Ar_l ρ Ar_l ρ Ar_v k Ar.liq <br />

<br />

Tube outer_dia µ Ar_l T ice T Ar<br />

<br />

h Ar_fg<br />

<br />

<br />

<br />

1<br />

4<br />

h Ar_cond<br />

<br />

Reh Ar_condi <br />

use the real portion of the 4th root solution<br />

ref: Heat, Mass and Momentum Transfer, by Rohsenow, 1961,<br />

pg 248, Condensation on horizontal tube formula.<br />

q <br />

2π<br />

r ice<br />

<br />

Lh Ar_cond T ice T Ar<br />

outer ice layer <strong>heat</strong> <strong>transfer</strong> formula<br />

arranged to solve for <strong>heat</strong><br />

<strong>transfer</strong>red.<br />

Find the solution to the given equations<br />

Find( q)<br />

q 214.57319W<br />

wall ice 0.06621mm<br />

q<br />

<strong>heat</strong>flux Mi 2π<br />

r Mo L<br />

<strong>heat</strong>flux Mi 11.76293 kW<br />

<br />

<br />

m 2<br />

h Ar_cond 2880.66079<br />

W<br />

m 2 K<br />

6 of 11

Summary of results for require Q of: Q req 4212W<br />

T N2<br />

<br />

77.3 K<br />

wall ice<br />

<br />

0.06621mm<br />

T Mi 77.30942K<br />

T Mo 78.39797K<br />

T ice<br />

<br />

83.8 K<br />

T Ar<br />

<br />

87.8 K<br />

Estimate the Total HX <strong>area</strong> based on outside tube diameter:<br />

HX <strong>area</strong>_o<br />

HX tube_count<br />

Q req<br />

2π<br />

r Mo L<br />

HX <strong>area</strong>_o 3.85428ft 2<br />

q<br />

HX <strong>area</strong>_o<br />

HX tube_count 19.62967<br />

2π<br />

L<br />

r Mo<br />

N2 Mass flux<br />

Massflux N2 <br />

Massflow N2<br />

2<br />

HX tube_count π<br />

r Mi<br />

The N2 massflux for the number of<br />

tubes needed should be equal or<br />

higher than the N2 massflux for the<br />

N2 boiling <strong>heat</strong> <strong>transfer</strong> coefficient.<br />

<br />

Ans if Massflux N2 N2 massflux_for_h<br />

"solution is good"<br />

"massflux low for N2 h data"<br />

<br />

Ans<br />

"solution is good"<br />

Massflux N2 80.77943<br />

kg<br />

m 2 s<br />

7 of 11

Calc <strong>heat</strong> flux for tube inside surface<br />

Heatflux i <br />

2π<br />

Q req<br />

r Mi<br />

L<br />

Q req<br />

q<br />

Heatflux i 15158.41968<br />

W m 2<br />

Calc of overall U<br />

U all<br />

Q req<br />

W<br />

U all 1120.2794<br />

T N2 T Ar HX <strong>area</strong>_o<br />

m 2 U all 197.29261 <br />

K<br />

BTU<br />

hrft 2<br />

R<br />

Calc of tube inlet velocity<br />

V tube_inlet<br />

Massflux N2<br />

V tube_inlet 0.32841<br />

ft<br />

s<br />

ρ N2_liq<br />

8 of 11

N2 Horizontal Tube boiling <strong>heat</strong> <strong>transfer</strong> estimate<br />

Shah Correlation with adjustment for horizontal plain tubes<br />

ref: Engineering Databook III by Wolverine Tube, Inc.<br />

Vapor quality to use in calc<br />

x 0.1<br />

Liquid Froude number<br />

2<br />

Massflux N2<br />

Fr L Fr L 0.20728<br />

2<br />

ρ N2_liq g<br />

Tubeinner_dia<br />

IF Fr.L is greater than 0.04 then the following calc applies<br />

calc Shah's C.o factor<br />

<br />

<br />

1 x<br />

C o <br />

x<br />

<br />

<br />

<br />

0.8<br />

<br />

<br />

<br />

<br />

ρ N2_gas<br />

ρ N2_liq<br />

<br />

<br />

<br />

0.5<br />

C o 0.43308<br />

set Shah's N parameter equal to C.o for this method<br />

N<br />

<br />

C o<br />

9 of 11

calc liquid Reynolds number<br />

<br />

<br />

Massflux N2 1 x Tube inner_dia<br />

Re L Re L 2211.3819<br />

µ N2_l<br />

calc liquid Prandtl number<br />

Cp N2_l µ N2_l<br />

Pr L Pr L 0.86625<br />

k N2_liq<br />

calc liquid phase convective <strong>heat</strong> <strong>transfer</strong> coefficient<br />

by Dittus-Boelter correlation<br />

k N2_liq<br />

0.8 0.4<br />

α L 0.023Re L Pr L <br />

α L 300.776<br />

Tube inner_dia<br />

W<br />

m 2 K<br />

calc convective boiling <strong>heat</strong> <strong>transfer</strong> coefficient from the<br />

liquid phase convective <strong>heat</strong> <strong>transfer</strong> coefficient<br />

α cb<br />

1.8α L<br />

α cb 277.18293<br />

N 0.8<br />

W<br />

m 2 K<br />

10 of 11

calc the boiling number which characterizes nucleate boiling<br />

B o<br />

<br />

Heatflux i<br />

Massflux N2 Hvap N2<br />

B o 0.00094<br />

set appropriate value for Shah's F.s constant<br />

F s 15.43<br />

F.s equals 14.7 when B.o is greater than 0.0011<br />

F.s equals 15.43 when B.o is less than 0.0011<br />

calc the nucleate boiling <strong>heat</strong> <strong>transfer</strong> coefficient<br />

α nb<br />

<br />

0.5<br />

α L F s B o exp 2.74N<br />

0.15<br />

<br />

<br />

α nb 401.84662<br />

W<br />

m 2 K<br />

the two phase flow boiling <strong>heat</strong> <strong>transfer</strong> coefficient is taken<br />

as the larger valve of conventive boiling or nucleate boiling<br />

α tp<br />

<br />

<br />

max α cb α nb<br />

α tp 401.84662<br />

W<br />

m 2 K<br />

The Steiner and Taborek (1992) database has the nucleate boiling <strong>heat</strong> <strong>transfer</strong><br />

coefficient for Nitrogen as 4380 W/m2-K.<br />

The literature value used, 1500 W/m2-K for Nitrogen boiling falls within between<br />

the conservative estimate and the database value of Steiner and Taborek. The<br />

values uses is not too conservative and not too aggressive.<br />

ref: Engineering Data Book III, Wolverine Tube, Inc.<br />

11 of 11