General Catalogue RITMO - KIV Marketing Corporation

General Catalogue RITMO - KIV Marketing Corporation

General Catalogue RITMO - KIV Marketing Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

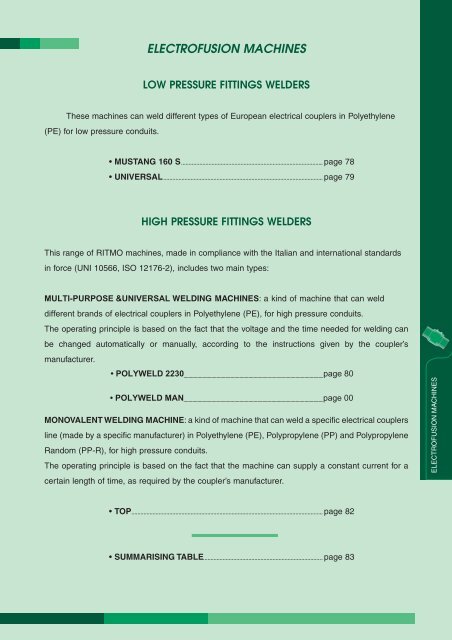

ELECTROFUSION MACHINES<br />

LOW PRESSURE FITTINGS WELDERS<br />

These machines can weld different types of European electrical couplers in Polyethylene<br />

(PE) for low pressure conduits.<br />

• MUSTANG 160 S page 78<br />

• UNIVERSAL page 79<br />

HIGH PRESSURE FITTINGS WELDERS<br />

This range of <strong>RITMO</strong> machines, made in compliance with the Italian and international standards<br />

in force (UNI 10566, ISO 12176-2), includes two main types:<br />

MULTI-PURPOSE &UNIVERSAL WELDING MACHINES: a kind of machine that can weld<br />

different brands of electrical couplers in Polyethylene (PE), for high pressure conduits.<br />

The operating principle is based on the fact that the voltage and the time needed for welding can<br />

be changed automatically or manually, according to the instructions given by the coupler’s<br />

manufacturer.<br />

• POLYWELD 2230______________________________page 80<br />

• POLYWELD MAN______________________________page 00<br />

MONOVALENT WELDING MACHINE:a kind of machine that can weld a specific electrical couplers<br />

line (made by a specific manufacturer) in Polyethylene (PE), Polypropylene (PP) and Polypropylene<br />

Random (PP-R), for high pressure conduits.<br />

The operating principle is based on the fact that the machine can supply a constant current for a<br />

certain length of time, as required by the coupler’s manufacturer.<br />

ELECTROFUSION MACHINES<br />

• TOP page 82<br />

• SUMMARISING TABLE page 83

MUSTANG 160 S<br />

MUSTANG 160 S<br />

This electrofusion machine is suitable for welding electrical couplers in<br />

Polyethylene (PE) from Ø 32 to Ø 160 mm, for low-pressure conduits.<br />

The MUSTANG 160 S is made in compliance with the current safety<br />

standards and Directives. This welding machine’s structure is lightweight, so<br />

it is extremely easy to carry around. It is distinguished by the automatic<br />

setting of the welding parameters, by the self-compensation of the current<br />

supplied (according to the ambient temperature) and by the self-diagnosis, in<br />

the event of any malfunction that could occur before or during welding.<br />

The machine features cables with pins, a transport bag and a manual<br />

scraper, most useful to remove the layer of oxidation from the pipe (which<br />

could undermine the good result of the welding).<br />

Machine body<br />

SUPPLIED WITH<br />

- Welding machine complete with cables with pins, Trevira bag and<br />

manual scraper (see page 96).<br />

ELECTROFUSION MACHINES<br />

- LOWER PRESSURE FITTINGS -<br />

Transport bag<br />

Manual scraper<br />

TECHNICAL FEATURES<br />

Working range<br />

Electrical couplers brands<br />

(low pressure HDPE)<br />

Power supply<br />

Maximum output current<br />

Maximum absorbed power<br />

Outside temperature range<br />

Temperature compensation<br />

Dimensions (W x D x H)<br />

Weight<br />

32 ÷ 160 mm<br />

Akatherm-Euro, Co.e.s., Geberit,<br />

Valsir, Wavin (Waviduo)<br />

230 V - Single phase - 50/60 Hz<br />

5 A<br />

900 W<br />

-5 ÷ +40°C<br />

Automatic electronic<br />

300 x 120 x 280 mm<br />

3,00 Kg<br />

78

UNIVERSAL<br />

This electrofusion machine is suitable for welding electrical couplers in<br />

Polyethylene (PE) from Ø 32 mm to Ø 315 mm, for low pressure conduits.<br />

The UNIVERSAL is made in compliance with the current safety standards<br />

and Directives. This welding machine’s structure is lightweight, so it is<br />

extremely easy to carry around. It is controlled by a microprocessor that<br />

allows the recognition of four different types of cable with pins, identified by a<br />

code (written on each one of them), which the operator can confirm by<br />

looking at the display. The different cables are necessary to adapt to the<br />

different kinds of electrical coupler available in the market. The main features<br />

include self-compensation of the current supplied (according to the ambient<br />

temperature) and self-diagnosis of any malfunction that could occur before or<br />

during welding.<br />

UNIVERSAL<br />

The machine features four cables with pins, a transport bag and a manual<br />

scraper, most useful to remove the layer of oxidation from the pipe (which<br />

could undermine the good result of the welding).<br />

Machine body<br />

SUPPLIED WITH<br />

- Welding machine complete with four cables with pins, Trevira bag<br />

and manual scraper (see page 96).<br />

TECHNICAL FEATURES<br />

Working range – (1)<br />

Electrical couplers brands<br />

(low pressure HDPE)<br />

Working range – (2)<br />

Electrical couplers brands<br />

(low pressure HDPE)<br />

Power supply<br />

Maximum output current<br />

Maximum absorbed power<br />

Outside temperature range<br />

Temperature compensation<br />

Dimensions (W x D x H)<br />

Weight<br />

Ø 32 ÷ 160 mm<br />

Akatherm-Euro, Co.e.s.,<br />

Geberit, Valsir, Wavin<br />

(Wavisolo & Waviduo)<br />

Ø 200 ÷ 315 mm<br />

Akatherm-Euro, Geberit,<br />

Valsir, Wavin (Wavisolo)<br />

230 V-Single phase-50/60 Hz<br />

10,7 A<br />

2500 W<br />

-5 ÷ +40°C<br />

Automatic electronic<br />

245 x 210 x 280 mm<br />

3,90 Kg<br />

Cables with pins<br />

ELECTROFUSION MACHINES<br />

- LOWER PRESSURE FITTINGS -<br />

Manual scraper<br />

79

POLYWELD 2230 & POLYWELD 2048<br />

POLYWELD<br />

Welding cable + optical pen<br />

These universal-kind of electrofusion machines are suitable for welding<br />

low voltage Polyethylene (PE) couplers (from 8 to 48 Volts) for high pressure<br />

conduits.<br />

The POLYWELD machines are made in compliance with the current<br />

European standards and directives, and distinguish themselves only by the<br />

input: 230 V for the POLYWELD 2230, and 48 V for the POLYWELD 2048.<br />

Both of them have a computer control of the welding cycle, and feature an<br />

optical pen for reading the couplers bar codes. It is possible to set<br />

voltage/time parameters manually, to store up to 150 welding cycles and to<br />

transfer them directly to a PC or printer. Any kind of information (even<br />

regarding malfunctions that could occur before or during welding) can be<br />

viewed on the display, thanks to the machines’ software.<br />

The machines are supplied with a cable with Ø 4 mm connectors, a set of<br />

Ø 4,7 mm adapters and a manual scraper, most useful to remove the layer<br />

of oxidation from the pipe (which could undermine the good result of the<br />

welding).<br />

SUPPLIED WITH<br />

- Welding machine complete with optical pen, cable with Ø 4 mm<br />

connectors and Ø 4,7 mm adapters;<br />

- Manual scraper;<br />

- Transport wooden case.<br />

Manual scraper<br />

ON REQUEST (ACCESSORIES)<br />

ELECTROFUSION MACHINES<br />

- HIGH PRESSURE FITTINGS -<br />

Transport wooden case<br />

Ø 4 / 4,7 mm adapters<br />

Special adapters for<br />

GF Elgef 24V coupler<br />

- 230 V / 48 V voltage transformer (for POLYWELD 2048);<br />

- Special adapters for electrical couplers type GF Elgef 24 V;<br />

- Special adapters for electrical couplers type FRIALEN double-wire;<br />

- Parallel printer data transfer kit, in order to transfer the welding data<br />

from the machine directly to a parallel printer (includes a Serial/Parallel<br />

converter and a Parallel/Centronics cable);<br />

- Serial printer data transfer kit, in order to transfer the welding data<br />

from the machine directly to a yard serial printer (includes a printer and<br />

a DIN/DB9 cable);<br />

- Parallel printer MEMO device with data transfer kit, in order to store<br />

the welding data and then transfer them into a parallel printer (includes<br />

a “MEMO” device with power supply and a Parallel/Centronics cable);<br />

- PC MEMO device with data transfer kit, in order to store the welding<br />

data and then transfer them into a PC (includes a “MEMO” device with<br />

power supply, a PC data transfer/management software and a<br />

DIN/DB25 cable);<br />

- PC data transfer kit, in order to transfer the welding data from the<br />

machine directly into a PC (includes a PC data transfer/management<br />

software, a DIN/DB25 M cable, a DB25 F/F adapter and a DB25 M/DB9<br />

F adapter).<br />

Special adapters for FRIALEN<br />

double-wire coupler<br />

80

TECHNICAL FEATURES<br />

Working range<br />

Electrical couplers main brands (*)<br />

(high pressure HDPE)<br />

Memory capacity<br />

Power supply<br />

Maximum output current<br />

Maximum absorbed power<br />

Welding output voltage<br />

Protection degree<br />

External T° reading probe precision<br />

Outside temperature range<br />

Display<br />

Welding hose length<br />

Connectors diameter<br />

Adapters diameter<br />

DIMENSIONS (W x D x H)<br />

Welding machine<br />

Transport wooden case<br />

WEIGHT<br />

Welding machine<br />

Transport wooden case<br />

POLYWELD POLYWELD<br />

2048 2230<br />

Various diameters - HDPE<br />

Agru, Durapipe (Durafuse),<br />

Eurostandard (Euro), Friatec<br />

(Frialen), Fusion (Fusamatic)<br />

GF (Elgef plus), Innogaz, PE<br />

Industries, Nupi (Elofit), Plasson<br />

(Fusamatic), Plastitalia (Plast),<br />

Simona, Strengweld (Streng)<br />

Uponor, Wavin (Lu-Monoline)<br />

150 welding cycles<br />

48 V 230 V<br />

Single phase 50 Hz<br />

80 A (peak at 110 A)<br />

2800 W (3500VA)<br />

8 ÷ 48 V OUTPUT<br />

IP 54<br />

±1 °C<br />

-10 ÷ +50°C<br />

4 x 20 Alphanumerical,<br />

backlighted LCD<br />

3 mt<br />

4,0 mm<br />

4,7 mm<br />

280 x 325 x 290 mm<br />

430 x 330 x 370 mm<br />

9,00 Kg 15,00 Kg<br />

9,00 Kg<br />

Parallel printer data transfer kit<br />

Serial printer data transfer kit<br />

Parallel printer MEMO device with<br />

transfer kit<br />

PC MEMO device with data transfer kit<br />

PC data transfer kit<br />

(*) Any other brand not mentioned in this list but with the same design features, that is, a<br />

constant welding voltage (ranging between 8 and 48V), with or without a bar code, and<br />

with standard Ø 4 or Ø 4.7 mm connectors, can be welded with these machines.<br />

230/48V Transformer<br />

ELECTROFUSION MACHINES<br />

- HIGH PRESSURE FITTINGS -<br />

81

TOP<br />

TOP<br />

This monovalent electrofusion machine is suitable for welding<br />

“ROLLMAPLAST” couplers, for Polyethylene (up to Ø 160 mm) and<br />

Polypropylene (up to Ø 110 mm) high pressure conduits.<br />

The TOP is made in compliance with the current safety standards and<br />

directives. The machine’s structure is lightweight, so it is extremely easy to<br />

carry around. The TOP supplies a constant current to the coupler (with an<br />

automatic current self-compensation, according to the ambient temperature),<br />

and makes a self-diagnosis of any malfunction that can occur before or<br />

during the welding.<br />

The machine is supplied with cables with pins, a transport bag and a manual<br />

scraper, most useful to remove the layer of oxidation from the pipe (which<br />

could undermine the good result of the welding).<br />

Machine body<br />

SUPPLIED WITH<br />

- Welding machine complete with cables with pins, Trevira bag<br />

and manual scraper (see page 96 ).<br />

TECHNICAL FEATURES<br />

“ROLLMAPLAST” couplers<br />

Electrical<br />

couplers brands<br />

ROLLMAPLAST<br />

(Wavin)<br />

Working range<br />

I Series Ø 20 ÷ 160 mm - PE 80<br />

LI Series Ø 20 ÷ 160 mm - PE 80<br />

LI Series Ø 20 ÷ 125 mm - PE 100<br />

Ø 20 ÷ 110 mm - PP, PP-R<br />

ELECTROFUSION MACHINES<br />

- HIGH PRESSURE FITTINGS -<br />

Manual scraper<br />

Power supply<br />

Maximum output current<br />

Maximum absorbed power<br />

Room temperature range<br />

Temperature compensation<br />

Dimensions (W x D x H)<br />

Weight<br />

230 V - Single phase - 50/60 Hz<br />

5 A<br />

890 W<br />

-5 ÷ +40°C<br />

Automatic electronic<br />

300 x 120 x 280 mm<br />

3,00 Kg<br />

82

BRAND<br />

MODEL<br />

MUSTANG 160<br />

UNIVERSAL<br />

TOP<br />

POLYWELD<br />

20 25 32 40 50 63 75 90 110 125 140 160 180 200 225 250 280 315 355<br />

L<br />

O<br />

W<br />

P<br />

R<br />

E<br />

S<br />

S<br />

U<br />

R<br />

E<br />

AKATHERM-EURO<br />

CO.E.S<br />

GEBERIT<br />

VALSIR<br />

WAVIN – Waviduo<br />

WAVIN – Wavisolo<br />

H<br />

I<br />

G<br />

H<br />

P<br />

R<br />

E<br />

S<br />

S<br />

U<br />

R<br />

E<br />

AGRU<br />

DURAPIPE – Durafuse<br />

EUROSTANDARD -Euro<br />

FRIATEC – Frialen<br />

FUSION - Fusamatic<br />

GEORG FISCHER - Elgef<br />

INNOGE – Innogaz<br />

NUPI – Elofit<br />

PLASSON – Fusamatic<br />

PLASTITALIA – Plast<br />

SIMONA<br />

STRENGWELD – Streng<br />

UPONOR<br />

Rollmaplast - PP<br />

W<br />

Rollmaplast - I PE 80<br />

A<br />

Rollmaplast - LI PE 80<br />

V<br />

Rollmaplast - LI PE 100<br />

I<br />

LU - Monoline PE 80<br />

N<br />

LU - Monoline PE 100<br />

ELECTROFUSION MACHINES<br />

20 25 32 40 50 63 75 90 110 125 140 160 180 200 225 250 280 315 355<br />

Ø not previewed<br />

Ø that can’t be welded<br />

83