LC Accessories

LC Accessories

LC Accessories

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Column Hardware<br />

L C A C C E S S O R I E S<br />

Omnifit ® Low Pressure Column Hardware<br />

• Borosilicate heavy wall glass with precision threaded<br />

ends and patented “strain free” endfittings<br />

• Bore diameter constant to ± 0.1mm<br />

• Higher pressure limits than other low pressure<br />

column hardware<br />

Each Omnifit ® glass column includes two PTFE<br />

end pieces (one fixed, one adjustable), two 1/4-28<br />

polypropylene outer caps, one frit kit (2 each: 10µm<br />

polyethylene, 10µm PTFE and 25µm PTFE), two<br />

flangeless tube endings, two gripper fittings, and two<br />

meters of 1/16" PTFE tubing.<br />

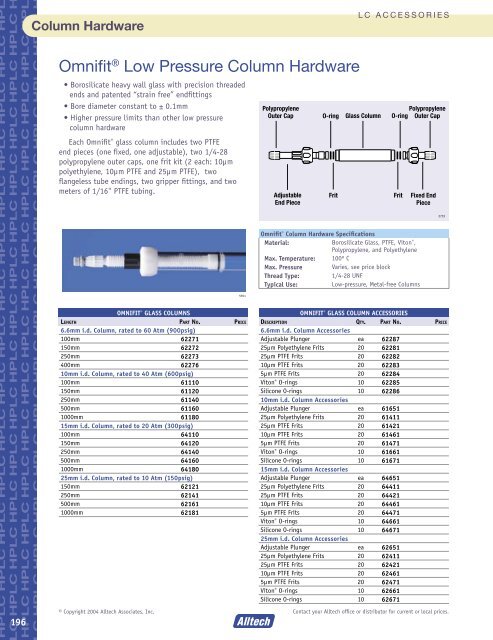

Polypropylene<br />

Outer Cap<br />

Adjustable<br />

End Piece<br />

O-ring<br />

Frit<br />

Glass Column<br />

O-ring<br />

Frit<br />

Polypropylene<br />

Outer Cap<br />

Fixed End<br />

Piece<br />

2719<br />

Omnifit ® Column Hardware Specifications<br />

Material: Borosilicate Glass, PTFE, Viton ® ,<br />

Polypropylene, and Polyethylene<br />

Max. Temperature: 100º C<br />

Max. Pressure Varies, see price block<br />

Thread Type: 1/4-28 UNF<br />

Typical Use:<br />

Low-pressure, Metal-free Columns<br />

5551<br />

196<br />

OMNIFIT ® GLASS COLUMNS<br />

LENGTH PART NO. PRICE<br />

6.6mm i.d. Column, rated to 60 Atm (900psig)<br />

100mm 62271<br />

150mm 62272<br />

250mm 62273<br />

400mm 62276<br />

10mm i.d. Column, rated to 40 Atm (600psig)<br />

100mm 61110<br />

150mm 61120<br />

250mm 61140<br />

500mm 61160<br />

1000mm 61180<br />

15mm i.d. Column, rated to 20 Atm (300psig)<br />

100mm 64110<br />

150mm 64120<br />

250mm 64140<br />

500mm 64160<br />

1000mm 64180<br />

25mm i.d. Column, rated to 10 Atm (150psig)<br />

150mm 62121<br />

250mm 62141<br />

500mm 62161<br />

1000mm 62181<br />

© Copyright 2004 Alltech Associates, Inc.<br />

OMNIFIT ® GLASS COLUMN ACCESSORIES<br />

DESCRIPTION QTY. PART NO. PRICE<br />

6.6mm i.d. Column <strong>Accessories</strong><br />

Adjustable Plunger ea 62287<br />

25µm Polyethylene Frits 20 62281<br />

25µm PTFE Frits 20 62282<br />

10µm PTFE Frits 20 62283<br />

5µm PTFE Frits 20 62284<br />

Viton ® O-rings 10 62285<br />

Silicone O-rings 10 62286<br />

10mm i.d. Column <strong>Accessories</strong><br />

Adjustable Plunger ea 61651<br />

25µm Polyethylene Frits 20 61411<br />

25µm PTFE Frits 20 61421<br />

10µm PTFE Frits 20 61461<br />

5µm PTFE Frits 20 61471<br />

Viton ® O-rings 10 61661<br />

Silicone O-rings 10 61671<br />

15mm i.d. Column <strong>Accessories</strong><br />

Adjustable Plunger ea 64651<br />

25µm Polyethylene Frits 20 64411<br />

25µm PTFE Frits 20 64421<br />

10µm PTFE Frits 20 64461<br />

5µm PTFE Frits 20 64471<br />

Viton ® O-rings 10 64661<br />

Silicone O-rings 10 64671<br />

25mm i.d. Column <strong>Accessories</strong><br />

Adjustable Plunger ea 62651<br />

25µm Polyethylene Frits 20 62411<br />

25µm PTFE Frits 20 62421<br />

10µm PTFE Frits 20 62461<br />

5µm PTFE Frits 20 62471<br />

Viton ® O-rings 10 62661<br />

Silicone O-rings 10 62671<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Column Hardware<br />

Metal-Free Analytical<br />

Column Hardware<br />

• Ideal for ion chromatography or biological separations<br />

• The inertness of PEEK with the strength of stainless<br />

steel<br />

• Column i.d. of 2.1 and 4.6mm<br />

Alltech’s metal-free analytical columns introduce<br />

a new level of mechanical strength to PEEK column<br />

hardware. By using a stainless steel outer wall with<br />

a PEEK liner, these columns have higher pressure<br />

ratings than standard PEEK hardware, but still provide a<br />

completely inert flow path. The column consists of the<br />

column tube, two PEEK endfittings and two PAT ® frit/<br />

inserts (see Figure 1).<br />

Adapters and sealing rings are available for slurry<br />

packing your own columns. The packing adapter comes<br />

with a 1/4" precolumn tube which connects directly to<br />

the 1/4" slurry reservoir kit on page 202.<br />

Metal-Free Semi-Prep<br />

Column Hardware<br />

• Scale up ion chromatography or biological separations<br />

• Chemically inert PEEK construction<br />

• Column i.d. of 7.5mm<br />

Alltech’s metal-free semi-prep MF-Plus column<br />

hardware has the mechanical strength, biocompatibility,<br />

and chemical resistance that ion chromatography<br />

and biotechnology applications demand. The column<br />

consists of a threaded PEEK tube, two PEEK endfittings,<br />

and two PAT ® frits (see Figure 2).<br />

Adapters and sealing rings are available for slurry<br />

packing your own columns. The packing adapter comes<br />

with a 3/8" precolumn tube which connects directly to<br />

the 3/8" slurry reservoir kit on page 202.<br />

2µm PAT ® Frit/Insert<br />

PEEK Frit<br />

Retaining Ring<br />

PEEK Endfitting<br />

PEEK-Lined Stainless Steel<br />

Column Tube<br />

PEEK Endfitting<br />

PEEK Column Tube<br />

(7.5mm i.d.)<br />

2µm PAT ® Frit<br />

Figure 1 – Metal-Free Analytical PEEK-Lined Column<br />

5545<br />

Figure 2 – Metal-Free Semi-Prep MF-Plus Column<br />

5546<br />

Metal-Free Analytical Column Hardware Specifications<br />

Material:<br />

PEEK, PAT ® (PEEK alloyed with PTFE),<br />

Stainless Steel Outer Tube<br />

Max. Temperature: 100º C<br />

Max. Pressure 8,000psig<br />

Thread Type: 10-32 UNF (CPI Standard Ports)<br />

Typical Use:<br />

Analytical Ion Chromatography or<br />

Biological Separations<br />

Metal-Free Semi-Prep Column Hardware Specifications<br />

Material:<br />

PEEK, PAT ® (PEEK alloyed with PTFE)<br />

Max. Temperature: 100º C<br />

Max. Pressure 5,000psig<br />

Thread Type: 10-32 UNF (CPI Standard Ports)<br />

Typical Use:<br />

Semi-prep Ion Chromatography or<br />

Biological Separations<br />

DESCRIPTION<br />

METAL-FREE ANALYTICAL HARDWARE AND ACCESSORIES<br />

QTY.<br />

2.1MM<br />

PART NO.<br />

4.6MM<br />

PART NO.<br />

Complete Columns<br />

30mm ea 66183 66143<br />

50mm ea 66184 66144<br />

100mm ea 66185 66145<br />

150mm ea 66186 66146<br />

250mm ea 66187 66147<br />

300mm ea — 66148<br />

Replacement Parts<br />

Endfitting ea 75016 75016<br />

Frit/Insert, 2µm 5 66150 66149<br />

Packing <strong>Accessories</strong><br />

Packing Adapter ea 65189 65185<br />

Packing Seals 10 65181 66162<br />

PRICE<br />

METAL-FREE SEMI-PREP HARDWARE AND ACCESSORIES<br />

DESCRIPTION<br />

QTY.<br />

7.5MM<br />

PART NO.<br />

Complete Columns<br />

50mm ea 67202<br />

100mm ea 67204<br />

150mm ea 67206<br />

250mm ea 67208<br />

300mm ea 67220<br />

Replacement Parts<br />

Endfitting ea 67140<br />

PAT ® Frit, 2µm 5 67152<br />

Frit Retainer Ring 5 67192<br />

Packing <strong>Accessories</strong><br />

Packing Adapter ea 67216<br />

Packing Seals 10 67218<br />

PRICE<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.<br />

197

Column Hardware<br />

L C A C C E S S O R I E S<br />

Stainless Steel Analytical Column Hardware<br />

• Threaded tube for easy assembly<br />

• Type 316 stainless steel construction<br />

• Column i.d. of 2.1, 3.2, 3.9, 4.1, and 4.6mm<br />

Endfitting<br />

Ferrule<br />

Frit/Insert<br />

Stop Depth<br />

(0.100")<br />

Compression<br />

Screw<br />

Frit/Insert<br />

0765<br />

Threaded Column Tube<br />

Endfitting<br />

5319<br />

Figure 1 - Stainless steel analytical columns have ports<br />

with industry standard stop depth.<br />

Stainless steel analytical columns come complete<br />

with the threaded tube, two 2µm industry standard<br />

frit/inserts, and two stainless steel endfitting nuts. The<br />

industry standard frit/insert means it will contain a stop<br />

depth equal to 0.100" (see Figure 1). Optional 0.5µm<br />

porosity frit/inserts are also available.<br />

Adapters and sealing rings are available for slurry<br />

packing your own columns (see Figure 2). The packing<br />

adapter comes with a 1/4" precolumn tube which<br />

connects directly to the 1/4" slurry reservoirs on page<br />

202.<br />

Stainless Steel<br />

Analytical Column<br />

Sealing Ring<br />

Packing Adapter<br />

Figure 2 - Packing adapter threads directly onto stainless<br />

steel analytical column tube.<br />

2730<br />

Stainless Steel Analytical Column Hardware Specifications<br />

Material:<br />

316 Stainless Steel<br />

Max. Temperature: 100º C<br />

Max. Pressure 10,000psig<br />

Thread Type: 10-32 UNF (CPI Standard Ports)<br />

Typical Use:<br />

Analytical HP<strong>LC</strong> Columns<br />

DESCRIPTION<br />

2.1MM I.D.<br />

PART NO.<br />

STAINLESS STEEL ANALYTICAL HARDWARE AND ACCESSORIES<br />

3.2MM I.D.<br />

3.9MM I.D.<br />

4.1MM I.D.<br />

PRICE PART NO. PRICE PART NO. PRICE PART NO.<br />

PRICE<br />

4.6MM I.D.<br />

PART NO.<br />

Complete Columns<br />

50mm 65175 65170 65165 65160 65150<br />

100mm 65176 65171 65166 65161 65152<br />

150mm 65177 65172 65167 65162 65154<br />

250mm 65178 65173 65168 65163 65156<br />

300mm 65179 65174 65169 65164 65158<br />

Replacement Parts<br />

Endfitting (ea) 75001 75001 75001 75001 75001<br />

Frit/Insert, 2µm (5/pk) 75028 75026 75024 75022 75020<br />

Frit/Insert, 5µm (5/pk) 75029 75027 75025 75023 75021<br />

Packing <strong>Accessories</strong><br />

Packing Adapter (ea) 65189 65188 65187 65186 65185<br />

Sealing Rings (10/pk) 65199 65198 65197 65196 65195<br />

PRICE<br />

198<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Column Hardware<br />

Stainless Steel<br />

Preparative Column<br />

Hardware<br />

• Threaded format for easy assembly<br />

• Extended column life with Alltech’s patented<br />

continuously adjustable piston (CAP )<br />

• Column i.d. of 7, 10 and 22mm<br />

Alltech’s easy-to-use preparative format has threaded<br />

endfittings and a continuously adjustable piston/frit<br />

(CAP ). The piston/frit extends column life by<br />

compressing the packed bed to remove voids.<br />

Stainless Steel Swaged<br />

Column Hardware<br />

• Passivated stainless steel for a more inert surface<br />

• Uses precision bore tubing and OptiFlow endfittings<br />

• Column i.d. of 2.1, 3.2, 4.6, 10, and 22.5mm<br />

Stainless steel swaged hardware uses precision bore<br />

seamless tubing and OptiFlow endfittings. It is the ideal<br />

choice when standard column lengths are not desirable -<br />

just cut to your specification. OptiFlow endfittings have<br />

a flow distributor which spreads the sample and eluant<br />

across the entire frit surface to improve peak symmetry<br />

and prevent frit blockage.<br />

Column Tube<br />

Continuously<br />

Adjustable<br />

Piston/Frit<br />

Endfitting<br />

2µm<br />

SS Frit<br />

Distributor<br />

Disk<br />

Endfitting<br />

Tubing<br />

Nut and<br />

Ferrule<br />

CAP<br />

5544<br />

5568<br />

Stainless Steel Preparative Column Hardware Specifications<br />

Material:<br />

316 Stainless Steel, PEEK<br />

Max. Temperature: 100º C<br />

Max. Pressure 8,000psig<br />

Thread Type: 10-32 UNF (CPI Standard Ports)<br />

Typical Use:<br />

Prep HP<strong>LC</strong> Columns<br />

Precision Bore HP<strong>LC</strong> Column Tubing Specifications<br />

Material:<br />

316 Stainless Steel<br />

Max. Temperature: 500º C<br />

Max. Pressure 8,000psig<br />

Typical Use:<br />

HP<strong>LC</strong> Column Assembly w/Swageable<br />

Endfittings<br />

STAINLESS STEEL PREPARATIVE HARDWARE AND ACCESSORIES<br />

I.D. LENGTH QTY. PART NO. PRICE<br />

Complete Columns<br />

7mm 100mm ea 96500<br />

7mm 250mm ea 96501<br />

7mm 500mm ea 96502<br />

10mm 100mm ea 96510<br />

10mm 250mm ea 96511<br />

10mm 500mm ea 96512<br />

22mm 70mm ea 96524<br />

22mm 100mm ea 96520<br />

22mm 250mm ea 96521<br />

22mm 500mm ea 96522<br />

Replacement Endfittings<br />

7mm — ea 96505<br />

10mm — ea 96515<br />

22mm — ea 96525<br />

Replacement Piston/Frit, 2µm<br />

7mm — ea 96507<br />

10mm — ea 96517<br />

22mm — ea 96527<br />

Packing Adapters*<br />

7mm — ea 96508<br />

10mm — ea 96518<br />

Packing Seals*<br />

7mm — 10 96509<br />

10mm — 10 96519<br />

*22mm packing adapters and seals are not available<br />

© Copyright 2004 Alltech Associates, Inc.<br />

PRECISION BORE TUBING<br />

PER FOOT<br />

PART NO.<br />

OPTIFLOW ENDFITTINGS*<br />

PER METER<br />

PART NO.<br />

O.D. X I.D.<br />

PRICE<br />

Precision Bore Tubing<br />

1/8" x 2.1mm 3012 30120<br />

1/4" x 2.1mm 3013 30130<br />

1/4" x 3.2mm 3011 30110<br />

1/4" x 4.6mm 3015 30150<br />

PRICE<br />

FOR USE WITH<br />

DESCRIPTION TUBING I.D. QTY. PART NO. PRICE<br />

OptiFlow Endfittings<br />

1/4" 2.1, 3.2, 4.6 ea 400612<br />

3/8" 7.0 ea 10123<br />

1/2" 10.0 ea 9205<br />

1" 2.25 ea 9204<br />

*Each fitting is supplied with a nut and ferrule for 1/16" tubing, a two micron<br />

stainless steel frit and distributor disk.<br />

Contact your Alltech office or distributor for current or local prices.<br />

199

Frits<br />

L C A C C E S S O R I E S<br />

Stainless Steel Frits<br />

• Type 316 stainless steel<br />

• Heat-passivated for a more inert surface<br />

Stainless Steel Frit Specifications<br />

Material:<br />

316 Stainless Steel<br />

Max. Temperature: 500º C<br />

Max. Pressure 10,000psig<br />

Typical Use:<br />

Column Inlet/Outlet<br />

FRIT DIAMETER THICKNESS POROSITY<br />

STAINLESS STEEL FRITS<br />

5/PK<br />

PART NO.<br />

PRICE<br />

25/PK<br />

PART NO.<br />

1/4" (6.350mm) 0.031" (0.79mm) 0.5µm 720805 720825<br />

0.031" (0.79mm) 2.0µm 721005 721025<br />

0.063" (1.59mm) 2.0µm 716505 716525<br />

3/8" (9.525mm) 0.031" (0.79mm) 0.5µm 721205 721225<br />

0.031" (0.79mm) 2.0µm 721405 721425<br />

0.063" (1.59mm) 0.5µm 718005 718025<br />

0.063" (1.59mm) 2.0µm 718205 718225<br />

1/2" (12.7mm) 0.031" (0.79mm) 0.5µm 721605 721625<br />

0.031" (0.79mm) 2.0µm 721805 721825<br />

1" (25.4mm) 0.031" (0.79mm) 2.0µm 722205 722225<br />

0.063" (1.59mm) 2.0µm 718605 718625<br />

PRICE<br />

Metal-Free PAT ® Frits<br />

• Chemically inert and biocompatible<br />

• Ideal for ion chromatography and biological<br />

applications<br />

PAT ® frits are made from PEEK and PTFE resulting in<br />

an inert, high-strength alloy. PAT ® frits exhibit improved<br />

chemical strength and lower protein binding than<br />

ultrahigh molecular weight polyethylene (UHMWPE) frits<br />

used by other manufacturers.<br />

Metal-Free PAT ® Frit Specifications<br />

Material:<br />

PAT ® (PEEK alloyed with PTFE)<br />

Max. Temperature: 100º C<br />

Max. Pressure 10,000psig<br />

Typical Use:<br />

Column Inlet/Outlet<br />

FRIT DIAMETER THICKNESS QTY.<br />

METAL-FREE PAT ® FRITS<br />

2 MICRON<br />

PART NO.<br />

PRICE<br />

10 MICRON<br />

PART NO.<br />

1/16" (1.57mm) 0.031" (0.79mm) 5/pk 69001 69002<br />

0.063" (1.59mm) 5/pk 69003 69004<br />

1/8" (3.175mm) 0.031" (0.79mm) 5/pk 69005 69006<br />

0.063" (1.59mm) 5/pk 69007 69008<br />

1/4" (6.350mm) 0.031" (0.79mm) 5/pk 69009 69010<br />

0.063" (1.59mm) 5/pk 69011 69012<br />

3/8" (9.525mm) 0.031" (0.79mm) 5/pk 69013 69014<br />

0.063" (1.59mm) 5/pk 69015 69016<br />

1/2" (12.7mm) 0.031" (0.79mm) 5/pk 69017 69018<br />

0.063" (1.59mm) 5/pk 69019 69020<br />

PRICE<br />

How do I choose my frit dimensions?<br />

Match the frit diameter to the outer diameter<br />

of the column tube. The frit's thickness can affect<br />

the degree of filtration. The 0.031" thick frits<br />

are standard for most applications. The thicker,<br />

0.063" frits will provide better depth filtration, so<br />

is the ideal choice when you have a broad particle<br />

size distribution.<br />

Frit Diameter<br />

Thickness<br />

200<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Frits<br />

Encased Stainless Steel Frits<br />

• Improved sealing over conventional frits<br />

• Better mechanical stability<br />

FRIT DIAMETER RING DIAMETER THICKNESS<br />

ENCASED STAINLESS STEEL FRITS<br />

0.5 MICRON 2 MICRON<br />

(5/PK) (5/PK)<br />

PART NO. PART NO.<br />

Encased Stainless Steel Frit Specifications<br />

Material:<br />

316 Stainless Steel, PEEK, or Graph-Tite <br />

Max. Temperature: 100º C<br />

Max. Pressure 10,000psig<br />

Typical Use:<br />

Column Inlet/Outlet<br />

2 MICRON<br />

(10/PK)<br />

PART NO.<br />

PRICE<br />

2 MICRON<br />

(20/PK)<br />

PART NO.<br />

Stainless Steel Frits with PEEK Ring<br />

0.083" (2.1mm) 0.250" (6.4mm) 0.063" (1.59mm) — — 9900 99001<br />

0.125" (3.2mm) 0.250" (6.4mm) 0.063" (1.59mm) — — 9902 99021<br />

0.156" (4.0mm) 0.250" (6.4mm) 0.063" (1.59mm) — — 9906 99061<br />

0.273" (7.0mm) 0.375" (9.5mm) 0.063" (1.59mm) — — 9910 99101<br />

0.352" (10mm) 0.500" (12.7mm) 0.063" (1.59mm) — — 9912 99121<br />

Stainless Steel Frits with Stainless Steel Ring<br />

0.391" (10mm) 0.500" (12.7mm) 0.063" (1.59mm) — 72201 — — —<br />

0.859" (22mm) 1.000" (25.4mm) 0.063" (1.59mm) — 72202 — — —<br />

Stainless Steel Frits with Carbon-Reinforced PEEK Ring<br />

0.083" (2.1mm) 0.250" (6.4mm) 0.031" (0.79mm) 75015 75014 — — —<br />

0.125" (3.2mm) 0.250" (6.4mm) 0.031" (0.79mm) 75013 75012 — — —<br />

0.181" (4.6mm) 0.250" (6.4mm) 0.031" (0.79mm) 75006 75005 — — —<br />

PRICE<br />

Encased Metal-Free PAT ® Frits<br />

• Metal-free inert construction<br />

• Improved sealing over conventional frits<br />

Encased Metal-Free PAT ® Frit Specifications<br />

Material:<br />

PAT ® (PEEK alloyed with PTFE), PEEK<br />

Max. Temperature: 100º C<br />

Max. Pressure 10,000psig<br />

Typical Use:<br />

Column Inlet/Outlet<br />

ENCASED METAL-FREE PAT ® FRITS<br />

FRIT DIAMETER RING DIAMETER THICKNESS<br />

5 MICRON<br />

(5/PK)<br />

PART NO.<br />

PRICE<br />

10 MICRON<br />

(5/PK)<br />

PART NO.<br />

PAT ® Frits with PEEK Ring<br />

0.125" (3.2mm) 0.250" (6.4mm) 0.063" (1.59mm) 69025 69026<br />

0.181" (4.6mm) 0.250" (6.4mm) 0.063" (1.59mm) 68152 69027<br />

0.312" (7.9mm) 0.375" (9.5mm) 0.063" (1.59mm) 67152 69028<br />

PRICE<br />

What is the advantage of using encased<br />

frits and how do I choose the size?<br />

Encased frits seal better against the column<br />

tube. As shown in Figure 1, elimination of<br />

this stag nant flow pocket im proves peak<br />

symmetry. Match the frit diameter to the<br />

inside diameter of the column to prevent<br />

sample and mobile phase from en ter ing the<br />

space between the endfitting and the top of<br />

the column tube. Match the ring diameter to<br />

the outer diameter of the column tube.<br />

With Conventional Frit<br />

Poor<br />

Resolution<br />

With Encased Frit<br />

Increased<br />

Resolution<br />

Figure 1 - Matching frit diameter to column inner<br />

diameter improves resolution.<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.<br />

201

Packing Pumps<br />

L C A C C E S S O R I E S<br />

Analytical Slurry Packer<br />

High Capacity Slurry<br />

Packer<br />

This compact unit can be operated in any location<br />

that has a source of compressed air (50 to 125psig, 3-<br />

4CFM). Powered by an air amplification pump, it has a<br />

practical work ratio of 110:1 drive area to liquid plunger<br />

area (e.g. when driven with an inlet air pressure of<br />

100psig, the pump would produce 11,000psig hydraulic<br />

pressure), and is capable of packing analytical and<br />

semi-preparative columns (2.1mm to 10mm i.d.). An<br />

air regulator provides easy control of the packing<br />

pressure. All operating pressures are displayed on two<br />

large gauges. A two-way slider valve allows either of<br />

two pressurizing solvents or a wash solvent to be used<br />

without shutting down the system. The Analytical Slurry<br />

Packer comes with a 20mL slurry reservoir kit and a<br />

4.6mm i.d. pre-column assembly.<br />

5406<br />

This high-pressure pump is recommended for packing<br />

HP<strong>LC</strong> columns from 4.6mm i.d. to 1" i.d. The unit is safe<br />

to operate and, with the addition of a toggle valve to<br />

the air supply, may be activated from a remote location.<br />

The pump is a single-action, reciprocating-plunger<br />

pump. The drive is a pilot-controlled, continuouslycycling,<br />

double-acting, air cylinder. This pump has a<br />

practical work ratio of 122:1 drive area to liquid plunger<br />

area (e.g. when driven with an inlet air pressure of<br />

100psig, the pump would produce 12,200psig hydraulic<br />

pressure). The apparatus is intended for permanent<br />

installation, requiring that it be bolted or otherwise<br />

fixed to a benchtop. Solvent pressure gauge, slurry<br />

reservoir, and empty columns are not included.<br />

5375<br />

Analytical Slurry Packer Specifications<br />

Maximum Pressure: 10,000psig<br />

Amplification Ratio: 110:1 (drive area to liquid plunger area)<br />

Air Line Requirements: 50-125psig at 3-4CFM<br />

Air Inlet:<br />

1/4" Tube Fitting<br />

Liquid Outlet:<br />

1/16" SSI Fitting<br />

ANALYTICAL SLURRY PACKER<br />

DESCRIPTION PART NO. PRICE<br />

Analytical Slurry Packer 1666<br />

High Capacity Slurry Packer Specifications<br />

Maximum Pressure: 15,000psig<br />

Amplification Ratio: 122:1 (drive area to liquid plunger area)<br />

Air Line Requirements: 50-150psig at 4-5CFM<br />

Air Inlet:<br />

1/4" Tube Fitting<br />

Liquid Outlet:<br />

1/4" Tube Fitting<br />

HIGH CAPACITY SLURRY PACKER<br />

DESCRIPTION PART NO. PRICE<br />

High Capacity Slurry Packer 95551<br />

Slurry Reservoir Kits and Replacement Parts<br />

202<br />

SLURRY RESERVOIR KITS<br />

DESCRIPTION PART NO. PRICE<br />

Slurry Reservoirs Kits<br />

1/4" Outlet, 20mL 1668<br />

1/4" Outlet, 40mL 1671<br />

1/4" Outlet, 80mL 1672<br />

3/8" Outlet, 20mL 16772<br />

3/8" Outlet, 40mL 167731<br />

3/8" Outlet, 80mL 167741<br />

1/2" Outlet, 20mL 167751<br />

1/2" Outlet, 40mL 167761<br />

1/2" Outlet, 80mL 167781<br />

© Copyright 2004 Alltech Associates, Inc.<br />

5491 0916<br />

Nut Inlet Cap Housing Outlet Cap Nut Pre-Column<br />

SLURRY RESERVOIR REPLACEMENT PARTS<br />

DESCRIPTION PART NO. PRICE<br />

Replacement Parts and <strong>Accessories</strong><br />

20mL Reservoir Housings 011191<br />

40mL Reservoir Housings 011192<br />

80mL Reservoir Housings 011193<br />

Inlet Cap, 1/16" 010241<br />

Solvent Pressure Gauge, 0-10,000psig 66616<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Guard Cartridges<br />

HP<strong>LC</strong> Guard Column Selection Guide<br />

What is a Guard<br />

Column?<br />

As the name<br />

suggests, a guard<br />

“protects” your<br />

HP<strong>LC</strong> column by<br />

trapping all the contaminates<br />

that would otherwise collect on<br />

the head of the HP<strong>LC</strong> column.<br />

They are typically 1-3cm long<br />

with varying inner diameters<br />

and get installed just before the<br />

column.<br />

Will a Guard<br />

Change my<br />

Chromatography?<br />

Guards should<br />

not effect the<br />

separation or<br />

decrease efficiency. Packing<br />

them with the same media as<br />

what’s used in the column will<br />

avoid mismatched selectivity<br />

and separation changes. To<br />

minimize band broadening, use<br />

zero dead volume connectors.<br />

Which Guard<br />

Format Should I<br />

Choose?<br />

Ideally, the guard<br />

should have the<br />

same or slightly<br />

smaller i.d. as the HP<strong>LC</strong> column.<br />

Efficiency will suffer, if the<br />

guard i.d. is larger than that<br />

of the column. The chart below<br />

summarizes Alltech’s entire<br />

guard offering — Find your<br />

HP<strong>LC</strong> column i.d., to determine<br />

the best guard format(s).<br />

If you<br />

have:<br />

Choose:<br />

COLUMN I.D.: GUARD FORMAT GUARD<br />

DIMENSIONS<br />

150µm Cap-Guard 125µm i.d. x<br />

12.5mm L<br />

300µm Cap-Guard 250µm i.d. x<br />

23.5mm L<br />

6619<br />

PACKINGS AVAILABLE COMMENTS GUARD PAGE<br />

Alltech capillary<br />

packings, matched<br />

media.<br />

Alltech capillary<br />

packings, matched<br />

media.<br />

Hand-Tight, direct-connect,<br />

disposable design, no holder<br />

needed, 0.12µL internal<br />

volume.<br />

Hand-Tight, direct-connect,<br />

disposable design, no holder<br />

needed, 1µL internal volume.<br />

204<br />

204<br />

6619<br />

2.0-4.6mm Micro-Guard 1mm i.d. x<br />

14mm L<br />

General Purpose<br />

25-40µm Media<br />

Hand-Tight, direct-connect,<br />

disposable design, no holder<br />

needed, 12µL internal volume.<br />

204<br />

2.1-3.0mm All-Guard 2.1mm i.d. x<br />

7.5mm L<br />

6614<br />

All packings,<br />

matched media<br />

Inexpensive cartridge system,<br />

holder required, connects to<br />

column with coupler.<br />

205-207<br />

6617<br />

3.0-4.0mm All-Guard 3.0mm i.d. x<br />

7.5mm L<br />

All packings,<br />

matched media<br />

Inexpensive cartridge system,<br />

holder required, connects to<br />

column with coupler.<br />

205-207<br />

6617<br />

4.1-7.0mm All-Guard 4.6mm i.d. x<br />

7.5mm L<br />

All packings,<br />

matched media<br />

Inexpensive cartridge system,<br />

holder required, connects to<br />

column with coupler.<br />

205-207<br />

6617<br />

2.0-7.0mm Refillable Guard 2mm i.d. x<br />

20mm L<br />

General purpose<br />

35-70µm media<br />

Empty hardware that you dry<br />

pack with porous media. Most<br />

economical.<br />

209<br />

5552<br />

2.0-7.0mm Refillable Guard 9.5mm i.d. x<br />

30mm L<br />

General purpose<br />

35-70µm media<br />

Empty hardware that you dry<br />

pack with porous media. Most<br />

economical.<br />

209<br />

10-22mm Prep-Guard 7.0mm i.d. x<br />

33mm L<br />

5553<br />

Alltech preparative<br />

packings, matched<br />

media<br />

High capacity guard column,<br />

no holder required, connects<br />

to column with coupler.<br />

208<br />

6615<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.<br />

203

Guard Cartridges<br />

L C A C C E S S O R I E S<br />

Cap-Guard Columns Micro-Guard Columns<br />

• Protect your capillary<br />

column investment<br />

• Ultra-low volumes maintain<br />

capillary efficiencies<br />

• Matched media retains<br />

selectivity<br />

• Simple finger-tight<br />

connection, no holder<br />

needed<br />

Alltech’s Cap-Guard is the<br />

ideal solution to extend the life of capillary <strong>LC</strong> columns.<br />

Smaller than a fitting, patented* Cap-Guards connect<br />

directly into the inlet of your column for a zero-dead<br />

volume connection every time. The floating stainless<br />

steel stem self-adjusts to any 10-32 port. This simple,<br />

disposable design requires no holder – a great option<br />

for efficient labs that want to save money. Cap-Guards<br />

are available with all of Alltech’s capillary <strong>LC</strong> column<br />

packings.<br />

Cap-Guard Specifications<br />

Dimensions: 125µm i.d. x 12.5mm L<br />

250µm i.d. x 23.5mm L<br />

Wetted Materials: Stainless Steel<br />

Max Pressure: 5000psig<br />

Connections: 10-32 UNF, Zero-Dead Volume Direct Connect<br />

For Use With: 125µm i.d. Guard for 150µm i.d. Columns<br />

250µm i.d. Guard for 300µm i.d. Columns<br />

Cap-Guards Maintain Capillary Efficiency<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

1. DMSO<br />

2. Phenol<br />

3. N,N-Diethyl-m-<br />

Toluamide<br />

4. Toluene<br />

5. Naphthalene<br />

6620<br />

• Zero dead volume design<br />

is ideal for micro-<strong>LC</strong><br />

columns<br />

• General purpose media<br />

suitable for use with a<br />

variety of columns<br />

• Finger-tight and<br />

completely disposable<br />

Designed in the shape<br />

5492<br />

of an HP<strong>LC</strong> compression fitting, the Alltech Micro-<br />

Guard patented* guard column is simple to use with<br />

any analytical column. It requires no holder, seals, or<br />

complicated parts to connect. The innovative 2-piece<br />

construction contains a self-adjusting stem that adjust<br />

to deliver a zero dead volume connection every time.<br />

Micro-Guards are packed with general purpose, 25-40µm<br />

packing, and therefore can be used with a variety of<br />

columns.<br />

Micro-Guard Specifications<br />

Dimensions: 1.0mm i.d. x 14mm L<br />

Wetted Materials: Polyphenylene Sulfide, PEEK<br />

Max Pressure: 5000psig<br />

Connections: 10-32 UNF, Zero-Dead Volume, Direct Connect<br />

For Use With: 2.0-4.6mm i.d. HP<strong>LC</strong> Columns<br />

Micro-Guard Design<br />

5µm Frit<br />

2µm Frit<br />

<br />

<br />

Cap-Guard and Column<br />

<br />

Column: ProSphere 100 C18, 5µm<br />

Mobile Phase: 58/42 Acetonitrile/Water<br />

Flow Rate: 5µL/min<br />

Detector: UV at 220nm<br />

DESCRIPTION<br />

Column Only<br />

CAP-GUARD GUARD COLUMNS<br />

PART NO.<br />

EA<br />

PRICE<br />

PART NO.<br />

3/PK<br />

125µm Cap-Guard Guard Column<br />

Alltima C18 100551 100555<br />

ProSphere C18, 300Å 100552 100556<br />

ProSphere C18, 100Å 100553 100557<br />

ProSphere PHR 100554 100558<br />

ProSphere C4, 300Å 100559 100560<br />

250µm Cap-Guard Guard Column<br />

Alltima C18 200551 200555<br />

ProSphere C18, 300Å 200552 200556<br />

ProSphere C18, 100Å 200553 200557<br />

ProSphere PHR 200554 200558<br />

ProSphere C4, 300Å 200559 200560<br />

PRICE<br />

Packing<br />

Depth filtration design extends life of the Micro-Guard .<br />

MICRO-GUARD COLUMNS<br />

PACKING QTY. PART NO. PRICE<br />

Micro-Guard Columns<br />

C18 (Violet) 5 51130<br />

C8 (Yellow) 5 51131<br />

Phenyl (Green) 5 51133<br />

CN (Blue) 5 51135<br />

NH2 (Red) 5 51137<br />

Anion Exchanger (Black) 5 51138<br />

Cation Exchanger (White) 5 51139<br />

Silica (Orange) 5 51132<br />

* US Patent #5,525,303; #5,730,943; #5,911,954. Packed in Optimize Technologies, Opti-Guard Hardware.<br />

2742<br />

204<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Guard Cartridges<br />

Analytical All-Guard Cartridge System<br />

• Change cartridges in seconds<br />

• Matched media and low dead volume maintain<br />

chromatographic performance<br />

Alltech’s All-Guard system protects your valuable<br />

columns from damaging mobile phase and sample<br />

contaminants without changing your separation. The<br />

system consists of a durable stainless steel holder and<br />

inexpensive guard cartridges. This elegantly simple<br />

design is less likely to leak and easier to assemble, use,<br />

and maintain than other guard cartridge systems.<br />

The All-Guard System’s unique holder is open on<br />

the side for fast installation. Just drop the cartridge in<br />

and hand-tighten the holder nut. Connect to your HP<strong>LC</strong><br />

system with any standard 10-32 threaded fittings. The<br />

low dead volume Direct-Connect coupler is included<br />

with every All-Guard holder and is ideal for joining the<br />

cartridge system to the HP<strong>LC</strong> Column. Cartridges are<br />

available in over 100 popular packing ma te ri als. Fast<br />

delivery on custom All-Guard Cartridges is available for<br />

media not shown.<br />

Change cartridges in seconds without tools<br />

All-Guard Cartridges Specifications<br />

Dimensions: 4.6mm i.d. x 7.5mm L<br />

3.0mm i.d. x 7.5mm L<br />

2.1mm i.d. x 7.5mm L<br />

Wetted Materials: Stainless Steel<br />

Max Pressure: 5000psig<br />

Connections: 10-32 UNF<br />

For Use With: 4.6mm i.d. for 4.6-7.0mm i.d. HP<strong>LC</strong> Columns<br />

3.0mm i.d. for 3.0-4.1mm i.d. HP<strong>LC</strong> Columns<br />

2.1mm i.d. for 2.1-3.0mm i.d. HP<strong>LC</strong> Columns<br />

Comments: Requires All-Guard Holder<br />

1656<br />

All-Guard Cartridge<br />

Direct-Connect <br />

Column Coupler<br />

(Part No. 28195)<br />

Female Tip - Black<br />

(Part No. 28002 )<br />

All-Guard Holder<br />

(Part No. 80101)<br />

Waters Tip - Red<br />

(Part No. 28004)<br />

Every All-Guard holder comes with 1 Direct-Connect Column Coupler, 1 female tip, and 1 Waters Tip<br />

2694<br />

ALL-GUARD CARTRIDGE HOLDER AND ACCESSORIES<br />

DESCRIPTION PART NO. PRICE<br />

All-Guard Cartridge Holder* 80101<br />

Replacement Parts<br />

Direct-Connect Column Coupler 28195<br />

Female Tip 28002<br />

Waters Tip 28004<br />

*Includes Direct-Connect Column Coupler with tips.<br />

5419<br />

Looking for ion<br />

chromatography guards?<br />

See page 316 for full product<br />

offering.<br />

What are the Advantages<br />

to Matching the Guard<br />

and Column Packing?<br />

Guard columns act as an extension of the<br />

analytical column. If the guard column<br />

selectivity or efficiency doesn’t match<br />

the analytical column, performance<br />

deteriorates. Retention, resolution, and<br />

peak symmetry may suffer.<br />

© Copyright 2004 Alltech Associates, Inc.<br />

<br />

Column Only<br />

<br />

<br />

<br />

1. Uracil<br />

2. Pyridine<br />

3. Phenol<br />

4. Phenylvaleric acid<br />

5. Dimethylaniline<br />

6. Toulene<br />

Column and Matched Media<br />

All-Guard <br />

<br />

<br />

Column: Alltima C18, 150 x 4.6mm, 5µm<br />

Mobile Phase: Acetonitrile/Phosphate buffer<br />

<br />

Contact your Alltech office or distributor for current or local prices.<br />

<br />

<br />

<br />

<br />

<br />

<br />

205

Guard Cartridges<br />

L C A C C E S S O R I E S<br />

PACKING<br />

ALLTECH ALL-GUARD CARTRIDGES, 3/PK<br />

4.6MM<br />

PART NO.<br />

3.0MM<br />

PART NO.<br />

2.1MM<br />

PART NO.<br />

Adsorbosphere ®<br />

C18 96041 96355 —<br />

C8 96042 96356 —<br />

TMS 96043 — —<br />

Phenyl 96045 — —<br />

CN 96047 — —<br />

CN-AQ 96048 — —<br />

NH2 96044 — —<br />

Silica 96046 — —<br />

SAX 96049 — —<br />

SCX 96075 — —<br />

Catecholamine 96076 — —<br />

Nucleotide/<br />

Nucleoside<br />

96077 — —<br />

OPA 96078 — —<br />

Adsorbosphere ® HS<br />

HS, C18 96079 96357 —<br />

HS, Silica 96284 — —<br />

Adsorbosphere ® UHS<br />

UHS, C18 82181 96358 —<br />

Adsorbosphere ® XL<br />

90Å C18 96088 96359 —<br />

90Å C18-B 96089 — —<br />

90Å C8 96090 96360 —<br />

90Å TMS 96093 — —<br />

90Å Silica 96097 — —<br />

90Å SAX 96098 — —<br />

90Å SCX 96099 — —<br />

300Å HAAX 96400 — —<br />

Allsphere <br />

Silica 96401 — —<br />

ODS-1 96402 — —<br />

ODS-2 96403 — —<br />

Octyl 96404 — —<br />

Hexyl 96405 — —<br />

Phenyl 96406 — —<br />

Methyl 96407 — —<br />

Cyano 96408 — —<br />

Amino 96409 — —<br />

SAX 96410 — —<br />

SCX 96411 — —<br />

Alltima <br />

C18 96080 96361 96680<br />

C18-LL 96285 96433 96432<br />

AQ 96344<br />

C8 96081 96362 96441<br />

Phenyl 96082 96445 96442<br />

CN 96084 — —<br />

NH2 96085 — —<br />

Silica 96083 — 96450<br />

Alltima HP<br />

C18 87684 87622 87683<br />

C18 HiLoad 87702 87624 87701<br />

C18 Amide 87738 87625 87737<br />

C18 EPS 87720 87623 87719<br />

C8 87756 87627 87755<br />

Cyano 87784 87626 87783<br />

Silica 87804 87628 87803<br />

PRICE<br />

PACKING<br />

ALLTECH ALL-GUARD CARTRIDGES, 3/PK<br />

4.6MM<br />

PART NO.<br />

3.0MM<br />

PART NO.<br />

2.1MM<br />

PART NO.<br />

alphaBond <br />

C18 77082 — —<br />

C18 96086 — —<br />

C8 77059 — —<br />

Phenyl 77060 — —<br />

Cyano 77061 — —<br />

Amino 77062 — —<br />

Silica 96087 — —<br />

Apollo<br />

C18 96454 — 96688<br />

C8 96463 — —<br />

Phenyl 96430 — —<br />

Silica 96419 — —<br />

Brava<br />

C18 BDS 96472 — —<br />

ODS 96477 — —<br />

C8 96478 — —<br />

C8 BDS 96473 — —<br />

Phenyl 96480 — —<br />

Cyano 96479 — —<br />

Cyano BDS 96474 — —<br />

Amino 96475 — —<br />

Silica BDS 96476 — —<br />

Carbohydrate<br />

Amino 96107 — —<br />

Cation 96109 — —<br />

OH-100 Anomer 96113 — —<br />

Econosphere <br />

C18 96121 — —<br />

C8 96122 — —<br />

CN 96123 — —<br />

NH2 96124 — —<br />

Silica 96125 — —<br />

Macrosphere 300<br />

WAX 96135 — —<br />

WCX 96137 — —<br />

SAX 96139 — —<br />

SCX 96141 — —<br />

GPC-300 96133 — —<br />

Mixed-Mode <br />

RP18/Cation, 100Å 96145 — —<br />

RP8/Anion, 100Å 96147 — —<br />

RP8/Cation, 100Å 71379 — —<br />

Platinum <br />

C18, 100Å 32606 99115 96685<br />

C8, 100Å 32612 — —<br />

Phenyl, 100Å 32619 — —<br />

Cyano, 100Å 32620 — —<br />

NH2, 100Å 32621 — —<br />

Silica, 100Å 32622 — —<br />

Silica, 300Å 32623 — —<br />

SAX, 100Å 32787 — —<br />

Platinum EPS,<br />

C18 EPS, 100Å 32607 99117 96686<br />

C8 EPS, 100Å 32614 — —<br />

PRICE<br />

206<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Guard Cartridges<br />

PACKING<br />

ALLTECH ALL-GUARD CARTRIDGES, 3/PK (CONT’D)<br />

4.6MM<br />

PART NO.<br />

3.0MM<br />

PART NO.<br />

2.1MM<br />

PART NO.<br />

Prevail <br />

Select C18 96455 99119 96691<br />

C18 99286 99350 96682<br />

C8 99287 99351 99128<br />

Phenyl 99288 99352 99130<br />

Cyano 99289 99353 99131<br />

Amino 99290 — —<br />

Silica 99291 99354 99133<br />

OA 96429 — —<br />

Amide 96443 — —<br />

ProSphere <br />

C18, 300Å 34003 99123 —<br />

C18, 100Å 35095 99125 —<br />

C4 34005 99127 —<br />

P 35054 — —<br />

P-HR 35136 — —<br />

PRICE<br />

PACKING<br />

MERCK KGAA ALL-GUARD CARTRIDGES, PK/3<br />

PARTICLE<br />

SIZE<br />

4.6MM<br />

PART NO.<br />

3.0MM<br />

PART NO.<br />

LiChrosorb ®<br />

RP-18 5µm 96171 96374<br />

RP-8 5µm 96173 96373<br />

RP-Select B 5µm 96181 —<br />

Diol 5µm 96177 —<br />

NH2 5µm 96175 —<br />

LiChrospher ®<br />

RP-18 5µm 96185 —<br />

RP-18 Endcapped 5µm 96183 —<br />

RP-Select B 5µm 96425 —<br />

RP-8 5µm 96189 —<br />

RP-8 Endcapped 5µm 96187 —<br />

NH2 5µm 96191 —<br />

Diol 100 5µm 96195 —<br />

Si-60 5µm 96199 —<br />

Si-100 5µm 96201 —<br />

PRICE<br />

PACKING<br />

PACKING<br />

AKZO NOBEL ALL-GUARD CARTRIDGES, PK/3<br />

PARTICLE<br />

SIZE<br />

GL SCIENCES ALL-GUARD CARTRIDGES, PK/3<br />

PARTICLE<br />

SIZE<br />

4.6MM<br />

PART NO.<br />

4.6MM<br />

PART NO.<br />

3.0MM<br />

PART NO.<br />

Kromasil <br />

C18 5µm 96163 96371<br />

C8 5µm 96164 96372<br />

C4 5µm 96165 —<br />

NH2 5µm 96166 —<br />

Silica-100Å 5µm 96167 —<br />

3.0MM<br />

PART NO.<br />

Inertsil ® , 150Å<br />

ODS-2 5µm 96204 —<br />

C8 5µm 96205 —<br />

Phenyl 5µm 96206 —<br />

Silica 5µm 96207 —<br />

PACKING<br />

MACHEREY-NAGEL ALL-GUARD CARTRIDGES, PK/3<br />

PARTICLE<br />

SIZE<br />

4.6MM<br />

PART NO.<br />

3.0MM<br />

PART NO.<br />

Nucleosil ® 100Å<br />

C18 5µm 96210 —<br />

C8 5µm 96211 —<br />

Phenyl 7µm 96214 —<br />

CN 5µm 96213 —<br />

NH2 5µm 96212 —<br />

Silica 5µm 96215 —<br />

PRICE<br />

PRICE<br />

PRICE<br />

PACKING<br />

PACKING<br />

WATERS ALL-GUARD CARTRIDGES, PK/3<br />

WHATMAN ALL-GUARD CARTRIDGES, PK/3<br />

6617<br />

PARTICLE<br />

SIZE<br />

PARTICLE<br />

SIZE<br />

4.6MM<br />

PART NO.<br />

4.6MM<br />

PART NO.<br />

3.0MM<br />

PART NO.<br />

Waters Spherisorb ®<br />

ODS-1 5µm 96218 —<br />

ODS-2 5µm 96219 —<br />

C8 5µm 96220 —<br />

C6 5µm 96221 —<br />

Phenyl 5µm 96226 —<br />

CN 5µm 96225 —<br />

NH2 5µm 96224 —<br />

Silica 5µm 96227 —<br />

SAX 5µm 96228 —<br />

3.0MM<br />

PART NO.<br />

Partisil ®<br />

ODS 10µm 96252 —<br />

ODS-2 10µm 96253 —<br />

ODS-3 5µm 96254 96383<br />

C8 5µm 96255 96384<br />

PAC 5µm 96256 —<br />

Silica 5µm 96257 —<br />

SAX 10µm 96259 —<br />

SCX 10µm 96258 —<br />

ALL-GUARD CARTRIDGE HOLDER AND ACCESSORIES<br />

PRICE<br />

PRICE<br />

DESCRIPTION QTY. PART NO. PRICE<br />

Custom Stainless Steel Cartridges* 4 C-9800<br />

Custom Metal-Free Cartridges † 4 C-9400<br />

*Available in 4.6, 3.2 or 2.1mm i.d.<br />

†<br />

Available in 4.6mm i.d. only<br />

Your Media not Shown on<br />

Pages 206 or 207?<br />

Order custom packed All-Guard <br />

cartridges! Be sure to specify packing<br />

material, particle size, and guard i.d.<br />

along with the part number.<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.<br />

207

Guard Cartridges<br />

L C A C C E S S O R I E S<br />

Prep-Guard Columns<br />

• Excellent retention of soluble and particulate<br />

contaminants<br />

• No holder required<br />

Alltech’s Prep-Guard protects your valuable<br />

preparative HP<strong>LC</strong> columns from damaging mobile phases<br />

and sample contaminants without changing your<br />

separation. Columns last longer and performance is more<br />

consistent. Troubleshooting is made easier when peak<br />

shapes begin to deteriorate or backpressures increase<br />

by simply replacing the guard as a first step in restoring<br />

system performance.<br />

Every Prep-Guard is individually packed and pressure<br />

tested to ensure a consistent, high quality product every<br />

time. Connect the Prep-Guard to the column using<br />

Alltech’s Direct-Connect column coupler (Figure 1) or<br />

with fittings and tubing (Figure 2). All of our most<br />

popular prep column packings are offered in a Prep-<br />

Guard format. Fast delivery on custom Prep-Guard <br />

Columns is available for media not shown, or use one of<br />

the “general purpose” packings to accommodate a wide<br />

range of C18 or Silica prep columns.<br />

Prep-Guard Column Specifications<br />

Dimensions:<br />

7mm i.d. x 33mm L<br />

Wetted Materials: Stainless Steel<br />

Max Pressure:<br />

5000psig<br />

Connections:<br />

10-32 UNF<br />

For Use With:<br />

10–25mm i.d. HP<strong>LC</strong> columns<br />

Comments:<br />

Requires Coupler<br />

3806<br />

PREP-GUARD COLUMNS<br />

ALLTECH PACKING PARTICLE SIZE PART NO. PRICE<br />

Alltima C18 10µm 970203<br />

Alltima Silica 10µm 970204<br />

Prevail C18 10µm 970211<br />

Prevail Silica 10µm 970212<br />

Apollo C18 10µm 970205<br />

Apollo Silica 10µm 970206<br />

ProSphere C18 - 300Å 10µm 970213<br />

ProSphere C18 - 100Å 10µm 970221<br />

ProSphere C4 - 300Å 10µm 970214<br />

ProSphere P-PREP 5µm 970220<br />

Econosphere C18 10µm 970209<br />

Econosphere Silica 10µm 970210<br />

General Purpose C18 10µm 970200<br />

General Purpose Silica 10µm 970202<br />

Custom Prep-Guard Any C-6000PG CALL<br />

Figure 1 - Connect with Direct-Connect <br />

coupler. (Part No. 28195)<br />

Figure 2 - Connect with fittings and tubing.<br />

(Part No. 9549)<br />

6286<br />

6285<br />

208<br />

PREP-GUARD ACCESSORIES<br />

DESCRIPTION PART NO. PRICE<br />

Direct-Connect Column Coupler 28195<br />

In-Line Connector 9549<br />

© Copyright 2004 Alltech Associates, Inc.<br />

How Often Should I Change my<br />

Guard Column?<br />

Ideally you want to change a<br />

guard before it becomes saturated.<br />

Obviously, this is difficult to judge,<br />

which leaves the option to either<br />

change at a predetermined time<br />

interval (i.e. every week), or use the<br />

chromatography as a gauge. Peak<br />

shape deterioration and backpressure<br />

increases are visual reminders.<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Guard Cartridges<br />

Analytical Refillable<br />

Guard Columns<br />

Analytical refillable guard columns are the inexpensive<br />

alternative to prepacked guard cartridges. Use the<br />

included funnel to dry-pack the guard hardware with<br />

your choice of 35-70µm porous packing. Analytical<br />

guards are available in two formats: Direct-Connect and<br />

In-Line. The Direct-Connect format connects to any<br />

analytical column using one of the two included colorcoded<br />

tips which serve as internal tubing and ferrule.<br />

The In-Line format is ideal for situations where direct<br />

attachment is not desirable.<br />

Preparative Refillable<br />

Guard Columns<br />

Preparative refillable guard columns provide an<br />

economical means to extend the life of expensive prep<br />

columns. They are available as an in-line format, and<br />

are supplied with a column coupler for attachment to<br />

any column with industry standard female fittings (CPI).<br />

It's easy to dry-pack the large 9.5mm internal diameter<br />

hardware with your choice of 35-70µm porous packings.<br />

No funnel necessary.<br />

Analytical Refillable Guard Specifications<br />

Dimensions: 2mm i.d. x 20mm L<br />

Wetted Materials: Stainless Steel, Kel-F<br />

Max Pressure: 5000psig<br />

Connections: 10-32 UNF<br />

For Use With: 2-7.0mm i.d. HP<strong>LC</strong> columns<br />

Preparative Refillable Guard Specifications<br />

Dimensions: 9.5mm i.d. x 30mm L<br />

Wetted Materials: Stainless Steel<br />

Max Pressure: 5000psig<br />

Connections: 10-32 UNF<br />

For Use With: 10-25mm i.d. HP<strong>LC</strong> columns<br />

Analytical Direct-Connect Guard Column Kit<br />

includes:<br />

• 2 analytical refillable column (20 x 2mm) hardware<br />

• 3g of porous packing (particle size 35-70µm)<br />

• 1 filling funnel<br />

• 10 2µm prefilters<br />

• Complete instructions<br />

Guard Column<br />

Hardware<br />

Porous<br />

Packing<br />

Material<br />

Preparative In-Line Guard Column Kit includes:<br />

• 2 preparative refillable column (30 x 9.5mm)<br />

hardware<br />

• 10g of porous packing (particle size 35-70µm)<br />

• Column coupler<br />

• 4 2µm prefilters<br />

• Complete instructions<br />

Guard Column<br />

Hardware<br />

Porous<br />

Packing<br />

Material<br />

Funnel<br />

Prefilters<br />

5552<br />

Column Coupler<br />

Prefilters<br />

5553<br />

ANALYTICAL REFILLABLE GUARD COLUMN KITS<br />

DESCRIPTION PART NO. PRICE<br />

Analytical Direct-Connect Guard Column Kits<br />

C18 28960<br />

Silica 28964<br />

Replacement Parts and <strong>Accessories</strong><br />

Direct-Connect Column Hardware*, 2mm i.d. 28950<br />

Tip for Female Fittings (Black), ea 28002<br />

Tip for Waters Fittings (Red), ea 28004<br />

Tip for Valco ® Fittings (Blue), ea 28006<br />

In-Line Column Hardware**, 2mm i.d. 28951<br />

2µm Frits, 5/pk 28642<br />

0.5µm Frits, 5/pk 28646<br />

Filling Funnel 28980<br />

Porous Packing Material, 3g<br />

C18 28970<br />

Silica 28974<br />

* Includes 1 guard column hardware, 2 color-coded tips, 1 filling funnel<br />

** Includes 1 guard column hardware, 1 filling funnel<br />

© Copyright 2004 Alltech Associates, Inc.<br />

PREPARATIVE REFILLABLE GUARD COLUMN KITS<br />

DESCRIPTION PART NO. PRICE<br />

Preparative In-Line Guard Column Kits<br />

C18 28120<br />

Silica 28124<br />

Replacement Parts and <strong>Accessories</strong><br />

In-Line Column Hardware, 9.5mm i.d. 28000<br />

2µm Frits for Preparative Guard, 10/pk 99122<br />

One-Piece Coupler 28191<br />

Universal Column Coupler 28638<br />

Porous Packing Material, 10g<br />

C18 28551<br />

Silica 28550<br />

Contact your Alltech office or distributor for current or local prices.<br />

209

Prefilters<br />

L C A C C E S S O R I E S<br />

Direct-Connect Filter Kit<br />

• Threads into column inlet for minimal dead volume<br />

• Interchangeable tips connect to all column formats<br />

• Inexpensive replaceable filter elements<br />

Stainless Steel<br />

Filter House<br />

In-Line Filter Kit<br />

• Available in metal-free or stainless steel<br />

• Comes with connecting fittings<br />

• Replaceable filter element<br />

Metal-Free<br />

In-Line Filter<br />

Interchangeable<br />

Tips<br />

5557<br />

SofGrip <br />

Stainless Steel<br />

In-Line Filter<br />

6382 6610<br />

Alltech’s Direct-Connect filter reduces dead volume<br />

and preserves efficiency. It is placed between the<br />

injection valve and the column to remove particulate<br />

matter that might otherwise clog the column inlet<br />

frit. Particles in the mobile phase, sample, or from<br />

deteriorating valve seals will be trapped before they<br />

lodge in the column inlet. This eliminates the need to<br />

remove the column endfitting and risk damage to the<br />

packed bed or the column hardware.<br />

This In-Line filter is placed between the injection<br />

valve and column and is available in stainless steel or<br />

metal-free. The metal-free consists of a reusable PEEK<br />

holder and inexpensive PAT ® (PEEK Alloyed with PTFE)<br />

replacement filter elements. Only inert, high-strength<br />

polymers contact the fluid stream. The stainless steel<br />

version has 316 stainless steel holder and filters<br />

Direct-Connect Filter Specifications<br />

Material: 316 Stainless Steel, PTFE, and Kel-F ®<br />

Max. Temperature: 100º C<br />

Max. Pressure 5,000psig<br />

Thread Type: 10-32 UNF<br />

In-Line Filter Specifications<br />

Material:<br />

See Price Block<br />

Max. Temperature: 100º C<br />

Max. Pressure 5,000psig<br />

Thread Type: 10-32 UNF<br />

Direct-Connect Filter Kit<br />

In-Line Filter Kit<br />

SofGrip <br />

Fitting<br />

Filter Housing<br />

2µm Prefilter<br />

Distributor<br />

Disk<br />

Waters<br />

Female<br />

Valco<br />

Interchangeable<br />

Tips<br />

SofGrip <br />

Fitting<br />

Filter Housing<br />

2µm Prefilter<br />

Distributor<br />

Disk<br />

SofGrip <br />

Fitting<br />

Use correct tip for direct connection into column.<br />

0724 0724A<br />

Use SofGrip fittings to connect 1/16" tubing at inlet and outlet.<br />

210<br />

© Copyright 2004 Alltech Associates, Inc.<br />

DIRECT-CONNECT FILTER<br />

DESCRIPTION POROSITY PART NO. PRICE<br />

Direct-Connect Filter Kit<br />

Direct-Connect Filter Kit 2.0µm 28689<br />

Replacement Parts<br />

Housing — 27005<br />

Stainless Steel Filter, 5/pk 2.0µm 28640<br />

Female Tip — 28002<br />

Waters Tip — 28004<br />

Valco Tip — 28006<br />

Distributor Disks — 28008<br />

IN-LINE FILTERS<br />

DESCRIPTION POROSITY PART NO. PRICE<br />

In-Line Filter Kit<br />

Metal-Free Filter Kit* 2.0µm 68250<br />

Stainless Steel Filter Kit** 2.0µm 27000<br />

Replacement Parts<br />

PAT ® Filter, 5/pk 2.0µm 68152<br />

Stainless Steel Filter, 5/pk 2.0µm 28640<br />

Stainless Steel Housing — 27010<br />

* Includes PEEK holder, PAT ® filter, and 2 SofGrip Fittings.<br />

**Includes 316 Stainless Steel Holder, Stainless Steel Filter, and 2 SofGrip <br />

Fittings.<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Prefilters<br />

Universal Mini Filters<br />

• Low volume directconnect<br />

design<br />

• Ideal for <strong>LC</strong>/MS<br />

applications<br />

• Depth filter for greater<br />

capacity without band spreading<br />

The Universal Mini Filter is a hand-tight,<br />

automatically adjusting filter. It has a 1mm filter<br />

diameter and an internal volume of either 1.2µL or<br />

0.3µL (see price block). Use with any low volume column<br />

or in front of a mass spec detector to protect from<br />

particulates. Perfect dead volume connections result<br />

from the floating tube. It’s completely disposable and<br />

holder-free.<br />

Universal Mini Filter Specifications<br />

Material:<br />

316 Stainless Steel<br />

Max. Temperature: 100º C<br />

Max. Pressure 7,000psig<br />

Thread Type: 10-32 UNF<br />

UNIVERSAL MINI FILTERS, 5/PK<br />

DESCRIPTION INTERNAL VOLUME POROSITY PART NO. PRICE<br />

Mini Filter 1.2µL 0.5µm 77166<br />

Mini Filter 1.2µL 2.0µm 77167<br />

Mini Filter 0.3µL 1.0µm 77168<br />

*Patent #5,525,303; #5,730,943; #5,911,954.<br />

Rheodyne ® Column<br />

In-Line Filter Kit<br />

• Install between injector and<br />

column<br />

• Use 3mm filter kit for<br />

4.6mm columns<br />

• Use 1.5mm filter kit for 1<br />

and 2mm columns<br />

Rheodyne Column In-Line Filter Specifications<br />

Material:<br />

316 Stainless Steel<br />

Max. Temperature: 500º C<br />

Max. Pressure 7,000psig<br />

Thread Type: 10-32 UNF<br />

RHEODYNE ® COLUMN IN-LINE FILTERS, EA<br />

DESCRIPTION POROSITY PART NO. PRICE<br />

Column In-Line Filter Kit*<br />

1.5mm Filter Diameter 0.5µm 7315RV<br />

3mm Filter Diameter 0.5µm 7335RV<br />

Replacement Parts<br />

1.5mm Filter Element 0.5µm 7315-010<br />

3mm Filter Element 0.5µm 7335-010<br />

* Comes with 1 holder, 1 filter, 3 fittings, and 2 connecting tubes 6cm x .007" i.d.<br />

© Copyright 2004 Alltech Associates, Inc.<br />

6679<br />

5420<br />

High-Pressure In-Line<br />

Column Filter<br />

• Install between injector and<br />

column<br />

• Filter has surface area of 7.1mm 2<br />

This column filter introduces a minimum of unswept<br />

volume between the injector and column. All prefilter<br />

disks have a surface area of 7.1mm 2 .<br />

High Pressure In-Line Filter Specifications<br />

Material:<br />

316 Stainless Steel<br />

Max. Temperature: 500º C<br />

Max. Pressure 15,000psig<br />

Thread Type: 1/4-28 UNF for SSI ports<br />

10-32 UNF for CPI and Waters ports<br />

HIGH-PRESSURE IN-LINE COLUMN PREFILTER, EA<br />

FILTER CONNECTION O.D. POROSITY PART NO. PRICE<br />

In-Line Column Prefilter<br />

SSI 1/16" 2.0µm 05-0148<br />

SSI 1/16" 0.5µm 05-0149<br />

Industry Standard CPI 1/16" 0.5µm 25-0149<br />

Waters 1/16" 2.0µm 35-0148<br />

Waters 1/16" 0.5µm 35-0149<br />

Replacement Parts<br />

Filter Elements, 10/pk – 2.0µm 05-0154<br />

Filter Elements, 10/pk – 0.5µm 05-0155<br />

High-Capacity In-Line<br />

Filters<br />

• Place between the pump<br />

and the injector<br />

• Filter has a surface area of<br />

2.5cm 2<br />

High Capacity In-Line Filter Specifications<br />

Material:<br />

316 Stainless Steel<br />

Max. Temperature: 500º C<br />

Max. Pressure 15,000psig<br />

Thread Type: 1/4-28 UNF for SSI ports<br />

10-32 UNF for CPI<br />

HIGH-CAPACITY IN-LINE FILTERS, EA<br />

FILTER CONNECTION POROSITY PART NO. PRICE<br />

High-Capacity In-Line Filters<br />

SSI 0.5µm 050105<br />

SSI 2.0µm 050108<br />

Industry Standard CPI 0.5µm 250105<br />

Industry Standard CPI 2.0µm 250108<br />

Replacement Parts<br />

Filter Elements, 2/pk 0.5µm 050106<br />

Filter Elements, 2/pk 2.0µm 050107<br />

Contact your Alltech office or distributor for current or local prices.<br />

5560<br />

5561<br />

211

Traps<br />

L C A C C E S S O R I E S<br />

Optimize Technologies Trap Cartridges<br />

• Concentrate and/or purify analytes<br />

• Desalt buffers<br />

• Remove detergents<br />

• Elute selective analytes<br />

Trap cartridges are an effective means of handling<br />

sample cleanup and preconcentration tasks in an on-line<br />

environment. Before MS detection, use traps to capture<br />

sample from buffered matrices and divert salts to waste;<br />

or use traps to remove detergents from a sample matrix.<br />

Additionally, traps can be used to selectively elute single<br />

analytes from a complex mixture via solvent or salt<br />

gradients, or they may even serve as a simple analytical<br />

column for rapid <strong>LC</strong>/MS analysis.<br />

Optimize's versatile trapping system comes in two<br />

formats. The 3 smallest bed volumes (0.25µL, 0.5µL,<br />

5.0µL) are packed in the Opti-Pak format which threads<br />

directly into any 10-32 port and self-adjusts for a zero<br />

dead volume connection. The 3 larger bed volumes<br />

(20µL, 40µL, 100µL) come in the Opti-Lynx format.<br />

This quick-connect holder gives you instant quarter-turn<br />

access to trap cartridges. Additional sizes available<br />

upon request.<br />

Opti-Pak for 0.25µL, 0.5µL and 5µL Bed Volumes<br />

6700<br />

Self-adjusting<br />

stem for zero<br />

dead volume<br />

connection<br />

Ultra low volume Opti-Pak traps are ideal for samplelimited<br />

and volume-sensitive assays. US patent #5,525,303<br />

Opti-Lynx for 20µL, 40µL and 100µL Bed Volumes<br />

Trap Cartridge<br />

6699<br />

Opti-Lynx <br />

Holder<br />

6701<br />

6702<br />

Higher capacity Opti-Lynx traps are housed in a 10-32<br />

threaded quick-connect holder. US patent #6,095,572<br />

Bed Selection Guide<br />

Bed Volume: 0.25µL 0.5µL 5µL 20µL 40µL 100µL<br />

Sample Capacity: 1µg 2µg 20µg 80µg 160µg 400µg<br />

Sample Volume: 0.05µL-50µL 0.1µL-100µL 1.0µL-1mL 4µL-4mL 8µL-8mL 20µL-20mL<br />

Load Rate: 2.5-10µL/min 5.0-20µL/min 50-200µL/min 200-800µL/min 0.4-1.6mL/min 1-4mL/min<br />

Format: Opti-Pak Opti-Pak Opti-Pak Opti-Lynx Opti-Lynx Opti-Lynx <br />

OPTIMIZE TECHNOLOGIES TRAP CARTRIDGES, PK/5<br />

DESCRIPTION C18 C18AQ DVB SAX SCX PRICE<br />

0.25µL Opti-Pak Kit 33431 33432 33433 33434 33435<br />

0.5µL Opti-Pak Kit 33401 33402 33403 33404 33405<br />

5µL Opti-Pak Kit 33407 33408 33409 33410 33411<br />

20µL Opti-Lynx * 33413 33414 33415 33416 33417<br />

40µL Opti-Lynx * 33419 33420 33421 33422 33423<br />

100µL Opti-Lynx * 33425 33426 33427 33428 33429<br />

Opti-Lynx Holder 33430 33430 33430 33430 33430<br />

*<br />

Opti-Lynx cartridges require Opti-Lynx holder to be purchased separately.<br />

212<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Organizers & Test Mixes<br />

HP<strong>LC</strong> Organizers<br />

Organize HP<strong>LC</strong> Columns and <strong>Accessories</strong><br />

The portable unit<br />

holds up to 10 HP<strong>LC</strong><br />

columns, and has<br />

17 compartments to<br />

store everything from<br />

fittings to wipes. PVC<br />

construction.<br />

12"H x 24"W x 6"D<br />

5507<br />

Plastic Box with Removable Dividers<br />

This plastic box has<br />

a hinged lid and 13<br />

removable dividers. It<br />

is ideal for organizing<br />

small pieces, such as<br />

fittings and bore-cut<br />

tubing.<br />

6348<br />

HP<strong>LC</strong> SUPPLIES ORGANIZER<br />

DESCRIPTION PART NO. PRICE<br />

HP<strong>LC</strong> Supplies Organizer 5238<br />

Organize and Protect HP<strong>LC</strong> Columns<br />

Store and protect up<br />

to 30 HP<strong>LC</strong> columns for<br />

instant identification<br />

and access. Wallmounts<br />

with two screws.<br />

PVC construction with<br />

acrylic doors. 17 3/8"H<br />

x 15"W x 2 7/8"D.<br />

PLASTIC BOX WITH REMOVABLE DIVIDERS<br />

DESCRIPTION PART NO. PRICE<br />

Plastic Storage Box 803880<br />

Organize Laboratory <strong>Accessories</strong><br />

This extra-large<br />

lab organizer has 14<br />

adjustable dividers and<br />

4 shelves. Arrange the<br />

dividers to create the<br />

desired bin size. Made<br />

from PVC. 20"H x 24"W<br />

x 10.5"D<br />

5509<br />

5508<br />

HP<strong>LC</strong> COLUMN STORAGE UNIT<br />

DESCRIPTION PART NO. PRICE<br />

HP<strong>LC</strong> Column Storage Unit 5240<br />

LAB ORGANIZER<br />

DESCRIPTION PART NO. PRICE<br />

Lab Organizer 5242<br />

HP<strong>LC</strong> Column Test Mixtures<br />

Reversed-Phase Test Mix<br />

Separate this Reversed-Phase Test Mix with C18 and<br />

C8 columns using an organic/aqueous mobile phase. Use<br />

toluene to measure column efficiency, phenol or<br />

N,N-diethyl-m-toluamide to assess peak symmetry<br />

(tailing), and Uracil as a void volume marker.<br />

Reversed-Phase Test Mix Specifications<br />

COMPONENT<br />

CONCENTRATION<br />

Uracil<br />

0.015mg/mL<br />

Phenol (Acid Probe)<br />

0.7mg/mL<br />

N,N-Diethyl-M-Toluamide (Base Probe)<br />

0.6mg/mL<br />

Toluene<br />

4.0mg/mL<br />

Dissolved in Acetonitrile:Water (58:42)<br />

Normal-Phase Test Mix<br />

Separate this Normal-Phase Test Mix with amino,<br />

cyano, diol, or silica packings using an ethanol/hexane<br />

mobile phase. Assess efficiency and peak symmetry by<br />

using either of the phthalate peaks. Toluene is the void<br />

volume marker.<br />

Normal-Phase Test Mix Specifications<br />

COMPONENT<br />

Toluene<br />

Diethyl Phthalate<br />

Dimethyl Phthalate<br />

CONCENTRATION<br />

1.0mg/mL<br />

1.0mg/mL<br />

1.0mg/mL<br />

Dissolved in Ethanol:Hexane (5:95)<br />

REVERSED-PHASE TEST MIX<br />

DESCRIPTION PART NO. PRICE<br />

Reversed-Phase Test Mix, 1mL 1895<br />

© Copyright 2004 Alltech Associates, Inc.<br />

NORMAL-PHASE TEST MIX<br />

DESCRIPTION PART NO. PRICE<br />

Normal Phase Test Mix, 1mL 1096<br />

Contact your Alltech office or distributor for current or local prices.<br />

213

Fittings & Tubing<br />

L C A C C E S S O R I E S<br />

SofGrip One-Piece High Pressure Fittings<br />

• Soft elastomer cushion makes hand-tightening<br />

comfortable<br />

• Graph-Tite construction is three times stronger<br />

than PEEK<br />

• One-piece integrated ferrule eliminates handling<br />

small pieces<br />

• No-Slip version stays on tubing between<br />

connections<br />

Other<br />

Fittings<br />

No-Slip <br />

SofGrip <br />

4615<br />

4614<br />

Alltech’s SofGrip HP<strong>LC</strong> Fittings are ergonomic high<br />

pressure fittings. They are made from Graph-Tite <br />

(graphitized-PEEK) material which is three times stronger<br />

than other polymers, 100% biocompatible, and inert to<br />

nearly all HP<strong>LC</strong> and IC solvents. The head of the fitting<br />

is wrapped with a soft elastomer cushion, resulting in a<br />

comfortable finger-tight connection. Use with any 10-32<br />

port, regardless of stop depth, for a leak-free seal up to<br />

5000psig.<br />

SofGrip fittings come in two versions, standard and<br />

No-Slip . The No-Slip version incorporates barrel tines<br />

in the bore of the fitting that lightly grip the tubing<br />

(Figure 1). This added convenience keeps the fitting in<br />

place when changing columns or modifying plumbing.<br />

6280<br />

Integral barrel tines in No-Slip SofGrip fittings lightly<br />

grip tubing. This holds the fitting in place between<br />

connections.<br />

SofGrip One-Piece Fitting Specifications<br />

Material:<br />

Graph-Tite (Carbon-Reinforced PEEK)<br />

Max. Temperature: 100°C<br />

Max. Pressure: 5000psig<br />

Thread Type: 10-32 UNF<br />

Typical Use: 1/16" o.d. Tubing Connections<br />

6361<br />

Short SofGrip Fitting<br />

Long SofGrip Fitting<br />

GRAPHIC LENGTH COLOR QTY.<br />

A<br />

6392 6423<br />

SOFGRIP ONE-PIECE FITTINGS<br />

STANDARD<br />

SOFGRIP <br />

PART NO.<br />

B<br />

PRICE<br />

NO-SLIP <br />

SOFGRIP <br />

PART NO.<br />

SofGrip One-Piece Fittings<br />

A Short Black 10 40501 40511<br />

A Short Red 10 40502 40512<br />

A Short Blue 10 40503 40513<br />

A Short Green 10 40504 40514<br />

A Short Yellow 10 40505 40515<br />

B Long Black 10 40506 40516<br />

A Short Assort. 10 40507 40517<br />

PRICE<br />

214<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.

L C A C C E S S O R I E S<br />

Fittings & Tubing<br />

One-Piece High Pressure Fittings<br />

• PEEK or Graph-Tite construction is inert and<br />

biocompatible<br />

• One-piece integrated ferrule eliminates handling<br />

small pieces<br />

• No-Slip version stays on tubing between<br />

connections<br />

Other<br />

Fittings<br />

No-Slip <br />

Fittings<br />

4615<br />

One-piece fittings are made from PEEK or Graphitized<br />

PEEK, are inert to nearly all HP<strong>LC</strong> and IC solvents, and<br />

100% biocompatible. They form reliable, leak-free<br />

connections on any 10-32 port. A knurled, finger-tight<br />

handle allows quick and easy connection without tools<br />

at pressures up to 5,000psig. For higher pressures, or<br />

cramped connections, hex-head versions are available.<br />

These one piece fittings come in two versions,<br />

standard and No-Slip . The No-Slip version incorporates<br />

barrel tines in the bore of the fitting that lightly grip<br />

the tubing. This added convenience keeps the fitting in<br />

place when changing columns or modifying plumbing.<br />

5425<br />

Integral barrel tines in No-Slip fittings lightly grip tubing.<br />

This holds the fitting in place between connections.<br />

One-Piece Fitting Specifications<br />

Material:<br />

PEEK or Graph-Tite (Carbon Reinforced PEEK)<br />

Max. Temperature: 100°C<br />

Max. Pressure: Finger-Tight : 5000psig<br />

Wrench-Tight : 8000psig<br />

Thread Type: 10-32 UNF<br />

Typical Use: 1/16" o.d. Tubing Connections<br />

4614<br />

5058<br />

A<br />

5426 5464 5465 5466<br />

B<br />

C<br />

D<br />

ONE-PIECE FITTINGS<br />

GRAPHIC* LENGTH COLOR MATERIAL QTY.<br />

STANDARD<br />

ONE-PIECE<br />

PART NO.<br />

One-Piece Fittings, Finger-Tight <br />

A Short Natural PEEK 10 32233 32293<br />

A Short Red PEEK 10 32072 32936<br />

A Short Yellow PEEK 10 32074 32935<br />

A Short Blue PEEK 10 32076 32933<br />

A Short Green PEEK 10 32078 32931<br />

A Short Black Graph-Tite † 10 32343 31001<br />

A Short Assorted* PEEK 12 32070 32937<br />

B Long Natural PEEK 10 32235 — —<br />

B Long Black Graph-Tite † 10 — — 31002<br />

One-Piece Fittings, Hex-Head<br />

C Short Natural PEEK 10 32236 32297<br />

C Short Black Graph-Tite † 10 32347 31003<br />

D Long Natural PEEK 10 32238 32299<br />

D Long Black Graph-Tite † 10 32349 31004<br />

*Assortment includes two of each color.<br />

†<br />

Carbon Reinforced PEEK.<br />

PRICE<br />

NO-SLIP <br />

ONE-PIECE<br />

PART NO.<br />

PRICE<br />

© Copyright 2004 Alltech Associates, Inc.<br />

Contact your Alltech office or distributor for current or local prices.<br />

215

Fittings & Tubing<br />

L C A C C E S S O R I E S<br />

Two-Piece DSF High Pressure Fittings<br />

• Double-sided ferrule (DSF) provides twice the gripping<br />

power<br />

• PEEK or Graph-Tite construction is inert and<br />

biocompatible<br />

• Economical two-piece design<br />

DSF fittings have a double-sided ferrule which grips<br />

tubing in two places. This increases the holding power<br />

and decreases the force on one area of the tubing. A<br />

unique Wrench/Finger-Tight design is available and<br />

combines the convenience of a finger-tight fitting with<br />

the option to wrench-tighten when higher pressures are<br />

used.<br />

Two-Piece DSF Fitting Specifications<br />

Material:<br />

PEEK or Graph-Tite (Carbon-Reinforced PEEK)<br />

Max. Temperature: 100°C<br />

Max. Pressure: Finger-Tight : 5000psig<br />

Wrench-Tight : 10,000psig<br />

Thread Type: 10-32 UNF<br />

Typical Use: 1/16" o.d. Tubing Connections<br />

5429<br />

COLOR MATERIAL QTY.<br />

5434 5437 5436<br />

A B C<br />

WRENCH/FINGER-TIGHT <br />

PART NO. (A)<br />

TWO-PIECE DSF FITTINGS<br />

PRICE<br />

SHORT HEX-HEAD<br />

PART NO. (B)<br />

PRICE<br />

LONG HEX-HEAD<br />

PART NO. (C)<br />

Two-Piece DSF Fittings<br />

Natural PEEK 10 35753 35744 35735<br />

Black PEEK 10 35077 37087 37097<br />

Red PEEK 10 35072 37082 37092<br />

Blue PEEK 10 35076 37086 37096<br />

Green PEEK 10 35078 37088 37098<br />

Black Graph-Tite † 10 35062 35068 35066<br />

Assorted* PEEK 12 35070 37080 37090<br />

Replacement Ferrules (DSF)<br />

Natural PEEK 10 35740 35740 35740<br />

Natural Kel-F ® 5 32025 32025 32025<br />

PRICE<br />

Two-Piece Wing-Nut High Pressure Fittings<br />

• “Wing-Nut” provides<br />

Finger-Tight operation<br />

to 6,000psig<br />

• Easier to make and break<br />

con nec tions by hand.<br />

• Economical two-piece<br />

design<br />