MELSERVO-J3 New Product News

MELSERVO-J3 New Product News

MELSERVO-J3 New Product News

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

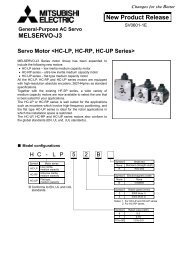

<strong>New</strong> <strong>Product</strong> <strong>New</strong>s<br />

General-Purpose AC Servo<br />

<strong>MELSERVO</strong>-<strong>J3</strong><br />

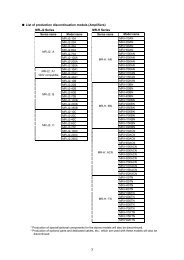

Servo Motor HF-SP 1000r/min Series<br />

The medium inertia, medium capacity motor series HF-SP<br />

1000r/min has been introduced into the <strong>MELSERVO</strong>-<strong>J3</strong> series.<br />

For the HF-SP series, a rated speed of 1000r/min or 2000r/min is<br />

now available, for you to use according to your purpose.<br />

By adapting to smaller connector use, the HF-SP 1000r/min<br />

series enables more compact system to be designed.<br />

Typically suitable for the following applications: conveyor<br />

machines, robots or X-Y tables.<br />

The HF-SP 1000r/min series also conforms to global standards<br />

(EN, UL, cUL standards).<br />

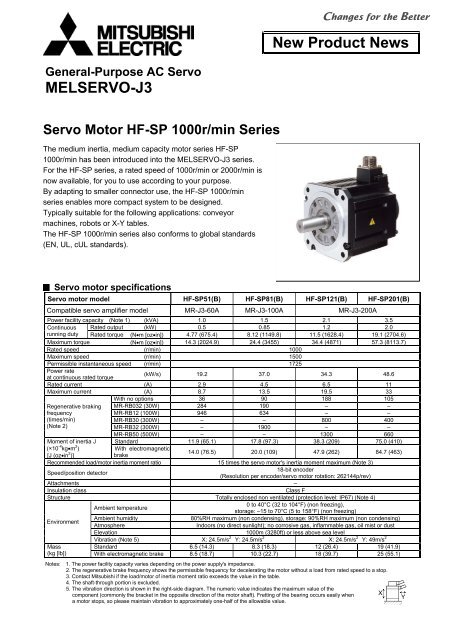

Servo motor specifications<br />

Servo motor model HF-SP51(B) HF-SP81(B) HF-SP121(B) HF-SP201(B)<br />

Compatible servo amplifier model MR-<strong>J3</strong>-60A MR-<strong>J3</strong>-100A MR-<strong>J3</strong>-200A<br />

Power facility capacity (Note 1) (kVA) 1.0 1.5 2.1 3.5<br />

Continuous Rated output (kW) 0.5 0.85 1.2 2.0<br />

running duty Rated torque (N•m [oz•in]) 4.77 (675.4) 8.12 (1149.8) 11.5 (1628.4) 19.1 (2704.6)<br />

Maximum torque (N•m [oz•in]) 14.3 (2024.9) 24.4 (3455) 34.4 (4871) 57.3 (8113.7)<br />

Rated speed (r/min) 1000<br />

Maximum speed (r/min) 1500<br />

Permissible instantaneous speed (r/min) 1725<br />

Power rate<br />

at continuous rated torque<br />

(kW/s) 19.2 37.0 34.3 48.6<br />

Rated current (A) 2.9 4.5 6.5 11<br />

Maximum current (A) 8.7 13.5 19.5 33<br />

With no options 36 90 188 105<br />

Regenerative braking MR-RB032 (30W) 284 190 – –<br />

frequency<br />

MR-RB12 (100W) 946 634 – –<br />

(times/min)<br />

MR-RB30 (300W) – – 800 400<br />

(Note 2)<br />

MR-RB32 (300W) – 1900 – –<br />

MR-RB50 (500W) – – 1300 660<br />

Moment of inertia J Standard 11.9 (65.1) 17.8 (97.3) 38.3 (209) 75.0 (410)<br />

(×10 -4 kg•m 2 )<br />

With electromagnetic<br />

[J (oz•in 2 )]<br />

brake<br />

14.0 (76.5) 20.0 (109) 47.9 (262) 84.7 (463)<br />

Recommended load/motor inertia moment ratio 15 times the servo motor's inertia moment maximum (Note 3)<br />

Speed/position detector<br />

18-bit encoder<br />

(Resolution per encoder/servo motor rotation: 262144p/rev)<br />

Attachments –<br />

Insulation class<br />

Class F<br />

Structure Totally enclosed non ventilated (protection level: IP67) (Note 4)<br />

Ambient temperature<br />

0 to 40°C (32 to 104°F) (non freezing),<br />

storage: –15 to 70°C (5 to 158°F) (non freezing)<br />

Environment<br />

Ambient humidity<br />

80%RH maximum (non condensing), storage: 90%RH maximum (non condensing)<br />

Atmosphere<br />

Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust<br />

Elevation<br />

1000m (3280ft) or less above sea level<br />

Vibration (Note 5) X: 24.5m/s 2 Y: 24.5m/s 2 X: 24.5m/s 2 Y: 49m/s 2<br />

Mass<br />

Standard 6.5 (14.3) 8.3 (18.3) 12 (26.4) 19 (41.9)<br />

(kg [lb]) With electromagnetic brake 8.5 (18.7) 10.3 (22.7) 18 (39.7) 25 (55.1)<br />

Notes: 1. The power facility capacity varies depending on the power supply's impedance.<br />

2. The regenerative brake frequency shows the permissible frequency for decelerating the motor without a load from rated speed to a stop.<br />

3. Contact Mitsubishi if the load/motor of inertia moment ratio exceeds the value in the table.<br />

4. The shaft-through portion is excluded.<br />

5. The vibration direction is shown in the right-side diagram. The numeric value indicates the maximum value of the<br />

component (commonly the bracket in the opposite direction of the motor shaft). Fretting of the bearing occurs easily when X<br />

a motor stops, so please maintain vibration to approximately one-half of the allowable value.<br />

Y

Servo motor torque characteristics<br />

HF-SP51(B) (Note 1,2) HF-SP81(B) (Note 1) HF-SP121(B) (Note 1) HF-SP201(B) (Note 1)<br />

Torque (oz in)<br />

2100<br />

1400<br />

700<br />

0<br />

Torque (N m)<br />

15<br />

10<br />

5<br />

0<br />

Peak<br />

running range<br />

Continuous<br />

running range<br />

500 1000<br />

Speed (r/min)<br />

Torque (oz in)<br />

4200<br />

2800<br />

Torque (N m)<br />

30<br />

20<br />

Peak<br />

running range<br />

Torque (oz in)<br />

5600<br />

4200<br />

2800<br />

Torque (N m)<br />

40<br />

30<br />

20<br />

Peak<br />

running range<br />

1400 10<br />

2800 20<br />

1400 10<br />

Continuous<br />

Continuous<br />

Continuous<br />

running range<br />

running range<br />

running range<br />

0<br />

0<br />

0<br />

1500 0 500 1000 1500 0 500 1000 1500<br />

0 500 1000 1500<br />

Speed (r/min) Speed (r/min) Speed (r/min)<br />

Torque (oz in)<br />

8400<br />

5600<br />

Torque (N m)<br />

60<br />

40<br />

Peak<br />

running range<br />

Notes: 1. : For 3-phase 200VAC.<br />

2. : For 1-phase 230VAC.<br />

Servo motor dimensions<br />

HF-SP51(B), HF-SP81(B)<br />

(Note 3)<br />

(Note 3)<br />

(Note 3)<br />

79.9(3.15)<br />

(Note 3)<br />

50.9(2.00)<br />

13<br />

(0.51)<br />

Encoder connector<br />

CM10-R10P<br />

Brake connector<br />

CM10-R2P (Note 3)<br />

L<br />

38.2(1.5)<br />

<br />

55(2.17)<br />

50(1.97)<br />

12(0.47) 3(0.12)<br />

(Note 3)<br />

59(2.32)<br />

(Note 3)<br />

(Note 3)<br />

20.9(0.82)<br />

(Note 3)<br />

Brake<br />

(Note 3)<br />

(Note 3)<br />

KL<br />

Power supply connector<br />

MS3102A18-10P<br />

W<br />

V<br />

24h6<br />

0<br />

( 0.9449 0.0005 )<br />

C<br />

B<br />

110h7<br />

D<br />

A<br />

0<br />

( 4.331 0.0014 )<br />

4- 9 (0.354) mounting hole<br />

Use hexagonal cap head bolts.<br />

112.5(4.43)<br />

U<br />

13.5<br />

(0.53)<br />

Earth<br />

130(5.12)<br />

58<br />

(2.28)<br />

45<br />

29(1.14)<br />

(Note 3)<br />

165(6.496)<br />

145(5.709)<br />

Model<br />

HF-SP51(B)<br />

HF-SP81(B)<br />

Variable dimensions<br />

L<br />

140.5(5.53)<br />

<br />

162.5(6.4)<br />

<br />

KL<br />

79.8<br />

(3.14)<br />

101.8<br />

(4.01)<br />

Unit:mm (inch)<br />

Brake static<br />

friction torque<br />

(N⋅m [oz⋅in])<br />

8.5(1203)<br />

8.5(1203)<br />

Brake connector pin assignment<br />

Motor flange direction<br />

Power supply connector pin assignment<br />

Motor flange direction<br />

HF-SP121(B), HF-SP201(B)<br />

4- 13.5(0.531) mounting hole<br />

Use hexagonal cap head bolts.<br />

Unit:mm (inch)<br />

(Note 3)<br />

44(1.73)<br />

(Note 3)<br />

(Note 3)<br />

(Note 3)<br />

50.9(2.00)<br />

96.9(3.81)<br />

(Note 3)<br />

38.5(1.52)<br />

18(0.71)<br />

<br />

(Note 3)<br />

13<br />

(0.51)<br />

66.5<br />

(2.62)<br />

(Note 3)<br />

Encoder connector<br />

CM10-R10P<br />

Brake connector<br />

CM10-R2P (Note 3)<br />

(Note 3)<br />

Brake<br />

(Note 3)<br />

L<br />

24.8(0.98)<br />

KL<br />

79(3.11)<br />

75(2.95)<br />

3(0.12)<br />

35 0.010<br />

0<br />

Power supply connector<br />

MS3102A22-22P<br />

W<br />

V<br />

0.0004<br />

( 1.3780 0 )<br />

C<br />

B<br />

114.3 0 0.025<br />

0<br />

( 4.5<br />

0.0010<br />

)<br />

D<br />

A<br />

U<br />

140.9(5.55)<br />

Earth<br />

176(6.93)<br />

82<br />

(3.23)<br />

45<br />

200(7.874)<br />

230(9.055)<br />

Model<br />

HF-SP121(B) 143.5(5.65)<br />

<br />

HF-SP201(B) 183.5(7.22)<br />

<br />

Variable dimensions<br />

L<br />

KL<br />

79.8<br />

(3.14)<br />

119.8<br />

(4.72)<br />

Brake static<br />

friction torque<br />

(N⋅m [oz⋅in])<br />

44(6230)<br />

44(6230)<br />

Brake connector pin assignment<br />

Motor flange direction<br />

Power supply connector pin assignment<br />

Motor flange direction<br />

Notes: 1. Use a friction coupling to fasten a load.<br />

2. Dimensions inside < > are for the models with electromagnetic brake.<br />

3. Only for the models with electromagnetic brake.<br />

4. For dimensions where there is no tolerance listed, use general tolerance.<br />

MEE(0412)