VARIANT - HESS Group

VARIANT - HESS Group

VARIANT - HESS Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

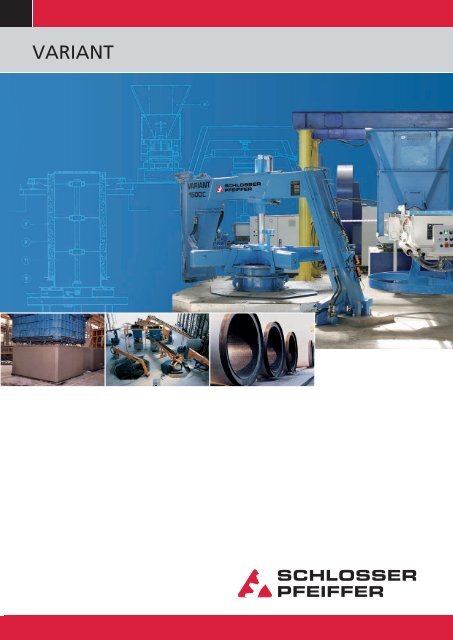

<strong>VARIANT</strong>

<strong>VARIANT</strong><br />

Effective and flexible production of concrete pipes in the diameter<br />

range of 300 mm up to 6,000 mm<br />

The <strong>VARIANT</strong> by Schlosser-Pfeiffer produces pipes in<br />

all shapes and sizes in top-rate high-density quality.<br />

The <strong>VARIANT</strong> by Schlosser-Pfeiffer combines the outstanding<br />

compacting qualities of Schlosser-Pfeiffer’s<br />

proprietary vibration technology with a wide choice of<br />

sizes and shapes and impresses with its largeness and<br />

strength, which are both prerequisites for producing<br />

large-sized pipes.<br />

Reinforced concrete pipes of 300mm internal diameter<br />

up to 6000 mm outside diameter, length up to 5 m and<br />

maximum product weight 30 to, jacking pipes, manhole<br />

pipes with or without taper, manholes with bottom,<br />

manholes and tapers, box culverts, ovoid pipes, elliptical<br />

pipes, pipes with special bottom section, pipes with or<br />

without flat base as well as pipes with embedded steel<br />

cylinder. All pipes can also be produced with PE or PVC<br />

inner lining.<br />

Each machine is individually adjusted for every application<br />

and combines user friendliness with reliability and<br />

easy maintenance. The machine will process just about<br />

any product of the user’s choice, making it versatile and<br />

capable of meeting the various and ever-changing market<br />

demands.<br />

The <strong>VARIANT</strong> by Schlosser-Pfeiffer guarantees optimised<br />

compacting results for all products, for first-rate quality<br />

and compliance with the relevant standards. The production<br />

range attests to the wide variety of sizes and products:<br />

Variant, D, R.indd 3 17.04.2007 10:19:02

Compaction<br />

The <strong>VARIANT</strong> by Schlosser-Pfeiffer works „below floor<br />

level“ to keep noise emissions reduced to a minimum and<br />

absorbs the vibrations occurring during production.<br />

The concrete is filled evenly into the mould by a rotating feeding<br />

belt. Concrete filling speed is individually adjustable for all production<br />

circumstances. The vibration are generated by a central<br />

vibrator connected to the core via a hydraulic clamping device.<br />

This design allows rapid mould changes. The mould jacket with<br />

base pallet is rubber-buffer isolated and mounted separately<br />

from the other machine components to ensure proper induction<br />

of the vibration into the product. The centrifugal force is<br />

also individually adjustable in accordance with product type and<br />

diameter.<br />

The advantages of this feeding and vibration technology by<br />

Schlosser-Pfeiffer include high-grade and uniform compacting,<br />

consistent product wall thickness, perfect coating of the reinforcements,<br />

smooth inside and outside surfaces, and dimensional<br />

accuracy.<br />

To shape the spigot ends, the spigot forming ring is first applied<br />

with its dead weight only (free load), hence allowing even distribution<br />

of the concrete. A hydraulic superimposed load may be<br />

added as needed. The spigot end is smoothed by the oscillating<br />

rotary movements of the spigot forming ring. The result: Perfectly<br />

and precisely shaped spigot ends suitable even for gaskets<br />

designed for narrow tolerances.<br />

Variant, D, R.indd 4 17.04.2007 10:19:17

<strong>VARIANT</strong><br />

Effective and flexible production of concrete<br />

pipes in a diameter range of up to<br />

6,000mm<br />

Demoulding<br />

The pipes remain inside their mould jackets while being<br />

transported to the demoulding area to ensure their<br />

dimensional accuracy. Hydraulic cylinders are optional<br />

available as demoulding aids to reduce crane load.<br />

Operation<br />

Easy operation requiring only two operators maximum,<br />

including crane operator. The use of a bridge crane is<br />

recommended for mould handling.<br />

Variant, D, R.indd 5 17.04.2007 10:19:25

Return transport<br />

During the return transport back to the <strong>VARIANT</strong>, the<br />

reinforcing cage and the next base pallet are loaded and<br />

again inserted into the machine.<br />

Reinforcements may be designed as single or multiple<br />

cages, as required. Precision positioning is also possible<br />

via the hydraulically operated centring units at the mould<br />

jacket.<br />

Control<br />

Control is a Siemens S7 PLC. All production parameters<br />

for every pipe size can be stored. The frequency<br />

(optionally) is adjustable and modifiable, depending on<br />

filling height.<br />

Variant, D, R.indd 6 17.04.2007 10:19:36

<strong>VARIANT</strong><br />

Options<br />

Machine output:<br />

Machine design is modular and can be upgraded<br />

by a number of additional functions:<br />

Adjustable central vibrators (frequency and centrifugal force)<br />

Contour controls for producing a wide variety of<br />

odd shaped products<br />

Material hopper weighing for automatic concrete<br />

requisitioning<br />

Automatic spigot-end production<br />

Additional equipment for the production of lined<br />

concrete pipe<br />

Remote maintenance<br />

<br />

<br />

<br />

<br />

<br />

Type: SP <strong>VARIANT</strong><br />

<br />

<br />

<br />

<br />

<br />

<br />

Twin machine<br />

3.5m length<br />

Twin machine<br />

2.0m length<br />

Single machine<br />

3.5m length<br />

Single machine<br />

2.0m length<br />

Nominal diameter DN [mm]<br />

Technical data:<br />

Type: SP <strong>VARIANT</strong><br />

Model ranges: 1500 2500 3600 6000<br />

A 12400 17000 22000 29000<br />

B 4600 5800 7100 8520<br />

C 1510 2110 3170 6300<br />

D 3870 5670 5290 4730<br />

H 3730 3730 3730 3930<br />

T* 4270 4270 4270 4270<br />

*for 3.0m laying length Right of technical modifications reserved<br />

Variant, D, R.indd 7 17.04.2007 10:20:34

Development - Design & Engineering -<br />

Manufacture<br />

Our machines are developed and designed using stateof-the-art<br />

3D CAD/CAE systems. The materials and<br />

components used in the manufacture of our machines<br />

and plants are selected to meet the strictest quality<br />

requirements and are quality-checked on a regular basis by<br />

in-house quality audits.<br />

Our machine components are manufactured from certified<br />

steel qualities, using CNC welding, milling and drilling<br />

technologies. The resulting machines and plants are<br />

characterised by low manufacturing tolerances and a<br />

correspondingly high quality standard.<br />

Variant, D, R.indd 8 17.04.2007 10:21:22

We put concrete into shape<br />

SCHLOSSER-PFEIFFER GmbH<br />

Scheidertalstrasse, Tor 4<br />

D-65326 Aarbergen<br />

Telephone: +49 (0) 6120 282901<br />

Fax: +49 (0) 6120 282931<br />

E-Mail: post@schlosser-pfeiffer.com<br />

Internet: www.schlosser-pfeiffer.com<br />

VAR_0407_E1<br />

Variant, D, R.indd 1 17.04.2007 10:18:50