VARIANT - HESS Group

VARIANT - HESS Group

VARIANT - HESS Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Compaction<br />

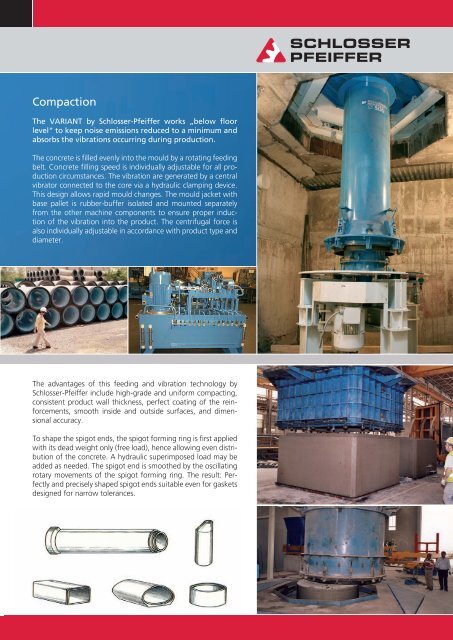

The <strong>VARIANT</strong> by Schlosser-Pfeiffer works „below floor<br />

level“ to keep noise emissions reduced to a minimum and<br />

absorbs the vibrations occurring during production.<br />

The concrete is filled evenly into the mould by a rotating feeding<br />

belt. Concrete filling speed is individually adjustable for all production<br />

circumstances. The vibration are generated by a central<br />

vibrator connected to the core via a hydraulic clamping device.<br />

This design allows rapid mould changes. The mould jacket with<br />

base pallet is rubber-buffer isolated and mounted separately<br />

from the other machine components to ensure proper induction<br />

of the vibration into the product. The centrifugal force is<br />

also individually adjustable in accordance with product type and<br />

diameter.<br />

The advantages of this feeding and vibration technology by<br />

Schlosser-Pfeiffer include high-grade and uniform compacting,<br />

consistent product wall thickness, perfect coating of the reinforcements,<br />

smooth inside and outside surfaces, and dimensional<br />

accuracy.<br />

To shape the spigot ends, the spigot forming ring is first applied<br />

with its dead weight only (free load), hence allowing even distribution<br />

of the concrete. A hydraulic superimposed load may be<br />

added as needed. The spigot end is smoothed by the oscillating<br />

rotary movements of the spigot forming ring. The result: Perfectly<br />

and precisely shaped spigot ends suitable even for gaskets<br />

designed for narrow tolerances.<br />

Variant, D, R.indd 4 17.04.2007 10:19:17