subchapter c -- federal hazardous substances act regulations

subchapter c -- federal hazardous substances act regulations

subchapter c -- federal hazardous substances act regulations

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

°F. divisions, and conforming to thermometer<br />

9F. of ASTM Standard E 1. For flashpoints<br />

from 20 °F. to 40 °F., use ASTM Tag Closed<br />

Tester, Low Range, Thermometer 57F. For<br />

flashpoints below 20 °F., use ASTM<br />

Thermometer 33F. The original Tag Open-Cup<br />

(Paper Scale) Thermometer will be a<br />

permissible alternate until January 1, 1962. It<br />

is calibrated to -20 °F.<br />

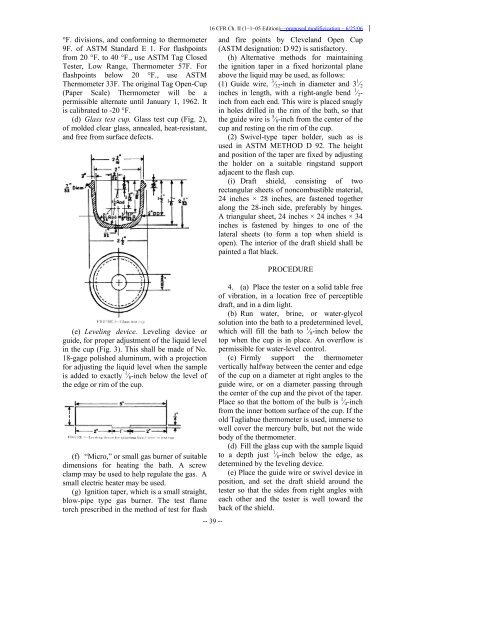

(d) Glass test cup. Glass test cup (Fig. 2),<br />

of molded clear glass, annealed, heat-resistant,<br />

and free from surface defects.<br />

(e) Leveling device. Leveling device or<br />

guide, for proper adjustment of the liquid level<br />

in the cup (Fig. 3). This shall be made of No.<br />

18-gage polished aluminum, with a projection<br />

for adjusting the liquid level when the sample<br />

is added to ex<strong>act</strong>ly 1 ⁄ 8 -inch below the level of<br />

the edge or rim of the cup.<br />

(f) “Micro,” or small gas burner of suitable<br />

dimensions for heating the bath. A screw<br />

clamp may be used to help regulate the gas. A<br />

small electric heater may be used.<br />

(g) Ignition taper, which is a small straight,<br />

blow-pipe type gas burner. The test flame<br />

torch prescribed in the method of test for flash<br />

16 CFR Ch. II (1–1–05 Edition)—proposed modificication – 6/25/06<br />

-- 39 --<br />

and fire points by Cleveland Open Cup<br />

(ASTM designation: D 92) is satisf<strong>act</strong>ory.<br />

(h) Alternative methods for maintaining<br />

the ignition taper in a fixed horizontal plane<br />

above the liquid may be used, as follows:<br />

(1) Guide wire, 3 ⁄ 32 -inch in diameter and 3 1 ⁄ 2<br />

inches in length, with a right-angle bend 1 ⁄ 2 -<br />

inch from each end. This wire is placed snugly<br />

in holes drilled in the rim of the bath, so that<br />

the guide wire is 5 ⁄ 8 -inch from the center of the<br />

cup and resting on the rim of the cup.<br />

(2) Swivel-type taper holder, such as is<br />

used in ASTM METHOD D 92. The height<br />

and position of the taper are fixed by adjusting<br />

the holder on a suitable ringstand support<br />

adjacent to the flash cup.<br />

(i) Draft shield, consisting of two<br />

rectangular sheets of noncombustible material,<br />

24 inches × 28 inches, are fastened together<br />

along the 28-inch side, preferably by hinges.<br />

A triangular sheet, 24 inches × 24 inches × 34<br />

inches is fastened by hinges to one of the<br />

lateral sheets (to form a top when shield is<br />

open). The interior of the draft shield shall be<br />

painted a flat black.<br />

PROCEDURE<br />

4. (a) Place the tester on a solid table free<br />

of vibration, in a location free of perceptible<br />

draft, and in a dim light.<br />

(b) Run water, brine, or water-glycol<br />

solution into the bath to a predetermined level,<br />

which will fill the bath to 1 ⁄ 8 -inch below the<br />

top when the cup is in place. An overflow is<br />

permissible for water-level control.<br />

(c) Firmly support the thermometer<br />

vertically halfway between the center and edge<br />

of the cup on a diameter at right angles to the<br />

guide wire, or on a diameter passing through<br />

the center of the cup and the pivot of the taper.<br />

Place so that the bottom of the bulb is 1 ⁄ 4 -inch<br />

from the inner bottom surface of the cup. If the<br />

old Tagliabue thermometer is used, immerse to<br />

well cover the mercury bulb, but not the wide<br />

body of the thermometer.<br />

(d) Fill the glass cup with the sample liquid<br />

to a depth just 1 ⁄ 8 -inch below the edge, as<br />

determined by the leveling device.<br />

(e) Place the guide wire or swivel device in<br />

position, and set the draft shield around the<br />

tester so that the sides from right angles with<br />

each other and the tester is well toward the<br />

back of the shield.