Interface Drawings - MicroE Systems

Interface Drawings - MicroE Systems

Interface Drawings - MicroE Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

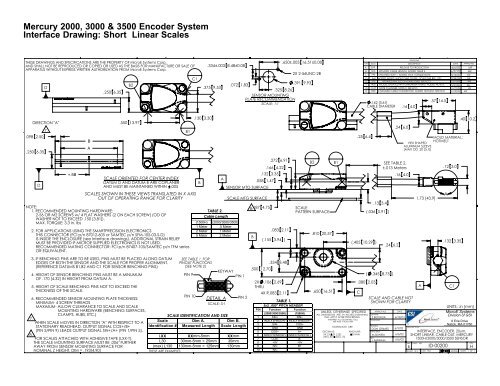

Mercury 2000, 3000 & 3500 Encoder System<br />

<strong>Interface</strong> Drawing: Short Linear Scales<br />

6<br />

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF <strong>MicroE</strong> <strong>Systems</strong> Corp.<br />

AND SHALL NOT BE REPRODUCED OR COPIED OR USED AS THE BASIS FOR MANUFACTURE OR SALE OF<br />

APPARATUS WITHOUT EXPRESS WRITTEN AUTHORIZATION FROM <strong>MicroE</strong> <strong>Systems</strong> Corp.<br />

C1<br />

B2<br />

D<br />

.250 6.35<br />

.334±.003 8.48±0.08<br />

.375 9.53<br />

.072<br />

.650±.003<br />

16.51±0.08<br />

.391<br />

1.83<br />

.325 8.26<br />

SENSOR MOUNTING<br />

PLATE RECOMMENDATION<br />

SCALE: 1:1<br />

2X 2-56UNC-2B<br />

9.93<br />

LTR<br />

ECO<br />

REVISIONS<br />

DESCRIPTION<br />

D 960 ADDED M3500, SNOUT DIMS TO REF., SCALE THK REF. .037 9/24/02 MF<br />

E 979 UPDATED PIN 3 (COS+) WAS GND. SEE ECO. 11/19/02 MF<br />

F 1426 MODEL UPDATED WITH SHRUNKEN HYBRID. ADDED NOTE 8. 5/31/05 SB<br />

G 1517 NOTE CHANGES, NOTE 2. SEE ECO 11/22/05 VB<br />

H 1939 CHANGED CABLE CONNECTOR, ADDED HOTMELT. SEE ECO 11/30/07 MF<br />

1<br />

DATE<br />

APPROVED<br />

A 879 RELEASE TO PRODUCTION<br />

6/6/02 MF<br />

B 900 UPDATED CABLE LENGTH, ADDED TABLE 2.<br />

6/27/02 MF<br />

C 946 UPDATED NOTE 1, ADDED MAX. TORQUE NOTE 8/14/02 MF<br />

.142 [3.61]<br />

CABLE DIAMETER<br />

.16 4.0<br />

.57 14.5<br />

DIRECTION "A"<br />

7.<br />

.098 2.50<br />

.250 6.35<br />

B<br />

A<br />

.550 13.97<br />

B1<br />

.130 3.30<br />

.25 6.4<br />

.24 6.0<br />

MOLD MATERIAL:<br />

HOTMELT<br />

HEX SHAPED<br />

ALUMINUM SLEEVE<br />

(MAX OD .20 [5.1])<br />

.40 10.2<br />

D<br />

=.5B<br />

SCALE ORIENTED FOR CENTER INDEX<br />

DATUM D AND DATUM B ARE COPLANER B<br />

AND MUST BE MAINTAINED WITHIN .005<br />

SCALES SHOWN IN THESE VIEWS TRANSLATED IN X AXIS<br />

OUT OF OPERATING RANGE FOR CLARITY<br />

NOTE:<br />

1. RECOMMENDED MOUNTING HARDWARE:<br />

2-56 OR M2 SCREWS w/ 4 FLAT WASHERS (2 ON EACH SCREW) (OD OF<br />

WASHER NOT TO EXCEED .150 [3.81]).<br />

MAX. TORQUE: 3.3 in. lbs<br />

2. FOR APPLICATIONS USING THE SMARTPRECISION ELECTRONICS<br />

THIS CONNECTOR (FCI p/n 87012-605 or SAMTEC p/n SFM-105-03-S-D)<br />

IS INSIDE THE ENCLOSURE (see <strong>Interface</strong> drawings). ADDITIONAL STRAIN RELIEF<br />

MUST BE PROVIDED IF MICROE SUPPLIED ELECTRONICS IS NOT USED.<br />

RECOMMENDED MATING CONNECTOR: FCI p/n 87407-105/SAMTEC p/n TFM series<br />

OR EQUIVALENT.<br />

3. IF BENCHING PINS ARE TO BE USED, PINS MUST BE PLACED ALONG DATUM<br />

EDGES OF BOTH THE SENSOR AND THE SCALE FOR PROPER ALIGNMENT.<br />

(REFERENCE DATUMS B1,B2 AND C1 FOR SENSOR BENCHING PINS)<br />

4. HEIGHT OF SENSOR BENCHING PINS MUST BE A MINUMUM<br />

OF .170 [4.32] IN HEIGHT FROM DATUM A.<br />

5. HEIGHT OF SCALE BENCHING PINS NOT TO EXCEED THE<br />

THICKNESS OF THE SCALE.<br />

6. RECOMMENDED SENSOR MOUNTING PLATE THICKNESS:<br />

MINIMUM- 4 SCREW THREADS<br />

MAXIMUM- ALLOW CLEARANCE TO SCALE AND SCALE<br />

MOUNTING HARDWARE (BENCHING SURFACES,<br />

CLAMPS, HUBS, ETC.)<br />

7.<br />

WHEN SCALE MOVES IN DIRECTION "A" WITH RESPECT TO A<br />

STATIONARY READHEAD, OUTPUT SIGNAL COS+/B+<br />

(PIN 5/PIN 9) LEADS OUTPUT SIGNAL SIN+/A+ (PIN 1/PIN 5).<br />

8.<br />

FOR SCALES ATTACHED WITH ADHESIVE TAPE (LXX-T),<br />

THE SCALE MOUNTING SURFACE MUST BE .006" FURTHER<br />

AWAY FROM SENSOR MOUNTING SURFACE FOR<br />

NOMINAL Z HEIGHT. DIM = .193[4.90]<br />

PIN 9<br />

PIN 10<br />

TABLE 2.<br />

Cable Length<br />

(1500H) (2000/3000/3500)<br />

1 Meter .5 Meter<br />

2 Meter 1 Meter<br />

5 Meter 2 Meter<br />

SEE TABLE 1. FOR<br />

PINOUT FUNCTIONS<br />

(SEE NOTE 2)<br />

DETAIL A<br />

SCALE: 3:1<br />

KEYWAY<br />

PIN 1<br />

SCALE IDENTIFICATION AND SIZE<br />

Scale Dim A. Dim B.<br />

Identification # Measured Length Scale Length<br />

LXX XXmm-5mm XXmm<br />

L30 30mm-5mm = 25mm 30mm<br />

(max) L130 130mm-5mm = 125mm 130mm<br />

THESE ARE EXAMPLES<br />

A<br />

SENSOR MTG SURFACE<br />

SCALE MTG SURFACE<br />

PIN 2<br />

8. .187 4.75<br />

B<br />

.500 12.70<br />

.166 4.22<br />

.132 3.35<br />

.058 1.47<br />

.272 6.91<br />

.083 2.11<br />

(.155 3.94 )<br />

.334 8.48<br />

2X .106 2.69<br />

THRU<br />

4X R.083 2.11<br />

B2<br />

SCALE<br />

PATTERN SURFACE<br />

TABLE 1.<br />

5x2, .050" PITCH HEADER<br />

PIN Function Function<br />

(2000/3000/3500) (1500H)<br />

1 SIN+ SIN+<br />

2 INDEX WINDOW- INDEX WINDOW-<br />

3 SIN- COS+<br />

4 GND GND<br />

5 COS+ A+<br />

6 INDEX WINDOW+ INDEX WINDOW+<br />

7 COS- A-<br />

8 +5V +5V<br />

9 N/C B+<br />

10 N/C B-<br />

.810 20.57<br />

.650 16.51<br />

B1<br />

UNLESS OTHERWISE SPECIFIED<br />

ALL DIMENSIONS ARE IN INCHES [millimeters]<br />

DIM. APPLY AFTER PROCESSING<br />

INTERPRET ALL GEOMETRIC TOLS.<br />

PER ANSI Y14.5M-1994<br />

TOLERANCES ARE:<br />

C<br />

DECIMALS: ANGULAR:<br />

.XX [.X] .01 [.25] 30 MIN.<br />

.XXX [.XX] .005 [.13]<br />

(.405 10.29 )<br />

(<br />

.080 2.03<br />

.13 3.4<br />

(.036 0.91 )<br />

SEE TABLE 2.<br />

±.013 Meters<br />

.16 4.0<br />

APPROVALS<br />

DRAWN<br />

S.BUTURLIA<br />

CHECKED<br />

ENGRG.<br />

DON GRIMES<br />

MFG ENG<br />

M.SKWIRA<br />

QA<br />

J.FARNAM<br />

.24 6.2<br />

.345 8.75 )<br />

SCALE AND CABLE NOT<br />

SHOWN FOR CLARITY<br />

DATE<br />

4/18/01<br />

6/5/02<br />

6/6/02<br />

6/6/02<br />

DESCRIPTION:<br />

SIZE<br />

B<br />

DWG. NO.<br />

CAD FILE:<br />

UNITS: .in [mm]<br />

<strong>MicroE</strong> <strong>Systems</strong><br />

Division of GSI<br />

8 Erie Drive<br />

Natick, MA 01760<br />

INTERFACE, ENCODER, 20um,<br />

SHORT LINEAR, CABLE OUT, MERCURY<br />

1500H/2000/3000/3500 SENSOR<br />

SCALE:<br />

2:1<br />

1.73 [43.9]<br />

A<br />

A<br />

ID-00200<br />

.12 3.0<br />

.132 3.35<br />

1<br />

C1<br />

3rd ANGLE<br />

PROJECTION<br />

REV.<br />

H<br />

SHEET 1 OF 1

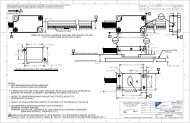

Mercury 2000, 3000 & 3500 Encoder System<br />

<strong>Interface</strong> Drawing: Long Linear Scales<br />

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF <strong>MicroE</strong> <strong>Systems</strong> Corp. AND SHALL<br />

NOT BE REPRODUCED OR COPIED OR USED AS THE BASIS FOR MANUFACTURE OR SALE OF<br />

APPARATUS WITHOUT EXPRESS WRITTEN AUTHORIZATION FROM <strong>MicroE</strong> <strong>Systems</strong> Corp.<br />

.519 13.18<br />

B2<br />

D<br />

C1<br />

.650 ±.003 16.51±0.076<br />

.334±.003 8.48±0.076<br />

.375 9.53<br />

.072 1.83<br />

.325 8.26<br />

SENSOR MOUNTING<br />

PLATE RECOMMENDATION<br />

SCALE: 1:1<br />

2X 2-56UNC-2B<br />

.391 9.93<br />

.142 [3.61]<br />

CABLE DIAMETER<br />

REVISIONS<br />

ECO<br />

LTR DESCRIPTION DATE APPROVED<br />

A 879 RELEASE TO PRODUCTION<br />

6/6/02 MF<br />

B 900 UPDATED CABLE LENGTHS, ADDED TABLE 6/27/02 MF<br />

2.<br />

C 946 UPDATED NOTE 1., ADDED MAX. TORQUE NOTE 8/14/02 MF<br />

D 960 ADDED M3500, SNOUT DIMS REFERENCE. 9/24/02 MF<br />

E 979 UPDATED TABLE 1. PIN 3 (COS+) WAS GND<br />

11/19/02 MF<br />

F 1270 FIXED SCALE DIMENSIONS. REVERSED "A" AND "B". SEE ECO 4/13/04 MF<br />

G 1426 MODEL UPDATED WITH SHRUNKEN HYBRID. ADDED NOTE 8. 5/31/05 SB<br />

H 1517 UPDATE NOTE 2. SEE ECO<br />

11/28/05 MF<br />

I 1939 CHANGED CABLE CONNECTOR, ADDED HOTMELT. SEE ECO 11/30/07 MF<br />

.57 14.5<br />

.16 4.0<br />

D<br />

7.<br />

DIRECTION "A"<br />

B<br />

.098 2.50<br />

A<br />

.550 13.97<br />

SCALE ORIENTED FOR END INDEX<br />

B1<br />

.130 3.30<br />

SCALES SHOWN IN THESE VIEWS TRANSLATED IN X AXIS<br />

OUT OF OPERATING RANGE FOR CLARITY<br />

B<br />

.24 6.0<br />

HEX SHAPED<br />

ALUMINUM SLEEVE<br />

(MAX OD .20 [5.1])<br />

.25 6.4<br />

.40 10.2<br />

MOLD MATERIAL:<br />

HOTMELT<br />

.787 20.00<br />

D<br />

=.5B<br />

.269 6.82<br />

SCALE ORIENTED FOR CENTER INDEX<br />

B<br />

.132 3.35<br />

A<br />

.058 1.47<br />

SENSOR MTG SURFACE<br />

SCALE MTG SURFACE<br />

8.<br />

.249 6.33<br />

.272 6.91<br />

.166 4.22<br />

B2<br />

B1<br />

SCALE PATTERN<br />

SURFACE<br />

SEE TABLE 2.<br />

.013 Meters<br />

1.73 [43.9]<br />

.13 3.4<br />

(.098 2.50 )<br />

A<br />

.12 3.0<br />

.16 4.0<br />

C<br />

B<br />

NOTES:<br />

1. RECOMMENDED MOUNTING HARDWARE: 2-56 OR M2 SCREWS w/ 4 FLAT<br />

WASHERS (2 ON EACH SCREW) (OD OF WASHER NOT TO EXCEED .150 [3.81]).<br />

MAX. TORQUE: 3.3 in. lbs<br />

2. FOR APPLICATIONS USING THE SMARTPRECISION ELECTRONICS THIS CONNECTOR<br />

(FCI p/n 87012-605 or SAMTEC p/n SFM-105-03-S-D) IS INSIDE THE ENCLOSURE<br />

(see <strong>Interface</strong> drawings). ADDITIONAL STRAIN RELIEF MUST BE PROVIDED IF<br />

MICROE SUPPLIED ELECTRONICS IS NOT USED.<br />

RECOMMENDED MATING CONNECTOR: FCI p/n 87407-105/SAMTEC p/n TFM SERIES<br />

OR EQUIVALENT.<br />

3. IF BENCHING PINS ARE TO BE USED, PINS MUST BE PLACED ALONG DATUM<br />

7.<br />

8.<br />

WHEN SCALE MOVES IN DIRECTION "A" WITH RESPECT<br />

TO A STATIONARY READHEAD, OUTPUT SIGNAL COS+/B+<br />

(PIN 5/PIN 9) LEADS OUTPUT SIGNAL SIN+/A+ (PIN 1/PIN 5).<br />

FOR SCALES ATTACHED W/ADHESIVE TAPE (LXX-T),<br />

THE SCALE MOUNTING SURFACE MUST BE .006"<br />

FURTHER AWAY FROM SENSOR MOUNTING SURFACE<br />

FOR NOMINAL Z HEIGHT. DIM = .255[6.48]<br />

TABLE 2.<br />

Cable Length<br />

(1500H) (2000/3000/3500)<br />

1 Meter .5 Meter<br />

2 Meter 1 Meter<br />

5 Meter 2 Meter<br />

4. HEIGHT OF SENSOR BENCHING PINS MUST BE A MINIMUM OF .170 [4.32]<br />

IN HEIGHT FROM DATUM A.<br />

PIN 10<br />

DETAIL A<br />

SCALE: 3:1<br />

5. HEIGHT OF SCALE BENCHING PINS NOT TO EXCEED THE THICKNESS OF THE SCALE.<br />

6. RECOMMENDED SENSOR MOUNTING PLATE THICKNESS: MINIMUM- 4 SCREW THREADS<br />

MAXIMUM- ALLOW CLEARANCE TO SCALE AND SCALE MOUNTING<br />

HARDWARE (BENCHING SURFACES, CLAMPS, HUBS, ETC.)<br />

SCALE IDENTIFICATION AND SIZE<br />

PIN 9<br />

EDGES OF BOTH THE SENSOR AND THE SCALE FOR PROPER ALIGNMENT. SEE TABLE 1. FOR<br />

(REFERENCE DATUMS B1, B2 AND C1 FOR SENSOR BENCHING PINS) PINOUT FUNCTIONS<br />

(SEE NOTE 2)<br />

LXX XXmm-5mm XXmm<br />

L155 155mm-5mm = 150mm 155mm<br />

(max) L2025 2025mm-5mm = 2020mm 2025mm<br />

THESE ARE EXAMPLES<br />

KEYWAY<br />

PIN 1<br />

Scale Dim A. Dim B.<br />

Identification # Measured Length Scale Length<br />

B<br />

.500 12.70<br />

2X .106<br />

THRU<br />

.083 2.11<br />

.155 3.93<br />

.334 8.48<br />

2.69<br />

PIN 2<br />

4X R.083 2.11<br />

TABLE 1.<br />

5x2, .050" PITCH HEADER<br />

PIN Function Function<br />

(2000/3000/3500) (1500H)<br />

1 SIN+ SIN+<br />

2 INDEX WINDOW- INDEX WINDOW-<br />

3 SIN- COS+<br />

4 GND GND<br />

5 COS+ A+<br />

6 INDEX WINDOW+ INDEX WINDOW+<br />

7 COS- A-<br />

8 +5V +5V<br />

9 N/C B+<br />

10 N/C B-<br />

.810 20.57<br />

.650 16.51<br />

UNLESS OTHERWISE SPECIFIED APPROVALS<br />

DRAWN<br />

ALL DIMENSIONS ARE IN INCHES [millimeters]<br />

DIM. APPLY AFTER PROCESSING S.BUTURLIA<br />

INTERPRET ALL GEOMETRIC TOLS.<br />

CHECKED<br />

PER ANSI Y14.5M-1994<br />

TOLERANCES ARE:<br />

DECIMALS: ANGULAR:<br />

.XX [.X] .01 [.25]<br />

.XXX .XX] .005 [.13]<br />

30 MIN.<br />

(.405 10.29 )<br />

C<br />

(<br />

.24 6.1<br />

DATE<br />

4/18/01<br />

ENGRG.<br />

DON GRIMES 6/5/02<br />

MFG ENG<br />

M.SKWIRA 6/6/02<br />

QA<br />

J.FARNAM<br />

.345 8.75 )<br />

.080 2.03<br />

SCALE AND CABLE NOT<br />

SHOWN FOR CLARITY<br />

6/6/02<br />

DESCRIPTION:<br />

.132 3.35<br />

A<br />

C1<br />

UNITS: .in [mm]<br />

A<br />

<strong>MicroE</strong> <strong>Systems</strong><br />

Division of GSI<br />

8 Erie Drive<br />

Natick, MA 01760<br />

INTERFACE, ENCODER, 20um,<br />

LONG LINEAR, CABLE OUT, MERCURY<br />

1500H/2000/3000/3500 SENSOR<br />

SIZE DWG. NO.<br />

REV.<br />

B ID-00201<br />

I<br />

3rd ANGLE<br />

SCALE: 2:1 CAD FILE:<br />

PROJECTION SHEET 1 OF 1<br />

1

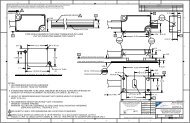

Mercury 2000, 3000 & 3500 Encoder System<br />

<strong>Interface</strong> Drawing: Rotary Scales with Hub<br />

D<br />

B<br />

A<br />

THESE DRAWINGS AND SPECIFICATIONS ARE THE PROPERTY OF <strong>MicroE</strong> <strong>Systems</strong> Corp. AND SHALL<br />

NOT BE REPRODUCED OR COPIED OR USED AS THE BASIS FOR MANUFACTURE OR SALE<br />

OF APPARATUS WITHOUT EXPRESS WRITTEN AUTHORIZATION FROM <strong>MicroE</strong> <strong>Systems</strong> Corp.<br />

NOTE:<br />

1. RECOMMENDED MOUNTING HARDWARE:<br />

2-56 OR M2 SCREWS w/ 4 FLAT WASHER (2 ON EACH SCREW)<br />

(OD OF WASHERS NOT TO EXCEED .150 [3.81]).<br />

MAX TORQUE: 3.3 in. lbs<br />

ON A BOLT CIRCLE<br />

2. FOR APPLICATIONS USING THE SMARTPRECISION ELECTRONICS<br />

THIS CONNECTOR (FCI p/n 87012-605 or SAMTEC p/n SFM-105-03-S-D)<br />

IS INSIDE THE ENCLOSURE (see <strong>Interface</strong> drawings). ADDITIONAL STRAIN<br />

RELIEF MUST BE PROVIDED IF MICROE SUPPLIED ELECTRONICS IS NOT USED.<br />

RECOMMENDED MATING CONNECTOR: FCI p/n 87407-105/SAMTEC p/n TFM SERIES<br />

OR EQUIVALENT.<br />

3. IF BENCHING PINS ARE TO BE USED, PINS MUST BE PLACED ALONG DATUM<br />

EDGES OF SENSOR FOR PROPER ALIGNMENT.<br />

(REFERENCE DATUMS B1, B2 AND C1).<br />

4. HEIGHT OF SENSOR BENCHING PINS MUST BE A MINUMUM<br />

OF .170 [4.32] IN HEIGHT FROM DATUM A.<br />

5. RECOMMENDED SENSOR MOUNTING PLATE THICKNESS:<br />

MINIMUM- 4 SCREW THREADS<br />

MAXIMUM- ALLOW CLEARANCE TO SCALE AND SCALE MOUNTING<br />

HARDWARE (BENCHING SURFACES, CLAMPS, HUBS, ETC.)<br />

6. WHEN SCALE MOVES IN DIRECTION "A" WITH RESPECT<br />

TO A STATIONARY READHEAD, OUTPUT SIGNAL COS+/B+<br />

(PIN 5/PIN 9) LEADS OUTPUT SIGNAL SIN+/A+ (PIN 1/PIN 5).<br />

.334±.003 8.48±0.08<br />

.072 1.83<br />

TABLE 2.<br />

Cable Length<br />

(1500H) (2000/3000/3500)<br />

1 Meter .5 Meter<br />

2 Meter 1 Meter<br />

5 Meter 2 Meter<br />

.650±.003 16.51±0.08<br />

2X 2-56UNC-2B<br />

.391 9.93<br />

.325 8.26<br />

SENSOR MOUNTING PLATE RECOMMENDATION<br />

SCALE: 1:1<br />

SCALE IDENTIFICATION AND SIZE. DIMENSIONS IN INCHES [MILLIMETERS]<br />

A<br />

E<br />

MOUNTING HOLE AND<br />

THREAD F. EQ. SPACED<br />

H<br />

SENSOR MTG SURFACE<br />

SCALE MTG SURFACE<br />

.132<br />

.058 1.47<br />

.151 3.84<br />

2X<br />

B<br />

B<br />

.500 12.70<br />

A<br />

.272 6.91<br />

.166 4.22<br />

3.35<br />

J<br />

C<br />

D<br />

.550 13.97<br />

.083 2.11<br />

.106 2.69 THRU.<br />

B2<br />

SCALE<br />

PATTERN SURFACE<br />

.810 20.57<br />

B1<br />

.405±.003<br />

10.29±0.08<br />

B<br />

.375 9.53<br />

.130 3.30<br />

L<br />

E<br />

MACHINE AXIS<br />

6.<br />

DIRECTION "A"<br />

K<br />

C1<br />

.13 3.4<br />

(.155 3.93 ) (.405 10.29 )<br />

( .345 8.75 )<br />

.334 8.48<br />

4X R.083 2.11<br />

.650 16.51<br />

.080 2.03<br />

C<br />

Scale Counts/ Dim. A Scale I.D. Dim. B Dim. C Dim D. Dim E. Thread F Dim H. Dim. J Dim. K Dim. L<br />

Identification Rev Scale O.D. Optical Dia. Mounting Dim. Hub I.D. Mounting Hole Dia. Bolt Circle Hub Height Scale Thickness Hub Relief<br />

R1206 1,650 0.472 .250+/-.005 0.413 0.348+/-.002 0.1253+.0005/-.0000 N/A N/A N/A 0.040 .036+/-.002 0.045<br />

[12.00] [6.35+/-.13] [10.50] [8.84+/-.05] [3.182+.013/-.000]<br />

[1.02] [.91+/-.05] [1.14]<br />

R1910 2,500 0.750 .375+/-.005 0.627 0.454+/-.002 0.1253+.0005/-.0000 0.047 0.250 0.040 .090+/-.004 0.105<br />

[19.05] [9.53+/-0.13] [15.92] [11.53+/-.05] [3.182+.013/-.000] [1.19] 0-80 [6.35] [1.02] [2.29+/-.10] [2.67]<br />

R3213 4,096 1.250 .500+/-.005 1.027 0.654+/-.002 0.2503+.0005/-.0000 0.070 0.370 0.050 .090+/-.004 0.105<br />

[31.75] [12.70+/-0.13] [26.08] [16.62+/-.05] [6.357+.013/-.000] [1.78] 2-56 [9.40] [1.27] [2.29+/-.10] [2.67]<br />

R5725 8,192 2.250 1.000+/-.005 2.053 1.168+/-.002 0.5003+.0005/-.0000 0.136 0.750 0.060 .090+/-.004 0.105<br />

[57.15] [25.40+/-0.13] [52.15] [29.66+/-.05] [12.707+.013/-.000] [3.45] 8-32 [19.05] [1.52] [2.29+/-.10] [2.67]<br />

R10851 16,384 4.250 2.000+/-.005 4.106 2.194+/-.002 1.0003+.0005/-.0000 0.136 1.375 0.080 .090+/-.004 0.105<br />

[107.95] [50.80+/-0.13] [104.30] [55.73+/-.05] [25.408+.013/-.000] [3.45] 8-32 [34.93] [2.03] [2.29+/-.10] [2.67]<br />

.24 6.2<br />

SEE TABLE 2.<br />

±.013 Meters<br />

.142 [3.61]<br />

CABLE DIAMETER<br />

.16 4.0<br />

.16 4.0<br />

C 945 ADDED MAX TORQUE SPEC. TO NOTES 8/9/02 MF<br />

D 954 CORRECTED DIMS IN TABLE (Dim D), mm CONVERSION INCORRECT 8/29/02 MF<br />

E 960 ADDED M3500, ADDED R1206 TO TABLE, SNOUT DIMS REF. 9/24/02 MF<br />

F 979 UPDATED TABLE 1. PIN 3 (COS+) WAS GND. SEE ECO<br />

11/19/02 MF<br />

G 1124 UPDATED SCALE TABLE, ADDED HUB ID, HEIGHT TO R1206. DIM L.<br />

6/23/03 MF<br />

H 1159 UPDATED SCALE THICKNESS TOLERANCE, WAS ±.008 (.090"). SEE ECO<br />

3/8/04 MF<br />

I 1357 ADDED DIMENSION IN ZONE D4, .405±.003[10.29±0.08]<br />

9/16/04 SB<br />

J 1517 UPDATED NOTE 2. SEE ECO<br />

11/23/05 MF<br />

K 1939 CHANGED CABLE CONNECTOR, ADDED HOTMELT. SEE ECO 11/30/07 MF<br />

1.73 [43.9]<br />

UNLESS OTHERWISE SPECIFIED APPROVALS<br />

ALL DIMENSIONS ARE IN DRAWN<br />

INCHES [millimeters] S.BUTURLIA<br />

DIM. APPLY AFTER PROCESSING CHECKED<br />

INTERPRET ALL GEOMETRIC TOLS.<br />

PER ANSI Y14.5M-1994<br />

TOLERANCES ARE:<br />

DECIMALS: ANGULAR:<br />

.XX [.X] .01 [.25] 30 MIN.<br />

.XXX [.XX] .005 [.13]<br />

REVISIONS<br />

LTR ECO<br />

DESCRIPTION DATE APPROVED<br />

A 879 RELEASE TO PRODUCTION<br />

B 900 UPDATED CABLE LENGTHS, ADDED TABLE 2.<br />

HEX SHAPED<br />

ALUMINUM SLEEVE<br />

(MAX OD .20 [5.1])<br />

.25 6.4<br />

.132 3.35<br />

A<br />

SCALE AND CABLE NOT<br />

SHOWN FOR CLARITY<br />

ENGRG.<br />

DON GRIMES<br />

DATE<br />

A<br />

MFG ENG<br />

M.SKWIRA 6/6/02<br />

QA<br />

J.FARNAM<br />

.57 14.5<br />

C1<br />

4/20/01<br />

6/5/02<br />

6/6/02<br />

DESCRIPTION:<br />

SCALE:<br />

.12 3.0<br />

TABLE 1.<br />

5x2, .050" PITCH HEADER<br />

PIN Function Function<br />

(2000/3000/3500) (1500H)<br />

1 SIN+ SIN+<br />

2 INDEX WINDOW- INDEX WINDOW-<br />

3 SIN- COS+<br />

4 GND GND<br />

5 COS+ A+<br />

6 INDEX WINDOW+ INDEX WINDOW+<br />

7 COS- A-<br />

8 +5V +5V<br />

9 N/C B+<br />

10 N/C B-<br />

8 Erie Drive<br />

Natick, MA 01760<br />

INTERFACE, ENCODER, 20um,<br />

ROTARY w/HUB, CABLE OUT, MERCURY<br />

1500H/2000/3000/3500 SENSOR<br />

SIZE DWG. NO.<br />

REV.<br />

B ID-00202<br />

K<br />

2:1<br />

MOLD MATERIAL:<br />

HOTMELT<br />

.24 6.0<br />

.40 10.2<br />

PIN 10<br />

CAD FILE:<br />

DETAIL A<br />

SCALE: 3:1<br />

UNITS: .in [mm]<br />

<strong>MicroE</strong> <strong>Systems</strong><br />

Division of GSI<br />

1<br />

6/6/02 MF<br />

6/27/02 MF<br />

SEE TABLE 1. FOR<br />

PINOUT FUNCTIONS<br />

(SEE NOTE 2)<br />

KEYWAY<br />

PIN 9<br />

PIN 1<br />

3rd ANGLE<br />

PROJECTION<br />

PIN 2<br />

SHEET 1 OF 1

Mercury 3000 Dual Axis Averager<br />

<strong>Interface</strong> Drawing: SmartPrecision Electronics Module (Interpolator)<br />

THESE DRAWINGS AND SPECIFICATIONS ARE<br />

THE PROPERTY OF <strong>MicroE</strong> <strong>Systems</strong> Corp. AND SHALL<br />

NOT BE REPRODUCED OR COPIED OR USED<br />

AS THE BASIS FOR MANUFACTURE OR SALE<br />

OF APPARATUS WITHOUT EXPRESS WRITTEN<br />

AUTHORIZATION FROM <strong>MicroE</strong> <strong>Systems</strong> Corp.<br />

.49 12.4<br />

2X 1.38 35.1<br />

3.57 90.6<br />

3.44 87.4<br />

2X .18 4.5 THRU.<br />

REVISIONS<br />

LTR ECO<br />

DESCRIPTION DATE APP'D<br />

S1 PRELIMINARY 3/29/04<br />

S2 1397 ADDED DIMENSIONS, NOTES, TABLES 1, 2 & 3 AND DETAILS FOR 2/16/05 SB<br />

MOUNTING SCREWS AND THRU HOLES.<br />

A 1727 RELEASE TO PRODUCTION<br />

11/13/06 SB<br />

B 1847 COVER MODIFIED, CHANGED LENGTH OF JACKSCREWS,<br />

4/3/08 VB<br />

ADDED DIMENSIONS. LABEL RESIZED DUE TO COVER CHANGE.<br />

PIN 14<br />

PIN 1<br />

CABLE FROM SENSOR 2<br />

1.99 50.5<br />

2.29 58.2<br />

CABLE FROM SENSOR 1<br />

PIN 25<br />

PIN 13<br />

DB25 MALE<br />

(SEE TABLES 1 &<br />

2 FOR PINOUTS)<br />

.15 3.8<br />

USB MINI-B RECEPTACLE<br />

(SEE TABLE 3 FOR PINOUTS)<br />

TABLE 1<br />

SS-300cA DB25 PINOUTS<br />

1 A1+ 14 A3-<br />

2 A1- 15 B3+<br />

3 B1+ 16 B3-<br />

4 B1- 17 I3+<br />

5 I1+ 18 I3-<br />

6 I1- 19 N/C<br />

7 A2+ 20 N/C<br />

8 A2- 21 TXD/D-<br />

9 B2+ 22 RXD/D+<br />

10 B2- 23 ALARM<br />

11 I2+ 24 +5V<br />

12 I2- 25 GND<br />

13 A3+<br />

.25<br />

NOTES:<br />

.50 12.7<br />

6.4<br />

PIN 1<br />

TABLE 3<br />

USB CONNECTOR PINOUTS<br />

1 VBUS 4 N/C<br />

2 D- 5 GND<br />

3 D+<br />

1. RECOMMENDED MOUNTING HARDWARE 8-32 UNC OR M4 SCREWS<br />

WITH FLAT WASHERS (OD OF WASHER NOT TO EXCEED .320[8.13])<br />

1.14<br />

PIN 5<br />

2. THIS DRAWING APPLIES TO BOTH MODEL NUMBERS SS-300cA AND SS300-cASi.<br />

29<br />

.85 21.6<br />

UNLESS OTHERWISE SPECIFIED<br />

ALL DIMENSIONS ARE IN INCHES[millimeters]<br />

DIM. APPLY AFTER PROCESSING<br />

INTERPRET ALL GEOMETRIC TOLS.<br />

PER ANSI Y14.5M-1994<br />

TOLERANCES ARE:<br />

DECIMALS: ANGULAR:<br />

.XX[.X] .01[.25] 30 MIN.<br />

.XXX[.XX] .005[.13]<br />

APPROVALS<br />

DATE<br />

DRAWN<br />

PAUL DEVINE 1/19/04<br />

CHECKED<br />

ENGRG.<br />

CJ 11/13/06<br />

MFG ENG<br />

THOMAS GARCIA 11/13/06<br />

QA<br />

A. VILLARROEL 11/13/06<br />

DESCRIPTION:<br />

SIZE<br />

B<br />

SCALE:<br />

TABLE 2<br />

SS-300cASi DB25 PINOUTS<br />

1 SD01+ 14 SD03-<br />

2 SD01- 15 CS3+<br />

3 CS1+ 16 CS3-<br />

4 CS1- 17 SCLK3+<br />

5 SCLK1+ 18 SCLK3-<br />

6 SCLK1- 19 FBCLK+<br />

7 SD02+ 20 FBCLK-<br />

8 SD02- 21 TXD/D-<br />

9 CS2+ 22 RXD/D+<br />

10 CS2- 23 ALARM<br />

11 SCLK2+ 24 +5V<br />

12 SCLK2- 25 GND<br />

13 SD03+<br />

ID-00283<br />

<strong>MicroE</strong> <strong>Systems</strong><br />

Division of GSI<br />

8 Erie Drive<br />

Natick, MA 01760<br />

INTERFACE, INTERPOLATOR,<br />

DUAL AXIS AVERAGER<br />

DWG. NO.<br />

1.5<br />

CAD FILE:<br />

1<br />

3rd ANGLE<br />

PROJECTION<br />

REV.<br />

B<br />

SHEET 1 OF 1