PaintChecker AUTOMATION - OptiSense GmbH & Co. KG

PaintChecker AUTOMATION - OptiSense GmbH & Co. KG

PaintChecker AUTOMATION - OptiSense GmbH & Co. KG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PaintChecker</strong> <strong>AUTOMATION</strong><br />

Release: 06/2012<br />

105011_001/001<br />

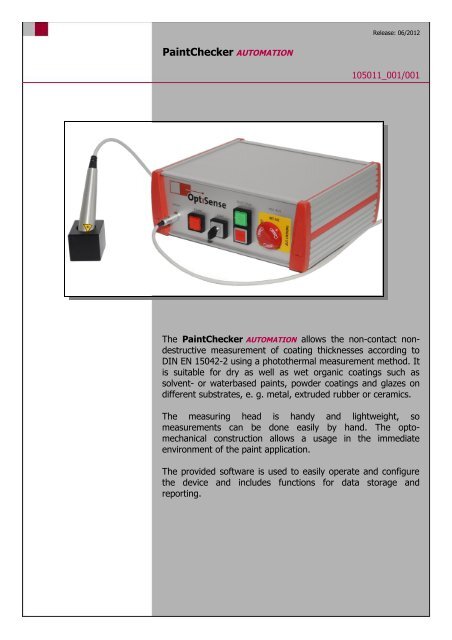

The <strong>PaintChecker</strong> <strong>AUTOMATION</strong> allows the non-contact nondestructive<br />

measurement of coating thicknesses according to<br />

DIN EN 15042-2 using a photothermal measurement method. It<br />

is suitable for dry as well as wet organic coatings such as<br />

solvent- or waterbased paints, powder coatings and glazes on<br />

different substrates, e. g. metal, extruded rubber or ceramics.<br />

The measuring head is handy and lightweight, so<br />

measurements can be done easily by hand. The optomechanical<br />

construction allows a usage in the immediate<br />

environment of the paint application.<br />

The provided software is used to easily operate and configure<br />

the device and includes functions for data storage and<br />

reporting.

Fig. 1: Measuring head<br />

Fig. 2: Meas. head & Evaluation unit<br />

Fig. 3: User Interface, Software<br />

<strong>PaintChecker</strong> <strong>AUTOMATION</strong><br />

Measuring head<br />

Release: 06/2012<br />

105011_001/001<br />

The measuring head made of aluminium has been optimized for<br />

manual handling and contains the laser and the data<br />

acquisition.<br />

The ready-for-use cable to connect the measuring head to the<br />

evaluation unit has a length of 2 m.<br />

Description Value / Range<br />

Thickness typ. 0 - 300 µm (metallic substrate) *<br />

typ. 0 - 60 µm (non-metallic substrate) *<br />

Spot size Ø = 0.5 mm<br />

Repitition rate Max. 1 Hz *<br />

Meas. duration 8 .. 512 ms *<br />

Laser class 3R<br />

Laser power max. 0,5 W<br />

Mode of operation pulsed<br />

Resolution approx. 3% of actual measurement **<br />

Accuracy approx. 5% of actual measurement **<br />

Measuring distance 16 mm<br />

Tolerance, distance ± 1 mm<br />

Tolerance, angle ± 15°<br />

Dimensions L = 110 mm, Ø = 25 mm<br />

Weight approx. 50 g<br />

(*) depending on coating thickness / parameter set<br />

(**) depending on coating / substrate<br />

Evaluation unit<br />

The evaluation unit contains in a robust aluminium housing the<br />

supply and control unit for the measuring head as well as<br />

components for data evaluation and storage of basic<br />

parameters. A connected PC communicates with this unit via<br />

network and allows to control the measuring procedure and to<br />

store the results in a database using the provided software.<br />

Description Value / Range<br />

Power supply 230V AC, 50 Hz, max. 40 W<br />

Interface Ethernet 10 Mbit/s (RJ45)<br />

Dimensions L x B x H = 227 x 267 x 100 mm³<br />

Weight approx. 2,2 kg

Fig. 4: Scope of delivery, portable case<br />

Fig. 5: Auxiliary Equioment<br />

Fig. 6: <strong>PaintChecker</strong> online, integrated<br />

<strong>Co</strong>ntact person:<br />

Georg Nelke,<br />

Geschäftsführer<br />

nelke@optisense.com, Durchwahl: -13<br />

Gesellschaft für<br />

optische Prozessmesstechnik mbH & <strong>Co</strong>. <strong>KG</strong><br />

<strong>PaintChecker</strong> <strong>AUTOMATION</strong><br />

Scope of delivery<br />

Release: 06/2012<br />

105011_001/001<br />

The system is delivered in a rugged portable case<br />

including:<br />

• measuring head including connection cable<br />

• evaluation unit<br />

• power cord and network cable<br />

• parking station for measuring head<br />

• software (CD)<br />

• user manual (German)<br />

• laser reference standard<br />

Auxiliary equipment<br />

The following auxiliary equipment is available as an option:<br />

• distance cap for an easy fixation<br />

• height-adjustable measurement stand<br />

• calibrations for special applications<br />

• programming interface<br />

Further products<br />

For highly automated systems with particular requirements<br />

on measurement speed or in case of special applications<br />

we recommend to use the <strong>PaintChecker</strong> ONLINE. The<br />

device contains a high-power laser and a high-precision<br />

infrared detector and provides interfaces for industrial<br />

requirements in a closed evaluation unit; the measuring<br />

distance is 200 mm. Software tools are available for<br />

database-supported storage and statistical analysis of<br />

measurement results.<br />

© 2010 <strong>OptiSense</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong>.<br />

Die Informationen wurden sorgfältig überprüft. Dennoch ist das Auftreten von Fehlern<br />

nicht völlig auszuschließen. Wir übernehmen daher keine Verantwortung für inhaltliche<br />

Richtigkeit oder Vollständigkeit. Spezifikationen können ohne vorherige oder<br />

gesonderte Ankündigung geändert werden.<br />

(Informations are checked carefully, nevetherless there may be faults. We do not<br />

guarantee correctness or completeness of informations. Specifications are subject to<br />

changes without notification.)<br />

Annabergstraße 134<br />

45721 Haltern am See<br />

Tel.: +49 2364 50882-10<br />

Internet: www.optisense.com<br />

E-Mail: info@optisense.com<br />

HRA 4517 Amtsgericht Gelsenkirchen, PhG: <strong>OptiSense</strong> Verwaltungs-<strong>GmbH</strong> • HRB 10610 Amtsgericht Gelsenkirchen, Geschäftsführer: Josef Kirchbeck, Georg Nelke