Drill Screws HWH, Pan, Pancake, Countersunk - Triangle Fastener

Drill Screws HWH, Pan, Pancake, Countersunk - Triangle Fastener

Drill Screws HWH, Pan, Pancake, Countersunk - Triangle Fastener

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Visit our website for the most up-to-date product and technical information!<br />

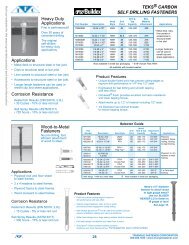

BLAZER<br />

R<br />

DRILL SCREWS<br />

A<br />

B<br />

C<br />

D<br />

E<br />

HEX WASHER HEAD<br />

High Hex for better driving stability!<br />

HEX DRIVE SIZE<br />

#8 dia: 1/4" <strong>HWH</strong><br />

#10 dia: 5/16" <strong>HWH</strong><br />

#12 dia: 5/16" <strong>HWH</strong><br />

1/4 dia: 3/8" <strong>HWH</strong><br />

5/16 dia: 3/8" <strong>HWH</strong><br />

A<br />

B<br />

HIGH PERFORMANCE DRILL SCREWS<br />

FOR COMMERCIAL CONSTRUCTION<br />

The hex washer head is the most popular drive system and<br />

provides the best stability during installation.<br />

Available with TRI-SEAL TM long life coating for the ultimate<br />

corrosion protection...1,000 hrs salt spray with no red rust!<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

Size<br />

#8-18 x 1/2"<br />

#8-18 x 5/8"<br />

#8-18 x 3/4"<br />

#8-18 x 1"<br />

#8-18 x 1-1/4"<br />

#8-18 x 1-1/2"<br />

#8-18 x 2"<br />

#10-16 x 1/2"<br />

#10-16 x 5/8"<br />

#10-16 x 3/4"<br />

#10-16 x 1"<br />

#10-16 x 1-1/2"<br />

#10-16 x 2"<br />

#10-16 x 3"<br />

Point<br />

Type<br />

DP2<br />

DP2<br />

DP2<br />

DP2<br />

DP2<br />

DP2<br />

DP2<br />

DP3<br />

DP3 (HH)<br />

DP3 (HH)<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

<strong>Drill</strong>ing<br />

Thickness<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

Attachment<br />

Thickness<br />

.205"<br />

.330"<br />

.455"<br />

.705"<br />

1.000"<br />

1.205"<br />

1.750"<br />

.150"<br />

.200"<br />

.325"<br />

.575"<br />

1.075"<br />

1.500"<br />

2.500"<br />

Box<br />

Quantity<br />

10M<br />

10M<br />

10M<br />

7.5M<br />

5M<br />

5M<br />

1.5M<br />

10M<br />

10M<br />

7.5M<br />

5M<br />

3M<br />

2M<br />

1M<br />

"HH" Denotes High Hex<br />

MATERIAL: C1018-1022 Carbon Steel<br />

PLATING: Standard: .0003” Min. Electro Zinc (46hrs Salt Spray - ASTM B117)<br />

Meets ASTM C 1513-04 and AISI TS-4-02 Standards<br />

F<br />

G<br />

H<br />

Metal Roof Clip Screw<br />

Heavy Gauge Applications - DP4 & DP5 Points<br />

• <strong>Drill</strong> and tap up to 1/2” thick steel.<br />

• Supplied with our TRI-SEAL TM long life coating for<br />

superior corrosion protection.<br />

• Lengths up to 8” for retrofi t metal roof base attachment.<br />

I<br />

J<br />

K<br />

C<br />

Size<br />

#12-14 x 3/4"<br />

#12-14 x 1"<br />

#12-14 x 1-1/4"<br />

#12-14 x 1-1/2"<br />

#12-14 x 2"<br />

#12-14 x 2-1/2"<br />

#12-14 x 3"<br />

Point<br />

Type<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

<strong>Drill</strong>ing<br />

Thickness<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

Attachment<br />

Thickness<br />

.290"<br />

.525"<br />

.750"<br />

1.000"<br />

1.500"<br />

2.000"<br />

2.500"<br />

Box<br />

Quantity<br />

5M<br />

3.5M<br />

3M<br />

2M<br />

2M<br />

1M<br />

1M<br />

D #12-14 x 1-1/4" DP2 LP .036" - .200" .750" 3.5M<br />

E 1/4-14 x 7/8" DP1 W/VRT .036" - .090" .325" 2.5M<br />

F<br />

1/4-14 x 3/4"<br />

1/4-14 x 1"<br />

1/4-14 x 1-1/4"<br />

1/4-14 x 1-1/2"<br />

1/4-14 x 2"<br />

1/4-14 x 2-1/2"<br />

1/4-14 x 3"<br />

1/4-14 x 4"<br />

1/4-14 x 5"<br />

1/4-14 x 6"<br />

1/4-14 x 8"<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

.036" -.250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.210"<br />

.460"<br />

.710"<br />

.960"<br />

1.460"<br />

1.750"<br />

2.250"<br />

3.460"<br />

4.460"<br />

5.460"<br />

7.460"<br />

2.5M<br />

2.5M<br />

2M<br />

2M<br />

1.5M<br />

1M<br />

1,000<br />

500<br />

500<br />

250<br />

250<br />

G #12-14 x 1-1/4" DP2 SHLDR .036" - .200" .750" 3.5M<br />

H<br />

I<br />

J<br />

K<br />

5/16-18 x 1"<br />

5/16-18 x 1-1/4"<br />

5/16-18 x 1-1/2"<br />

#12-24 x 7/8"<br />

#12-24 x 1-1/4"<br />

#12-24 x 1-1/4"<br />

#12-24 x 1-1/2"<br />

#12-24 x 2"<br />

1/4-20 x 1-1/2"<br />

1/4-20 x 2-1/4"<br />

1/4-20 x 3"<br />

1/4-20 x 4"<br />

1/4-20 x 5"<br />

1/4-20 x 6"<br />

1/4-20 x 8"<br />

DP3<br />

DP3<br />

DP3<br />

DP4<br />

DP4<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

.100" - .250"<br />

.100" - .250"<br />

.100" - .250"<br />

.125" - .137"<br />

.125" - .137"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.460"<br />

.710"<br />

.960"<br />

.325"<br />

.375"<br />

.375"<br />

.625"<br />

1.125"<br />

.500"<br />

1.250"<br />

2.000"<br />

3.000"<br />

4.000"<br />

5.000"<br />

7.000"<br />

1.5M<br />

1.5M<br />

1.5M<br />

5M<br />

3.5M<br />

2.5M<br />

2.5M<br />

2M<br />

2M<br />

1M<br />

500<br />

250<br />

250<br />

250<br />

150<br />

R<br />

8<br />

MATERIAL: C1018-1022 Carbon Steel<br />

PLATING: Long-Life: TRI-SEAL Coating (1,000hrs Salt Spray - ASTM B117)<br />

Meets ASTM C 1513-04 and AISI TS-4-02 Standards<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

BLAZER<br />

R<br />

DRILL SCREWS<br />

Innovative features assure<br />

High performance and<br />

easy installation.<br />

• DP5 drills up to 1/2” thick steel<br />

with less effort.<br />

• TRI-SEAL coating provides<br />

1,000 hrs salt spray.<br />

HIGH PERFORMANCE FASTENERS FOR<br />

HEAVY GAUGE APPLICATIONS<br />

<strong>Fastener</strong>s for Heavy Gauge use provides<br />

superior pullover.<br />

We stock a full line of 1/4-20 diameter BLAZER®<br />

drill screws for drilling and tapping up to 1/2”<br />

thick steel.<br />

BLAZER® self-drilling screws are engineered to drill<br />

and tap high tensile steels more consistently with<br />

less effort.<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

Size<br />

Point<br />

Type<br />

Attachment<br />

Thickness<br />

Box<br />

Quantity<br />

1/4-20 x 1-1/2” DP5 .500" 2,000<br />

1/4-20 x 2-1/4” DP5 1.250" 1,000<br />

1/4-20 x 3” DP5 2.000" 500<br />

1/4-20 x 4” DP5 3.000" 250<br />

1/4-20 x 5” DP5 4.000" 250<br />

1/4-20 x 6” DP5 5.000" 150<br />

1/4-20 x 8” DP5 7.000" 150<br />

Visit our website for the most up-to-date product and technical information!<br />

• Shank slot and spiral fl utes<br />

reduce tapping torque.<br />

• 5/8” O.D. washer face produces<br />

greater pullover resistance.<br />

Great for retrofit metal<br />

roofing base attachment!<br />

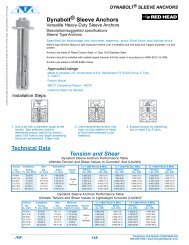

TECHNICAL DATA<br />

Pullout Test Results<br />

GAGE THICKNESS & ROCKWELL HARDNESS<br />

OF THE TEST PLATE<br />

Size<br />

3/16"<br />

(.188")<br />

83-85Rb<br />

1/4"<br />

(.250")<br />

92-96RB<br />

1/2"<br />

(.500")<br />

92-93RB<br />

1/4-20 DP5 3,853 4,283* 4,680*<br />

* Exceeds Tensile Strength Rev. JC060614<br />

Pullover Test Results<br />

GAGE THICKNESS & ULTIMATE PULLOVER<br />

IN POUNDS (55 KSI STEEL)<br />

26 Ga. 24 GA. 22 Ga. 20 Ga. 18 Ga.<br />

Size<br />

(.018") (.024") (.030") (.036") (.046")<br />

1/4-20 DP5 928 1,238 1,547 1,856 2,475<br />

Note: Estimated pullover for fasteners without sealing washers can be calculated<br />

using the following formula per AISI.<br />

Pullover force = 1.5 X Thickness of the member in contact with the screw head.<br />

X Larger of the screw head diameter or washer diameter. X Tensile strength of<br />

the member in contact with the screw head.<br />

Physical Properties<br />

Nominal Major Diameter (In.) Minor Diameter (In.) Area of Minor<br />

Screw<br />

Diameter (Sq. In.)<br />

Size Diameter Max Min Max Min<br />

1/4-20 DP5 0.250 0.250 0.242 0.218 0.214 0.0360<br />

Performance Specifications<br />

Size<br />

Torsional<br />

(In/Lbs.)<br />

Tensile<br />

(Lbs.)<br />

Shear<br />

(Lbs.)<br />

1/4-20 DP5 156 4,275 2,700<br />

DISCLAIMER: ALL TESTS RESULTS AND SPECIFICATIONS ARE A RESULT OF LABORATORY TESTS. APPROPRIATE SAFETY FACTORS SHOULD BE USED BY THE USER OR SPECIFIER. DE-<br />

TERMINING THE PROPER FASTENER IS THE RESPONSIBILITY OF THE USER OR SPECIFIER. SINCE APPLICATION CONDITIONS VARY AND ARE UNCONTROLLABLE BY TFC, WE ASSUME<br />

NO LIABILITY FOR THE USE OF THIS INFORMATION.<br />

TRIANGLE FASTENER<br />

CORPORATION<br />

R<br />

8-A<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Visit our website for the most up-to-date product and technical information!<br />

BLAZER<br />

R<br />

DRILL SCREWS<br />

Special shoulder keeps screw<br />

from “over-clamping” the rake<br />

support, allowing for thermal<br />

expansion.<br />

RAKE ANGLE ATTACHMENT<br />

Proprietary standoff screw designed to allow<br />

thermal expansion of the rake support angle<br />

We designed a BLAZER ® <strong>Drill</strong> Screw specifically for attaching<br />

a sliding rake plate used in metal roofi ng.<br />

The screw has an oversize washer face that provides more<br />

bearing surface between the fastener and the rake plate angle<br />

that allows superior movement capabilities.<br />

TYPICAL APPLICATION<br />

5/16” hex drive is the same size as<br />

other standard metal roofi ng fasteners<br />

for easy installation.<br />

Oversize washer face provides over<br />

45% more surface area that is in<br />

contact with the rake support!<br />

SIZE<br />

Size<br />

Point<br />

Type<br />

Head<br />

Size<br />

Attachment<br />

Thickness<br />

Box<br />

Quantity<br />

1/4-14 x 1-1/4” DP3<br />

5/16”<br />

<strong>HWH</strong><br />

.150”<br />

standoff<br />

2,000<br />

Finish: JS500 | Zinc Plating.<br />

Salt Spray<br />

400 hours | No red rust per ASTM B117<br />

TECHNICAL DATA<br />

Pullout Test Results<br />

Size<br />

18 Ga.<br />

(.048")<br />

GAGE THICKNESS<br />

14 Ga.<br />

(.075")<br />

3/16"<br />

(.188")<br />

1/4"<br />

(.250")<br />

1/4-14 DP3 533 1077 3,863 4,493*<br />

Rev. JC060614<br />

* Exceeds Tensile Strength<br />

Pullover Test Results<br />

GAGE THICKNESS & ULTIMATE PULLOVER<br />

IN POUNDS (55 KSI STEEL)<br />

Size<br />

26 Ga.<br />

(.018")<br />

24 GA.<br />

(.024")<br />

22 Ga.<br />

(.030")<br />

20 Ga.<br />

(.036")<br />

18 Ga.<br />

(.046")<br />

1/4-14 DP3 928 1,238 1,547 1,856 2,475<br />

Note: Estimated pullover for fasteners without sealing washers can be calculated<br />

using the following formula per AISI.<br />

Pullover force = 1.5 X Thickness of the member in contact with the screw head.<br />

X Larger of the screw head diameter or washer diameter. X Tensile strength of<br />

the member in contact with the screw head.<br />

Physical Properties<br />

Nominal Major Diameter (In.) Minor Diameter (In.) Area of Minor<br />

Screw<br />

Diameter (Sq. In.)<br />

Size Diameter Max Min Max Min<br />

1/4-14 DP3 0.250 0.250 0.242 0.218 0.214 0.0360<br />

Performance Specifications<br />

Size<br />

Torsional<br />

(In/Lbs.)<br />

Tensile<br />

(Lbs.)<br />

Shear<br />

(Lbs.)<br />

1/4-14 DP3 150 4,275 2,600<br />

DISCLAIMER: ALL TESTS RESULTS AND SPECIFICATIONS ARE A RESULT OF LABORATORY TESTS. APPROPRIATE SAFETY FACTORS SHOULD BE USED BY THE USER OR SPECIFIER.<br />

DETERMINING THE PROPER FASTENER IS THE RESPONSIBILITY OF THE USER OR SPECIFIER. SINCE APPLICATION CONDITIONS VARY AND ARE UNCONTROLLABLE BY TFC, WE<br />

ASSUME NO LIABILITY FOR THE USE OF THIS INFORMATION.<br />

TRIANGLE FASTENER<br />

CORPORATION<br />

R<br />

8-B<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

BLAZER<br />

R<br />

DRILL SCREWS<br />

A<br />

B<br />

C<br />

<strong>Pan</strong> Framer Head<br />

Round Washer Head<br />

<strong>Pan</strong> Head<br />

<strong>Pan</strong> Head<br />

PAN FRAMER - ROUND WASHER - PAN HEAD<br />

#2 Cross<br />

Recess Drive<br />

HIGH PERFORMANCE DRILL SCREWS<br />

FOR COMMERCIAL CONSTRUCTION<br />

General framing applications<br />

Cross recess (phillips) drive.<br />

Size<br />

Point<br />

Type<br />

<strong>Drill</strong>ing<br />

Thickness<br />

Attachment<br />

Thickness<br />

MATERIAL: C1018-1022 Carbon Steel<br />

PLATING: .0002” Min. Electro Zinc (24hrs Salt Spray)<br />

Box<br />

Quantity<br />

A #7-16 x 3/4" DP2 .036" - .100" .375" 10M<br />

B<br />

C<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

#8-18 x 1/2"<br />

#8-18 x 5/8"<br />

#8-18 x 3/4"<br />

#8-18 x 1"<br />

#8-18 x 1-1/4"<br />

#8-18 x 1-1/2"<br />

#8-18 x 2"<br />

#10-16 x 1/2"<br />

#10-16 x 5/8"<br />

#10-16 x 3/4"<br />

#10-16 x 1"<br />

#10-16 x 1-1/4"<br />

#10-16 x 1-1/2"<br />

DP2<br />

DP2<br />

DP2<br />

DP2<br />

DP2<br />

DP2<br />

DP2<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.205"<br />

.330"<br />

.455"<br />

.705"<br />

1.000"<br />

1.205"<br />

1.750"<br />

.150"<br />

.200"<br />

.325"<br />

.575"<br />

.825"<br />

1.075"<br />

10M<br />

10M<br />

10M<br />

7.5M<br />

5M<br />

5M<br />

1.5M<br />

10M<br />

10M<br />

7.5M<br />

5M<br />

3.5M<br />

3M<br />

Visit our website for the most up-to-date product and technical information!<br />

PANCAKE HEAD SCREWS<br />

<strong>Pan</strong>cake head provides extra clearance<br />

compared to round washer head fasteners.<br />

#2 Square/cross recess for exceptional driving<br />

stability...NO CAM-OUT!<br />

D<br />

E<br />

#2 Square<br />

Drive Power Bit<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

Size<br />

Point<br />

Type<br />

<strong>Drill</strong>ing<br />

Thickness<br />

Attachment<br />

Thickness<br />

MATERIAL: C1018 - 1022 Carbon Steel<br />

PLATING: .0003” Min. Electro Zinc with yellow di-chromate<br />

(48hrs Salt Spray)<br />

Box<br />

Quantity<br />

D #10-16 x 5/8" DP3 .036" - .175" .200" 10M<br />

E #10-24 x 5/8" DP3 .036" - .210" .200" 10M<br />

LONG PILOT AND STRESS-LESS FEATURE<br />

Long-pilot Point<br />

Standard STRESS-LESS<br />

Great for steel framing when multiple<br />

thicknesses are used.<br />

STRESS-LESS undercut head is designed<br />

to eliminate stress that concentrates under<br />

the head of fasteners.<br />

F<br />

Great for Mini-Storage!<br />

Radius under the<br />

head concentrates<br />

stress that can<br />

cause failure.<br />

STRESS-LESS<br />

undercut distributes<br />

stress across<br />

the washer face.<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

Size<br />

Point<br />

Type<br />

<strong>Drill</strong>ing<br />

Thickness<br />

Attachment<br />

Thickness<br />

Box<br />

Quantity<br />

F #12-14 x 7/8" DP3 .036" - .210" .325" 2.5M<br />

G 1/4-14 x 7/8" DP3 .036" - .250" .325" 2.5M<br />

G<br />

MATERIAL: C1018-1022 Carbon Steel<br />

PLATING: .0003” Min. Zinc w/TRI-SEAL Coating (1,000hrs Salt Spray)<br />

STRESS-LESS TM<br />

Great for Retrofit Framing<br />

HEAD TYPE<br />

#12 dia: 5/16" <strong>HWH</strong><br />

1/4 dia: 5/16" <strong>HWH</strong><br />

TRIANGLE FASTENER<br />

CORPORATION<br />

R<br />

9<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Visit our website for the most up-to-date product and technical information!<br />

BLAZER<br />

R<br />

DRILL SCREWS<br />

A<br />

B<br />

C<br />

D<br />

E<br />

410 STAINLESS STEEL DRILL SCREWS<br />

HEAD TYPE<br />

#8 dia: 1/4" <strong>HWH</strong><br />

#10 dia: 5/16" H WH<br />

#12 dia: 5/16" <strong>HWH</strong><br />

*1/4 dia: 5/16" <strong>HWH</strong><br />

1/4 dia: 3/8 <strong>HWH</strong><br />

HIGH PERFORMANCE DRILL SCREWS<br />

FOR COMMERCIAL CONSTRUCTION<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

<br />

<br />

<br />

Size<br />

#8-18 x 1/2"<br />

#8-18 x 3/4"<br />

Provides corrosion resistance in<br />

mild atmospheres.<br />

Plated to resist surface rust and to reduce<br />

drive torque.<br />

For additional corrosion protection,<br />

specify TRI-SEAL long-life coating.<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

#10-16 x 3/4"<br />

#10-16 x 1"<br />

#10-16 x 1-1/2"<br />

#12-14 x 3/4"<br />

*#12-14 x 1"<br />

*#12-14 x 1-1/4"<br />

*#12-14 x 1-1/2"<br />

#12-14 x 2"<br />

*#12-24 x 1-1/4"<br />

#12-24 x 1-1/2"<br />

*1/4-14 x 7/8"<br />

*1/4-14 x 1-1/8"<br />

*1/4-14 x 3/4"<br />

*1/4-14 x 1"<br />

*1/4-14 x 1-1/2"<br />

1/4-14 x 2"<br />

1/4-14 x 4"<br />

Point<br />

Type<br />

DP2<br />

DP2<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3 LP<br />

DP3<br />

DP3<br />

DP5<br />

DP5<br />

DP1<br />

DP1<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

<strong>Drill</strong>ing<br />

Thickness<br />

.036" - .100"<br />

.036" - .100"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.250" - .500"<br />

.250" - .500"<br />

.036" - .090"<br />

.036" - .090"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

Max Attachment<br />

Thickness<br />

.205"<br />

.455"<br />

.325"<br />

.575"<br />

1.075"<br />

.290"<br />

.525"<br />

.550"<br />

1.000"<br />

1.500"<br />

.375"<br />

.625"<br />

.375"<br />

.875"<br />

.210"<br />

.460"<br />

.960"<br />

1.460"<br />

3.460"<br />

Box<br />

Qty.<br />

10M<br />

10M<br />

7.5M<br />

5M<br />

3M<br />

5M<br />

3.5M<br />

2.5M<br />

2.5M<br />

2M<br />

5M<br />

5M<br />

2.5M<br />

2.0M<br />

2.5M<br />

2.5M<br />

2M<br />

1.5M<br />

500<br />

F<br />

WOOD-TO-METAL DRILL SCREWS<br />

EG102512<br />

MATERIAL: 410 Stainless Steel<br />

PLATING: Passivated (24hrs Salt Spray), Zinc Plated (48hrs Salt Spray),<br />

* Denotes TRI-SEAL TM Coated (1,000hrs Salt Spray)<br />

Fasten wood-to-metal.<br />

No pre-drilling required.<br />

TRI-SEAL coated for use in ACQ lumber.<br />

G<br />

H<br />

I<br />

J<br />

K<br />

L<br />

M<br />

NEW!<br />

BLAZER ® HEADER Heavy Gauge (1/2” SD) designed<br />

to attach up to 1/2” thick steel.<br />

Flat Wafer<br />

Flat Wafer Head<br />

#2 Sq. Recess Drive<br />

(#3 Square Recess)<br />

Size<br />

Point<br />

Type<br />

<strong>Drill</strong>ing<br />

Thickness<br />

Attachment<br />

Thickness<br />

MATERIAL: Carbon Steel<br />

PLATING: .0003” min zinc TRI-SEAL TM Coated (1,000hrs Salt Spray)<br />

Box<br />

Quantity<br />

G #10-24 x 1-7/16" DP3 WW .036" - .210" .750" 4M<br />

H<br />

I<br />

J<br />

#12-14 x 1-3/4"<br />

#12-14 x 2-1/2"<br />

#12-24 x 2"<br />

#12-24 x 2-1/2"<br />

1/4-20 x 2-3/4"<br />

1/4-20 x 3-1/4"<br />

1/4-20 x 3-3/4"<br />

DP2 WW<br />

DP2 WW<br />

DP4 WW<br />

DP4 WW<br />

DP4 WW<br />

DP4 WW<br />

DP4 WW<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.125" - .375"<br />

.125" - .375"<br />

.125" - .375"<br />

.750"<br />

1.625"<br />

1.250"<br />

1.750"<br />

2.000"<br />

2.750"<br />

3.000"<br />

2M<br />

1M<br />

2M<br />

1M<br />

900<br />

900<br />

500<br />

K 1/4-20 x 3-1/8" DP5 WW .125" - .500" 1.625" 1M<br />

"WW" Denotes With Wings<br />

Size<br />

Point<br />

Type<br />

<strong>Drill</strong>ing<br />

Thickness<br />

Attachment<br />

Thickness<br />

Box<br />

Quantity<br />

L #10-16 x 1-3/4" DP3 .036" - .175" .750" 2.5M<br />

M<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

MATERIAL: Carbon Steel<br />

PLATING: .0003” min zinc TRI-SEAL TM Coated (1,000hrs Salt Spray)<br />

#10-24 x 3/4"<br />

#10-24 x 1"<br />

#10-24 x 1-1/4"<br />

#10-24 x 1-1/2"<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .175"<br />

.375"<br />

.500"<br />

.750"<br />

.875"<br />

5M<br />

5M<br />

3.5M<br />

3M<br />

R<br />

10<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

BLAZER<br />

R<br />

DRILL SCREWS<br />

WOOD-TO-METAL DRILL SCREWS<br />

Header Light Gauge<br />

Header Heavy Gauge<br />

SPECIAL FASTENERS FOR<br />

WOOD-TO-METAL APPLICATIONS<br />

Our wood-to-metal drill screws are engineered to provide high performance and easy installation.<br />

Thin or thick metal...TFC has the fastener for your application!<br />

A<br />

B<br />

Need to attach wood to thin gauge metal?<br />

Then use our #12-14 BLAZER ® Header Light Gauge that is designed<br />

to fasten to metal as thin as 18-gauge! The threads and wings are<br />

engineered for optimal performance when used in thin metal applications.<br />

Need to attach wood to steel that is 1/2” thick?<br />

Then use our new 1/4-20 BLAZER ® Header Heavy Gauge (1/2” SD),<br />

the only wood-to-metal fastener that will drill and tap steel up to 1/2”<br />

thick. Engineered for use in heavy steel, it has a special hex-countersunk<br />

head that provides optimal driving stability and can also be installed<br />

flush to the surface of the wood.<br />

Both fasteners have “wings” that remove the wood to minimize jacking<br />

and provide drilling consistency.<br />

Attach Into Thin Metal<br />

<br />

<br />

#3 square recess drive provides<br />

stability during installation and<br />

eliminates camout!<br />

Special thread, wing, and drill point<br />

designed to fasten into steel ranging<br />

from 18 ga. up to 1/8” thick.<br />

Visit our website for the most up-to-date product and technical information!<br />

C<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

Sizes<br />

Point<br />

Type<br />

Part<br />

Number<br />

Max<br />

Attachment<br />

Thickness<br />

Box<br />

Quantity<br />

A #12-14 x 1 3/4” DP2 12175SF3CSTA .750” 2,000<br />

B #12-14 x 2 1/2” DP2 12250SF3CSTA 1.625” 1,000<br />

C 1/4-20 x 3 1/8” DP5 14312HCSH5CSEC 1.625” 1,000<br />

Attach up to 1/2” Thick Steel<br />

<br />

<br />

Flat hex countersunk head provides<br />

exceptional stability during installation<br />

and can be installed flush to the<br />

wood surface.<br />

DP5 drill point is engineered to drill<br />

and tap steel up to 1/2” thick.<br />

Recommended Screw Gun Speed:<br />

2,000 RPM Max<br />

TECHNICAL DATA<br />

Specifications<br />

Head Type: #12-14 (#3 Square Recess/Flat <strong>Countersunk</strong>)<br />

1/4-20 (5/16” Hex countersunk)<br />

<strong>Drill</strong>ing Capability: #12-14 (.036” - .210”)<br />

1/4-20 (.125” - .500”)<br />

Material: C-1022 Carbon steel<br />

Finish: .0003” min. zinc and yellow TRI-ACQ<br />

Salt Spray: 1,000hrs<br />

Compatible for use in ACQ and fi re treated lumber.<br />

Produced to SAE J78 specifi cations.<br />

Pullout Test Results (Average Ultimate in Pounds)<br />

DISCLAIMER: ALL TESTS RESULTS AND SPECIFICATIONS ARE A RESULT OF LABORATORY TESTS. APPROPRIATE SAFETY FACTORS SHOULD BE USED BY THE USER OR SPECIFIER.<br />

DETERMINING THE PROPER FASTENER IS THE RESPONSIBILITY OF THE USER OR SPECIFIER. SINCE APPLICATION CONDITIONS VARY AND ARE UNCONTROLLABLE BY TFC, WE ASSUME<br />

NO LIABILITY FOR THE USE OF THIS INFORMATION.<br />

Rev. 12213JS<br />

R<br />

Gauge Thickness<br />

18 Ga. 16 Ga. 14 Ga. 12 Ga. 1/8” 3/16" 1/4" 1/2"<br />

Size (.048”) (.060”) (.075”) (.105”) (.125”) (.188") (.250") (500")<br />

#12-14 577 790 1,137 1,697 1,920 2,973*<br />

1/4-20 1,066 1,634 2,015 3,853 4,283* 4,680*<br />

* Exceeds Tensile Strength<br />

10-A<br />

Physical Properties<br />

Nominal<br />

Screw<br />

Major<br />

Diameter (Inch)<br />

Minor<br />

Diameter (Inch)<br />

Size Diameter Max Min Max Min<br />

#12-14 0.216 0.215 0.209 0.164 0.157<br />

1/4-20 0.250 0.250 0.242 0.218 0.214<br />

Performance Specifications<br />

Torsional Tensile Shear<br />

Size (Inch/Lbs.) (Lbs.) (Lbs.)<br />

#12-14 92 2,778 2,000<br />

1/4-20 156 4.275 2,700<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Bi-Flex <strong>Screws</strong><br />

304 STAINLESS STEEL DRILL SCREWS<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

304 STAINLESS STEEL<br />

DRILL SCREWS<br />

<strong>Triangle</strong> <strong>Fastener</strong> offers a full line of fasteners manufactured from 304<br />

stainless steel. The fastener head and threads are produced from<br />

corrosion resistant stainless steel producing exceptional corrosion<br />

protection and superior ductility. A carbon steel drill point is hardened<br />

and welded to the body allowing the fastener to drill and tap in steel<br />

up to 1/2" thick!<br />

Visit our website for the most up-to-date product and technical information!<br />

R<br />

11<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Visit our website for the most up-to-date product and technical information!<br />

BLAZER<br />

R<br />

DRILL SCREWS<br />

SECURITY SCREWS<br />

A<br />

SECURITY SCREWS<br />

Security screws specifically designed for metal<br />

siding and roofing applications<br />

TORX ® PIN-HEAD<br />

Maximum torque transfer and positive tool engagement means<br />

easier drive installation with less pressure and slippage. Torx®<br />

Pin Head offers a high degree of security and requires matching<br />

drive bit. Available in button head for neat appearance and<br />

TRI-SEAL 1,000 hours salt spray coating for additional<br />

corrosion protection.<br />

T-27 Torx Pin<br />

Recess Drive<br />

<br />

Does your building need security?<br />

Mini Storage<br />

Prisons<br />

Government Buildings<br />

Banks<br />

Dealerships<br />

Assembled with a BOND-SEALER sealing washer<br />

that has EPDM vulcanized to a 20 Gauge galvanized<br />

backing that will withstand harsh weather conditions.<br />

B<br />

To assure a proper seal, torque the fastener until the EPDM<br />

sealant extrudes to the outer edge of the backing material.<br />

C<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

Size<br />

Point<br />

Type<br />

<strong>Drill</strong>ing<br />

Thickness<br />

MATERIAL: C1018-1022 Carbon Steel<br />

PLATING: .TRI-SEAL 1,000 hours salt spray coating<br />

Attachment<br />

Thickness<br />

Box<br />

Quantity<br />

A #12-14 x 2 DP3 .036" - .210" 1.500" 2.0M<br />

B #12-14 x 1-1/2" DP3 LP .036" - .210" 1.000" 2.0M<br />

CORRECT<br />

Slight circle of sealant<br />

extrudes to outer edge.<br />

TOO TIGHT!<br />

Metal backing<br />

begins to turn up.<br />

TOO LOOSE<br />

Sealant is not compressed<br />

and can not form a seal.<br />

C 1/4-14 x 7/8" DP1 .036" - .090" .325" 2.5M We supply insert bits to<br />

make installation fast<br />

and easy!<br />

Pullout Test Result - Ultimate Average in Pounds<br />

<strong>Fastener</strong><br />

Size<br />

26 Ga.<br />

(.018")<br />

45-49Rb<br />

GAGE THICKNESS & ROCKWELL HARDNESS OF THE TEST PLATE<br />

24 Ga.<br />

(.024")<br />

46-52Rb<br />

22 Ga.<br />

(.030")<br />

61-67Rb<br />

20 Ga.<br />

(.036")<br />

54-62Rb<br />

18 Ga.<br />

(.048")<br />

64-73Rb<br />

16 Ga.<br />

(.060")<br />

65-67Rb<br />

14 Ga.<br />

(.075")<br />

68-70Rb<br />

12 Ga.<br />

(.105")<br />

74-86Rb<br />

1/8"<br />

(.125")<br />

75-91Rb<br />

#12-14 DP3 533 752 1163 1947 2250<br />

1/4-14 DP1 173 240 337 387 657 1250<br />

Contact <strong>Triangle</strong> <strong>Fastener</strong> for additional sizes and types of security screws.<br />

DISCLAIMER: ALL TEST RESULTS AND SPECIFICATIONS ARE A RESULT OF LABORATORY TESTS. APPROPRIATE SAFETY FACTORS SHOULD BE USED BY THE USER OR<br />

SPECIFIER. DETERMINING THE PROPER FASTENER IS THE RESPONSIBILITY OF THE USER OR SPECIFIER. SINCE APPLICATION CONDITIONS VARY AND ARE UNCONTROLLABLE<br />

BY TFC, WE ASSUME NO LIABILITY FOR THE USE OF THIS INFORMATION.<br />

R<br />

12<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Pat. No. 8,360,701<br />

C<br />

Light Gauge Applications<br />

Maximum <strong>Drill</strong>ing Thickness: .090”<br />

Description<br />

1/4” -14 X 7/8” DP1/LAP w/VRT ®<br />

CONCEALOR ® <strong>Pan</strong>cake Head<br />

w/Bonded Sealing Washer<br />

TRI-SEAL Coated<br />

1,000Hrs Salt Spray<br />

1/4” -14 X 7/8” DP1/LAP w/VRT ®<br />

BLAZER ® Flange Head<br />

w/Sealing Washer<br />

TRI-SEAL Coated<br />

1,000Hrs Salt Spray<br />

1/4” -14 X 7/8” DP1/LAP w/VRT ®<br />

BLAZER ®<br />

TRI-SEAL Coated<br />

1,000Hrs Salt Spray<br />

1/4” -14 X 7/8” DP1/LAP w/VRT ®<br />

BLAZER ®<br />

w/Bonded Sealing Washer<br />

TRI-SEAL Coated<br />

1,000Hrs Salt Spray<br />

1/4” -14 X 7/8” DP1/LAP w/VRT ®<br />

BLAZER ® Stainless Cap Head<br />

w/Sealing Washer<br />

TRI-SEAL Coated<br />

1,000Hrs Salt Spray<br />

1/4” -14 X 7/8” DP1/LAP w/VRT ®<br />

BLAZER ® Zinc Cap Head<br />

w/Sealing Washer<br />

TRI-SEAL Coated<br />

1,000Hrs Salt Spray<br />

1/4” -14 X 1-1/8” DP1/LAP w/VRT ®<br />

BLAZER ® Stainless Cap Head<br />

w/Sealing Washer<br />

TRI-SEAL Coated<br />

1,000Hrs Salt Spray<br />

#17-14 X 1” TYPE AB w/VRT ®<br />

TAPPER<br />

w/Bonded Sealing Washer (3/4”OD)<br />

TRI-SEAL Coated<br />

1,000Hrs Salt Spray<br />

Our Vibration Resistant Thread (VRT ® ) is<br />

designed to significantly increase back-out<br />

torque and reduce the potential for leaks.<br />

VRT ® keeps the fastener tighter in<br />

applications where expansion, contraction<br />

and vibration are a concern.<br />

Independent tests verify that VRT ®<br />

produces 3-1/2 times more back-out<br />

resistance than a standard thread.<br />

Part Number<br />

14087C1TSVBW<br />

14087HW1CSTSVW<br />

14087HW1CSTSV<br />

14087HW1CSTSVBW<br />

14087HW1CSTSVWSC<br />

14087HW1CSTSVWZC<br />

14112HW1CSTSVWSC<br />

17100HHACSTSVOW<br />

BACK-OUT RESISTANT SCREWS<br />

Carton<br />

Quantity<br />

2,500 pcs<br />

250/Bag<br />

2,500 pcs<br />

250/Bag<br />

2,500 pcs<br />

250/Bag<br />

2,500 pcs<br />

250/Bag<br />

2,500 pcs<br />

250/Bag<br />

2,000 pcs<br />

250/Bag<br />

2,000 pcs<br />

250/Bag<br />

2,000 pcs<br />

250/Bag<br />

WT Per<br />

M Pcs<br />

13.5#<br />

13.5#<br />

10.2#<br />

13.5#<br />

13.5#<br />

13.5#<br />

19.3#<br />

20#<br />

Technical Data<br />

Specifi cations<br />

BLAZER <strong>Drill</strong> <strong>Screws</strong><br />

conforms to SAE J-78 for<br />

self-drilling tapping screws.<br />

#17 TAPPER conforms to<br />

ANSI/ASME B18.6.4 for<br />

tapping screws.<br />

Material<br />

Carbon Steel: C1022<br />

Stainless Cap: 304 SS<br />

Zinc Cap: Zamac 5<br />

Tensile Strength<br />

1/4-14: 4,275 lbs.<br />

#17-14: 5,200 lbs.<br />

Torsional Strength<br />

1/4-14: 150 lbs-inch<br />

#17-14: 175 lbs-inch<br />

*Pullout (Pounds)<br />

1/4-14 #17-14<br />

26ga 173 201<br />

24ga 240 280<br />

22ga 337 342<br />

20ga 387 395<br />

18ga 657 725<br />

16ga 1,250 1,345<br />

Corrosion Resistance<br />

TRI-SEAL<br />

Salt Spray: 1,000 hrs<br />

minimum.<br />

No Red Rust<br />

Sealing Washers<br />

Flange Head:<br />

EPDM Cut Tubular<br />

Bonded Washer:<br />

EPDM Vulcanized to<br />

G-90 Galvanized Steel.<br />

(15MM O.D.).<br />

* Pullout values are<br />

ultimate averages based<br />

on laboratory tests.<br />

Appropriate factors of<br />

safety should be used. TFC<br />

assumes no liability for the<br />

use if this information.<br />

Visit our website for the most up-to-date product and technical information!<br />

R<br />

13<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Pat. No. 8,360,701<br />

The next generation of self-drilling screws specifically designed to resist back-out<br />

which can cause leaks in metal panel laps and joints.<br />

PROBLEM<br />

<strong>Screws</strong> with standard threads can back-out<br />

easily with little force. This can cause joint<br />

failure resulting in leaks.<br />

SOLUTION<br />

Our Vibration Resistant Thread (VRT) is<br />

designed to signifi cantly increase back-out torque<br />

and reduce the potential for leaks.<br />

Notice how standard<br />

screw threads offer little<br />

resistance to back-out.<br />

Innovative patent pending<br />

VRT thread increases friction<br />

as the screw loosens.<br />

Why VRT ?<br />

You can see how the shape of<br />

VRT is designed to increase the<br />

resistance to back-out, compared<br />

to a standard thread. VRT<br />

keeps the fastener tighter in<br />

applications where expansion,<br />

contraction and vibration<br />

are a concern.<br />

Test Results<br />

VRT<br />

Thread<br />

Standard<br />

Thread<br />

Sizes<br />

Available only on<br />

BLAZER ® self-drilling<br />

screws with your choice<br />

of sealing washers.<br />

Size<br />

1/4-14 x 7/8” DP1/LAP<br />

Contact TFC for<br />

Availability<br />

FLANGE<br />

SEALER<br />

Independent tests verify that VRT produces over 3-1/2 times more back-out resistance<br />

than standard threads due to it’s innovative thread design that increases friction.<br />

BOND<br />

SEALER<br />

(Installed torque = 40 in-lb)<br />

LEAK<br />

ZONE<br />

Over 250%<br />

More<br />

Torque!<br />

Form # JS100808<br />

Copyright 2008 <strong>Triangle</strong> <strong>Fastener</strong> Corporation<br />

TRIANGLE FASTENER CORPORATION<br />

Fastening Systems and Solutions for Commercial Construction

Visit our website for the most up-to-date product and technical information!<br />

BLAZER<br />

R<br />

DRILL SCREWS<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

BLAZER ® WITH BONDED SEALING WASHER<br />

LP denotes long-pilot design for metal<br />

roofing and siding<br />

WASHER DETAILS<br />

20 ga G-90 Galvanized Steel<br />

Vulcanized to .062” thick EPDM<br />

15MM OD Washer<br />

HEAD TYPE<br />

#10 dia: 5/16" <strong>HWH</strong><br />

#12 dia: 5/16" <strong>HWH</strong><br />

*1/4 dia: 5/16" <strong>HWH</strong><br />

1/4 dia: 3/8" <strong>HWH</strong><br />

A<br />

B<br />

C<br />

<br />

<br />

Size<br />

BOND-SEALER is a sealing washer that has<br />

EPDM vulcanized to a 20 Gauge galvanized backing<br />

that will withstand harsh weather conditions.<br />

TRI-SEAL long life coated for superior<br />

corrosion protection.<br />

#10-16 x 1"<br />

#10-16 x 1-1/2"<br />

#12-14 x 3/4"<br />

#12-14 x 1"<br />

#12-14 x 1-1/4"<br />

#12-14 x 1-1/2"<br />

#12-14 x 2"<br />

#12-14 x 2-1/2"<br />

#12-14 x 3"<br />

#12-24 x 1-1/4"<br />

#12-24 x 1-1/2"<br />

#12-24 x 2"<br />

Point<br />

Type<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3 LP<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP5<br />

DP5<br />

DP5<br />

<strong>Drill</strong>ing<br />

Thickness<br />

.036" - .175"<br />

.036" - .175"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

Attachment<br />

Thickness<br />

.575"<br />

1.075"<br />

.290"<br />

.525"<br />

.750"<br />

1.000"<br />

1.500"<br />

2.000"<br />

2.500"<br />

.375"<br />

.625"<br />

1.125"<br />

Box<br />

Quantity<br />

5M<br />

3M<br />

5M<br />

3.5M<br />

3.5M<br />

2.5M<br />

2M<br />

1M<br />

1M<br />

3.5M<br />

2.5M<br />

2M<br />

D 1/4-14 x 7/8" DP1 W/VRT* .036" - .090" .325" 2.5M<br />

E<br />

F<br />

HIGH PERFORMANCE DRILL SCREWS<br />

FOR COMMERCIAL CONSTRUCTION<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

1/4-14 x 3/4"<br />

1/4-14 x 1"<br />

1/4-14 x 1-1/4"<br />

1/4-14 x 1-1/2"<br />

1/4-14 x 2"<br />

1/4-14 x 2-1/2"<br />

1/4-14 x 3"<br />

1/4-14 x 4"<br />

1/4-14 x 5"<br />

1/4-14 x 6"<br />

1/4-20 x 4"<br />

1/4-20 x 5"<br />

1/4-20 x 6"<br />

1/4-20 x 7"<br />

1/4-20 x 8"<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP3<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

DP5<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.250" - .500"<br />

.210"<br />

.460"<br />

.710"<br />

.960"<br />

1.460"<br />

1.750"<br />

2.250"<br />

3.460"<br />

4.460"<br />

5.460"<br />

3.000"<br />

4.000"<br />

5.000"<br />

6.000"<br />

7.000"<br />

2.5M<br />

2.5M<br />

2M<br />

2M<br />

1.5M<br />

1,000<br />

1M<br />

500<br />

500<br />

250<br />

500<br />

500<br />

250<br />

150<br />

150<br />

Proper <strong>Fastener</strong> Installation<br />

MATERIAL: C1018-1022 Carbon Steel<br />

PLATING: .0003” Min. Zinc w/TRI-SEAL TM Coating (1,000hrs Salt Spray)<br />

CORRECT<br />

Slight circle of sealant extrudes<br />

to outer edge.<br />

TOO TIGHT!<br />

Metal backing<br />

begins to turn up.<br />

TOO LOOSE<br />

Sealant is not compressed<br />

and can not form a seal.<br />

To assure a proper seal, torque the fastener until the EPDM<br />

sealant extrudes to the outer edge of the backing material.<br />

G<br />

H<br />

I<br />

BLAZER ® FLANGE-SEAL HEAD WITH EPDM WASHER<br />

FLANGE-SEAL self-sealing fastener has a deep<br />

undercut head that entraps the EPDM sealing washer<br />

to assure a leak free seal.<br />

R<br />

LP denotes long-pilot design for metal<br />

roofing and siding<br />

HEAD TYPE<br />

#12 dia: 5/16" <strong>HWH</strong><br />

1/4 dia: 5/16" <strong>HWH</strong><br />

WASHER DETAILS<br />

.125” Thick EPDM<br />

14<br />

G<br />

TRI-SEAL long-life coated for superior<br />

corrosion protection.<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

Size<br />

#12-14 x 3/4"<br />

#12-14 x 1"<br />

#12-14 x 1-1/4"<br />

#12-14 x 1-1/2"<br />

#12-14 x 2"<br />

#12-14 x 2-1/2"<br />

Point<br />

Type<br />

DP2/DP3<br />

DP2/DP3<br />

DP2/DP3 LP<br />

DP2/DP3<br />

DP2/ DP3<br />

DP2/DP3<br />

<strong>Drill</strong>ing<br />

Thickness<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

Attachment<br />

Thickness<br />

.290"<br />

.525"<br />

.750"<br />

1.000"<br />

1.500"<br />

2.000"<br />

MATERIAL: C1018-1022 Carbon Steel<br />

PLATING: .0003” Min. Zinc w/TRI-SEAL TM Coating (1,000hrs Salt Spray)<br />

Box<br />

Quantity<br />

5M<br />

3.5M<br />

3.5M<br />

2.5M<br />

2M<br />

1M<br />

H 1/4-14 x 7/8" DP1 W/VRT* .036" - .090" .325" 2.5M<br />

I<br />

1/4-14 x 3/4"<br />

1/4-14 x 1"<br />

1/4-14 x 1-1/2"<br />

DP3*<br />

DP3*<br />

DP3*<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.210"<br />

.460"<br />

.960"<br />

2.5M<br />

2.5M<br />

2M<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

BLAZER<br />

R<br />

DRILL SCREWS<br />

BLAZER ® STAINLESS CAP HEAD WITH EPDM SEALING WASHER<br />

304 stainless steel cap head for exceptional<br />

corrosion resistance.<br />

F<br />

Our special head is designed to produce maximum<br />

torsional strength and a leak free seal.<br />

TRI-SEAL ® long life coated shank for superior<br />

corrosion protection.<br />

G<br />

H<br />

I<br />

J<br />

K<br />

L<br />

WASHER DETAILS<br />

.100” Thick EPDM<br />

HEAD TYPE<br />

5/16" <strong>HWH</strong><br />

F<br />

G<br />

H<br />

Size & Point<br />

BLAZER ® ZINC CAP HEAD WITH EPDM SEALING WASHER<br />

HIGH PERFORMANCE DRILL SCREWS<br />

FOR COMMERCIAL CONSTRUCTION<br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

#12-14 x 1" DP2/DP3<br />

#12-14 x 1-1/4" DP2/DP3 LP<br />

#12-14 x 1-1/2" DP2/DP3<br />

#12-14 x 2" DP2/DP3<br />

1/4-14 x 7/8" DP1 W/VRT<br />

1/4-14 x 1 1/8" DP1W/VRT<br />

1/4-14 x 1-1/4" DP3<br />

1/4-14 x 3" DP3<br />

1/4-14 x 4" DP3<br />

<strong>Drill</strong>ing<br />

Thickness<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .090"<br />

.030"-.090"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

Attachment<br />

Thickness<br />

.525"<br />

.750"<br />

1.000"<br />

1.500"<br />

.325"<br />

.750"<br />

.375"<br />

2.250"<br />

3.250"<br />

Box<br />

Qty<br />

3.5M<br />

3.5M<br />

2.5M<br />

2M<br />

2.5M<br />

2M<br />

2M<br />

500<br />

500<br />

I #17-14 x 1" TYPE AB W/VRT 20ga or less .750" 2.5M<br />

J #12-14 | 1/4-14 x 1-7/8" DP3 .036"-.210" .875"-1.125" 2,000<br />

K #12-14 | 1/4-14 x 2-1/4" DP3 .036"-.210" 1.125"-1.625" 1,000<br />

L #12-14 | 1/4-14 x 3-1/4" DP3 .036"-.210" 1.750"-2.437" 1,000<br />

LP denotes long-pilot design for metal roofing and siding<br />

MATERIAL<br />

HEAD: 304 Stainless Steel<br />

THREAD: Carbon Steel<br />

PLATING<br />

HEAD: Passivated<br />

THREAD: .0003” Min. Zinc with TRI-SEAL ® Long-life Coating<br />

CORROSION<br />

HEAD: >2,000hrs Salt Spray<br />

THREAD: 1,000hrs Salt Spray<br />

Visit our website for the most up-to-date product and technical information!<br />

A<br />

ZAMAC 5 zinc alloy cap head for premium corrosion<br />

resistance WILL NOT RED RUST!<br />

Special head is designed to produce maximum torsional<br />

strength and a leak free seal.<br />

B<br />

C<br />

D<br />

E<br />

TRIANGLE FASTENER<br />

CORPORATION<br />

Need a 3/8” Hex Washer Head?<br />

Contact us for available sizes.<br />

R<br />

WASHER DETAILS<br />

.125” Thick EPDM<br />

HEAD TYPE<br />

5/16" <strong>HWH</strong><br />

SIZES AND PERFORMANCE SPECIFICATIONS<br />

15<br />

A<br />

Size & Point<br />

#12-14 x 1" DP2/DP3<br />

#12-14 x 1-1/4" DP2/DP3 LP<br />

#12-14 x 1-1/2" DP2/DP3<br />

#12-14 x 2" DP2/DP3<br />

<strong>Drill</strong>ing<br />

Thickness<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

.036" - .210"<br />

Attachment<br />

Thickness<br />

.525"<br />

.750"<br />

1.000"<br />

1.500"<br />

Box<br />

Quantity<br />

3.5M<br />

3.5M<br />

2.5M<br />

2M<br />

B 1/4-14 x 7/8" DP1 W/VRT .036" - .090" .325" 2.5M<br />

C<br />

1/4-14 x 3/4" DP3<br />

1/4-14 x 1" DP3<br />

1/4-14 x 1-1/4" DP3<br />

1/4-14 x 1-1/2" DP3<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.036" - .250"<br />

.210"<br />

.460"<br />

.375"<br />

.960"<br />

2.5M<br />

2.5M<br />

2M<br />

2M<br />

D 1/4-14 x 1" TYPE AB 20ga or less .750" 2.5M<br />

E #17-14 x 1" TYPE AB 20ga or less .750" 2.5M<br />

LP denotes long-pilot design for metal roofing and siding<br />

MATERIAL<br />

HEAD: Zamac 5 Zinc Alloy<br />

THREAD: Carbon Steel<br />

PLATING<br />

HEAD: Plain Finish<br />

THREAD: .0003” Min. Zinc with TRI-SEAL ® Long-life Coating.<br />

CORROSION RESISTANCE<br />

HEAD: No Red Rust<br />

THREAD: 1,000hrs Salt Spray<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Visit our website for the most up-to-date product and technical information!<br />

BLAZER<br />

R<br />

DRILL SCREWS<br />

BLAZER ® ENGINEERING DATA<br />

TECHNICAL DATA<br />

Physical Properties<br />

BLAZER ® self-drilling fasteners<br />

are produced and perform to<br />

SAEJ78, ASME/ANSI 18.18.<br />

and AISI TS-4-02 specifications.<br />

Conforms to ICCESAC18<br />

acceptance criteria for tapping<br />

screw fasteners.<br />

The following information is compiled to assist the design professional in selecting the<br />

appropriate fastener for the application. Data supplied is compiled from fastener standards<br />

and independent tests. An engineering professional should be consulted to determine<br />

expected loads on the connection, environmental effects, and any other conditions that<br />

could effect the performance of the fastener. Selecting a fastener is the responsibility of<br />

the engineer and changes to a fastener should not be made without approval. Using the<br />

wrong fastener can lead to failure.<br />

TFC WILL NOT WARRANTY, EITHER EXPRESSED OR IMPLIED,<br />

THE USE OF THIS INFORMATION.<br />

Thread Description<br />

MINOR<br />

MAJOR<br />

Torsional<br />

<strong>Fastener</strong> Nominal Screw<br />

Major<br />

Minor<br />

Area Of Minor Torsional Tensile Shear<br />

Diameter Diameter<br />

Diameter (inch)<br />

Diameter (inch)<br />

Dia. (sq in.) (Lb-In.) (Pounds) (Pounds)<br />

Max Min Max Min<br />

#6-20 0.138 0.139 0.135 0.104 0.099 0.0077 25 1,125 750<br />

#8-18 0.164 0.166 0.161 0.122 0.116 0.0106 42 1,575 1,000<br />

#10-16 0.190 0.189 0.183 0.141 0.135 0.0143 61 2,100 1,400<br />

#10-24 0.190 0.190 0.182 0.144 0.137 0.0147 65 3,400 2,275<br />

#12-14 0.216 0.215 0.209 0.164 0.157 0.0194 92 2,778 2,000<br />

#12-24 0.216 0.216 0.209 0.189 0.185 0.0269 100 3,188 2,100<br />

1/4-14 0.250 0.246 0.240 0.192 0.185 0.0269 150 3,850 2,600<br />

1/4-20 0.250 0.250 0.242 0.218 0.214 0.0360 156 4,275 2,700<br />

#18-9 0.306 0.306 0.300 0.217 0.209 0.0343 170 4,550 2,576<br />

5/16-18 0.313 0.329 0.327 0.309 0.299 0.0702 250 8,550 5,700<br />

Tensile<br />

TECHNICAL DATA<br />

Shear<br />

REV.JES082712<br />

Material: C1018-C1022 / 410 SS<br />

Heat Treatment: Case Harden<br />

Case Hardness: 52-58 Rockwell C<br />

Case Depth:<br />

#6 Dia = .002” - .007”<br />

#8, #10, #12 Dia = .004” - .009”<br />

1/4” = .005” - .011”<br />

Core Hardness<br />

Carbon Steel: 32-40 Rockwell C<br />

410 Stainless: 42-48 Rockwell C<br />

Ductility: 5 Degree minimum bend<br />

PULLOVER TEST RESULTS<br />

These pullover results are for self-sealing<br />

fasteners listed in this catalog.<br />

Pounds - Ultimate Average<br />

Steel<br />

Thickness<br />

BOND-SEALER<br />

12.7MM OD<br />

15MM OD<br />

FLANGE<br />

SEALER<br />

ZINC<br />

CAP HEAD<br />

English to Metric<br />

Formula to Use<br />

Decimal to Millimeters Decimal x 25.4<br />

PSI to Newton / Millimeters² PSI x .007<br />

Pounds Force to Newtons Pounds Force x 4.448<br />

DISCLAIMER: ALL TEST RESULTS AND SPECIFICATIONS<br />

ARE A RESULT OF LABORATORY TESTS. APPROPRIATE<br />

SAFETY FACTORS SHOULD BE USED BY THE USER OR<br />

SPECIFIER. DETERMINING THE PROPER FASTENER IS<br />

THE RESPONSIBILITY OF THE USER OR SPECIFIER.<br />

SINCE APPLICATION CONDITIONS VARY AND ARE<br />

UNCONTROLLABLE BY TFC, WE ASSUME NO LIABILITY<br />

FOR THE USE OF THIS INFORMATION.<br />

STAINLESS<br />

CAP HEAD<br />

22 ga 945 1,249 1,298 1,647 1,298<br />

24 ga 704 1,056 1,102 1,310 1,102<br />

26 ga 519 654 692 794 692<br />

Note: Estimated pullover for fasteners<br />

without sealing washers can be<br />

calculated using the following formula<br />

per AISI.<br />

Pullover force = 1.5 -x- Thickness of the<br />

member in contact with the screw head.<br />

-x- Larger of the screw head diameter or<br />

washer diameter. -x- Tensile strength of<br />

the member in contact with the screw<br />

head.<br />

Gauge<br />

Thickness<br />

Decimal Metric<br />

29 GA .013" .33mm<br />

28 GA .015" .38mm<br />

26 GA .018" .46mm<br />

24 GA .024" .61mm<br />

22 GA .030" .76mm<br />

20 GA .036" .91mm<br />

18 GA .048" 1.22mm<br />

16 GA .060" 1.52mm<br />

14 GA .075" 1.91mm<br />

12 GA .105" 2.67mm<br />

1/8" .125" 3.18mm<br />

10 GA .135" 3.43mm<br />

1/4" .250" 6.35mm<br />

5/16" .312" 7.92mm<br />

3/8" .375" 9.53mm<br />

1/2" .500" 12.7mm<br />

R<br />

16<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

BLAZER<br />

R<br />

DRILL SCREWS<br />

PULLOUT TEST RESULTS<br />

The following fastener pullout loads are a result<br />

of independent tests conducted at Stork Herron<br />

Testing Laboratories. The results are ultimate<br />

averages as a result of conducting three pullouts<br />

per fastener size in each material thickness.<br />

Pullout Test Result - Ultimate Average in Pounds<br />

GAGE THICKNESS & ROCKWELL HARDNESS OF THE TEST PLATE<br />

<strong>Fastener</strong><br />

Size<br />

26 Ga.<br />

(.018")<br />

45-49Rb<br />

24 Ga.<br />

(.024")<br />

46-52Rb<br />

22 Ga.<br />

(.030")<br />

61-67Rb<br />

20 Ga.<br />

(.036")<br />

54-62Rb<br />

18 Ga.<br />

(.048")<br />

64-73Rb<br />

Setup of<br />

Pullout Test<br />

Hole Diameter: 1.500”<br />

16 Ga.<br />

(.060")<br />

65-67Rb<br />

14 Ga.<br />

(.075")<br />

68-70Rb<br />

<strong>Fastener</strong> pulled<br />

in this direction<br />

12 Ga.<br />

(.105")<br />

74-86Rb<br />

1/8"<br />

(.125")<br />

75-91Rb<br />

3/16"<br />

(.188")<br />

83-85Rb<br />

1/4"<br />

(.250")<br />

92-96Rb<br />

1/2"<br />

(500")<br />

92-93Rb<br />

#6-20 DP2 120 183 248 296 241 679 847<br />

#8-18 DP2 120 193 243 297 447 703 910<br />

#10-16 DP3 153 207 243 293 487 710 900 1327 1503<br />

#10-24 DP2 161 238 293 324 517 638 787 1272<br />

#12-14 DP2 577 790 1137 1697 1920 2973*<br />

#12-14 DP3 533 752 1163 1947 2250 2870<br />

#12-24 DP5 687 986 1850 1670 2673 3844* 1873<br />

1/4-14 DP1 173 240 337 387 657 1250<br />

1/4-14 DP3 343 533 1 579 1077 2170 2060 3863 4493*<br />

1/4-20 DP5 3853 4283* 4680*<br />

5/16-18 DP3 457 706 1609 1707 2831 2915 3745<br />

* Exceeds Tensile Strength<br />

1 Tested at Farabaugh Testing Lab | 58KSI | 12.03.13<br />

F<br />

TECHNICAL DATA<br />

Install the fastener through the<br />

center of the hole.<br />

A minimum of three (3) full<br />

threads must extend beyond<br />

the test coupon<br />

Fixture (Secured)<br />

Test Coupon<br />

Stork Herron Report #<br />

TRI081-05-01-88910-1<br />

Test Material: 55ksi - 100ksi<br />

Visit our website for the most up-to-date product and technical information!<br />

SHEAR TEST RESULTS<br />

Load<br />

Load<br />

Size<br />

26 Ga.<br />

(.018")<br />

24 Ga.<br />

(.024")<br />

22 Ga.<br />

(.030")<br />

20 Ga.<br />

(.036")<br />

18 Ga.<br />

(.048")<br />

16 Ga.<br />

(.060")<br />

14 Ga.<br />

(.075")<br />

12 Ga.<br />

(.105")<br />

#6-20 DP2 278 466 526 758 845<br />

#8-18 DP2 294 496 560 740 1,060<br />

#10-16 DP3 728 1,266 1,540 1,552<br />

#12-14 DP3 769 1,358 1,620 1,970 1,986<br />

#12-24 DP5 2,650<br />

1/4-14 DP3 930 1,442 2,100 2,584 2,650<br />

1/4-20 DP4 2,650<br />

Shear tests are a result of installation of the<br />

fastener in the noted gauge thickness and<br />

applying load until failure occurs.<br />

DISCLAIMER: ALL TEST RESULTS AND SPECIFICATIONS ARE A RESULT OF<br />

LABORATORY TESTS. APPROPRIATE SAFETY FACTORS SHOULD BE USED<br />

BY THE USER OR SPECIFIER. DETERMINING THE PROPER FASTENER IS THE<br />

RESPONSIBILITY OF THE USER OR SPECIFIER. SINCE APPLICATION CONDITIONS<br />

VARY AND ARE UNCONTROLLABLE BY TFC, WE ASSUME NO LIABILITY FOR THE<br />

USE OF THIS INFORMATION.<br />

TRIANGLE FASTENER<br />

CORPORATION<br />

R<br />

17<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Visit our website for the most up-to-date product and technical information!<br />

C<br />

SALT SPRAY RESULTS<br />

The chart to the right provides general information with<br />

regard to corrosion resistance of various plating and<br />

coatings. Contact TFC for detailed information.<br />

CORROSION PROTECTION INFORMATION<br />

The following information was compiled from known data that compares various finishes<br />

in a controlled environment. The material set forth herein is for general information only<br />

and cannot be construed as a substitute for competent professional advice or service.<br />

Any part considering application use of this information does so at their own risk and<br />

assumes any and all liability from application or use. Consult a corrosion specialist to<br />

determine the best fastener for your condition.<br />

FASTENER COMPATIBILITY FOR METAL ROOFING AND WALL CLADDING<br />

Table developed by the Metal Construction Association Members ( Revised by TFC: 12813JS)<br />

<strong>Fastener</strong> Material<br />

Zinc Plated<br />

Steel<br />

<strong>Screws</strong> 2<br />

Organic<br />

Coated Steel<br />

<strong>Screws</strong> 2<br />

Hot-Dip<br />

Galvanized<br />

Steel Nails 3<br />

and <strong>Screws</strong><br />

Zinc-Alloy<br />

Head Steel<br />

<strong>Screws</strong><br />

Stainless<br />

Capped Head<br />

Steel <strong>Screws</strong><br />

TECHNICAL DATA<br />

SALT SPRAY Per ASTM F1941 & B117 (0% red rust) Rev. 042111<br />

Carbon steel and 410 stainless steel materials<br />

Coating<br />

Salt Spray<br />

.00015” min. (3 um) zinc plating with clear chromate 15hrs<br />

.0002” min. (6um) zinc plating with clear chromate 24hrs<br />

Passivated 410 Stainless Steel<br />

48hrs<br />

.0003” min. (8 um) zinc plating with clear chromate 48hrs<br />

.0003” min. (8 um) zinc plating with yellow di-chromate 120hrs<br />

.0005” min. (12 um) zinc plating with clear chromate 72hrs<br />

.0007” min. (14 um) mechanical zinc with clear chromate 72hrs<br />

Epoxy (E-Coat) (ACQ Compatible)<br />

100hrs<br />

TRI-SEAL Long-life coating<br />

1,000hrs<br />

300<br />

Series<br />

Stainless<br />

Steel<br />

400<br />

Series<br />

Stainless<br />

Steel<br />

Metal Roof or<br />

Wall Cladding Material<br />

Aluminum<br />

Copper and<br />

Copper Alloys<br />

Unpainted Galvanized Steel Yes 4 Yes Yes Yes Yes Yes No Yes Yes<br />

Painted Galvanized Steel Yes 4 Yes Yes Yes Yes Yes No Yes Yes<br />

Unpainted Galvalume Steel Yes 4 Yes 4 Yes Yes Yes Yes No Yes Yes<br />

Painted Galvalume Steel Yes 4 Yes 4 Yes Yes Yes Yes No Yes 4 Yes 4<br />

Aluminum No Yes 4 No Yes Yes Yes No Yes No<br />

Copper & Copper Alloys No No No No No No Yes Yes Yes4<br />

Stainless Steel No No No Yes Yes Yes Yes Yes Yes<br />

Zinc alloy No No No Yes No Yes No Yes Yes<br />

Chart was revised by TFC based on various panel manufacturer's specifications and actual job-site performace.<br />

Note 1: Cautionary Guideline: This table serves as a guideline for the selection of fasteners used with metal roofing. The performance<br />

of compatible fasteners shown in this table matches the expected life of the metal roof or wall cladding materials. However, in highly<br />

corrosive environments such as heavy industrial, coastal marine, high airborne pollutants or salt spray, preservative treated lumber or<br />

fire-retardant lumber, the compatibility of certain fasteners with metal roofing or wall cladding materials may be affected. In those types of<br />

applications, the manufacturers of the fastener and metal panel will have specific and unique recommendations.<br />

In addition, in the event that certain coating barriers are damaged or scratched through to the substrate there is increased potential for<br />

premature corrosion. Care should be taken during installation and during routine maintenance of the panels in order to protect the integrity<br />

of the coatings used for metal panels.<br />

Note 2: <strong>Screws</strong> should be plated/coated per ASTM F1941<br />

Note 3: Nails should be galvanized per ASTM A153<br />

Note 4: Not recommended for coastal and heavy industrial environments<br />

Special Note: Preservative-Treated Lumber Applications<br />

ACQ, Penta, CA or CBA preservative-treated lumber can be incompatible with certain types of fasteners. In those cases where any type<br />

of metal roof or wall cladding materials are being attached to preservative treated lumber, the following fasteners are not compatible: zinc<br />

plated screws, zinc-alloy headed screws, stainless capped screws, aluminum, copper and copper alloy. When attaching metal panels to<br />

those types of preservative-treated lumber, a moisture barrier should be used between the lumber and the panel material. Metal panel<br />

fasteners that are compatible with preservative-treated lumber are stainless steel fasteners, or hot dip galvanized nails manufactured<br />

to ASTM A153 class D or heavier. Other types of fasteners coated with proprietary anti-corrosive technologies are also available for use<br />

with preservative-treated lumber. In addition, zinc-plated screws can be used in CCA and MCQ pressure-treated lumber.<br />

R<br />

18<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

C<br />

Salt Spray Test Results<br />

1,000hrs Per ASTM B117<br />

Compatible for use in treated lumber<br />

SEM IMAGING<br />

TECHNICAL DATA<br />

TRI-SEAL LONG-LIFE COATING<br />

TRI-SEAL Long-Life Coating is a high performance dip spin fi nish,<br />

developed to minimize corrosion when used in exterior building applications. It<br />

consists of three layers; the fi rst layer is a metallic zinc layer, the second layer<br />

is a high-grade anti-corrosion chemical conversion fi lm and the third, outer<br />

layer, is a baked ceramic surface coating.<br />

The distinguishing feature of TRI-SEAL is the tight joining of the baked<br />

ceramic surface coating and the chemical conversion fi lm. These two layers<br />

are bonded together through chemical reactions, and this unique method of<br />

combining layers result in a rigid combination of the coating fi lms.<br />

■ Excellent resistance against gas, weather, and other kinds<br />

of corrosion factors, including salt water.<br />

■ Compatible for use in ACQ and Fire Treated Lumber.<br />

■ Composite layers minimize the effect of scratches on the<br />

protection coating.<br />

■ Compatible for use in aluminum applications.<br />

Layer 1 - Baked Ceramic Surface Coating Layer<br />

Corrosive elements are intercepted by the<br />

strong paint fi lm made of ceramic materials.<br />

Layer 2 - Chemical Conversion Coating Layer<br />

Rust proof performance is improved as the<br />

chemical conversion inactivates the zinc plated<br />

surface and creates a tight adhesion between<br />

the chemically converted layer and the<br />

paint layer.<br />

Visit our website for the most up-to-date product and technical information!<br />

Layer 3 - Metallic Zinc Layer<br />

The steel / iron substrate is protected from<br />

corrosion by the self-sacrifi cial galvanic effect<br />

of the zinc coating.<br />

Layer 4 - <strong>Fastener</strong><br />

MATERIAL PROPERTIES<br />

Test Items Test Methods Test Results<br />

Hardness Peeling test by pencil hardness Over 4H<br />

Adhesion<br />

Peeling test by adhesive tape on cross scribed test<br />

piece in 1 mm width<br />

Nothing abnormal<br />

Acid Resistance Immersion in 5% sulfuric acid solution for 24 hours Nothing abnormal<br />

Alkali Resistance Immersion in 5% sodium hydroxide solution for 72 hours Nothing abnormal<br />

Corrosion Testing<br />

Salt Spray: 1,000hrs.<br />

Per ASTM B117.<br />

No red rust<br />

Kesternich: 30 cycles.<br />

Per DIN 50018<br />

Heat Resistance Exposure to 250 C (482 F) heat for an hour Nothing abnormal<br />

Accelerated Weathering Sunshine weather-0-meter test for 1,000 hours Free from red rust<br />

Contact Corrosion<br />

w/other Metals<br />

Corrosive investigation after Salt Spray Test (JIS Z2371)<br />

done comparatively on surface treated steel bolts/nuts<br />

tightened on a stainless steel plate<br />

Clearly superior to zinc<br />

electroplated (colored<br />

chromate) and hot<br />

dip galvanizing<br />

Contact TFC for additional details on TRI-SEAL TM .<br />

DISCLAIMER: ALL TEST RESULTS AND SPECIFICATIONS ARE A RESULT OF LABORATORY TESTS. APPROPRIATE SAFETY FACTORS SHOULD BE USED BY THE<br />

USER OR SPECIFIER. DETERMINING THE PROPER FASTENER IS THE RESPONSIBILITY OF THE USER OR SPECIFIER. SINCE APPLICATION CONDITIONS VARY<br />

AND ARE UNCONTROLLABLE BY TFC, WE ASSUME NO LIABILITY FOR THE USE OF THIS INFORMATION.<br />

R<br />

19<br />

TRIANGLE FASTENER CORPORATION<br />

800.486.1832 / www.trianglefastener.com

Visit our website for the most up-to-date product and technical information!<br />

#10, #12, & 1/4" GIMLET POINTS AND DRILL POINTS<br />

WOOD OR THIN METAL<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

®<br />

A-1<br />

Zinc Plated available<br />

for interior use only.<br />

A<br />

A-1<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

Sizes<br />

Description<br />

#10-13 X 1” GP<br />

Long-life TRI-SEAL coated<br />

#10-9 X 1” Type 17<br />

Zinc Plated | Interior Use Only<br />

#10-13 X 1” GP<br />

302 Stainless Steel<br />

#10-9 X 1-1/8” TYPE 17<br />

Long-life TRI-SEAL coated<br />

#10-13 X 1-1/2” GP<br />

Long-life TRI-SEAL coated<br />

#10-13 X 1-1/2” GP<br />

302 Stainless Steel<br />

#10-13 X 2” GP<br />

Long-life TRI-SEAL coated<br />

#12-11 X 1” GP<br />

Long-life TRI-SEAL coated<br />

THE LARGEST SELECTION OF LOW<br />

PROFILE PANCAKE HEAD SCREWS<br />

CONCEALOR ® low profile head fasteners are engineered to perform<br />

in a variety of applications. They are specified in many metal roofing<br />

systems to attached SSR clips to metal or wood. They are easy to install<br />

and provides optimal strength.<br />

<strong>Drill</strong>ing<br />

Thickness<br />

Part Number<br />

Box<br />

Quantity<br />

WT Per<br />

Box<br />

®<br />

CONCEALOR<br />

ULTRA LOW PROFILE FASTENER<br />

Need it Ultra Low?<br />

50% thinner than a standard<br />

pancake head.<br />

No more dimpling of the panel.<br />

Special taper<br />

Increase head strength and<br />

countersinks into the wood.<br />

Coarse thread<br />

Pulls fastener tight into the<br />

wood without stripping and<br />

increases pullout.<br />

Minimum 1" thread length<br />

Provides full thread engagement<br />

for increased pullout!<br />

Sharp gimlet point<br />

Fast penetration into steel<br />

clips up to 24 gauge thick!<br />

ULTRA LOW PROFILE<br />

FASTENERS<br />

Use the original ultra low profile fastener...<br />

CONCEALOR ® ULP<br />

The CONCEALOR ® ULP is an ultra low profile screw<br />

engineered to attach standing seam roof clips to wood.<br />

They are the preferred screw for attaching clip-less<br />

metal roof panels, and are easy to install providing<br />

optimal strength. ULP's are supplied with TRI-SEAL<br />

1,000-hours salt spray coating which can be used in ACQ<br />

and fire treated lumber.<br />

Visit our website for the most up-to-date product and technical information!<br />

A<br />

B<br />

C<br />

D<br />

Now available in lengths<br />

up to 2-1/8"!<br />

Zinc Plated available<br />

for interior use only.<br />

#2 Square<br />

Recess Drive<br />

A<br />

A-1<br />

B<br />

C<br />

D<br />

Sizes<br />

Description<br />

#10-9 X 1-1/8” ULP (CS)<br />

Long-life TRI-SEAL coated<br />

#10-9 X 1-1/8” ULP (CS)<br />

Zinc Plated Interior Use Only<br />

#10-9 X 1-1/8” ULP (410 SS)<br />

Passivated<br />

#10-9 X 1-5/8” ULP (CS)<br />

Long-life TRI-SEAL coated<br />

#10-9 X 2-1/8” ULP(CS)<br />

Long-life TRI-SEAL coated<br />

<strong>Drill</strong>ing<br />

Thickness<br />

24ga maximum<br />

Bagged 250 pcs. per bag<br />

for your convenience!<br />

Part Number<br />

Box<br />

Quantity<br />

WT Per<br />

Box<br />

Visit our website for the most up-to-date product and technical information!<br />

CLIP DETAILS<br />

1-7/8”<br />

2-1/4”<br />

®<br />

STANDING SEAM ROOF CLIP<br />

AND SCREWS - LOAD TESTED<br />

Are you tired of having to calculate the uplift loads<br />

of SSR clips used in your metal roof assembly?<br />

We have a solution...the SSR CLIP KIT!<br />

We provide a 1-7/8" tall fixed clip that is UL classified and has<br />

been independently tested to certify its ultimate uplift load<br />

capacity.<br />

Clips are supplied with approved fasteners that meet your<br />

specific application requirement.<br />

Our SSR fixed clips are engineered to high standards. They are<br />

produced to tight tolerances so they install easily and perform with<br />

many different panel brands. Specifically designed for a Snap-Lock<br />

style SSR panel.<br />

• Clip is high strength 18ga. galvanized steel for superior performance.<br />

• 1-7/8" tall providing additional clearance between the panel and the<br />

decking for better air flow and energy efficiency.<br />

• UL classified.<br />

• Compatible for PAK-CLAD, Snap-Clad,and Fabral thin seam panels.<br />

FASTENER DETAILS<br />

Our CONCEALOR® low profile head screws are engineered to<br />

perform in a variety of applications. They are easy to install and<br />

provide exceptional pullout.<br />

• High performance CONCEALOR® Low Profile Clip<br />

<strong>Screws</strong> for a variety of substrates.<br />

• Carbon steel with TRI-SEAL long-life coating or<br />

stainless steel.<br />

• Square recess drive for optimal installation stability.<br />

• #10, #12, #14 diameters in lengths up to 9" long!<br />

• MIAMI-DADE approved!<br />

TECHNICAL DATA<br />

These loads are from tests conducted<br />

at an independent laboratory. They are<br />

values for the clip assembly; where the<br />

clip is attached to the substrate using<br />

two (2) screws.<br />

A load was applied to the vertical leg<br />

of the clip until failure LOAD<br />

occurred.<br />

Loads are ultimate for<br />

each clip and screw<br />

assembly.<br />

Report #JS031711<br />

Concealor is a registered trademark of<br />

<strong>Triangle</strong> <strong>Fastener</strong> Corporation. Copyright 2011<br />

R<br />