Lafferty Air Foamer Manual - Pumps & Pressure Inc.

Lafferty Air Foamer Manual - Pumps & Pressure Inc.

Lafferty Air Foamer Manual - Pumps & Pressure Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

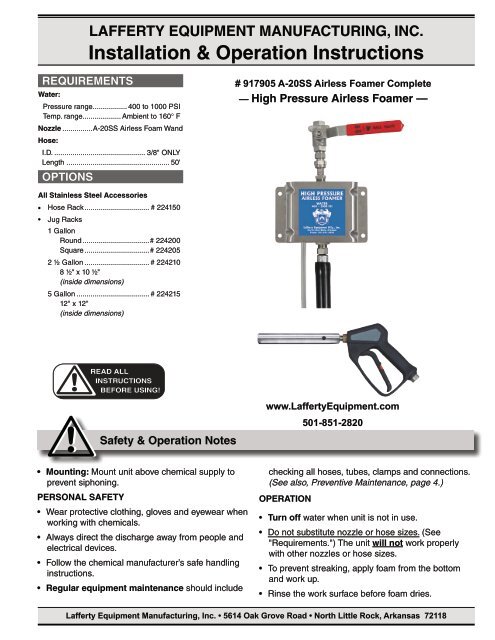

LAFFERTY EQUIPMENT MANUFACTURING, INC.<br />

Installation & Operation Instructions<br />

REQUIREMENTS<br />

Water:<br />

<strong>Pressure</strong> range................. 400 to 1000 PSI<br />

Temp. range................... Ambient to 160° F<br />

Nozzle................A-20SS <strong>Air</strong>less Foam Wand<br />

Hose:<br />

I.D............................................... 3/8" ONLY<br />

Length ................................................... 50'<br />

OPTIONS<br />

# 917905 A-20SS <strong>Air</strong>less <strong>Foamer</strong> Complete<br />

— High <strong>Pressure</strong> <strong>Air</strong>less <strong>Foamer</strong> —<br />

All Stainless Steel Accessories<br />

• Hose Rack................................. # 224150<br />

• Jug Racks<br />

1 Gallon<br />

Round..................................# 224200<br />

Square.................................# 224205<br />

2 ½ Gallon................................. # 224210<br />

8 ½" x 10 ½"<br />

(inside dimensions)<br />

5 Gallon..................................... # 224215<br />

12" x 12"<br />

(inside dimensions)<br />

www.<strong>Lafferty</strong>Equipment.com<br />

501-851-2820<br />

!Safety & Operation Notes<br />

• Mounting: Mount unit above chemical supply to<br />

prevent siphoning.<br />

Personal Safety<br />

• Wear protective clothing, gloves and eyewear when<br />

working with chemicals.<br />

• Always direct the discharge away from people and<br />

electrical devices.<br />

• Follow the chemical manufacturer’s safe handling<br />

instructions.<br />

• Regular equipment maintenance should include<br />

checking all hoses, tubes, clamps and connections.<br />

(See also, Preventive Maintenance, page 4.)<br />

OPERATION<br />

• Turn off water when unit is not in use.<br />

• Do not substitute nozzle or hose sizes. (See<br />

"Requirements.") The unit will not work properly<br />

with other nozzles or hose sizes.<br />

• To prevent streaking, apply foam from the bottom<br />

and work up.<br />

• Rinse the work surface before foam dries.<br />

<strong>Lafferty</strong> Equipment Manufacturing, <strong>Inc</strong>. • 5614 Oak Grove Road • North Little Rock, Arkansas 72118

Model # 917905 A-20SS <strong>Air</strong>less <strong>Foamer</strong> Complete<br />

Principles of Operation:<br />

For use with 400-1000 PSI water systems, <strong>Lafferty</strong> High <strong>Pressure</strong> <strong>Air</strong>less <strong>Foamer</strong>s<br />

are water-driven venturi systems that will draw chemical concentrates from any<br />

container, providing up to 21 different dilution ratios, and apply foam to any surface.<br />

Foam is created instantly in the venturi airless foam wand.<br />

TO INSTALL refer to diagram<br />

Read all Safety and Operational Precautions on page 1.<br />

1. Mount the unit above chemical supply to prevent siphoning.<br />

2. Connect the discharge hose assembly as shown in the diagram.<br />

3. Select and install metering tip into chemical check valve.<br />

Push the chemical tube over the check valve and immerse the chemical strainer<br />

into your chemical concentrate.<br />

How to Select the Correct Metering Tip<br />

• The dilution ratios provided in the Metering Tip Selection Chart, at right, are<br />

based on water-thin chemical with a water pressure of 700 PSI. Use the<br />

Metering Tip Selection Formula if you have water pressure other than 700<br />

PSI.<br />

• Due to varying chemical viscosities, you may need to increase the metering<br />

tip size. (See chemical label for dilution recommendation.)<br />

4. Connect water supply. (400 PSI water pressure minimum.)<br />

TO FOAM<br />

1. Open the water ball valve and move to the area to be cleaned.<br />

• Hold the trigger gun firmly and direct the discharge in a safe direction.<br />

• Pull the trigger and begin application. Observe foam quality.<br />

• If foam quality is poor, keep trying the next larger sized metering tip until the foam<br />

and cleaning results are acceptable.<br />

2. When foaming is completed, release the trigger. Return to the unit and close the<br />

inlet ball valve, then squeeze the trigger to relieve pressure in the hose. Rinse the<br />

work surface before the chemical dries.<br />

3. If <strong>Foamer</strong> will not be used for a period of time it is BEST to draw fresh water<br />

thru the pick up tube to prevent chemical from drying inside the check valve or<br />

<strong>Foamer</strong> body or <strong>Air</strong>less Foam Wand.<br />

Metering Tip<br />

Color<br />

Metering Tip Selection<br />

Oz.<br />

per<br />

Min.<br />

Example:<br />

Dilution Ratio<br />

@ 700 PSI<br />

A-20SS<br />

Brown .84 500:1<br />

Clear 1.16 362:1<br />

Bright Purple 1.4 300:1<br />

White 2.0 210:1<br />

Pink 2.7 155:1<br />

Corn Yellow 3.4 123:1<br />

Dark Green 4.0 105:1<br />

Orange 5.3 79:1<br />

Gray 6.1 69:1<br />

Light Green 7.0 60:1<br />

Med. Green 8.5 49:1<br />

Clear Pink 9.2 46:1<br />

Yellow Green 11.2 37:1<br />

Burgundy 12.5 34:1<br />

Pale Pink 12.9 33:1<br />

Light Blue 14.2 30:1<br />

Dark Purple 17.6 24:1<br />

Navy Blue 21.4 20:1<br />

Clear Aqua 30.2 14:1<br />

Black 40.4 10:1<br />

No Tip — 8:1<br />

The dilution ratios provided above are<br />

approximate values. Your actual dilution<br />

ratio may be higher or lower due to<br />

variation in chemical viscosity.<br />

Metering Tip Selection Formula<br />

(GPM x 128)<br />

÷<br />

=<br />

Dilution Ratio<br />

Oz. per Min.<br />

See chart below for<br />

GPM and convert to oz.<br />

per min.<br />

20:1, 30:1, etc.<br />

Match to nearest number<br />

in chart above.<br />

Water Flow Rate Chart<br />

Water <strong>Pressure</strong> Water Flow Rate<br />

PSI<br />

GPM<br />

A-20SS <strong>Air</strong>less <strong>Foamer</strong><br />

400 2.50<br />

500 2.76<br />

600 3.04<br />

700 3.28<br />

800 3.52<br />

900 3.71<br />

1000 3.90<br />

! Always turn off water when unit is not in use.<br />

– Page 2 –

Model # 917905 A-20SS <strong>Air</strong>less <strong>Foamer</strong> Complete<br />

– Page 3 –

Troubleshooting Guide<br />

Model # 917905 A-20SS <strong>Air</strong>less <strong>Foamer</strong> Complete<br />

PROBLEM<br />

Possible Cause / Solution Categories<br />

Startup<br />

Maintenance<br />

A) <strong>Foamer</strong> will not draw chemical. 1, 4, 5, 6, 7 8, 9, 10, 11, 12, 13<br />

B) Water backing up into chemical container. 8<br />

C) Dilution too strong. 3<br />

D) Foam does not clean/perform properly. 2<br />

E) Chemical solution backing up into water line. 13<br />

Possible Cause / Solution<br />

Startup<br />

1. Inlet ball valve or discharge ball valve not<br />

completely open<br />

• Completely open the water and discharge ball valves.<br />

2. Not enough chemical - metering tip too small<br />

• Install larger metering tip.<br />

3. No metering tip installed or metering tip too large<br />

• Install smaller metering tip.<br />

4. Chemical tube not immersed in chemical or<br />

chemical depleted<br />

• Immerse tube or replenish.<br />

5. Discharge hose too long or wrong size or kinked<br />

(SEE REQUIREMENTS)<br />

• Straighten the hose - Replace hose with correct size.<br />

6. Foam wand wrong size (SEE REQUIREMENTS)<br />

7. Water pressure too low or water volume too low/<br />

inlet piping too small<br />

• <strong>Inc</strong>rease water pressure or water volume (SEE<br />

REQUIREMENTS).<br />

Maintenance<br />

8. Chemical check valve stuck or failed<br />

• Clean or replace.<br />

9. Chemical strainer or metering tip partially blocked<br />

• Clean or replace chemical strainer and/or metering tip.<br />

10. Chemical tube stretched out or pin hole/cut in chemical<br />

tube (sucking air in)<br />

• Cut off end of tube or replace tube.<br />

11. Vacuum leak in chemical pick-up connection<br />

• Tighten the connection.<br />

12. Chemical build-up may have formed in the foamer body<br />

or airless foam wand, causing poor or no chemical pickup<br />

• Follow Preventive Maintenance instructions below, using hot<br />

water and/or descaling acid. When there is no draw at all,<br />

carefully remove fittings and soak entire body in descaling acid.<br />

13. No backflow preventer installed<br />

• Install appropriate backflow preventer into water line.<br />

PREVENTIVE MAINTENANCE: When the unit will be out of service for extended periods, remove chemical tube from<br />

chemical concentrate and place in water. Completely open the water and discharge ball valves for a few seconds to flush<br />

chemical and help prevent chemical build-up. Check and/or clean chemical strainer; replace if missing.<br />

03/04/09 – Page 4 –<br />

917905_A-20SS_AF_Complete