View FM's It All Adds Up, Energy Conservation at the U flyer here

View FM's It All Adds Up, Energy Conservation at the U flyer here

View FM's It All Adds Up, Energy Conservation at the U flyer here

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

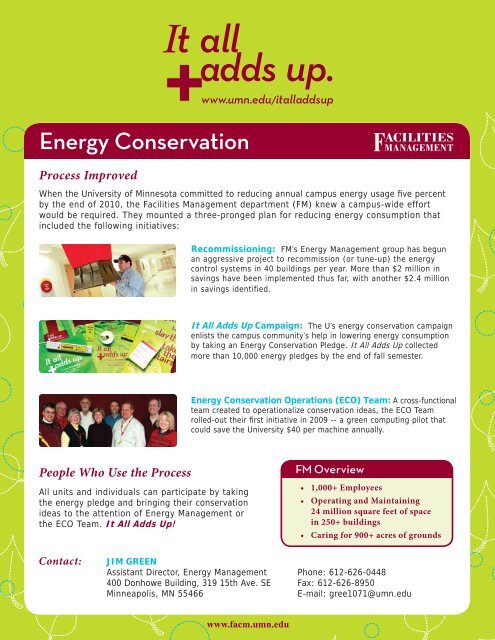

<strong>Energy</strong> <strong>Conserv<strong>at</strong>ion</strong><br />

Process Improved<br />

When <strong>the</strong> University of Minnesota committed to reducing annual campus energy usage five percent<br />

by <strong>the</strong> end of 2010, <strong>the</strong> Facilities Management department (FM) knew a campus-wide effort<br />

would be required. They mounted a three-pronged plan for reducing energy consumption th<strong>at</strong><br />

included <strong>the</strong> following initi<strong>at</strong>ives:<br />

Recommissioning: FM’s <strong>Energy</strong> Management group has begun<br />

an aggressive project to recommission (or tune-up) <strong>the</strong> energy<br />

control systems in 40 buildings per year. More than $2 million in<br />

savings have been implemented thus far, with ano<strong>the</strong>r $2.4 million<br />

in savings identified.<br />

<strong>It</strong> <strong>All</strong> <strong>Adds</strong> <strong>Up</strong> Campaign: The U’s energy conserv<strong>at</strong>ion campaign<br />

enlists <strong>the</strong> campus community’s help in lowering energy consumption<br />

by taking an <strong>Energy</strong> <strong>Conserv<strong>at</strong>ion</strong> Pledge. <strong>It</strong> <strong>All</strong> <strong>Adds</strong> <strong>Up</strong> collected<br />

more than 10,000 energy pledges by <strong>the</strong> end of fall semester.<br />

<strong>Energy</strong> <strong>Conserv<strong>at</strong>ion</strong> Oper<strong>at</strong>ions (ECO) Team: A cross-functional<br />

team cre<strong>at</strong>ed to oper<strong>at</strong>ionalize conserv<strong>at</strong>ion ideas, <strong>the</strong> ECO Team<br />

rolled-out <strong>the</strong>ir first initi<strong>at</strong>ive in 2009 -- a green computing pilot th<strong>at</strong><br />

could save <strong>the</strong> University $40 per machine annually.<br />

People Who Use <strong>the</strong> Process<br />

<strong>All</strong> units and individuals can particip<strong>at</strong>e by taking<br />

<strong>the</strong> energy pledge and bringing <strong>the</strong>ir conserv<strong>at</strong>ion<br />

ideas to <strong>the</strong> <strong>at</strong>tention of <strong>Energy</strong> Management or<br />

<strong>the</strong> ECO Team. <strong>It</strong> <strong>All</strong> <strong>Adds</strong> <strong>Up</strong>!<br />

FM Overview<br />

• 1,000+ Employees<br />

• Oper<strong>at</strong>ing and Maintaining<br />

24 million square feet of space<br />

in 250+ buildings<br />

• Caring for 900+ acres of grounds<br />

Contact:<br />

JIM GREEN<br />

Assistant Director, <strong>Energy</strong> Management Phone: 612-626-0448<br />

400 Donhowe Building, 319 15th Ave. SE Fax: 612-626-8950<br />

Minneapolis, MN 55466<br />

E-mail: gree1071@umn.edu<br />

www.facm.umn.edu

Quality Fair Poster<br />

Success Stories<br />

Variety Club Research Center Building Controls <strong>Up</strong>grade<br />

Savings: $60,000/year, 711 tons CO 2<br />

Emissions/year<br />

FM replaced an outd<strong>at</strong>ed He<strong>at</strong>ing, Ventil<strong>at</strong>ing and Air Conditioning (HVAC)<br />

control system with a modern Direct Digital Control (DDC) system. This<br />

allowed energy engineers to efficiently schedule HVAC system oper<strong>at</strong>ion.<br />

The systems had been running 24/7, or 168 hours per week in both labor<strong>at</strong>ory<br />

and office spaces. The new schedule lowered office space service by more<br />

than 90 hours per week.<br />

Ford Hall HVAC Variable Frequency Drive Install<strong>at</strong>ion<br />

Savings: $24,000/year, 284 tons CO 2<br />

Emissions/year<br />

Engineers installed variable frequency drives on Ford Hall’s large HVAC supply<br />

fans. Before recommissioning, <strong>the</strong> fans could only be oper<strong>at</strong>ed <strong>at</strong> full speed,<br />

regardless of how much air was needed. Occupancy sensors were installed<br />

throughout <strong>the</strong> building, so th<strong>at</strong> ventil<strong>at</strong>ion registers open only when rooms<br />

are occupied and require he<strong>at</strong>ing or air-conditioning. Recommissioning has<br />

reduced energy consumption in Ford Hall by approxim<strong>at</strong>ely 15 percent.<br />

Humphrey Center Lighting Efficiency <strong>Up</strong>grade<br />

Savings: $21,000/year, 249 tons CO 2<br />

Emissions/year<br />

After HVAC, interior lighting is <strong>the</strong> largest energy consuming system on<br />

campus. FM completed a lighting retrofit project in <strong>the</strong> Humphrey Center,<br />

replacing more than two hundred 110-w<strong>at</strong>t mercury vapor lights with energy<br />

efficient, 12-w<strong>at</strong>t LED lights.<br />

www.facm.umn.edu