Download - British Electric Flight Association

Download - British Electric Flight Association

Download - British Electric Flight Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

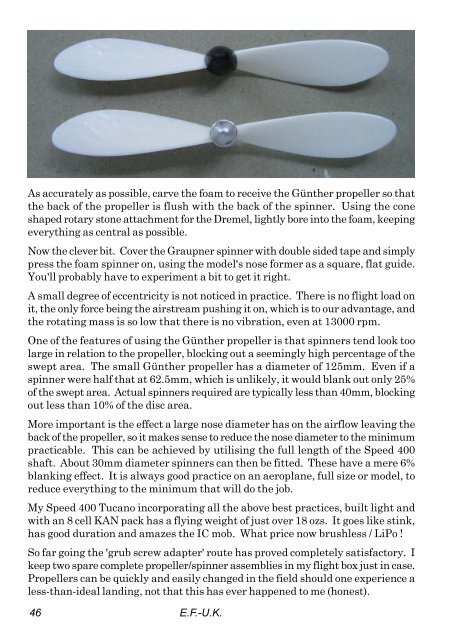

As accurately as possible, carve the foam to receive the Günther propeller so that<br />

the back of the propeller is flush with the back of the spinner. Using the cone<br />

shaped rotary stone attachment for the Dremel, lightly bore into the foam, keeping<br />

everything as central as possible.<br />

Now the clever bit. Cover the Graupner spinner with double sided tape and simply<br />

press the foam spinner on, using the model's nose former as a square, flat guide.<br />

You'll probably have to experiment a bit to get it right.<br />

A small degree of eccentricity is not noticed in practice. There is no flight load on<br />

it, the only force being the airstream pushing it on, which is to our advantage, and<br />

the rotating mass is so low that there is no vibration, even at 13000 rpm.<br />

One of the features of using the Günther propeller is that spinners tend look too<br />

large in relation to the propeller, blocking out a seemingly high percentage of the<br />

swept area. The small Günther propeller has a diameter of 125mm. Even if a<br />

spinner were half that at 62.5mm, which is unlikely, it would blank out only 25%<br />

of the swept area. Actual spinners required are typically less than 40mm, blocking<br />

out less than 10% of the disc area.<br />

More important is the effect a large nose diameter has on the airflow leaving the<br />

back of the propeller, so it makes sense to reduce the nose diameter to the minimum<br />

practicable. This can be achieved by utilising the full length of the Speed 400<br />

shaft. About 30mm diameter spinners can then be fitted. These have a mere 6%<br />

blanking effect. It is always good practice on an aeroplane, full size or model, to<br />

reduce everything to the minimum that will do the job.<br />

My Speed 400 Tucano incorporating all the above best practices, built light and<br />

with an 8 cell KAN pack has a flying weight of just over 18 ozs. It goes like stink,<br />

has good duration and amazes the IC mob. What price now brushless / LiPo !<br />

So far going the 'grub screw adapter' route has proved completely satisfactory. I<br />

keep two spare complete propeller/spinner assemblies in my flight box just in case.<br />

Propellers can be quickly and easily changed in the field should one experience a<br />

less-than-ideal landing, not that this has ever happened to me (honest).<br />

46<br />

E.F.-U.K.