2006 - GRS-Batterien

2006 - GRS-Batterien

2006 - GRS-Batterien

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Success Monitor<br />

Stiftung<br />

Gemeinsames Rücknahmesystem<br />

<strong>Batterien</strong><br />

Hamburg, March 2007 <strong>2006</strong>

2<br />

Table of contents<br />

1.<br />

2.<br />

3.<br />

4.<br />

5.<br />

Success Monitor in accordance with § 10(1) BattV<br />

(German Battery Decree)<br />

Table of contents 2<br />

Foreword 3<br />

Volume of batteries put into circulation / § 10(1)1. BattV 4<br />

Public relations 7<br />

Quality and environmental policy 8<br />

Volume of batteries collected,<br />

according to federal state / § 10(1)2. BattV 9<br />

Volume of batteries collected,<br />

according to origin / § 10(1)2. BattV 10<br />

6.<br />

7.<br />

8.<br />

9.<br />

10.<br />

11.<br />

Sorting of spent portable batteries 11<br />

Battery systems after sorting 12<br />

Recycling and disposal results /<br />

§ 10(1)3. BattV 13<br />

Summary of operative flow 16<br />

Prices paid for sorting,<br />

recycling and disposal / § 10(1)4. BattV 17<br />

Sources, abbreviations and definitions 18<br />

Imprint 19

1. Foreword<br />

<strong>GRS</strong> <strong>Batterien</strong> enjoyed extraordinary<br />

success in <strong>2006</strong>. Although there was no<br />

noticeable increase in the total weight<br />

of batteries and accumulators sold by<br />

manufacturers and importers, the quantity<br />

of batteries we collected nevertheless<br />

rose by 7 per cent year on year, to more<br />

than 13,000 tonnes. The targeted<br />

communication we have engaged in with<br />

our partners for many years is now<br />

beginning to show signs of paying off.<br />

The task we are now faced with is to<br />

maintain and improve this communication.<br />

We were also able to increase the<br />

proportion of returned batteries that are<br />

recycled to 88 per cent. And in spite of<br />

this increase in recycling, we were able<br />

to reduce specific costs in comparison<br />

to last year. This is partly due to the high<br />

price of metals in <strong>2006</strong>.<br />

It is important for us to be able to offer<br />

our customers excellent value for money.<br />

To do this, we are particularly interested<br />

in optimising costs while improving<br />

quality. Although the quantity of batteries<br />

collected has risen from approximately<br />

9,000 tonnes in 2000 to more than<br />

13,000 tonnes in <strong>2006</strong> and the proportion<br />

of batteries that are recycled has<br />

increased in that time from 33 % to 88 %,<br />

we have been able to keep disposal<br />

costs down at the same level as in 2000<br />

and have reimbursed our users with any<br />

surplus disposal fees.<br />

We endeavour to offer our customers<br />

outstanding services coupled with<br />

reasonable prices – something which we<br />

have achieved in the past and which we<br />

will continue to achieve in the future.<br />

We are therefore also grateful to our<br />

service providers and business partners<br />

for their dedicated engagement.<br />

We now intend to focus more on the<br />

EU’s environmental obligations,<br />

following the introduction of the new EU<br />

Battery Directive on 26 September <strong>2006</strong>.<br />

This directive must be enforced as<br />

national law by adapting Germany’s<br />

existing battery decree by October 2008<br />

at the latest. The new EU Battery<br />

Directive for the first time stipulates<br />

battery collection and recycling targets.<br />

<strong>GRS</strong> <strong>Batterien</strong> has already made<br />

provisions for this. The directive also<br />

lists fixed battery collection and<br />

recycling quotas for the first time. The<br />

minimum collection target has been<br />

pegged at 25 % for 2012 – <strong>GRS</strong> <strong>Batterien</strong><br />

has already surpassed this with<br />

approximately 38 %. <strong>GRS</strong> <strong>Batterien</strong> is also<br />

on course to meet the stipulated<br />

requirement that all identifiable batteries<br />

be recycled by 2009, as indicated by its<br />

recycling level of nearly 90 % in <strong>2006</strong>.<br />

In spite of these successes, there is no<br />

reason for us to rest on our laurels, as<br />

the battery collection quota stipulated<br />

by the EU for 2016 is 45 %, and this can<br />

only be achieved when all parties –<br />

from retailers to the municipalities and<br />

industry – continue to actively support<br />

the idea of battery collection.<br />

<strong>GRS</strong> <strong>Batterien</strong> has developed battery<br />

collection measures designed to help<br />

retailers, municipalities, and industrial<br />

users achieve the targets stipulated by<br />

the EU directive. Attention-grabbing<br />

promotions and intensive PR and media<br />

work motivate consumers to deposit<br />

batteries and accumulators at collection<br />

points.<br />

All future <strong>GRS</strong> <strong>Batterien</strong> communication<br />

activities will focus more heavily on the<br />

aspect of battery recycling: batteries<br />

contain raw materials that can be<br />

recovered and reused. And this is the key<br />

message that we want to communicate<br />

to consumers in order to encourage<br />

them to deposit their spent batteries for<br />

recycling. Some of <strong>GRS</strong> <strong>Batterien</strong>’s<br />

comprehensive PR work in 2007 will<br />

include highlights such as the BATT-<br />

Dr Jürgen Fricke<br />

Recycle Tour 2007 through 120 German<br />

towns and cities, recycling weeks hosted<br />

by trade partners, and the continuation<br />

of the ÖRE-Premium model (model<br />

for premium municipalities), which was<br />

launched successfully last year.<br />

Dr Jürgen Fricke,<br />

Chairman of the Board of <strong>GRS</strong> <strong>Batterien</strong><br />

Hamburg, March 2007<br />

3

4<br />

2. Volume of batteries put into circulation/§ 10(1)1. BattV<br />

As at 1 January <strong>2006</strong>, <strong>GRS</strong> <strong>Batterien</strong> had<br />

contractual relationships with 736 users.<br />

In the year under review, a further<br />

72 users took advantage of its services,<br />

thus increasing the number of manufacturers<br />

and importers that are contractual<br />

partners of <strong>GRS</strong> <strong>Batterien</strong> to 808 by the<br />

end of the year.<br />

A manufacturer is defined as anyone<br />

who manufactures batteries in Germany or<br />

has batteries manufactured, regardless<br />

of whether they are sold under a trademark<br />

or which trademark they bear. In<br />

the case of batteries without trademarks,<br />

whoever puts them into circulation for<br />

the first time in Germany is considered<br />

to be the manufacturer.<br />

This also applies to mail-order business.<br />

An importer is is defined as anyone who<br />

imports batteries into the Federal Republic<br />

of Germany and puts them into circulation<br />

for the first time there, regardless of the<br />

level of retail. (including mail-order<br />

business). This also applies to batteries<br />

built into appliances.<br />

The number of batteries sold by users<br />

in <strong>2006</strong> was at the same level as in the<br />

previous year. In comparison to 2005,<br />

the proportion of rechargeable (secondary)<br />

batteries rose again by one percentage<br />

point. Just under 22 % of all batteries sold<br />

in Germany in <strong>2006</strong> were rechargeable.<br />

Number of <strong>GRS</strong> <strong>Batterien</strong> users Development in battery sales according to battery types, 1999 – <strong>2006</strong><br />

Primary batteries Secondary batteries<br />

Source: KPMG; Deutsche Treuhandgesellschaft AG, Bielefeld

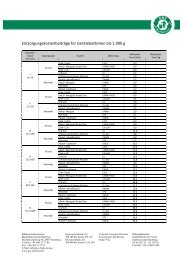

2. Volume of batteries put into circulation/§ 10(1)1. BattV<br />

Users of <strong>GRS</strong> <strong>Batterien</strong> put just short of<br />

1.5 billion batteries and accumulators into<br />

circulation in <strong>2006</strong>, which is 4 % more<br />

than in 2005. The total volume of batteries<br />

put into circulation amounted to<br />

34,736 tonnes, which is only slightly higher<br />

Primary batteries<br />

Secondary batteries<br />

than the previous year’s figure. There has<br />

been a drop in the weight per battery unit<br />

down the years, from 24.3 grams/unit in<br />

2005 to 23.4 grams/unit in the year under<br />

review. This is a reflection of the market<br />

trend towards smaller and smaller batteries.<br />

The majority of primary batteries continue<br />

to be alkaline-manganese (+3.2 % year on<br />

year), while sales of zinc-carbon batteries<br />

slumped again, by –23 % year on year. In<br />

<strong>2006</strong>, the proportion of primary zinc-carbon<br />

batteries was just 10 %. The sharpest rise<br />

among secondary batteries was achieved<br />

by lithium-ion accumulators. And while<br />

the volume of nickel-cadmium batteries<br />

rose by just under 3 %, the units of these<br />

batteries actually declined by 8 % year<br />

on year.<br />

Weight Quantity<br />

2005 <strong>2006</strong> Difference 2005 <strong>2006</strong> Difference<br />

kg % kg % kg % per 1,000 % per 1,000 % per 1,000 %<br />

Round cells** ZnC 4,717,446 13.6 3,616,472 10.4 –1,100,974 –23.3 194,505 13.6 151,551 10.2 –42,954 –22.1<br />

AlMn 22,162,384 64.0 22,874,233 65.9 711,849 3.2 889,728 62.4 941,372 63.5 51,644 5.8<br />

Zn-air 53,464 0.2 48,785 0.1 –4,679 –8.8 338 ‹0.1 359 ‹0.1 21 6.2<br />

Li, primary 218,979 0.6 219,666 0.6 687 0.3 14,639 1.0 14,646 1.0 7 ‹0.1<br />

Button cells AgO* 40,068 0.1 36,119 0.1 –3,949 –9.9 24,920 1.7 24,946 1.6 26 0.1<br />

AlMn* 163,300 0.5 148,777 0.4 –14,523 –8.9 57,889 4.1 84,019 5.7 26,130 45.1<br />

Zn-air 59,553 0.2 58,496 0.2 –1,057 –1.8 66,980 4.7 64,021 4.3 –2,959 –4.4<br />

Li, primary 169,080 0.5 244,112 0.7 75,032 44.4 52,661 3.7 60,456 4.1 7,795 14.8<br />

Sum 27,584,274 79.7 27,246,660 78.4 –337,614 –1.2 1,301,660 91.2 1,341,370 90.4 39,710 3.1<br />

Round cells** AlMn 40,642 0.1 75,662 0.2 35,020 86.2 1,564 0.1 2,164 0.1 600 38.4<br />

Li-ion 2,212,384 6.3 2,480,805 7.1 268,421 12.1 29,516 2.1 34,824 2.4 5,308 18.0<br />

NiMH 1,921,010 5.6 1,952,781 5.6 31,771 1.7 69,057 4.8 79,235 5.3 10,178 14.7<br />

Pb 1,015,389 2.9 1,069,969 3.1 54,580 5.4 823 ‹0.1 1,010 0.1 187 22.7<br />

NiCd 1,830,150 5.3 1,881,681 5.4 51,531 2.8 18,564 1.3 17,001 1.2 –1,563 –8.4<br />

Button cells Li-ion 7,747 ‹0.1 15,283 ‹0.1 7,536 97.3 2,848 0.2 5,115 0.3 2,267 79.6<br />

NiMH 12,789 ‹0.1 13,007 ‹0.1 218 1.7 2,404 0.2 2,677 0.2 273 11.4<br />

NiCd 295 ‹0.1 176 ‹0.1 –119 –40.3 87 ‹0.1 90 ‹0.1 3 3.4<br />

Sum 7,040,406 20.3 7,489,364 21.6 448,958 6.4 124,863 8.8 142,116 9.6 17,253 13.8<br />

Total 34,624,680 100.0 34,736,024 100.0 111,344 0.3 1,426,523 100.0 1,483,468 100.0 56,963 4.0<br />

Volume (kg) / quantity of batteries put into circulation by users<br />

Source: KPMG, Deutsche Treuhandgesellschaft AG, Bielefeld; the data is based on the quantities registered with <strong>GRS</strong> <strong>Batterien</strong> until this report was written<br />

* Includes round cells made up of button cells<br />

** Includes battery packs<br />

5

6<br />

AlMn 65.9 %<br />

2. Volume of batteries in circulation/§ 10(1)1. BattV<br />

Total<br />

34,736 tonnes of batteries and accumulators were<br />

brought into circulation on the German market by<br />

users of <strong>GRS</strong> <strong>Batterien</strong> in <strong>2006</strong>. 78.4 % of these were<br />

primary batteries (previous year 79.7 %) and 21.6 %<br />

were secondary batteries (previous year 20.3 %).<br />

Percentage of all batteries<br />

put into circulation, volume<br />

AlMn. secondary 0,2 %<br />

* All types of button cells<br />

Li-ion 7.1 %<br />

Pb 3.1 %<br />

ZnC 10.4 %<br />

Li, primary 0.6 %<br />

Zn-air 0.1 %<br />

Button cells* 1.6 %<br />

NiCd 5.4 %<br />

NiMH 5.6 %<br />

Percentage of batteries put into circulation by <strong>GRS</strong> <strong>Batterien</strong> users<br />

Source: KPMG, Deutsche Treuhandgesellschaft AG, Bielefeld<br />

Primary<br />

A total of 27,247 tonnes of primary batteries were put<br />

into circulation, which was 338 tonnes fewer than<br />

in the previous year. The main type of primary batteries<br />

continues to be alkaline-manganese batteries at<br />

84 %. In <strong>2006</strong>, their tonnage went up year on year<br />

by 712 tonnes to 22,874 tonnes. In contrast, the<br />

tonnage of zinc-carbon batteries slumped by more<br />

than 1,100 tonnes in <strong>2006</strong>, from 4,717 tonnes in the<br />

previous year to 3,616 tonnes.<br />

Percentage of primary batteries<br />

put into circulation, volume<br />

AlMn 83.9 %<br />

Zn-air 0.2 %<br />

Button cells* 1.8 %<br />

Li, primary 0.8 %<br />

ZnC 13.3 %<br />

Secondary<br />

While the volume of primary batteries put into<br />

circulation fell slightly year on year, the proportion<br />

of secondary batteries went up by 449 tonnes to<br />

7,489 tonnes. This can be attributed primarily to<br />

Li-ion batteries, the volume of which increased by<br />

no less than 268 tonnes brought into circulation<br />

year on year Li-ion batteries also account for 33 %<br />

of all rechargeable batteries.<br />

Percentage of secondary batteries<br />

put into circulation, volume<br />

NiCd 25.1 %<br />

NiMH 26.1 %<br />

AlMn 1.0 %<br />

Button cells* 0.4 %<br />

Pb 14.3 %<br />

Li-ion 33.1 %

3. Public relations<br />

Motivating everyone to play their part<br />

Once again in <strong>2006</strong>, <strong>GRS</strong> <strong>Batterien</strong><br />

managed to increasingly motivate private<br />

and industrial consumers, the industry,<br />

retail and municipalities to return spent<br />

batteries and accumulators with the help<br />

of numerous high-profile campaigns.<br />

Its dovetailed and highly congruous PR<br />

activities to boost battery collection<br />

met with resounding public approval.<br />

The ÖRE-Premium-Programm<br />

In <strong>2006</strong>, <strong>GRS</strong> <strong>Batterien</strong> devised a scheme<br />

for municipalities to expand their battery<br />

collection activities, offering them attractive<br />

services to that end. For example,<br />

<strong>GRS</strong> <strong>Batterien</strong> supported its premium<br />

partners’ battery collection weeks and<br />

similar events by providing promotional<br />

modules such as a pushalong car<br />

race and a painting studio. Both of these<br />

interactive promotions served as an<br />

entertaining way to encourage people to<br />

collect and return their batteries. In<br />

addition to advertising on refuse lorries,<br />

<strong>GRS</strong> <strong>Batterien</strong> also assisted municipalities<br />

with radio bulletins and ads and reports<br />

in local papers. It also provided “Mini-<br />

BATT” boxes (small battery collection<br />

boxes for individual households), handing<br />

them out as consumer giveaways at local<br />

recycling collection points. The scheme<br />

proved to be hugely popular and has<br />

therefore been extended into 2007 with<br />

new creative ideas. <strong>GRS</strong> <strong>Batterien</strong> was<br />

particularly successful in capitalising on<br />

the World Cup being in Germany in<br />

<strong>2006</strong>, launching an Internet-based game<br />

which allowed the municipalities to<br />

predict the scores of World Cup matches.<br />

The group that scored the most in the<br />

game won a free battery collection day,<br />

while the two runner-up teams were<br />

awarded a sum of money to be donated<br />

to an environmental project.<br />

Forum on the EU Battery Directive<br />

In October <strong>2006</strong>, <strong>GRS</strong> <strong>Batterien</strong> hosted<br />

an information and discussion forum<br />

in Berlin which was attended by battery<br />

manufacturers, experts from the environmental<br />

and waste disposal sector, trade<br />

reps and representatives of government<br />

authorities. The delegates addressed<br />

highly topical issues such as the obligations<br />

of the new EU Battery Directive<br />

and the status quo of battery collection,<br />

sorting and recycling in Germany. The<br />

issues discussed were also prepared for<br />

use in the daily press and in specialist<br />

publications, in order to reach as wide<br />

an audience as possible.<br />

Media power across the board<br />

Due to extensive PR work, the topic of<br />

battery collection was in the public eye<br />

VIPs at the forum on the EU Battery Directive:<br />

Dipl.-Ing. Otmar Frey, <strong>GRS</strong> <strong>Batterien</strong>, chairman of the<br />

advisory council; Victoria Herrmann, presenter;<br />

Dr Jürgen Fricke, <strong>GRS</strong> <strong>Batterien</strong>, chairman of the board<br />

of management; Dr Thomas Rummler, BMU, permanent<br />

ministerial secretary.<br />

throughout the year, with a total of nearly<br />

290 million contacts through all the<br />

media channels. Nearly 140 million of<br />

these contacts alone were radio bulletins,<br />

followed by 76 million publications in<br />

daily papers, general-interest magazines<br />

and the specialist press. Most contacts<br />

were in the form of ads and copy in<br />

high-circulation TV guides and retailers’<br />

consumer magazines. Some 66 million<br />

contacts were generated on the Internet.<br />

There were also TV reports on programmes<br />

such as “ARD Ratgeber Technik”<br />

and “ZDF drehscheibe Deutschland”. In<br />

addition, the website www.grs-batterien.<br />

de provides consumers and experts alike<br />

with interesting information relating to<br />

batteries and battery collection, ranging<br />

from the latest legal stipulations to<br />

teaching materials for schools.<br />

Collecting batteries for the common good<br />

We also ran numerous high-profile<br />

environmental campaigns, such as a<br />

pit stop for schoolkids run by the<br />

Verbraucherzentrale NRW (consumer<br />

advice centre) and a photography<br />

competition run in conjunction with the<br />

HDE (Association of German Retailers).<br />

There was also a great media response<br />

to other environmental initiatives such<br />

as the Energy Day run by the town of<br />

Plauen, a battery collection drive in<br />

Halle an der Saale and a similar drive run<br />

in conjunction with the Bergisch Gladbach<br />

town council and the local waste disposal<br />

company. In addition to these battery<br />

collection drives, <strong>GRS</strong> <strong>Batterien</strong> was also<br />

involved in other social projects, such<br />

as supporting the Fördergemeinschaft<br />

Kinderkrebs-Zentrum Hamburg e.V.<br />

(funding association for the Hamburg<br />

childhood cancer centre). It is this kind<br />

of activity that is given a high public<br />

profile, with the general public backing<br />

battery collection and getting the<br />

message across that it is an active form<br />

of environmental protection.<br />

7

8<br />

4. Quality and environmental policy<br />

The basic aspect of<br />

our quality and environmental policy<br />

is customer satisfaction<br />

<strong>GRS</strong> <strong>Batterien</strong> assumes responsibility<br />

for collecting batteries on behalf of its<br />

users along with all other conditions<br />

stipulated by the Battery Decree, and<br />

endeavours to achieve the following<br />

within an acceptable cost remit:<br />

• Increasing the quantity of spent<br />

portable batteries that are collected<br />

• Sorting the batteries in order<br />

to improve their recyclability<br />

• Increasing the proportion of and<br />

quality of recycled materials<br />

<strong>GRS</strong> <strong>Batterien</strong> undertakes to comply with<br />

all regulations and implement sustainable<br />

and forward-looking development.<br />

<strong>GRS</strong> <strong>Batterien</strong> avoids untenable risks in<br />

all its planning, development and<br />

implementation work. The primary objective<br />

is to keep the customers satisfied.<br />

And to do this, <strong>GRS</strong> <strong>Batterien</strong> has<br />

introduced a combined quality and<br />

environmental management system<br />

which addresses the needs of all the<br />

parties involved.<br />

Ongoing improvement is an integral part<br />

of all <strong>GRS</strong> <strong>Batterien</strong> corporate processes.<br />

In all of this,<br />

As value-added partners,<br />

the service providers play a substantial<br />

role in providing good quality<br />

In accordance with the German Battery<br />

Decree, the service providers are selected<br />

every three years via a process that<br />

promotes competition. Here too, <strong>GRS</strong><br />

<strong>Batterien</strong> sets great store by quality and<br />

environmental protection. The selection<br />

process therefore includes a suitability<br />

test for all sorting, recycling and waste<br />

disposal plants before the call for bids.<br />

Companies are not accepted as bidders<br />

until they are deemed to be suitable<br />

and the environmental friendliness of their<br />

services has been established. Once this<br />

elimination stage has been completed,<br />

the plants are invited to tender their bids<br />

in a public tendering procedure, which<br />

is used as the basis for the final decision.<br />

This drawn-out selection process is a<br />

success, as borne out by the fact that<br />

the complaints quota for battery and<br />

accumulator collection constantly remains<br />

below 1 %.<br />

A good choice for manufacturers<br />

and importers<br />

Another major advantage of this selection<br />

process is that services can be sourced<br />

at low prices, which gives manufacturers<br />

and importers who use <strong>GRS</strong> <strong>Batterien</strong><br />

services excellent value for money. We<br />

also have a team of experts at the ready<br />

to answer all of our customers’ questions<br />

relating to battery disposal.

5. Volume of batteries collected, according to federal state / § 10(1)2. BattV<br />

Federal state 2005 <strong>2006</strong> Difference<br />

t t t %<br />

Baden-Württemberg 1,683 1.800 117 7<br />

Bayern 2,143 2.353 210 10<br />

Berlin 416 421 5 1<br />

Brandenburg 297 313 16 5<br />

Bremen 115 114 –1 –1<br />

Hamburg 265 265 0 0<br />

Hessen 693 719 26 4<br />

Mecklenburg-Vorpommern 138 150 12 9<br />

Niedersachsen 1,579 1.522 –57 –4<br />

Nordrhein-Westfalen 2,554 2.942 388 15<br />

Rheinland-Pfalz 688 733 45 7<br />

Saarland 134 148 14 10<br />

Sachsen 488 507 19 4<br />

Sachsen-Anhalt 245 263 18 7<br />

Schleswig-Holstein 577 590 13 2<br />

Thüringen 248 298 50 20<br />

Total 12,263 13,138 875 7<br />

The quantity of spent portable batteries<br />

collected in <strong>2006</strong> increased by nearly<br />

900 tonnes to 13,138 tonnes, which is<br />

equivalent to a year-on-year increase<br />

of 7 %. The nationwide presence of <strong>GRS</strong><br />

<strong>Batterien</strong> in the retail and industry, good<br />

working relationships with municipalities,<br />

and extensive PR work contributed to an<br />

increase in the specific battery collection<br />

quantity (grams per head in the year<br />

under review to 159 g/head (previous<br />

year 149 g/head). There continue to be<br />

large differences between the quantities<br />

returned in the different federal states.<br />

This is partly because some retail chains<br />

and manufacturers collect batteries<br />

throughout the country and make them<br />

available to <strong>GRS</strong> <strong>Batterien</strong> in central<br />

warehouses.<br />

51 to 100 g / head.<br />

101 to 150 g / head.<br />

151 to 200 g / head.<br />

>200 g / head.<br />

Volume of<br />

batteries collected<br />

Ø 159 g / head.<br />

9

10<br />

5. Volume of batteries collected, according to origin / § 10(1)2. BattV<br />

As in previous years, the most popular<br />

channel for battery collection was in retail<br />

in <strong>2006</strong>. Just under half (49 %) of all spent<br />

batteries and accumulators collected by<br />

<strong>GRS</strong> <strong>Batterien</strong> were sourced from retail.<br />

The proportion of batteries coming from<br />

municipalities fell by a percentage point<br />

year on year, while the proportion coming<br />

from the trade industry rose by the same<br />

amount. There was next to no change<br />

year on year in the volume of batteries<br />

and accumulators sourced from waste<br />

electrical and electronic equipment being<br />

stripped down, suggesting that the EU<br />

Municipalities 25 %<br />

Municipalities 24 %<br />

Industry 25 %<br />

Industry 26 %<br />

directive on waste electrical and electronic<br />

equipment had had little effect. In the<br />

year under review, more collection points<br />

in the retail and industry were provided<br />

with collection containers.<br />

The origin of spent batteries and accumulators<br />

varies greatly from state to<br />

state. This is due to the very different<br />

waste disposal structures around the<br />

country. The proportion of municipalities<br />

in Hessen is just 5 %, because very<br />

few municipalities there make use of<br />

the <strong>GRS</strong> <strong>Batterien</strong> services.<br />

Armed forces 1 %<br />

Armed forces 1 %<br />

Retail 49 %<br />

Retail 49 %<br />

Municipalities Industry<br />

Retail Armed forces

6. Sorting of spent portable batteries<br />

The sorting process<br />

Portable batteries and accumulators are<br />

collected as a mixture, as consumers<br />

are not in a position to presort them. The<br />

batteries are then sorted into electrochemical<br />

systems after they have been<br />

collected. The <strong>GRS</strong> <strong>Batterien</strong> service<br />

providers use two different sorting<br />

methods:<br />

• X-ray method<br />

The batteries are sorted according to size<br />

and the round cells pass through an X-ray<br />

sensor. The type of battery is identified<br />

on the basis of the grey areas on the<br />

X-ray. This system is capable of sorting<br />

more than 20 batteries a second with<br />

accuracy of over 98 %.<br />

• Electromagnetic method<br />

This method identifies types of magnetic<br />

round cells with the help of an electromagnetic<br />

sensor. The sensor’s magnetic<br />

field changes according to the electrochemical<br />

battery type passing it, thus<br />

identifying up to six battery types a<br />

second. This system likewise has a sorting<br />

accuracy of 98 %.<br />

These sorting facilities have a total sorting<br />

capacity of more than 15,000 t/a.<br />

Mercury in batteries<br />

Year in, year out, <strong>GRS</strong> <strong>Batterien</strong> analyses<br />

the mercury content of the AlMn and<br />

ZnC batteries it collects. The results of this<br />

analysis indicate that the mercury<br />

content in batteries is steadily declining.<br />

This means it will be possible to recycle<br />

more and more of these type of batteries<br />

in the future.<br />

Recycling – the objective of sorting<br />

Sorting the collected batteries serves one<br />

purpose, that being inexpensive and<br />

environmentally friendly recycling. This<br />

means the sorting process must meet<br />

the specifications of the corresponding<br />

recycling plants. Once again in the year<br />

under review, <strong>GRS</strong> <strong>Batterien</strong> initiated<br />

two R&D projects with a view to aligning<br />

the battery sorting even more with the<br />

ultimate recycling processes.<br />

Sources: GMA (top), Uni-Cyc (bottom)<br />

11

12<br />

7. Sorted battery systems<br />

The majority of battery sorting was<br />

undertaken by the companies Uni-Cyc<br />

GmbH and GMA mbH & Co. KG. Sorting<br />

is a basic prerequisite for subsequent<br />

recycling. The total sum of batteries<br />

sorted in the year under review was<br />

12,426 tonnes. This includes some<br />

batteries that were collected in 2005,<br />

but that had been stored unsorted in<br />

intermediate storage or at the sorting<br />

plants. <strong>GRS</strong> <strong>Batterien</strong> requires NiCd<br />

and NiMH batteries to be sorted to an<br />

accuracy of at least 99 % for them to<br />

be recyclable, and expects an accuracy<br />

level of 98 % for all other battery types.<br />

As in the previous year, the majority of<br />

sorted batteries (79 %) were AlMn and ZnC<br />

batteries. Of these, the proportion of<br />

ZnC batteries in the waste stream had<br />

once again dropped year on year, to<br />

29.0 % (previous year 30.6 %). In comparison,<br />

sales of ZnC batteries accounted<br />

for just 10 % of all sales (average of<br />

previous three years 13.6 %). This is<br />

because batteries that can only be run<br />

2005 <strong>2006</strong> Difference<br />

t % t % t %<br />

ZnC 3,705 30.6 3,601 29.0 –104 –2.8<br />

AlMn 5,823 48.1 6,215 50.0 392 6.7<br />

Zn-air 179 1.5 199 1.6 20 11.2<br />

Li, primary 206 1.7 174 1.4 –32 –15.5<br />

Button cells* 61 0.5 62 0.5 1 1,6<br />

Summe 9,974 82.4 10,251 82.5 277 2.8<br />

Li-ion 61 0,5 50 0.4 –11 –18.0<br />

NiMH 73 0.6 75 0.6 2 2.7<br />

AIMn ** 0 0 0 0 0 0<br />

Pb 1,065 8.8 1,031 8.3 –34 –3.2<br />

NiCd 896 7.4 895 7.2 –1 –0.1<br />

Sum 2,095 17.3 2,051 16.5 –44 –2.1<br />

Sorting residuals 36 0.3 124 1.0 88 244.4<br />

Total*** 12,105 100 12,426 100 321 2.7<br />

Primary<br />

batteries<br />

Secondary<br />

batteries<br />

* Comprises all battery types ** In AlMn primary batteries<br />

*** Mixed batteries (unsortable) divided up on the basis of the proportions of sorted batteries<br />

flat once often do not find their way<br />

into the waste stream until years after<br />

having been sold.<br />

The ratio of primary batteries to secondary<br />

batteries remained unchanged from<br />

the previous year. Rechargeable NiMH and<br />

Li-ion batteries are long-life batteries so<br />

the rate of return for these remains low.<br />

An R&D trial was implemented in order<br />

to form a stronger link between sorting<br />

and recycling locations, and to fine-tune<br />

the sorting process to better meet the<br />

needs of the different recycling plants.<br />

Some recycling processes allow for zinccarbon<br />

and alkali-manganese batteries<br />

to be recycled together. <strong>GRS</strong> <strong>Batterien</strong><br />

will continue to endeavour to fine-tune<br />

battery sorting to the recycling processes<br />

and establish these sorting processes on<br />

the market.<br />

AlMn 50.0 % ZnC 29.0 %<br />

Sorting residuals 1.0 %<br />

Li-ion 0.4 %<br />

NiMH 0.6 %<br />

Zn-air 1.6 %<br />

Button cells* 0.5 %<br />

Li, primary 1.4 %<br />

Pb 8.3 %<br />

NiCd 7.2 %

8. Recycling and disposal results/§ 10(1)3. BattV<br />

8.1 Evaluation of the recycling and disposal proportions<br />

The proportion of batteries being recycled<br />

continued to rise in <strong>2006</strong>, to 88 % of all<br />

sorted batteries (previous year 82 %).<br />

The focus here is on recycling methods<br />

that result in high-quality products. One<br />

such method is the blast furnace at DK<br />

Recycling und Roheisen GmbH, which is<br />

used to recycle UV-coded AlMn batteries<br />

and extract raw materials such as pig<br />

iron, zinc concentrate and slag. There<br />

now follows a brief description of<br />

different recycling methods for specific<br />

battery types.<br />

Source: <strong>GRS</strong> <strong>Batterien</strong><br />

AlMn and ZnC batteries:<br />

There are other recycling methods in<br />

addition to the blast furnace. For example,<br />

the two companies Redux GmbH and<br />

GMA mbH & Co. KG grind down AlMn<br />

and ZnC batteries in a monitored process<br />

and separate the iron content from the<br />

zinc content. The iron is passed on to<br />

steelworks and the zinc-based fine fraction<br />

is turned into zinc oxide in rotary kilns.<br />

The electric arc furnace belonging to Valdi<br />

in Feurs (France) is used to turn batteries<br />

into materials such as ferromanganese<br />

and zinc oxide.<br />

Disposal Recycling<br />

Button cells containing mercury:<br />

The company NQR in Lübeck uses the<br />

ALD (atomic layer deposition) process,<br />

in which waste containing mercury<br />

undergoes vacuum thermal treatment.<br />

At temperatures ranging from 350° C<br />

to 650° C, the mercury evaporates, then<br />

condensates at a lower temperature,<br />

before being put back into economic<br />

use. The mercury-free steel is sold.<br />

NiCd batteries:<br />

Spent NiCd accumulators are recycled by<br />

Accurec in Mülheim and SNAM in France.<br />

The cadmium is usually distilled in a<br />

vacuum or in an inert atmosphere and<br />

the steel / nickel alloy that is left is passed<br />

on to the steelmaking industry. The<br />

resultant cadmium is generally used to<br />

make new NiCd batteries.<br />

NiMH batteries:<br />

The expertise of Redux in Dietzenbach<br />

lies in reclaiming nickel. As there is the<br />

risk of hydrogen being released when<br />

NiMH batteries are ground down, this is<br />

done in a monitored environment. Once<br />

the plastics have been separated, what<br />

is left is a high nickel containing product,<br />

and this serves as an important alloying<br />

component for the steelmaking industry.<br />

Lithium batteries:<br />

<strong>GRS</strong> <strong>Batterien</strong> commissions Accurec in<br />

Mülheim with the recycling of lithium<br />

primary batteries (LiMnO2) in a vacuum<br />

distillation process. This is primarily<br />

used to regain nickeliferous iron and<br />

ferromanganese. Lithium is used in the<br />

process as a reductant. Rechargeable<br />

lithium-type batteries (Li-ion and Lipolymer)<br />

are recycled by Falconbridge,<br />

which first and foremost recycles to<br />

regain cobalt, nickel and copper.<br />

13

14<br />

Final disposal<br />

1,550 t (12 %)<br />

Mixed batteries 81 %<br />

8. Recycling and disposal results/§ 10(1)3. BattV<br />

8.2 Quantitative recycling and disposal proportions<br />

Sorting residuals 7 %<br />

In the reporting period, 12,686 tonnes<br />

of batteries were either recycled or<br />

disposed of by the disposal plants. The<br />

proportion of recycled batteries rose<br />

once again, to 88 % (previous year 82 %).<br />

A total of 1,550 tonnes of batteries<br />

(12 %) were sent to hazardous waste<br />

disposal sites owned by IAG in Selmsdorf<br />

and HIM GmbH in Billigheim. The majority<br />

of batteries to be disposed of were<br />

unsortable batteries and non-UV-coded<br />

AlMn batteries.<br />

AlMn, uncoded 12 %<br />

Disposal<br />

12,686 t (100 %)<br />

The Battery Directive published in the<br />

EU’s Official Journal in September <strong>2006</strong><br />

must be enforced as national law by<br />

September 2008 and stipulates that all<br />

identifiable batteries must undergo material<br />

recycling by September 2009 (recycling<br />

proportion). It also stipulates that the<br />

following minimum recycling efficiency<br />

levels be achieved by September 2011:<br />

Recycling<br />

11,136 t (88 %)<br />

ZnC Hg-free 4 % AlMn, uncoded 35 %<br />

ZnC, uncoded 26 %<br />

AlMn Hg-free 13 %<br />

Mixed batteries 1 %<br />

NiMH 1 %<br />

Pb 8 %<br />

NiCd 8 %<br />

• 65 % of the average weight of lead<br />

batteries (lead content as technically<br />

feasible).<br />

• 75 % of the average weight of nickelcadmium<br />

accumulators (cadmium content<br />

as technically feasible).<br />

• 50 % of the average weight of all<br />

other batteries.<br />

A standard model for calculating recycling<br />

efficiency is currently being developed by<br />

the EU.<br />

Li, primary 2 %<br />

Li-ion 0.1 % Zn-air 2 %<br />

Button cells 0.1 %<br />

Battery disposal according to battery type, <strong>2006</strong><br />

The following table shows the types of batteries<br />

recycled by waste disposal service providers and lists<br />

the products regained from them (based on information<br />

provided by the recycling plants and not on the<br />

standard calculation model, which is in the process<br />

of being developed). The table also lists materials<br />

passed on to third parties for further processing.

8. Recycling and disposal results/§ 10(1)3. BattV<br />

8.3 Qualitative disposal results<br />

Total no. of recycled batteries AlMn, ZnC, Zn-air Pb NiCd NiMH Li Button cells Total<br />

9,146 923 719 73 211 50 11,122<br />

Products<br />

Plant<br />

Valdi, Redux,<br />

DK, Citron, GMA,<br />

Revatec<br />

VARTA ACCUREC,<br />

SNAM<br />

REDUX ACCUREC,<br />

Falcon bridge,<br />

Umicore<br />

Remondis<br />

Zinc and zinc compounds 2,373 0 0 0 0 5 2,378<br />

Ferromanganese 1,140 0 0 0 76 5 1,221<br />

Steels (iron / nickeliferous) 1,287 0 413 69 55 19 1,843<br />

Mercury and mercury compounds 0 0 0 0 0 3 3<br />

Lead and lead compounds 0 600 0 0 0 0 600<br />

Cadmium and cadmium compounds 0 0 102 0 0 0 102<br />

Other metals (aluminium, cobalt, copper, etc.) 10 0 4 0 9 1 24<br />

Carbons 516 55 0 0 4 0 575<br />

Plastics for recycling 184 0 0 0 0 0 184<br />

Slag for recycling 1,245 28 0 0 0 0 1,273<br />

Other residue for recycling 0 240 3 0 3 3 249<br />

Waste water / used air 1,087 0 127 4 37 4 1,259<br />

Plastics for disposal 50 0 69 0 4 0 123<br />

Slag for disposal 1,215 0 0 0 0 0 1,215<br />

Other residue for disposal 39 0 1 0 23 10 73<br />

Overall results of batteries recycled in <strong>2006</strong>, based on statistics from recycling plants<br />

Zinc and zinc compounds<br />

Ferromanganese<br />

Steels (iron / nickeliferous)<br />

Cadmium and cadmium compounds<br />

Lead and lead compounds<br />

Mercury and mercury compounds<br />

Other metals<br />

(aluminium, cobalt, copper, etc.)<br />

Synthetics for recycling<br />

Slag for recycling<br />

Other residue for recycling<br />

Carbons<br />

Waste water / used air<br />

Synthetics for disposal<br />

Slag for disposal<br />

Other residue for disposal<br />

1.7%<br />

21.4%<br />

11.0%<br />

0.7%<br />

0.2%<br />

10.9%<br />

16.6%<br />

1.1%<br />

11.3%<br />

0.9%<br />

5.4%<br />

0.1%<br />

11.4%<br />

2.2%<br />

5.2%<br />

15

16<br />

* Gross stocks incl, packaging<br />

** Incl, R&D quantities for sorting<br />

9, Summary of operative flow<br />

Volume of collected batteries acc, to § 10(1)2, BattV (all figures in t)<br />

13,138 t<br />

Retail 49 % Industry/armed forces 27 % Municipalities 24 %<br />

Input 6,366<br />

The flow of materials was monitored<br />

continuously throughout all the stages<br />

and tested by third parties, All <strong>GRS</strong><br />

<strong>Batterien</strong> service providers are audited<br />

by independent third parties to ensure<br />

they adhere to the stipulated quality<br />

standards,<br />

Recycling 88 %<br />

Input 11,136<br />

Initial quantity 01/01/06 609<br />

Output 31/12/06 624<br />

Recycled 11,122<br />

Input 3,615 Input 3,157<br />

Logistics<br />

Input 13,138<br />

Initial quantity 01/01/06 1,146<br />

End quantity 31/12/06 1,574 *<br />

Output 12,710<br />

Sorting<br />

Input 12,710<br />

Initial quantity,<br />

unsorted 01/01/06 829<br />

Initial quantity,<br />

sorted 01/01/06 651<br />

Sorted volume 12,426<br />

Output trade,<br />

unsorted 31/12/06 1,113 **<br />

Output,<br />

sorted 31/12/06 391<br />

Output recycling/disposal 12,686<br />

Disposal 12 %<br />

Input 1,550<br />

Initial quantity 01/01/06 0<br />

Output 31/12/06 0<br />

Disposed of 1,550

10, Prices paid for sorting, recycling and disposal/§10(1)4, BattV<br />

Primary batteries<br />

Secondary batteries<br />

Battery group Battery type Volume of Collected<br />

batteries batteries<br />

put into<br />

circulation<br />

(kg)<br />

1<br />

Recycled<br />

batteries<br />

(kg)<br />

2<br />

Disposed-of Cost of<br />

batteries disposal<br />

(kg)<br />

(kg)<br />

3<br />

Change in stocks<br />

Euro/kg<br />

6<br />

due to collection,<br />

logistics, sorting<br />

(kg)<br />

Round cells ZnC 3,442,388 2,812,900 2,457,030 1.20 –289,700<br />

AlMn 4<br />

22,852,334 6,629,522 5,352,425 186,400 7<br />

1.20 –35,757<br />

Zn-air 3,706 0 0<br />

1.35 –2,789<br />

Li 217,809 91,194 175,956 2.38 1,038<br />

Button cells<br />

1,363,790<br />

Unsortable<br />

battery<br />

mixture<br />

4<br />

AgO 36,119<br />

45,501<br />

0<br />

AlMn<br />

Zn-air<br />

148,776<br />

58,496<br />

71,021<br />

0<br />

0<br />

3.03<br />

0<br />

–7,182<br />

Li 244,112 0 0<br />

Block batteries ( > 500 g ) Zn-air<br />

ZnC<br />

45,079<br />

174,083<br />

199,853<br />

1,081,911<br />

230,008<br />

925,010<br />

1.35<br />

1.20<br />

–21,624<br />

14,334<br />

Round cells<br />

AlMn<br />

Li<br />

Li-ion<br />

NiMH<br />

21,901<br />

1,857<br />

2,480,805<br />

1,952,781<br />

0<br />

34,445<br />

55,131<br />

91,010<br />

58,590<br />

0<br />

33,919<br />

72,794<br />

1.20<br />

2.38<br />

0.87<br />

–1.47<br />

6,085<br />

–15,948<br />

4,855<br />

–334<br />

NiCd 1,881,681 953,353 854,431 0.54 7,940<br />

AlMn 4<br />

75,662 0 0 1.20 0<br />

Button cells 5<br />

NiCd 176 0 0<br />

0<br />

Li-ion 15,283 0 0 3.03<br />

0<br />

NiMH 13,007 0 0 0<br />

Small sealed lead batteries 1,069,969 1,117,843 930,425 0.81 38,926<br />

Total 34,736,024 13,138,183 11,136,089 1,550,190 1.12 –300,156<br />

1 Calculated on basis of sorting results<br />

2 Proportion of batteries recycled based on sorted batteries<br />

3 Expenses include costs incurred for PR work and administration<br />

in addition to the operative costs<br />

4 In cases in which sorting is not possible, the results comprise both primary and secondary batteries.<br />

The quantity of button cells collected is listed as a total, with no breakdown of individual battery types<br />

5 Included in the results for primary batteries<br />

6 For logistics and sorting stocks, see page 16 of the performance review<br />

7 Non-UV-coded<br />

17

18<br />

11. Sources, abbreviations and definitions<br />

Sources Definitions<br />

GMA, Gesellschaft für Materialkreislauf und Abfallwirtschaft mbH & Co. KG,<br />

Wiefels<br />

KPMG Deutsche Treuhand-Gesellschaft, Aktiengesellschaft,<br />

Wirtschaftsprüfungsgesellschaft, Bielefeld<br />

Uni-Cyc GmbH, Bremerhaven<br />

Abbreviations<br />

AlMn Alkali-manganese<br />

ZnC Zinc-carbon<br />

Zn-air Zinc-air<br />

Li, primary Lithium, non-rechargeable<br />

Li-ion Lithium, rechargeable<br />

NiCd Nickel-cadmium<br />

NiMH Nickel-metal hydride<br />

AgO Silver oxide<br />

Pb Lead<br />

Hg-frei Mercury-free<br />

Primary batteries Non-rechargeable batteries<br />

Secondary batteries Rechargeable batteries ( accumulators )<br />

UV-coded Certified to be Hg-free<br />

Non-UV-coded/ Undefined mercury content<br />

uncoded<br />

ÖRE Öffentlich-rechtlicher Entsorgungsträger (municipalities)<br />

BattV Decree pertaining to the collection and disposal of spent<br />

batteries and accumulators (BattV) dated 2 July 2001<br />

(revised 9 September 2001 by article 7 of the law on the<br />

conversion of environmental guidelines to the euro).<br />

Industrial/Commercial The term “industry” comprises all battery collection points<br />

not deemed to be retail points, property of the German<br />

armed forces or collection points of municipalities of which<br />

<strong>GRS</strong> <strong>Batterien</strong> has been made aware. Industry comprises<br />

industrial end-users and public institutions such as schools<br />

and hospitals.<br />

Battery mixture Mixed batteries are collected and ascribed the waste<br />

catalogue number 200133, before being sorted and<br />

subdivided into the numbers 160601 to 160605 and<br />

191111 or 191112. The code for the disposal method<br />

is D1 and the code for the recycling method is R4.

Stiftung<br />

Gemeinsames<br />

Rücknahmesystem<br />

<strong>Batterien</strong><br />

Heidenkampsweg 44<br />

20097 Hamburg<br />

Germany<br />

Tel. +49 (0)40 23 77 88<br />

Fax +49 (0)40 23 77 87<br />

Email info@grs-batterien.de<br />

www.grs-batterien.de<br />

Board:<br />

Dr Jürgen Fricke, Chairman<br />

Günter Lührsen<br />

19