Nytt i PFERD-programmet New in the PFERD Product Line

Nytt i PFERD-programmet New in the PFERD Product Line

Nytt i PFERD-programmet New in the PFERD Product Line

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PFERD</strong> has fur<strong>the</strong>r developed <strong>the</strong> ALU cut<br />

especially for stock removal of alum<strong>in</strong>ium. This<br />

cut is characterised by its high stock removal<br />

performance on all alum<strong>in</strong>ium materials.<br />

Note<br />

You can f<strong>in</strong>d <strong>the</strong> coated tungsten carbide ALU<br />

cut under tungsten carbide burrs HICOAT ® ,<br />

coat<strong>in</strong>g HC-NFE.<br />

Please refer to <strong>the</strong> PRAXIS “<strong>PFERD</strong> Tools for<br />

Use on Alum<strong>in</strong>ium” for <strong>in</strong>structions and fur<strong>the</strong>r<br />

<strong>in</strong>formation on work<strong>in</strong>g with alum<strong>in</strong>ium.<br />

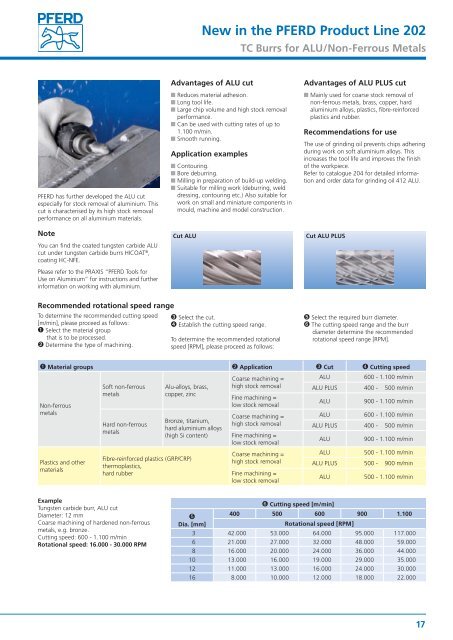

Recommended rotational speed range<br />

To determ<strong>in</strong>e <strong>the</strong> recommended cutt<strong>in</strong>g speed<br />

[m/m<strong>in</strong>], please proceed as follows:<br />

� Select <strong>the</strong> material group<br />

that is to be processed.<br />

� Determ<strong>in</strong>e <strong>the</strong> type of mach<strong>in</strong><strong>in</strong>g.<br />

Hard non-ferrous<br />

metals<br />

Advantages of ALU cut<br />

� Reduces material adhesion.<br />

� Long tool life.<br />

� Large chip volume and high stock removal<br />

performance.<br />

� Can be used with cutt<strong>in</strong>g rates of up to<br />

1.100 m/m<strong>in</strong>.<br />

� Smooth runn<strong>in</strong>g.<br />

Application examples<br />

� Contour<strong>in</strong>g.<br />

� Bore deburr<strong>in</strong>g.<br />

� Mill<strong>in</strong>g <strong>in</strong> preparation of build-up weld<strong>in</strong>g.<br />

� Suitable for mill<strong>in</strong>g work (deburr<strong>in</strong>g, weld<br />

dress<strong>in</strong>g, contour<strong>in</strong>g etc.) Also suitable for<br />

work on small and m<strong>in</strong>iature components <strong>in</strong><br />

mould, mach<strong>in</strong>e and model construction.<br />

Bronze, titanium,<br />

hard alum<strong>in</strong>ium alloys<br />

(high Si content)<br />

Coarse mach<strong>in</strong><strong>in</strong>g =<br />

high stock removal<br />

Advantages of ALU PLUS cut<br />

� Ma<strong>in</strong>ly used for coarse stock removal of<br />

non-ferrous metals, brass, copper, hard<br />

alum<strong>in</strong>ium alloys, plastics, fibre-re<strong>in</strong>forced<br />

plastics and rubber.<br />

Recommendations for use<br />

The use of gr<strong>in</strong>d<strong>in</strong>g oil prevents chips adher<strong>in</strong>g<br />

dur<strong>in</strong>g work on soft alum<strong>in</strong>ium alloys. This<br />

<strong>in</strong>creases <strong>the</strong> tool life and improves <strong>the</strong> f<strong>in</strong>ish<br />

of <strong>the</strong> workpiece.<br />

Refer to catalogue 204 for detailed <strong>in</strong>formation<br />

and order data for gr<strong>in</strong>d<strong>in</strong>g oil 412 ALU.<br />

� Material groups � Application � Cut � Cutt<strong>in</strong>g speed<br />

Coarse mach<strong>in</strong><strong>in</strong>g =<br />

ALU 600 - 1.100 m/m<strong>in</strong><br />

Soft non-ferrous Alu-alloys, brass, high stock removal<br />

ALU PLUS 400 - 500 m/m<strong>in</strong><br />

Non-ferrous<br />

metals<br />

copper, z<strong>in</strong>c<br />

F<strong>in</strong>e mach<strong>in</strong><strong>in</strong>g =<br />

low stock removal<br />

ALU 900 - 1.100 m/m<strong>in</strong><br />

metals<br />

ALU 600 - 1.100 m/m<strong>in</strong><br />

Plastics and o<strong>the</strong>r<br />

materials<br />

Fibre-re<strong>in</strong>forced plastics (GRP/CRP)<br />

<strong>the</strong>rmoplastics,<br />

hard rubber<br />

Example<br />

Tungsten carbide burr, ALU cut<br />

Diameter: 12 mm<br />

Coarse mach<strong>in</strong><strong>in</strong>g of hardened non-ferrous<br />

metals, e.g. bronze.<br />

Cutt<strong>in</strong>g speed: 600 - 1.100 m/m<strong>in</strong><br />

Rotational speed: 16.000 - 30.000 RPM<br />

<strong>New</strong> <strong>in</strong> <strong>the</strong> <strong>PFERD</strong> <strong>Product</strong> L<strong>in</strong>e 202<br />

Cut ALU Cut ALU PLUS<br />

� Select <strong>the</strong> cut.<br />

� Establish <strong>the</strong> cutt<strong>in</strong>g speed range.<br />

To determ<strong>in</strong>e <strong>the</strong> recommended rotational<br />

speed [RPM], please proceed as follows:<br />

TC Burrs for ALU/Non-Ferrous Metals<br />

F<strong>in</strong>e mach<strong>in</strong><strong>in</strong>g =<br />

low stock removal<br />

Coarse mach<strong>in</strong><strong>in</strong>g =<br />

high stock removal<br />

F<strong>in</strong>e mach<strong>in</strong><strong>in</strong>g =<br />

low stock removal<br />

� Cutt<strong>in</strong>g speed [m/m<strong>in</strong>]<br />

� Select <strong>the</strong> required burr diameter.<br />

� The cutt<strong>in</strong>g speed range and <strong>the</strong> burr<br />

diameter determ<strong>in</strong>e <strong>the</strong> recommended<br />

rotational speed range [RPM].<br />

ALU PLUS 400 - 500 m/m<strong>in</strong><br />

ALU 900 - 1.100 m/m<strong>in</strong><br />

ALU 500 - 1.100 m/m<strong>in</strong><br />

ALU PLUS 500 - 900 m/m<strong>in</strong><br />

ALU 500 - 1.100 m/m<strong>in</strong><br />

�<br />

400 500 600 900 1.100<br />

Dia. [mm]<br />

Rotational speed [RPM]<br />

3 42.000 53.000 64.000 95.000 117.000<br />

6 21.000 27.000 32.000 48.000 59.000<br />

8 16.000 20.000 24.000 36.000 44.000<br />

10 13.000 16.000 19.000 29.000 35.000<br />

12 11.000 13.000 16.000 24.000 30.000<br />

16 8.000 10.000 12.000 18.000 22.000<br />

17