Nytt i PFERD-programmet New in the PFERD Product Line

Nytt i PFERD-programmet New in the PFERD Product Line

Nytt i PFERD-programmet New in the PFERD Product Line

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Micro burrs type WRC and type RBF are<br />

optimally suitable for both manual and<br />

automatic mach<strong>in</strong><strong>in</strong>g tasks. They stand out<br />

thanks to <strong>the</strong> comb<strong>in</strong>ation of good stock<br />

removal and high-quality f<strong>in</strong>ish. Almost all<br />

materials up to a hardness of 60 HRC can be<br />

mach<strong>in</strong>ed. If higher stock removal is required,<br />

micro burrs can be used as support <strong>in</strong> areas<br />

where mounted po<strong>in</strong>ts are usually used.<br />

They work with little vibration.<br />

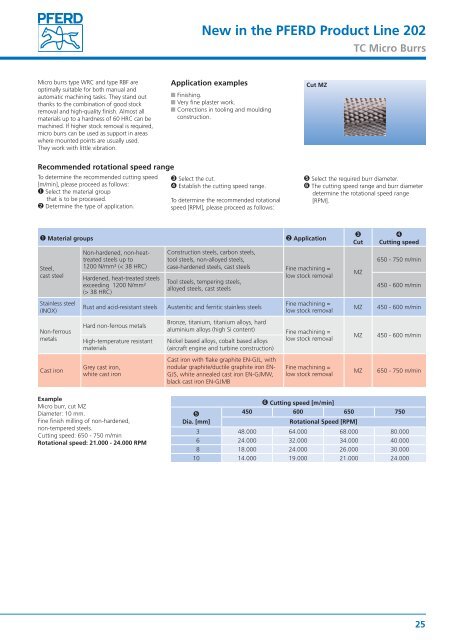

Recommended rotational speed range<br />

To determ<strong>in</strong>e <strong>the</strong> recommended cutt<strong>in</strong>g speed<br />

[m/m<strong>in</strong>], please proceed as follows:<br />

� Select <strong>the</strong> material group<br />

that is to be processed.<br />

� Determ<strong>in</strong>e <strong>the</strong> type of application.<br />

� Material groups � Application<br />

Steel,<br />

cast steel<br />

Sta<strong>in</strong>less steel<br />

(INOX)<br />

Non-ferrous<br />

metals<br />

Cast iron<br />

Non-hardened, non-heattreated<br />

steels up to<br />

1200 N/mm² (< 38 HRC)<br />

Hardened, heat-treated steels<br />

exceed<strong>in</strong>g 1200 N/mm²<br />

(> 38 HRC)<br />

Construction steels, carbon steels,<br />

tool steels, non-alloyed steels,<br />

case-hardened steels, cast steels F<strong>in</strong>e mach<strong>in</strong><strong>in</strong>g =<br />

Tool steels, temper<strong>in</strong>g steels,<br />

alloyed steels, cast steels<br />

Rust and acid-resistant steels Austenitic and ferritic sta<strong>in</strong>less steels<br />

Hard non-ferrous metals<br />

High-temperature resistant<br />

materials<br />

Grey cast iron,<br />

white cast iron<br />

Example<br />

Micro burr, cut MZ<br />

Diameter: 10 mm.<br />

F<strong>in</strong>e f<strong>in</strong>ish mill<strong>in</strong>g of non-hardened,<br />

non-tempered steels.<br />

Cutt<strong>in</strong>g speed: 650 - 750 m/m<strong>in</strong><br />

Rotational speed: 21.000 - 24.000 RPM<br />

Application examples<br />

� F<strong>in</strong>ish<strong>in</strong>g.<br />

� Very f<strong>in</strong>e plaster work.<br />

� Corrections <strong>in</strong> tool<strong>in</strong>g and mould<strong>in</strong>g<br />

construction.<br />

� Select <strong>the</strong> cut.<br />

� Establish <strong>the</strong> cutt<strong>in</strong>g speed range.<br />

To determ<strong>in</strong>e <strong>the</strong> recommended rotational<br />

speed [RPM], please proceed as follows:<br />

low stock removal<br />

F<strong>in</strong>e mach<strong>in</strong><strong>in</strong>g =<br />

low stock removal<br />

Bronze, titanium, titanium alloys, hard<br />

alum<strong>in</strong>ium alloys (high Si content) F<strong>in</strong>e mach<strong>in</strong><strong>in</strong>g =<br />

Nickel based alloys, cobalt based alloys low stock removal<br />

(aircraft eng<strong>in</strong>e and turb<strong>in</strong>e construction)<br />

Cast iron with flake graphite EN-GJL, with<br />

nodular graphite/ductile graphite iron EN-<br />

GJS, white annealed cast iron EN-GJMW,<br />

black cast iron EN-GJMB<br />

�<br />

Dia. [mm]<br />

<strong>New</strong> <strong>in</strong> <strong>the</strong> <strong>PFERD</strong> <strong>Product</strong> L<strong>in</strong>e 202<br />

Cut MZ<br />

� Select <strong>the</strong> required burr diameter.<br />

� The cutt<strong>in</strong>g speed range and burr diameter<br />

determ<strong>in</strong>e <strong>the</strong> rotational speed range<br />

[RPM].<br />

F<strong>in</strong>e mach<strong>in</strong><strong>in</strong>g =<br />

low stock removal<br />

�<br />

Cut<br />

MZ<br />

�<br />

Cutt<strong>in</strong>g speed<br />

650 - 750 m/m<strong>in</strong><br />

450 - 600 m/m<strong>in</strong><br />

MZ 450 - 600 m/m<strong>in</strong><br />

MZ 450 - 600 m/m<strong>in</strong><br />

MZ 650 - 750 m/m<strong>in</strong><br />

450<br />

� Cutt<strong>in</strong>g speed [m/m<strong>in</strong>]<br />

600 650 750<br />

Rotational Speed [RPM]<br />

TC Micro Burrs<br />

3 48.000 64.000 68.000 80.000<br />

6 24.000 32.000 34.000 40.000<br />

8 18.000 24.000 26.000 30.000<br />

10 14.000 19.000 21.000 24.000<br />

25