Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Accessories<br />

Volume Control Devices<br />

Outlet dampers, variable inlet vanes, and variable<br />

frequency drives are three popular devices used to<br />

control volume for fan systems.<br />

Outlet Dampers<br />

The closing of the damper adds to the resistance that<br />

the fan is working against. This moves the operating<br />

point to the left of the initial rating point. The savings<br />

in horsepower depends on the relative position on the<br />

fan curve and is usually much less than offered by<br />

other methods. Outlet dampers are typically the least<br />

expensive option and should be considered when<br />

infrequent operation at lesser capacity is desired or<br />

when handling hot, humid or particulate laden air.<br />

There are two types of outlet dampers: parallel<br />

blade and opposed blade.<br />

Parallel blade dampers are recommended for<br />

systems where air volume is modulated between fullopen<br />

to about 75% of open.<br />

Opposed blade dampers cost about 10% more<br />

and are recommended for systems where volume is<br />

modulated over the entire range. Opposed blades<br />

reduce air volume in a closer relationship to the control<br />

arm movement.<br />

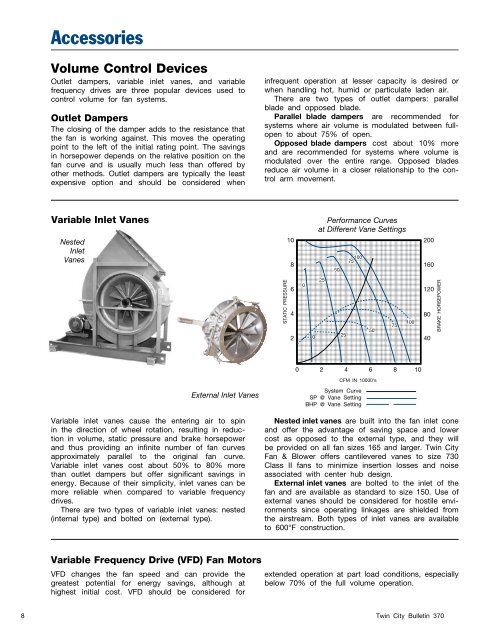

Variable Inlet Vanes<br />

Nested<br />

Inlet<br />

Vanes<br />

10<br />

8<br />

Performance Curves<br />

at Different Vane Settings<br />

50<br />

100<br />

75<br />

200<br />

160<br />

STATIC PRESSURE<br />

6<br />

4<br />

2<br />

0<br />

0<br />

25<br />

25<br />

50<br />

75<br />

100<br />

120<br />

80<br />

40<br />

BRAKE HORSEPOWER<br />

0 2 4 6 8 10<br />

CFM IN 10000's<br />

External Inlet Vanes<br />

Variable inlet vanes cause the entering air to spin<br />

in the direction of wheel rotation, resulting in reduction<br />

in volume, static pressure and brake horsepower<br />

and thus providing an infinite number of fan curves<br />

approximately parallel to the original fan curve.<br />

Variable inlet vanes cost about 50% to 80% more<br />

than outlet dampers but offer significant savings in<br />

energy. Because of their simplicity, inlet vanes can be<br />

more reliable when compared to variable frequency<br />

drives.<br />

There are two types of variable inlet vanes: nested<br />

(internal type) and bolted on (external type).<br />

System Curve<br />

SYSTEM CURVE<br />

SP @ Vane Setting<br />

SP @ VANE SETTING<br />

BHP @ Vane Setting<br />

BHP @ VANE SETTING<br />

Nested inlet vanes are built into the fan inlet cone<br />

and offer the advantage of saving space and lower<br />

cost as opposed to the external type, and they will<br />

be provided on all fan sizes 165 and larger. Twin City<br />

Fan & Blower offers cantilevered vanes to size 730<br />

Class II fans to minimize insertion losses and noise<br />

associated with center hub design.<br />

External inlet vanes are bolted to the inlet of the<br />

fan and are available as standard to size 150. Use of<br />

external vanes should be considered for hostile environments<br />

since operating linkages are shielded from<br />

the airstream. Both types of inlet vanes are available<br />

to 600°F construction.<br />

Variable Frequency Drive (VFD) Fan Motors<br />

VFD changes the fan speed and can provide the<br />

greatest potential for energy savings, although at<br />

highest initial cost. VFD should be considered for<br />

extended operation at part load conditions, especially<br />

below 70% of the full volume operation.<br />

8<br />

Twin City Bulletin 370