Universal Beer Agar - BVA Scientific

Universal Beer Agar - BVA Scientific

Universal Beer Agar - BVA Scientific

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Section III<br />

U-Z UVM Modified Listeria, cont.<br />

Expected Results<br />

Refer to appropriate references and procedures for results.<br />

References<br />

1. Murray, Webb and Swann. 1926. J. Pathol. Bacteriol. 29:407.<br />

2. Monk, Clavero, Beuchat, Doyle and Brackett. 1994. J. Food Prot. 57:969.<br />

3. Wehr. 1987. J. Assoc. Off. Anal. Chem. 70:769.<br />

4. Bremer and Osborne. 1995. J. Food Prot. 58:604.<br />

5. Grau and Vanderlinde. 1992. J. Food Prot. 55:4.<br />

6. Patel, Hwang, Beuchat, Doyle and Brackett. 1995. J. Food Prot. 58:244.<br />

7. Ryser and Donnelly. 2001. In Downes and Ito (ed.), Compendium of methods for the microbiological<br />

examination of foods, 4th ed. American Public Health Association, Washington, D.C.<br />

8. Kramer and Jones. 1969. J. Appl. Bacteriol. 32:381.<br />

9. Donnelly and Baigent. 1986. Appl. Environ. Microbiol. 52:689.<br />

10. McClain and Lee. May 24, 1989. Laboratory communication No. 57. Microbiology Division, Food<br />

Safety and Inspection Service, U.S. Department of Agriculture, Beltsville, Md.<br />

11. Bille, Rocourt and Swaminathan. 1999. In Murray, Baron, Pfaller, Tenover and Yolken (ed), Manual<br />

of clinical microbiology, 7th ed. American Society for Microbiology, Washington, D.C.<br />

12. Hayes, Graves, Swaminathan, Ajello, Marcolm, Weaver, Ransom, Deaver, Plikaytis, Schuchat, Wenger,<br />

Pinner, Broome and The Listeria Study Group. 1992. J. Food. Prot. 55:952.<br />

Availability<br />

Difco UVM Modified Listeria Enrichment Broth<br />

AOAC COMPF<br />

Cat. No. 222330 Dehydrated – 500 g<br />

222310 Dehydrated – 2 kg<br />

222320 Dehydrated – 10 kg<br />

<strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong><br />

Intended Use<br />

<strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong> (UBA Medium) is used for cultivating<br />

microorganisms of significance in the brewing industry.<br />

Summary and Explanation<br />

<strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong> is a basal medium to which beer is added.<br />

It is based on the formula developed by Kozulis and Page 1<br />

who compared it with other media commonly used in breweries<br />

for detecting microbial contamination. 2 The characteristics of<br />

<strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong> are closer to the natural environmental<br />

conditions found in the typical brewery than other media studied.<br />

It supports growth of more varieties of lactic acid bacteria and<br />

yields larger colonies in a shorter time than traditional brewer’s<br />

media. Due to the presence of beer in the medium, it is<br />

selective for growth of microorganisms that have adapted<br />

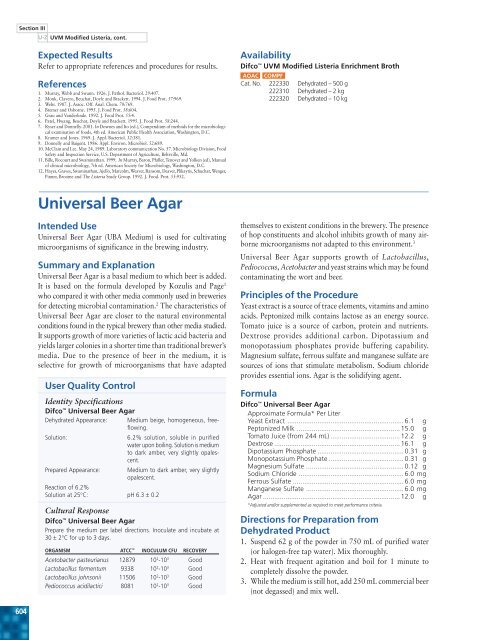

User Quality Control<br />

Identity Specifications<br />

Difco <strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong><br />

Dehydrated Appearance: Medium beige, homogeneous, freeflowing.<br />

Solution:<br />

6.2% solution, soluble in purified<br />

water upon boiling. Solution is medium<br />

to dark amber, very slightly opalescent.<br />

Prepared Appearance: Medium to dark amber, very slightly<br />

opalescent.<br />

Reaction of 6.2%<br />

Solution at 25°C: pH 6.3 ± 0.2<br />

Cultural Response<br />

Difco <strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong><br />

Prepare the medium per label directions. Inoculate and incubate at<br />

30 ± 2°C for up to 3 days.<br />

ORGANISM ATCC INOCULUM CFU RECOVERY<br />

Acetobacter pasteurianus 12879 10 2 -10 3 Good<br />

Lactobacillus fermentum 9338 10 2 -10 3 Good<br />

Lactobacillus johnsonii 11506 10 2 -10 3 Good<br />

Pediococcus acidilactici 8081 10 2 -10 3 Good<br />

themselves to existent conditions in the brewery. The presence<br />

of hop constituents and alcohol inhibits growth of many airborne<br />

microorganisms not adapted to this environment. 3<br />

<strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong> supports growth of Lactobacillus,<br />

Pediococcus, Acetobacter and yeast strains which may be found<br />

contaminating the wort and beer.<br />

Principles of the Procedure<br />

Yeast extract is a source of trace elements, vitamins and amino<br />

acids. Peptonized milk contains lactose as an energy source.<br />

Tomato juice is a source of carbon, protein and nutrients.<br />

Dextrose provides additional carbon. Dipotassium and<br />

monopotassium phosphates provide buffering capability.<br />

Magnesium sulfate, ferrous sulfate and manganese sulfate are<br />

sources of ions that stimulate metabolism. Sodium chloride<br />

provides essential ions. <strong>Agar</strong> is the solidifying agent.<br />

Formula<br />

Difco <strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong><br />

Approximate Formula* Per Liter<br />

Yeast Extract .............................................................. 6.1 g<br />

Peptonized Milk ....................................................... 15.0 g<br />

Tomato Juice (from 244 mL) ..................................... 12.2 g<br />

Dextrose ................................................................... 16.1 g<br />

Dipotassium Phosphate .............................................. 0.31 g<br />

Monopotassium Phosphate ........................................ 0.31 g<br />

Magnesium Sulfate .................................................... 0.12 g<br />

Sodium Chloride ........................................................ 6.0 mg<br />

Ferrous Sulfate ........................................................... 6.0 mg<br />

Manganese Sulfate .................................................... 6.0 mg<br />

<strong>Agar</strong> ......................................................................... 12.0 g<br />

*Adjusted and/or supplemented as required to meet performance criteria.<br />

Directions for Preparation from<br />

Dehydrated Product<br />

1. Suspend 62 g of the powder in 750 mL of purified water<br />

(or halogen-free tap water). Mix thoroughly.<br />

2. Heat with frequent agitation and boil for 1 minute to<br />

completely dissolve the powder.<br />

3. While the medium is still hot, add 250 mL commercial beer<br />

(not degassed) and mix well.<br />

604

<strong>Universal</strong> Preenrichment Broth<br />

4. Autoclave at 121°C for 10 minutes.<br />

5. Test samples of the finished product for performance using<br />

stable, typical control cultures.<br />

Procedure<br />

See appropriate references for specific procedures.<br />

Expected Results<br />

Refer to appropriate references and procedures for results.<br />

References<br />

1. Kozulis and Page. 1968. Proc. Am. Soc. Brewing Chemists, p. 52.<br />

2. Murphy and Saletan. 1970. Tech. Q. Master Brew. Assoc. Am. 7:182.<br />

3. MacFaddin. 1985. Media for isolation-cultivation-identification-maintenance medical bacteria, vol.<br />

1. Williams & Wilkins, Baltimore, Md.<br />

Availability<br />

Difco <strong>Universal</strong> <strong>Beer</strong> <strong>Agar</strong><br />

Cat. No. 285610 Dehydrated – 500 g<br />

Mexico<br />

Cat. No. 252644 Prepared Plates (60 × 15 mm-style) – Pkg. of 20*<br />

*Store at 2-8°C.<br />

<strong>Universal</strong> Preenrichment Broth<br />

Intended Use<br />

<strong>Universal</strong> Preenrichment Broth is used for recovering sublethally<br />

injured Salmonella and Listeria from food products.<br />

Summary and Explanation<br />

Traditional methods for recovering Salmonella and Listeria<br />

from food products require separate preenrichment media for<br />

each microorganism. 1,2 Some broth media recommended<br />

for preenrichment contain antibiotic inhibitors 3 or have<br />

insufficient buffering capacity which hinder recovery of sublethally<br />

injured cells. 3-5<br />

Bailey and Cox 3 formulated <strong>Universal</strong> Preenrichment Broth to<br />

permit simultaneous resuscitation of sublethally injured<br />

Salmonella and Listeria. The broth medium provides sufficient<br />

buffering capacity to prevent rapid decreases in pH and<br />

allows for repair of injured cells that might be sensitive to low<br />

pH values or inhibitory substances.<br />

Principles of the Procedure<br />

<strong>Universal</strong> Preenrichment Broth contains peptones as sources<br />

of carbon, nitrogen, vitamins and minerals. Sodium and<br />

potassium phosphates buffer the medium. Sodium chloride<br />

maintains the osmotic balance of the medium. Magnesium<br />

sulfate and ferric ammonium citrate provide essential ions.<br />

Dextrose is an energy source. Sodium pyruvate helps stimulate<br />

the metabolism of stressed organisms.<br />

User Quality Control<br />

Identity Specifications<br />

Difco <strong>Universal</strong> Preenrichment Broth<br />

Dehydrated Appearance: Light beige, free-flowing, homogeneous.<br />

Solution:<br />

3.8% solution, soluble in purified<br />

water. Solution is light to medium<br />

amber, slightly opalescent to opalescent,<br />

may have a precipitate.<br />

Prepared Appearance: Light to medium amber, slightly opalescent<br />

to opalescent, may have a<br />

precipitate.<br />

Reaction of 3.8%<br />

Solution at 25°C: pH 6.3 ± 0.2<br />

U -<br />

Z<br />

Cultural Response<br />

Difco <strong>Universal</strong> Preenrichment Broth<br />

Prepare the medium per label directions. Inoculate and incubate at 35 ±<br />

2°C for 18-24 hours.<br />

ORGANISM ATCC INOCULUM CFU RECOVERY<br />

Listeria monocytogenes 19115 10-10 2 Good<br />

Salmonella choleraesuis subsp.<br />

choleraesuis serotype Enteritidis 13076 10-10 2 Good<br />

Salmonella choleraesuis subsp.<br />

choleraesuis serotype Typhimurium 14028 10-10 2 Good<br />

Uninoculated<br />

Tube<br />

Salmonella<br />

typhimurium<br />

ATCC 14028<br />

605