RegO® Cylinder & Service Valves - Gas Equipment Company, Inc.

RegO® Cylinder & Service Valves - Gas Equipment Company, Inc.

RegO® Cylinder & Service Valves - Gas Equipment Company, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

RegO ® <strong>Cylinder</strong> & <strong>Service</strong> <strong>Valves</strong><br />

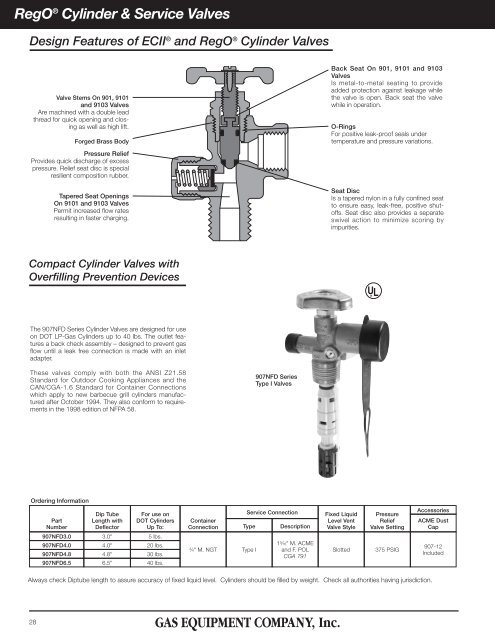

Design Features of ECII ® and RegO ® <strong>Cylinder</strong> <strong>Valves</strong><br />

Valve Stems On 901, 9101<br />

and 9103 <strong>Valves</strong><br />

Are machined with a double lead<br />

thread for quick opening and closing<br />

as well as high lift.<br />

Forged Brass Body<br />

Back Seat On 901, 9101 and 9103<br />

<strong>Valves</strong><br />

Is metal-to-metal seating to provide<br />

added protection against leakage while<br />

the valve is open. Back seat the valve<br />

while in operation.<br />

O-Rings<br />

For positive leak-proof seals under<br />

temperature and pressure variations.<br />

Pressure Relief<br />

Provides quick discharge of excess<br />

pressure. Relief seat disc is special<br />

resilient composition rubber.<br />

Tapered Seat Openings<br />

On 9101 and 9103 <strong>Valves</strong><br />

Permit increased flow rates<br />

resulting in faster charging.<br />

Seat Disc<br />

Is a tapered nylon in a fully confined seat<br />

to ensure easy, leak-free, positive shutoffs.<br />

Seat disc also provides a separate<br />

swivel action to minimize scoring by<br />

impurities.<br />

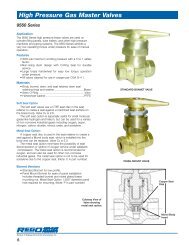

Compact <strong>Cylinder</strong> <strong>Valves</strong> with<br />

Overfilling Prevention Devices<br />

The 907NFD Series <strong>Cylinder</strong> <strong>Valves</strong> are designed for use<br />

on DOT LP-<strong>Gas</strong> <strong>Cylinder</strong>s up to 40 lbs. The outlet features<br />

a back check assembly – designed to prevent gas<br />

flow until a leak free connection is made with an inlet<br />

adapter.<br />

These valves comply with both the ANSI Z21.58<br />

Standard for Outdoor Cooking Appliances and the<br />

CAN/CGA-1.6 Standard for Container Connections<br />

which apply to new barbecue grill cylinders manufactured<br />

after October 1994. They also conform to requirements<br />

in the 1998 edition of NFPA 58.<br />

907NFD Series<br />

Type I <strong>Valves</strong><br />

Ordering Information<br />

Part<br />

Number<br />

Dip Tube<br />

Length with<br />

Deflector<br />

For use on<br />

DOT <strong>Cylinder</strong>s<br />

Up To:<br />

Container<br />

Connection<br />

<strong>Service</strong> Connection<br />

Type<br />

Description<br />

Fixed Liquid<br />

Level Vent<br />

Valve Style<br />

Pressure<br />

Relief<br />

Valve Setting<br />

Accessories<br />

ACME Dust<br />

Cap<br />

907NFD3.0 3.0" 5 lbs.<br />

907NFD4.0 4.0" 20 lbs.<br />

907NFD4.8 4.8" 30 lbs.<br />

907NFD6.5 6.5" 40 lbs.<br />

3<br />

⁄4" M. NGT Type I<br />

1 5 ⁄16" M. ACME<br />

and F. POL<br />

CGA 791<br />

Slotted<br />

375 PSIG<br />

907-12<br />

<strong>Inc</strong>luded<br />

Always check Diptube length to assure accuracy of fixed liquid level. <strong>Cylinder</strong>s should be filled by weight. Check all authorities having jurisdiction.<br />

28