Advances in Solid-State Joining at EWI

Advances in Solid-State Joining at EWI

Advances in Solid-State Joining at EWI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Temper<strong>at</strong>ure, C<br />

L<strong>in</strong>e Speed (m/m<strong>in</strong>)<br />

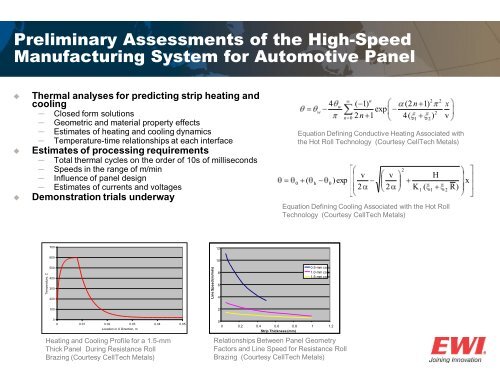

Prelim<strong>in</strong>ary Assessments of the High-Speed<br />

Manufactur<strong>in</strong>g System for Automotive Panel<br />

<br />

<br />

<br />

Thermal analyses for predict<strong>in</strong>g strip he<strong>at</strong><strong>in</strong>g and<br />

cool<strong>in</strong>g<br />

─<br />

─<br />

─<br />

─<br />

Closed form solutions<br />

Geometric and m<strong>at</strong>erial property effects<br />

Estim<strong>at</strong>es of he<strong>at</strong><strong>in</strong>g and cool<strong>in</strong>g dynamics<br />

Temper<strong>at</strong>ure-time rel<strong>at</strong>ionships <strong>at</strong> each <strong>in</strong>terface<br />

Estim<strong>at</strong>es of process<strong>in</strong>g requirements<br />

─<br />

─<br />

─<br />

─<br />

Total thermal cycles on the order of 10s of milliseconds<br />

Speeds <strong>in</strong> the range of m/m<strong>in</strong><br />

Influence of panel design<br />

Estim<strong>at</strong>es of currents and voltages<br />

Demonstr<strong>at</strong>ion trials underway<br />

w<br />

n<br />

4<br />

w<br />

( 1) (2n<br />

1)<br />

exp<br />

2 2<br />

2<br />

n 0 2n<br />

1 4(<br />

1 2) v<br />

Equ<strong>at</strong>ion Def<strong>in</strong><strong>in</strong>g Conductive He<strong>at</strong><strong>in</strong>g Associ<strong>at</strong>ed with<br />

the Hot Roll Technology (Courtesy CellTech Metals)<br />

0<br />

(<br />

h<br />

0<br />

)exp<br />

v<br />

2<br />

v<br />

2<br />

Equ<strong>at</strong>ion Def<strong>in</strong><strong>in</strong>g Cool<strong>in</strong>g Associ<strong>at</strong>ed with the Hot Roll<br />

Technology (Courtesy CellTech Metals)<br />

2<br />

K<br />

1<br />

(<br />

1<br />

H<br />

x<br />

2<br />

R)<br />

x<br />

700<br />

12<br />

600<br />

500<br />

400<br />

300<br />

10<br />

8<br />

6<br />

0.5-mm core<br />

1.0-mm core<br />

1.5-mm core<br />

200<br />

4<br />

100<br />

2<br />

0<br />

0 0.01 0.02 0.03 0.04 0.05<br />

Loc<strong>at</strong>ion <strong>in</strong> X Direction, m<br />

He<strong>at</strong><strong>in</strong>g and Cool<strong>in</strong>g Profile for a 1.5-mm<br />

Thick Panel Dur<strong>in</strong>g Resistance Roll<br />

Braz<strong>in</strong>g (Courtesy CellTech Metals)<br />

0<br />

0 0.2 0.4 0.6 0.8 1 1.2<br />

Strip Thickness (mm)<br />

Rel<strong>at</strong>ionships Between Panel Geometry<br />

Factors and L<strong>in</strong>e Speed for Resistance Roll<br />

Braz<strong>in</strong>g (Courtesy CellTech Metals)