ENGINEERING INFORMATION - ASCO Numatics

ENGINEERING INFORMATION - ASCO Numatics

ENGINEERING INFORMATION - ASCO Numatics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

00484GB-2006/R01<br />

Availability, design and specifi cations are subject to change without notice. All rights reserved.<br />

<strong>ENGINEERING</strong> <strong>INFORMATION</strong><br />

Pressures, fl ow coeffi cients and calculation of fl ow<br />

PRESSURES<br />

. Maximum allowable pressure (MAP) : The maximum allowable pressure (MAP) in pipework is the maximum effective pressure (in bar or in Pa)<br />

which can be applied to the pipework in a given system (1 bar = 10 2 kPa)<br />

. Inlet (or upstream) pressure : fl uid pressure at the entrance to the pneumatic component<br />

. Outlet (or downstream) pressure : fl uid pressure at the exit from the pneumatic component<br />

. Differential pressure Δ P : difference in pressure between the inlet (upstream) pressure and the outlet (downstream) pressure.<br />

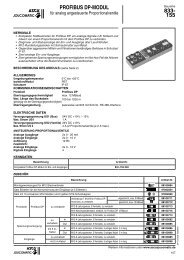

FLOW COEFFICIENTS<br />

. Kv (following standard NF E 29312) :<br />

The French KV value is an experimental coeffi cient based on laboratory conditions and expresses the volumetric fl ow across a valve. The KV<br />

coeffi cient is defi ned as the fl ow of water through a fully open valve in litres per minute with a pressure differential ΔP of 1 bar.<br />

. Cv : The imperial equivalent of the KV coeffi cient is the Cv coeffi cient defi ned as the fl ow of water through a valve in US gallon per minute at a<br />

differential pressure ΔP of 1 psi across the valve.<br />

Cv and Kv can be converted as follows : Kv = 14,3 Cv and Cv = 0,07 Kv<br />

. C and b (following standard ISO 6358) :<br />

Coeffi cients C (sonic conductance) and b (critical pressure ratio) following standard ISO 6358 allow fl ow calculation under sonic conditions<br />

(See spool valves 541 - 543 - sections E and F).<br />

C =<br />

C =<br />

q* m<br />

ρ p ο in<br />

q* v<br />

pin q* : mass fl ow rate q* (kg/s) or volume q* (m m v 3 /s) through a component at sonic fl ow<br />

p : inlet pressure (bar)<br />

in<br />

ρ ο = 1,3 kg/m 3 : density under standard conditions (p 0 = 1 bar, T 0 = 293,15 K and 65% relative humidity)<br />

b : pressure ratio below which the fl ow is sonic:<br />

q m<br />

q* m<br />

b =<br />

Pout Pin depending on P in , T 1<br />

and C<br />

P : outlet pressure (bar)<br />

out<br />

P : inlet pressure (bar)<br />

in<br />

0 b 1<br />

Sonic fl ow Subsonic fl ow<br />

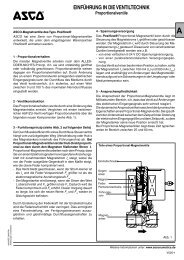

CALCULATION OF FLOW (for air and gas)<br />

. Defi ning fl ow at 6 bar :<br />

The corresponding leafl ets give for each product its mean fl ow in litres per minute at 6 bar at a standard reference atmosphere (ANR) conforming<br />

to ISO 8778 (with Δ P = 1 bar)<br />

. Calculation of fl ow :<br />

Δ P < P inlet /2<br />

Q = 28,16 x Kv x ΔP x P in<br />

including correction for temperature and density<br />

Q = 475 x Kv x (ΔP x P in )<br />

(T a x d)<br />

Q = Flow in l/min<br />

ΔP = Differential pressure, in bar<br />

. Flow graphs : (see following page).<br />

P in and T 1 are constant<br />

Ellipse quarter, depending on P in , T 1<br />

and C and b coeffi cients<br />

P out / P in<br />

Δ P ≥ P inlet /2<br />

(Maximum allowable fl ow)<br />

Q = 14 x Kv x P out<br />

P in = Absolute inlet pressure, in bar<br />

P out = Absolute outlet pressure, in bar<br />

T1, temperature (°K) measured when the fl ow is sonic<br />

including correction for temperature and density<br />

Q = 238,33 x Kv x P x 1<br />

out<br />

(T x d) a<br />

T a = Absolute temperature, in Celsius degrees<br />

d = Density compared with air<br />

All leafl ets are available on: www.asconumatics.eu<br />

P045-1<br />

A

All leafl ets are available on: www.asconumatics.eu<br />

P045-2<br />

Flow graphs - <strong>ENGINEERING</strong> <strong>INFORMATION</strong><br />

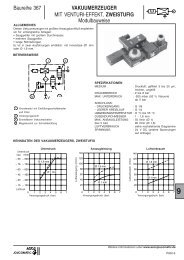

HOW TO USE THE GRAPHS<br />

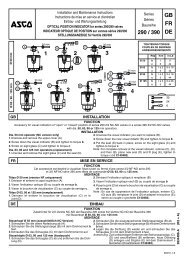

Depending on the supply pressure, use the appropriate graph: either 0 - 2 bar or 0 - 40 bar.<br />

The graph shows the relationship between the fl ow and the pressure drop Δp, depending upon the upstream pressure and the fl ow<br />

coeffi cient (Kv in litres per minute).<br />

Δp3<br />

KV 132<br />

P amont : 8 bar 950<br />

Upstream P : 8 bar<br />

AIR PRESSURE 0 to 2 bar<br />

Δp<br />

Example : Find the fl ow of a valve Ø 25 mm, KV = 132, under the following conditions :<br />

– upstream gauge pressure : 8 bar<br />

– pressure drop Δp : 3 bar<br />

Proceed as shown in the diagram to fi nd a fl ow = 950 m3 /h.<br />

If the pressure drop exceeds the values shown in the graph, the fl ow is identical to that with "critical<br />

pressure drop", so that :<br />

Δp = absolute downstream pressure = absolute upstream pressure<br />

2<br />

1<br />

0,5<br />

0,1<br />

0,05<br />

0,01<br />

0,005<br />

0,001<br />

KV<br />

1<br />

1<br />

0,5<br />

5<br />

10<br />

10<br />

5<br />

50<br />

100<br />

50<br />

100<br />

500<br />

1 000<br />

5 000<br />

10 000<br />

50 000<br />

0 0,5 1<br />

P : Upstream gauge pressure in bar<br />

15 0,1 0,5 1<br />

0,1<br />

5 10<br />

1<br />

100 1 000 10 000 100 000 m3/h (ANR)✻<br />

Q :Flow<br />

10 100 1 000 10 000 I/s (ANR)✻<br />

✻ ANR : Standard reference atmosphere<br />

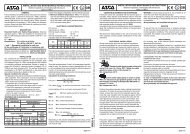

AIR PRESSURE 0 to 40 bar<br />

1<br />

0,5<br />

Δp<br />

0,1<br />

0,05<br />

0,01<br />

KV<br />

0 1 2 3 4 5 678910<br />

20 30 40 1 10<br />

P : Upstream gauge pressure in bar<br />

5<br />

10<br />

✻ ANR : Standard reference atmosphere<br />

500<br />

1 000<br />

5 000<br />

10 000<br />

0,1 1 10 100 1 000 10 000<br />

50 000<br />

100 000<br />

100 000<br />

100 1 000 10 000 100 000<br />

500 000<br />

100 000<br />

m3/h (ANR)✻<br />

Q :Flow<br />

I/s (ANR)✻<br />

00484GB-2006/R01<br />

Availability, design and specifi cations are subject to change without notice. All rights reserved.