You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

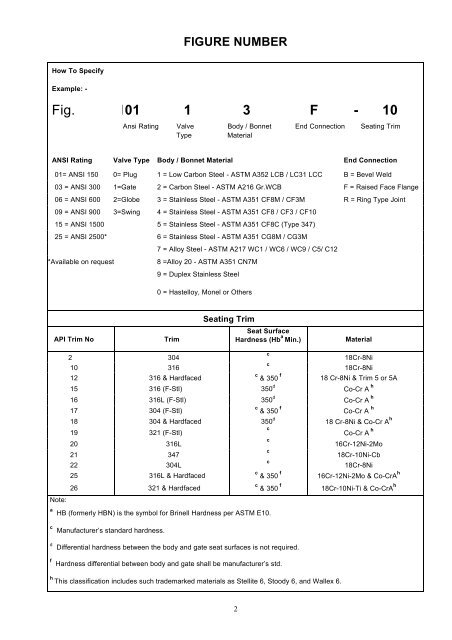

FIGURE NUMBER<br />

How To Specify<br />

Example: -<br />

Fig. 101 1 3 F - 10<br />

Ansi Rating Valve Body / Bonnet End Connection Seating Trim<br />

Type<br />

Material<br />

ANSI Rating Valve Type Body / Bonnet Material End Connection<br />

01= ANSI 150 0= Plug 1 = Low Carbon Steel - ASTM A352 LCB / LC31 LCC B = Bevel Weld<br />

03 = ANSI 300 1=Gate 2 = Carbon Steel - ASTM A216 Gr.WCB F = Raised Face Flange<br />

06 = ANSI 600 2=Globe 3 = Stainless Steel - ASTM A351 CF8M / CF3M R = Ring Type Joint<br />

09 = ANSI 900 3=Swing 4 = Stainless Steel - ASTM A351 CF8 / CF3 / CF10<br />

15 = ANSI 1500 5 = Stainless Steel - ASTM A351 CF8C (Type 347)<br />

25 = ANSI 2500* 6 = Stainless Steel - ASTM A351 CG8M / CG3M<br />

7 = Alloy Steel - ASTM A217 WC1 / WC6 / WC9 / C5/ C12<br />

*Available on request<br />

8 =Alloy 20 - ASTM A351 CN7M<br />

9 = Duplex Stainless Steel<br />

0 = Hastelloy, Monel or Others<br />

Seating Trim<br />

API Trim No<br />

Trim<br />

Seat Surface<br />

Hardness (Hb a Min.)<br />

Material<br />

2 304<br />

18Cr-8Ni<br />

10 316<br />

18Cr-8Ni<br />

12 316 & Hardfaced<br />

c f & 350 18 Cr-8Ni & Trim 5 or 5A<br />

15 316 (F-Stl) 350 d Co-Cr A h<br />

16 316L (F-Stl) 350 d Co-Cr A h<br />

17 304 (F-Stl)<br />

c f & 350 Co-Cr A h<br />

18 304 & Hardfaced 350 d 18 Cr-8Ni & Co-Cr A h<br />

19 321 (F-Stl)<br />

20 316L<br />

21 347<br />

22 304L<br />

25 316L & Hardfaced<br />

26 321 & Hardfaced<br />

Note:<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c f & 350<br />

c f & 350<br />

a HB (formerly HBN) is the symbol for Brinell Hardness per ASTM E10.<br />

Co-Cr A h<br />

16Cr-12Ni-2Mo<br />

18Cr-10Ni-Cb<br />

18Cr-8Ni<br />

16Cr-12Ni-2Mo & Co-CrA h<br />

18Cr-10Ni-Ti & Co-CrA h<br />

c<br />

d<br />

f<br />

Manufacturer’s standard hardness.<br />

Differential hardness between the body and gate seat surfaces is not required.<br />

Hardness differential between body and gate shall be manufacturer’s std.<br />

h This classification includes such trademarked materials as Stellite 6, Stoody 6, and Wallex 6.<br />

2