You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FORWARD<br />

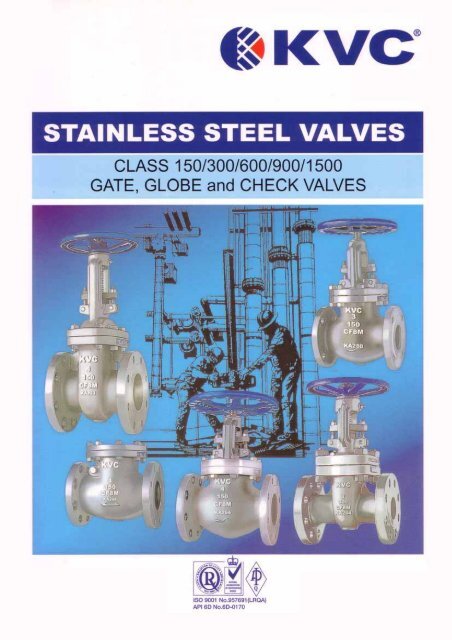

We take the pleasure in presenting our production of KVC ® Stainless Steel Gate, Globe and Swing<br />

Check Valves.<br />

KVC ® Stainless Steel Valves are widely used in the petroleum refineries and chemical processing<br />

industries and approved by most major oil and gas companies.<br />

KVC ® Stainless Steel Valves are designed and manufactured in strict accordance with the<br />

prescriptions and requirement of ASTM, ANSI, API, BS standards to meet the applicable-standards,<br />

in addition to KVC Co., Ltd's own ISO 9000-2000 procedure for quality control.<br />

Our basic policy for quality assurance is to manufacture products of excellent quality to obtain great<br />

trust and deep satisfaction of customers and to thoroughly assure this quality.

Index<br />

Index<br />

Figure Number<br />

Page l<br />

Page 2<br />

Gate Valve Page 3<br />

ANSI 150 Fig. 0113F Page 4 & 5<br />

ANSI 300 Fig. 0313F Page 6 & 7<br />

Gate Valve ANSI 600 Fig. 0613F_ Page 8<br />

ANSI 900 Fig. 0913F Page 9<br />

ANSI 1500 Fig. 1513F Page10<br />

Globe Valve Page 11<br />

ANSI 150 Fig. 0123F Page 12<br />

ANSI 300 Fig. 0323F Page 13<br />

Globe Valve ANSI 600 Fig. 0623F Page 14<br />

ANSI 900 Fig. 0923F Page 15<br />

ANSI 1500 Fig. 1523F Page 16<br />

Swing Check Valve Page 17<br />

ANSI 150 Fig. 0133F Page 18<br />

ANSI 300 Fig. 0333F Page 19<br />

Swing Check Valve ANSI 600 Fig. 0633F Page 20<br />

ANSI 900 Fig. 0933F Page 21<br />

ANSI 1500 Fig. 1533F Page 22<br />

Electrically / Gear operated Valves<br />

Welding End Details<br />

Reference Standards and Specification<br />

Comparison List for Casting and Forging<br />

Chemical and Physical Properties<br />

Steel Pipe Flanges<br />

Valve Wall Thickness<br />

Pressure Temperature Rating<br />

Optional Material<br />

Packing Material and Construction<br />

Gasket Material and Construction<br />

Terms and Condition of Sale<br />

Page 23<br />

Page 24<br />

Page 25<br />

Page 26<br />

Page 27<br />

Page 28 & 29<br />

Page 30<br />

Page 31<br />

Page 32<br />

Page 33<br />

Page 34 & 35<br />

Page 36<br />

We reserve the right to institute changes in any materials, designs and specification within this catalogue.<br />

1

FIGURE NUMBER<br />

How To Specify<br />

Example: -<br />

Fig. 101 1 3 F - 10<br />

Ansi Rating Valve Body / Bonnet End Connection Seating Trim<br />

Type<br />

Material<br />

ANSI Rating Valve Type Body / Bonnet Material End Connection<br />

01= ANSI 150 0= Plug 1 = Low Carbon Steel - ASTM A352 LCB / LC31 LCC B = Bevel Weld<br />

03 = ANSI 300 1=Gate 2 = Carbon Steel - ASTM A216 Gr.WCB F = Raised Face Flange<br />

06 = ANSI 600 2=Globe 3 = Stainless Steel - ASTM A351 CF8M / CF3M R = Ring Type Joint<br />

09 = ANSI 900 3=Swing 4 = Stainless Steel - ASTM A351 CF8 / CF3 / CF10<br />

15 = ANSI 1500 5 = Stainless Steel - ASTM A351 CF8C (Type 347)<br />

25 = ANSI 2500* 6 = Stainless Steel - ASTM A351 CG8M / CG3M<br />

7 = Alloy Steel - ASTM A217 WC1 / WC6 / WC9 / C5/ C12<br />

*Available on request<br />

8 =Alloy 20 - ASTM A351 CN7M<br />

9 = Duplex Stainless Steel<br />

0 = Hastelloy, Monel or Others<br />

Seating Trim<br />

API Trim No<br />

Trim<br />

Seat Surface<br />

Hardness (Hb a Min.)<br />

Material<br />

2 304<br />

18Cr-8Ni<br />

10 316<br />

18Cr-8Ni<br />

12 316 & Hardfaced<br />

c f & 350 18 Cr-8Ni & Trim 5 or 5A<br />

15 316 (F-Stl) 350 d Co-Cr A h<br />

16 316L (F-Stl) 350 d Co-Cr A h<br />

17 304 (F-Stl)<br />

c f & 350 Co-Cr A h<br />

18 304 & Hardfaced 350 d 18 Cr-8Ni & Co-Cr A h<br />

19 321 (F-Stl)<br />

20 316L<br />

21 347<br />

22 304L<br />

25 316L & Hardfaced<br />

26 321 & Hardfaced<br />

Note:<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c<br />

c f & 350<br />

c f & 350<br />

a HB (formerly HBN) is the symbol for Brinell Hardness per ASTM E10.<br />

Co-Cr A h<br />

16Cr-12Ni-2Mo<br />

18Cr-10Ni-Cb<br />

18Cr-8Ni<br />

16Cr-12Ni-2Mo & Co-CrA h<br />

18Cr-10Ni-Ti & Co-CrA h<br />

c<br />

d<br />

f<br />

Manufacturer’s standard hardness.<br />

Differential hardness between the body and gate seat surfaces is not required.<br />

Hardness differential between body and gate shall be manufacturer’s std.<br />

h This classification includes such trademarked materials as Stellite 6, Stoody 6, and Wallex 6.<br />

2

KVC ® STAINLESS STEEL GATE VALVES<br />

STEM<br />

The stem is in stainless steel and is part of the trim. The stem is<br />

provided with a T-head. A ground backseat is provided to<br />

ensure perfectly tight seal to the stuffing box when the valve is<br />

fully open. The stem is ground to minimize friction and prevent,<br />

damage to gland packing. The threading is trapezoidal ACME<br />

type. Dimensions comply with the applicable standard.<br />

GLAND AND FLANGE<br />

They are in stainless steel and are normally supplied in two<br />

pieces. The contact surfaces between gland and gland flange<br />

have a spherical profile to permit the eyebolts are unevenly<br />

tightened.<br />

YOKE SLEEVE<br />

The yoke sleeve is made from cast aluminum, bronze, stainless<br />

steel or ductile iron having high resistance to wear and a high<br />

melting point. It is designed to permit removal from the bonnet or<br />

the yoke while the valve is in service.<br />

HANDHWEEL<br />

The steel or nodular iron handwheels are well shaped and large<br />

enough to give ease of movement when operating the valve,<br />

even under maximum differential pressure.<br />

SEAT RINGS (If not integral)<br />

The rings are in stainless and are part of the trim. They are<br />

completely threaded outside and notched on their inner surface<br />

to ease installing and dismantling. Special attention is given to<br />

the sealing surface which are ground and lapped for a perfectly<br />

tight seal.<br />

BODY<br />

The body is in stainless steel and is carefully designed in<br />

all its details. The basic dimensions, i.e. wall thickness,<br />

face to face and flanges comply with the relevant API and<br />

ANSI standards. The sealing surfaces for connection to the<br />

bonnet are flat finish in ANSI rating150, recessed in 3001b<br />

class or may be ring joint in the ANSI rating 600 and<br />

above.<br />

The body standard is integral seats and may be threaded<br />

for renewable seats. Bosses may be provided for drain<br />

taps or by-pass piping.<br />

BONNET<br />

The bonnet is in stainless steel. It is machined to accept<br />

the yoke sleeve and incorporates a stuffing box<br />

dimensioned in accordance with the API standard.<br />

WEDGE<br />

The wedge is part of the trim. It is stainless steel. It is<br />

normally supplied as flexible or solid. It is connected to the<br />

stem by means of a T-joint. The guides on each side of the<br />

wedge are machined for proper alignment with the body<br />

guides. Special attention is given to the seating surface<br />

which are ground and lapped to insure a perfectly tight<br />

seal.<br />

BONNET BUSHING (If not integral)<br />

The bonnet bushing or backseat is in forged stainless steel and<br />

forms part of the trim. Special attention is given both to its<br />

machining and heat treatment to insure a proper seat.<br />

LANTERN (not shown)<br />

A lantern ring is fitted to all valves ANSI rating 300 and above. It<br />

is designed to be easily removable for re-packing.<br />

BONNET BOLTING<br />

Bonnet studs and nuts are manufactured from alloy or stainless<br />

steel to the relevant ASTM Standard.<br />

GLAND BOLTS AND NUTS<br />

The forged stainless steel gland bolts are of the eyebolt type<br />

which can be swung outward for ease of gland re-packing. They<br />

are fixed to the bonnet by stud bolts and nuts<br />

3

KVC ® STAINLESS STEEL GATE VALVE - ANSI 150<br />

4

KVC ® STAINLESS STEEL GATE VALVE - ANSI 150<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke<br />

Solid / Flexible Wedge<br />

Oval Bonnet with integral Yoke<br />

Rising Stem - Non-rising Handwheel<br />

Integral Seat Rings (Standard)<br />

Welded-In / Threaded Seat Rings (Optional)<br />

Full Port<br />

Raised Face Flanged Ends or Butwelding Ends<br />

Gear Operated recommended for size 14" above<br />

APPLICABLE STANDARDS<br />

Design: AP1600<br />

End Flange: ANSI B16.5<br />

Weld Ends: ANSI B16.25<br />

Face-to-Face: ANSI B16.10<br />

Shell and Seat Test: API 598<br />

Parts And Material List<br />

Fig. 0113F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

04 Wedge Stainless Steel ASTM A351 CF8M<br />

07 Stem Stainless Steel A276 316<br />

09 Yoke Sleeve Ductile Iron A439 D z C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

14 Yoke Cap Stainless Steel A276 304<br />

15 Handwheel Nut Stainless Steel A276 304<br />

18 Handwheel Ductile Iron A536<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35A Yoke Nut Stainless Steel A194 8<br />

35B Gland Nut Stainless Steel A194 8<br />

36 Hinge Pin Stainless Steel A276 304<br />

41 Set Screw Steel Stainless Steel<br />

46 Key Steel A108 1045 (1-1/2" & larger)<br />

47 Grease Nipple Steel Steel (Cr. Plated)<br />

51 Packing Reinforced Teflon PTFE P#4505L<br />

56 Gasket Reinforced Teflon Sheet PTFE P#4400<br />

73 Thrust Bearing Steel Steel<br />

* N Note : Wedge design - 3" & smaller: solid, 4" and larger: flexible<br />

Size<br />

Face -to-Face<br />

L<br />

Dia. of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

$ of Bolt Circle<br />

C<br />

Dimensional Data (mm)<br />

O.D. of RF<br />

g<br />

7hk of Flange<br />

t<br />

5<br />

Ht. of RF<br />

f<br />

$ of Bop Holes<br />

n-h<br />

~ of Handwheel<br />

O<br />

1f2" 108.0 12.7 88.9 60.5 35.1 11.2 1.6 4-15.8 100 200 3.0 3.4<br />

314" 117.5 19.1 98.6 69.9 42.9 11.2 1.6 4-15.8 100 212 3.1 3.9<br />

1 " 127.0 25.4 108.0 79.2 50.8 11.2 1.6 4-15.8 120 247 4.1 5.3<br />

1-1/2" 165.1 38.1 127.0 98.6 73.2 14.3 1.6 4-15.8 160 303 4.8 9.1<br />

2" 177.8 50.8 152.4 120.7 91.9 15.8 1.6 4-19.1 180 369 5.6 13.8<br />

2-1/2" 190.5 63.5 177.8 139.7 104.6 17.6 1.6 4-19.1 180 408 5.6 19.4<br />

3" 203.2 76.2 190.5 152.4 127.0 19.1 1.6 4-19.1 200 466 5.6 23.6<br />

4" 228.6 101.6 228.6 190.5 157.2 23.9 1.6 8-19.1 225 576 6.4 38.5<br />

5" 254.0 127.0 254.0 215.9 185.7 23.9 1.6 8-22.2 250 648 7.1 47.1<br />

6" 266.7 152.4 279.4 241.3 215.9 25.4 1.6 8-22.2 250 747 7.1 66.3<br />

8" 292.1 203.2 342.9 298.5 269.7 28.4 1.6 8-22.2 300 952 8.1 106.5<br />

10" 330.2 254.0 406.4 362.0 323.9 30.3 1.6 12-25.4 350 1145 8.6 150.3<br />

12" 355.6 304.8 482.6 431.8 381.0 31.8 1.6 12-25.4 400 1349 9.6 215.0<br />

14" 381.0 336.6 533.4 476.3 412.8 35.1 1.6 12-28.4 600 1474 10.4 291.3<br />

16" 406.4 387.4 596.9 539.8 469.9 36.6 1.6 16-28.4 560 1758 11.2 375.0<br />

18" 431.8 438.2 635.0 577.9 533.4 39.7 1.6 16-31.8 560 1910 11.9 518.0<br />

20" 457.2 489.0 698.5 635.0 584.2 43.0 1.6 20-31.8 630 2143 12.7 662.0<br />

24" 508.0 590.6 812.8 749.3 692.2 47.8 1.6 20-35.1 630 2472 14.5 955.0<br />

v<br />

Non-shock pressure rating: 275 PSIG @ -20°F to 100 °F per ANSI B16.34<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

Wt(Kg)

KVC ® STAINLESS STEEL GATE VALVE - ANSI 300<br />

6

KVC ® STAINLESS STEEL GATE VALVE - ANSI 300<br />

size: 10" -24"<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke Solid/Flexible Wedge<br />

Rising Stem - Non-rising Handwheel Integral<br />

Seat Rings (Standard)<br />

Welded-In / Threaded Seat Rings (Optional)<br />

Full Port<br />

Raised Face Flanged Ends or Butwelding Ends<br />

Gear Operated recommended for size 14" above<br />

APPLICABLE STANDARDS<br />

Design : API 600<br />

End Flange : ANSI B16.5<br />

Weld Ends : ANSI 16.25<br />

Face-to-Face : ANSI B16.10<br />

Shell and Seat Test : API 598<br />

Parts And Material List<br />

Fig. 0313F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

04 Wedge Stainless Steel ASTM A351 CF8M<br />

07 Stem Stainless Steel A276 316<br />

09 Yoke Sleeve Ductile Iron A439 D Z C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

14 Yoke Cap Stainless Steel A276 304<br />

15 Handwheel Nut Stainless Steel A276 304<br />

18 Handwheel Ductile Iron A536<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35A Yoke Nut Stainless Steel A194 8<br />

35B Gland Nut Stainless Steel A194 8<br />

36 Hinge Pin Stainless Steel A276 304<br />

41 Set Screw Steel Stainless Steel<br />

46 Key Steel A108 1045 (1" & larger)<br />

47 Grease Nipple Steel Steel (Cr. Plated)<br />

51 Packing Reinforced Teflon PTFE P#4505L<br />

56 Gasket* (see note) Reinforced Teflon Sheet PTFE P#4400<br />

73 Thrust Bearing Steel Steel<br />

Note : Gasket 10" and above - S.P.W. SS316/PTFE (P#2301-GGO)<br />

Wedge design - 2" & smaller, 3" and above: flexible<br />

Dimensional Data (mm)<br />

Size<br />

Face -to-Face<br />

L<br />

Dia. of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

~ of Bolt Circle<br />

C<br />

O.D. of RF<br />

g<br />

Thk of Flange<br />

t<br />

Ht, of RF<br />

f<br />

~ of Bolt Holes<br />

n-h<br />

~ of Handwheel<br />

O<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

Wt (Kg)<br />

½” 139.7 12.7 95.3 66.5 35.1 14.3 1.6 4-15.8 100 218 3.1 4.0<br />

¾” 152.4 19.1 19.1 82.6 42.9 15.8 1.6 4-19.1 100 227 3.8 5.3<br />

1” 165.1 25.4 25.4 88.9 50.8 17.6 1.6 4-19.1 180 292 4.8 9.3<br />

1-1/2” 190.5 38.1 155.4 114.3 73.2 20.6 1.6 4-22.2 200 375 4.8 17.0<br />

2” 215.9 50.8 165.1 127.0 91.9 22.2 1.6 8-19.1 200 403 6.4 18.2<br />

3” 282.6 76.2 209.6 168.1 127.0 28.4 1.6 8-22.2 225 469 7.1 41.6<br />

4” 304.8 101.6 254.0 200.2 157.2 31.8 1.6 8-22.2 250 602 7.8 64.1<br />

6” 403.2 152.4 317.5 269.7 215.9 36.6 1.6 12-22.2 350 832 9.6 125.0<br />

8” 419.1 203.2 381.0 330.2 269.7 41.2 1.6 12-25.4 400 1021 11.2 185.0<br />

10” 457.2 254.0 444.5 387.4 323.9 47.8 1.6 16-28.4 450 1228 12.7 272.0<br />

12” 501.7 304.8 520.7 450.9 381.0 50.8 1.6 16-31.8 500 1425 14.2 413.0<br />

14” 762.0 336.6 584.2 514.4 412.8 53.9 1.6 20-31.8 560 1638 15.8 549.0<br />

16” 838.2 387.4 647.7 571.5 469.9 57.2 1.6 20-35.1 560 1784 17.5 822.0<br />

18” 914.4 431.8 711.2 628.7 533.4 60.5 1.6 24-35.1 610 1972 19.0 1030.0<br />

20” 990.6 482.6 774.7 685.8 584.2 63.5 1.6 24-35.1 660 2200 20.6 1293.0<br />

24” 1143.0 584.2 914.4 812.8 692.2 69.9 1.6 24-41.2 660 2553 23.9 2327.0<br />

Non-stock pressure rating: 720 PSIG @ -20°F to 100°F per ANSI B16.34<br />

7

KVC ® STAINLESS STEEL GATE VALVE - ANSI 600<br />

size: 2" -4"<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke<br />

Flexible Wedge<br />

Rising Stem - Non-rising Handwheel<br />

Integral Seat Rings (Standard)<br />

Welded-In / Threaded Seat Rings (Optional)<br />

Full Port<br />

Raised Face Flanged Ends or Butwelding Ends<br />

Gear Operated recommended for size 8" above<br />

Size: 6" -12"<br />

Size: 6" -12"<br />

APPLICABLE STANDARDS<br />

Design: API 600<br />

End Flange: ANSI 1316.5<br />

Weld Ends: ANSI 1316.25<br />

Face-to-Face: ANSI B16.10<br />

Shell and Seat Test: API 598<br />

Dimensional Date<br />

Size (mm)<br />

Face -to-Face<br />

L<br />

Dia. of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

Ø of Bolt Circle<br />

C<br />

O.D. of RF<br />

g<br />

Thk of Flange<br />

t<br />

Ht. of RF<br />

f<br />

Ø of Bolt Holes<br />

n-h<br />

Ø of Handwheel<br />

O<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

Wt (Kg)<br />

2" 292.1 50.8 165.1 127.0 91.9 25.4 6.4 8-19.1 200 419 11.2 39.9<br />

2-1/2" 330.2 63.5 190.5 149.4 104.6 28.5 6.4 8-22.2 200 419 11.9 58.0<br />

3" 355.6 76.2 209.6 168.1 127.0 31.8 6.4 8-22.2 250 520 12.7 65.0<br />

4" 431.8 101.6 273.1 215.9 157.2 38.1 6.4 8-25.4 300 635 16.0 101.0<br />

Non-stock pressure rating: 1440 PSIG @ -20°F to 100°F per ANSI B16.34<br />

8

KVC ® STAINLESS STEEL GATE VALVE - ANSI 900<br />

Size: 2” -4”<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke<br />

Flexible Wedge<br />

Rising Stem - Non-rising Handwheel<br />

Integral Seat Rings (Standard)<br />

Welded-In / Threaded Seat Rings (Optional)<br />

Full Port<br />

Raised Face Flanged Ends, Butwelding Ends<br />

or Ring Joint Ends<br />

Gear Operated recommended for size 4" above<br />

Parts And Material List Fig. 0913F<br />

Size: 6” – 8 ”<br />

APPLICABLE STANDARDS<br />

Design: API 600<br />

End Flanged : ANSI B16.5<br />

Weld Ends : ANSI B16.25<br />

Face-to-Face: ANSI B16.10<br />

Shell and Seat Test: API 598<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

03 Yoke Stainless Steel ASTM A351 CF8<br />

04 Wedge Stainless Steel ASTM A351 CF8M<br />

07 Stem Stainless Steel A276 316<br />

09 Yoke Sleeve Ductile Iron A439 D Z C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

14 Yoke Cap Stainless Steel A276 304<br />

15 Handwheel Nut Stainless Steel A276 304<br />

18 Handwheel Ductile Iron A536<br />

21 Body Seat Ring Stainless Steel A182 F316<br />

23 Back Seat Ring Stainless Steel A182 316<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

32 Yoke Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35/B Gland Nut Stainless Steel A194 8<br />

35A Yoke Nut Stainless Steel A194 8<br />

36 Hinge Pin Stainless Steel A276 304<br />

41 Set Screw Steel Stainless Steel<br />

47 Grease Nipple Steel Steel (Cr. Plated)<br />

51 Packing Graphite + Carbon Fiber P#6610+ #6528<br />

56 Gasket Ring Joint Gasket P#1500G<br />

73 Thrust Bearing Steel Steel<br />

Dimensional Data (mm)<br />

Size<br />

Face 4o-Face<br />

L<br />

Dia. of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

Ø of Bolt Circle<br />

C<br />

O.D. Of RF<br />

g<br />

Thk of Flange<br />

t<br />

Hl. of RF<br />

f<br />

Ø of Bolt Holes<br />

n-h<br />

Ø of Handwheel<br />

O<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

Wt(Kg)<br />

2" 368.3 47.5 215.9 165.1 91.9 38.1 6.4 8-25.4 250 523 19.1 85.0<br />

2-1 2" 419.1 57.2 244.3 190.5 104.6 41.2 6.4 8-28.4 300 562 22.4 105.0<br />

3' 381.0 72.9 241.3 190.5 127.0 38.1 6.4 8-25.4 300 620 19.1 111.0<br />

4" 457.2 98.3 292.1 235.0 157.2 44.5 6.4 8-31.8 350 688 21.3 165.0<br />

6" 609.6 146.1 381.0 317.5 215.9 55.7 6.4 12-31.8 500 916 26.2 394.6<br />

8" 736.6 190.5 469.9 393.7 269.7 63.5 63.5 12-38.1 600 1107 31.8 594.0<br />

Non-shock pressure rating: 2160 PSIG @-20°F to 100°F per ANSI B16.34<br />

9

KVC ® STAINLESS STEEL GATE VALVE - ANSI 1500<br />

Size: 2" - 6"<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke<br />

Flexible Wedge<br />

Rising Stem - Non-rising Handwheel<br />

Integral Seat Rings (Standard)<br />

Welded-In / Threaded Seat Rings (Optional)<br />

Full Port<br />

Raised Face Flanged Ends, Butwelding Ends<br />

or Ring Joint Ends<br />

Gear Operated recommended for size 3" above<br />

Parts And Material List<br />

APPLICABLE STANDARDS<br />

Design: API 600<br />

End Flange: ANSI B16.5<br />

Weld Ends: ANSI B16.25<br />

Face-to-Face: ANSI B16.10<br />

Shell and Seat Test: API 598<br />

Fig. 1513F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

03 Yoke Stainless Steel ASTM A351 CF8<br />

04 Wedge Stainless Steel ASTM A351 CF8M<br />

07 Stem Stainless Steel A276 316<br />

09 Yoke Sleeve Ductile Iron A439 D 2 C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

14 Yoke Cap Stainless Steel A276 304<br />

15 Handwheel Nut Stainless Steel A276 304<br />

18 Handwheel Ductile Iron A536<br />

21 Body Seat Ring Stainless Steel A182 F316<br />

23 Back Seat Ring Stainless Steel A182 316<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

32 Yoke Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35 Yoke Nut Stainless Steel A194 8<br />

A<br />

35/ Gland Nut Stainless Steel A194 8<br />

B<br />

33 Yoke Nut Stainless Steel A194 8<br />

C<br />

36 Hinge Pin Stainless Steel A276 304<br />

41 Set Screw Steel Stainless Steel<br />

47 Grease Nipple Steel Steel (Cr. Plated)<br />

51 Packing Graphite + Carbon Fiber P#6610 +6528<br />

56 Gasket Ring Joint Gasket P#1500G<br />

73 Thrust Bearing Steel Steel<br />

Size<br />

Face -to-<br />

Face<br />

L<br />

Die. of<br />

Bore<br />

d<br />

O.D. of<br />

Flange<br />

D<br />

Dimensional Data (mm)<br />

ø of Bolt O.D. of RF Thk of Ht. of RF<br />

Circle<br />

Flange<br />

C g t f<br />

10<br />

ø of Bott<br />

Holes<br />

n-h<br />

ø of<br />

Handwheel<br />

O<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

Wt (Kg)<br />

2" 368.3 47.5 215.9 165.1 91.9 38.1 6.4 8-25.4 250 561 19.1 131.5<br />

2-1/2" 419.1 57.2 244.3 190.5 104.6 41.2 6.4 8-28.4 300 633 22.4 172.4<br />

3" 469.9 69.9 266.7 203.2 127.0 47.8 6.4 8-31.8 350 670 23.9 226.8<br />

4" 546.1 91.9 311.2 241.3 157.2 53.8 6.4 8-34.9 400 759 28.7 335.6<br />

6" 704.9 136.4 393.7 317.5 215.9 82.6 6.4 12-38.1 600 1048 38.1 662.0<br />

8" 831.9 177.8 482.6 393.7 269.7 91.9 6.4 12-44.5 680 1246 47.8 1180.0<br />

Non-shock pressure rating: 3600 PSIG @ -20°F to 100°F per ANSI B16.34

KVC ® STAINLESS STEEL GLOBE VALVES<br />

STEM<br />

The stem is in stainless steel and is part of the trim.<br />

A ground backseat is provide to ensure a perfectly<br />

tight seal to the stuffing box when the valve is fully<br />

open. The stem is attached to the disc by means of<br />

a threaded ring which allows the disc to rotate. The<br />

stem is ground to minimize friction and prevent<br />

damage to gland packing.<br />

SEAT RING (if not integral)<br />

The ring is in stainless steel and is part of the trim.<br />

Its outer diameter is threaded and its bore is notched<br />

to ease installation and dismantling. Special<br />

attention is given to the seating face which is ground<br />

and lapped, for a perfectly tight seal.<br />

YOKE SLEEVE<br />

The yoke sleeve is made from cast aluminum,<br />

bronze, stainless steel or ductile iron having high<br />

resistance to wear and a high melting point. It is<br />

screwed into the bonnet and properly sized to<br />

withstand the stresses which develop when opening<br />

and closing the valve.<br />

HANDWHEEL<br />

The steel or nodular iron handwheels are well<br />

shaped and large enough to give ease of movement<br />

when operating the valve, even under maximum<br />

differential pressure.<br />

BODY<br />

The body is in stainless steel. The basic dimensions, i.e.<br />

wall thickness face to face and flanges comply with the<br />

relevant API and ANSI standards. The body-to-bonnet<br />

flange is circular and the sealing surfaces for connection<br />

to 11ne bonnet are recessed in the ANSI rating 150 and<br />

300 ser4es or may be ring joint in the higher series. The<br />

body wa7dard is integral seat and may be threaded for a<br />

renewable seat. Bosses may be provided for drain taps<br />

or by pass piping.<br />

BONNET<br />

The bonnet is in stainless steel. It is machined to accept<br />

the yoke sleeve and incorporates a stuffing box<br />

dimensioned in accordance with the API standard.<br />

DISC<br />

The disc is part of the trim. It is in stainless steel. It is<br />

normally supplied of the flat, tapered or plug type or, on<br />

request, for the parabolic regulating type, always free to<br />

rotate on the stem. Special attention is given to the<br />

seating face which is ground and lapped, for a perfectly<br />

tight seal.<br />

BONNET BUSHING (if not integral)<br />

The bonnet bushing or backseat is in forged<br />

stainless steel and forms part of the trim. Special<br />

attention is given to its machining and heat<br />

treatment to insure a proper seat for gland repacking<br />

under pressure. Special attention is given to<br />

the seating face which is ground and lapped, for a<br />

perfectly tight seal.<br />

GLAND AND FLANGE<br />

They are in stainless steel and are normally supplied<br />

in two pieces. The contact surfaces between gland<br />

and gland flange have a spherical profile to permit<br />

the gland to descend parallel to the stem even if the<br />

eyebolts are unevenly tightened.<br />

BONNET BOLTING<br />

Bonnet studs and nuts are manufactured from alloy<br />

or stainless steel to the relevant ASTM standard.<br />

GLAND BOLTS AND NUTS<br />

The forged stainless steel gland bolts are of the<br />

eyebolt type which can be swing outward for ease of<br />

gland re-packing. They are fixed to the bonnet by<br />

stud bolts and nuts.<br />

11

KVC ® STAINLESS STEEL GLOBE VALVE - ANSI 150<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke<br />

Rising Stem - Handwheel<br />

Integral Seat Ring - Stellited (Standard)<br />

Welded or Threaded Seat Ring - Stellited (Optional)<br />

Yoke Integral with Bonnet<br />

Full Port<br />

Size: ½ -1”<br />

Size: 1½ -12”<br />

Parts And Material List<br />

Fig. 0123F<br />

No Part Name Material ASTM<br />

01 Body Stainless Steel ASTM S ifi A351 ti CF8M<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

04 Disc Stainless Steel ASTM A351 CF8M<br />

07 Stem Stainless Steel A276 316<br />

10 Yoke Bush Ductile Iron A439 D Z C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

13 Disc Nut Stainless Steel A276 316<br />

15 Handwheel Nut Stainless Steel A194 8<br />

19 Handwheel Ductile Iron A536<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35 Gland Nut Stainless Steel A194 8<br />

36 Hinge Pin Stainless Steel A276 304<br />

42 Washer Steel A167 304<br />

51 Packing Reinforced Teflon PTFE P#4505L<br />

56 Gasket Reinforced Teflon PTFE P#4400<br />

APPLICABLE STANDARDS<br />

Design: ANSI B16.34<br />

End Flange: ANSI B16.5<br />

Weld Ends: ANSI B16.25<br />

Face-to-Face: ANSI B16.10<br />

Shell and Seat Test: AP1598<br />

Face –to-Dimensional Data (mm)<br />

Size Face -to- Die. of O.D. of ø of Bolt O.D. of RF Thk of Ht. of RF ø of Bott ø of Height Wall Thk<br />

1/2" 108.0 12.7 88.9 60.5 35.1 11.2 1.6 4-15.8 100 191 3.0 3.5<br />

3/4" 117.5 19.1 98.6 69.9 42.9 11.2 1.6 4-15.8 100 200 3.1 4.8<br />

1" 127.0 25.4 108.0 79.2 50.8 11.2 1.6 4-15.8 120 215 4.1 5.2<br />

1-1/2" 165.1 38.1 127.0 98.6 73.2 14.3 1.6 4-15.8 200 284 4.8 12.1<br />

2" 203.2 50.8 152.4 120.7 91.9 15.8 1.6 4-19.1 200 282 5.6 14.6<br />

2-1/2" 215.9 63.5 177.8 139.7 104.6 17.6 1.6 4-19.1 250 360 5.6 24.3<br />

3" 241.3 76.2 190.5 152.4 127.0 19.1 1.6 4-19.1 250 386 5.6 31.0<br />

4" 292.1 101.6 228.6 190:5 157.2 23.9 1.6 8-19.1 300 409 6.4 45.0<br />

6" 406.4 152.4 279.4 241.3 215.9 25.4 1.6 8-22.2 350 512 7.1 81.6<br />

8" 495.3 203.2 342.9 298.5 269.7 28.4 1.6 8-22.2 400 626 8.1 137.0<br />

10" 622.3 254.0 406.4 362.0 323.9 30.3 1.6 12-25.4 450 641 8.6 240.0<br />

12" 698.5 304.8 482.6 431.8 381.0 31.8 1.6 12-25.4 500 8831 9.6 499.0<br />

Non-shock pressure rating: 275 PSIG @ -20°F to 100°F per ANSI B16.34<br />

12

KVC © STAINLESS STEEL GLOBE VALVE - ANSI 300<br />

FICATION<br />

Bonnet<br />

e Screw and Yoke<br />

Stem - Handwheel<br />

l Seat Rings (Standard)<br />

d-In / Threaded Seat Rings (Optional) Full Port<br />

Face Flanged Ends or Butwelding Ends Gear<br />

ed recommended for size 8" above<br />

Size: 1/2" - 1"<br />

Size: 1/2" - 12"<br />

APPLICABLE STANDARDS<br />

Design : ANSI B16.34<br />

End Flange : ANSI B16.5<br />

Weld Ends : ANSI B16.25<br />

Face-to-Face : ANSIB16.10<br />

Shell and Seat Test : API 598<br />

Parts And Material List<br />

Fig. 0123F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

04 Disc Stainless Steel ASTM A351 CF8M<br />

07 Stem Stainless Steel A276 316<br />

10 Yoke Bush Ductile Iron A439 D Z C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

13 Disc Nut Stainless Steel A276 316<br />

15 Handwheel Nut Stainless Steel A194 8<br />

19 Handwheel Ductile Iron A536<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35 Gland Nut Stainless Steel A194 8<br />

36 Hinge Pin Stainless Steel A276 304<br />

42 Washer Steel A167 304<br />

51 Packing Reinforced Teflon PTFE P#4505L<br />

56 Gasket Reinforced Teflon PTFE (See Note)<br />

Note: Size 8" & smaller - Gasket: PTFE Sheet (P#4400)<br />

Size 10" & larger - Gasket: S.P.W. P#2301-GGO<br />

Dimensional Data (mm)<br />

Face -to- Dia. of O.D, of Ø of Bolt O.D. of RF Thk of Ht. of RF Ø of Bolt Ø of Height Wall Thk<br />

Size Face Bore Flange Circle g Flange<br />

Holes Handwhee<br />

a min Wt (Kg)<br />

L d D C<br />

t f n-h l H<br />

½” 152.4 12.7 95.3 66.5 35.1 14.3 1.6 4-15.8 100 223 3.1 5.1<br />

¾” 177.8 19.1 117.3 82.6 42.9 15.8 1.6 4-19.1 100 226 3.8 6.8<br />

1” 203.2 25.4 124.0 88.9 50.8 17.6 1.6 4-19.1 120 282 4.8 8.9<br />

1-1/2” 228.6 38.1 155.4 114.3 73.2 20.6 1.6 4-22.2 200 314 4.8 17.9<br />

2” 266.7 50.8 165.1 127.0 91.9 22.2 1.6 8-19.1 200 324 6.4 23.2<br />

2-1,2" 292.1 63.5 190.5 149.4 104.6 25.2 1.6 8-22.2 250 375 6.4 35.3<br />

3" 317.5 76.2 209.6 168.1 127.0 28.4 1.6 8-22.2 300 416 7.1 44.7<br />

4" 355.6 101.6 254.0 200.2 157.2 31.8 1.6 8-22.2 350 471 7.8 67.0<br />

6" 444.5 152.4 317.5 269.7 215.9 36.6 1.6 12-22.2 430 618 9.6 124.0<br />

8" 558.8 203.2 381.0 330.2 269.7 41.2 1.6 12-25.4 500 715 11.2 200.0<br />

10" 622.3 254.0 444.5 387.4 323.9 47.8 1.6 16-28.4 560 920 12.7 342.0<br />

12" 711.2 304.8 520.7 450.9 381.0 50.8 1.6 16-31.8 630 1232 14.2 664.0<br />

Non-shock pressure rating: 720 PSIG @ -20°F to 100°F per ANSI B16.34<br />

13

KVC © STAINLESS STEEL GLOBE VALVE - ANSI 600<br />

Size : 2” to 6”<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke<br />

Rising Stem - Handwheel<br />

Integral Seat Rings (Standard)<br />

Welded-In / Threaded Seat Rings (Optional)<br />

Full Port<br />

Raised Face Flanged Ends or Butwelding Ends<br />

or Ring Joint Ends<br />

Gear Operated recommended for size 4" above<br />

en<br />

APPLICABLE STANDARDS Design:<br />

Parts And Material List<br />

Fig. 0623F<br />

No. Part Name Material ASTM Specification<br />

APPLICABLE STANDARDS<br />

Design : ANSI B16.34<br />

End Flange : ANSI B16.5<br />

Weld Ends : ANSI B16.25<br />

Face-to-Face : ANSI B16.10<br />

Shell and Seat Test : API 598<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

04 Disc Stainless Steel A276 316<br />

07 Stem Stainless Steel A276 316<br />

10 Yoke Bush Ductile Iron A439 D Z C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

13 Disc Nut Stainless Steel A276 316<br />

15 Handwheel Nut Stainless Steel A194 8<br />

19 Handwheel Ductile Iron A536<br />

21 Body Seat Ring Stainless Steel A182 F316<br />

23 Back Seat Ring Stainless Steel A182 316<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35 Gland Nut Stainless Steel A194 8<br />

36 Hinge Pin Stainless Steel A276 304<br />

42 Washer Steel A167 304<br />

51 Packing Graphite + Carbon Fiber P#6610 +#6528<br />

56 Gasket Ring Joint Gasket P#1500G<br />

Size<br />

Face -to-Face<br />

L<br />

Dia, of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

o of Bolt Circle<br />

C<br />

Dimensional Data (mm)<br />

O.D. of RF<br />

g<br />

Thk of Flange<br />

t<br />

14<br />

Ht. of RF<br />

f<br />

+of Bott Holes<br />

n-h<br />

~ of Handwheel<br />

O<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

2" 292.1 50.8 165.1 127.0 91.9 25.4 6.4 8-19.1 250 392 11.2 37.2<br />

3" 355.6 76.2 209.6 168.1 127.0 31.8 6.4 8-22.2 300 478 12.7 65.0<br />

4" 431.8 101.6 273.1 215.9 157.2 38.1 6.4 8-25.4 350 530 16.0 96.0<br />

Wt (Kg)<br />

6" 558.8 152.4 355.6 292.1 215.9 47.8 6.4 12-28.4 500 675 19.1 269.0<br />

8" 660.4 199.9 419.1 349.3 269.7 55.7 6.4 12-31.8 560 721 25.4 400.0<br />

10" 787.4 247.7 508.0 431.8 323.9 63.5 6.4 16-35.1 630 972 28.7 692.0<br />

12" 838.2 298.5 558.8 489.0 381.0 66.6 6.4 20-35.1 710 1074 31.8 907.0<br />

Non-shock pressure rating: 1440 PSIG @ -20°F to 1 00°F per ANSI 1316.34

KVC © STAINLESS STEEL GLOBE VALVE - ANSI 900<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke<br />

Rising Stem - Non-rising Handwheel<br />

Integral Seat Rings (Standard)<br />

Welded-In / Threaded Seat Rings (Optional)<br />

Full Port<br />

Raised Face Flanged Ends, Butwelding Ends<br />

or Ring Joint Ends<br />

Gear Operated recommended for size 3" above<br />

Parts And Material List<br />

Fig. 0923F<br />

Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

APPLICABLE STANDARDS<br />

Design : ANSI B16.34<br />

End Flange : ANSI B16.5<br />

Weld Ends : ANSI B16.25<br />

Face-to-Face : ANSI B16.10<br />

Shell and Seat Test : API 598<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

04 Disc * Stainless Steel ASTM 276 316 (`see note)<br />

07 Stem Stainless Steel A276 316<br />

09 Yoke Sleeve Ductile Iron A439 D Z C<br />

10 Yoke Bush Ductile Iron A439 D 2 C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

13 Disc Nut Stainless Steel A276 316<br />

14 Yoke Cap Stainless Steel A276 304<br />

15 Handwheel Nut Stainless Steel A194 8<br />

19 Handwheel * Ductile Iron / Cast Steel A536 / ASTM A216 Gr.WCB<br />

23 Back Seat Ring Stainless Steel A276 316<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35 Gland Nut Stainless Steel A194 8<br />

36 Hinge Pin Stainless Steel A276 304<br />

42 Washer Steel A167 304<br />

46 Guide Key Carbon Steel A108 1020<br />

46A Hammer Blow Key Carbon Steel A108 1020<br />

49 Snap Ring Carbon Tool Steel Carbon Tool Steel<br />

51 Packing Graphite + Carbon Fiber PTFE P#6610 + #6528<br />

56 Gasket Ring Joint Gasket P#1500G<br />

73 Thrust Bearing Steel Steel<br />

76* Spacer 1 Packing Washer Stainless Steel A276 316<br />

81 Hammer Blow Cast Steel A216 Gr.WCB<br />

* Note: Disc: A276 316 - Size 4" & smaller, A351 CF8M - Size 6" & above<br />

Handwheel: A216 Gr.WCB - Size: 8"<br />

Item 81: Size 8" - Packing Washer, Size: 2" - 6" - Spacer<br />

Size<br />

Face -to-<br />

Face<br />

L<br />

Die. of<br />

Bore<br />

d<br />

O.D. of<br />

Flange<br />

D<br />

ø of Bolt<br />

Circle<br />

C<br />

Dimensional Data (mm)<br />

O.D. of RF<br />

g<br />

15<br />

Thk of<br />

Flange<br />

t<br />

Ht. of RF<br />

f<br />

ø of Bott<br />

Holes<br />

n-h<br />

ø of<br />

Handwheel<br />

O<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

Wt (Kg)<br />

2” 368.3 47.5 215.9 165.1 91.9 38.1 6.4 8-25.4 350 509 19.1 120.0<br />

3” 381.0 72.9 241.3 190.5 127.0 38.1 6.4 8-25.4 430 682 19.1 132.0<br />

4” 457.2 98.3 292.1 235.0 157.2 44.5 6.4 8-31.8 450 738 21.3 209.0<br />

6” 609.6 146.1 381.0 317.5 215.9 55.7 6.4 12-31.8 450 870 26.2 504.0<br />

8” 736.6 190.5 469.9 393.7 269.7 63.5 6.4 12-38.1 750 1227 31.8 903.0<br />

Non-shock pressure rating: 2160 PSIG @ -20°F to 100°F per ANSI B16.34

KVC © STAINLESS STEEL GLOBE VALVE - ANSI 1500<br />

SPECIFICATION<br />

Bolted Bonnet<br />

Outside Screw and Yoke<br />

Rising Stem Non-rising Handwheel Integral Seat Ring<br />

(Standard)<br />

Welded-In / Threaded Seat Rings (Optional) Full Port<br />

Raised Face Flanged Ends, Butwelding Ends<br />

or Ring Joint Ends<br />

Gear Operated recommended for size 2" above<br />

Parts and Material List<br />

Fig. 1523F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Bonnet Stainless Steel ASTM A351 CF8M<br />

04 Disc Stainless Steel ASTM A351 CF8M<br />

07 Stem Stainless Steel A276 316<br />

10 Yoke Bush Ductile Iron A439 D 2 C<br />

11 Gland Flange Stainless Steel ASTM A351 CF8<br />

12 Packing Gland Stainless Steel A276 316<br />

13 Disc Nut Stainless Steel A276 316<br />

15 Handwheel Nut Stainless Steel A194 8<br />

19 Handwheel Ductile Iron A536<br />

31 Bonnet Bolt Stainless Steel A193 B8<br />

33 Bonnet Nut Stainless Steel A194 8<br />

APPLICABLE STANDARDS<br />

Design: ANSI B16.34<br />

End Flange: ANSI B16.5<br />

Weld Ends: ANSI B16.25<br />

Face-to-Face : ANSI 1316.10<br />

Shell and Seat Test: API 598<br />

34 Gland Bolt Stainless Steel A193 B8<br />

35 Gland Nut Stainless Steel A194 8<br />

36 Hinge Pin Stainless Steel A276 304<br />

42 Washer Steel A167 304<br />

51 Packing Graphite + Carbon Fiber P#6610 +#6528<br />

56 Gasket Ring Joint Gasket P#1500G<br />

Dimensional Data (mm)<br />

Size<br />

Face -to-<br />

Face<br />

L<br />

Dia. of Bore<br />

d<br />

O.D, of<br />

Flange<br />

D<br />

Ø of Bolt<br />

Circle<br />

C<br />

O.D. of RF<br />

g<br />

Thk of<br />

Flange<br />

t<br />

Ht. of RF<br />

f<br />

Ø of Bolt<br />

Holes<br />

n-h<br />

Ø of<br />

Handwheel<br />

O<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

Wt (Kg)<br />

2" 368.3 47.5 215.9 165.1 91.9 38.1 6.4 8-25.4 350 537 19.1 131<br />

3" 469.9 69.9 266.7 203.2 127.0 47.8 6.4 8-31.8 400 615 23.9 249<br />

4" 546.1 91.9 i311.2 241.3 157.2 53.8 6.4 8-34.9 450 689 28.7 354<br />

Non-shock pressure rating: 3600 PSIG @ -20°F to 100°F per ANSI B16.34<br />

16

KVC ® STAINLESS STEEL SWING CHECK VALVES<br />

BODY<br />

The body is in stainless steel, carefully designed to keep pressure drops to a minimum. A wide opening on the top of<br />

the body permits easy inspection and maintenance. The basic dimensions, i.e. wall thickness face to face and . comply<br />

with the relevant API and ANSI standards. The body-to-cover flange is circular. Threaded bosses are incorporated to<br />

ensure correct alignment to the hinge pin. Bosses may be provided for drain taps or by-pass piping.<br />

COVER<br />

The cover is in stainless steel. The sealing surfaces for the connection to the body are recessed in the ANSI rating 150<br />

and 300 and ring joint in the higher.<br />

DISC<br />

The disc is part of the trim. The back side has a threaded stud for attachment to the hinge with a stainless steel nut split<br />

and pin to insure a strong connection. The seating face is ground and lapped, for a perfectly tight seal.<br />

HINGE<br />

The hinge is in forged stainless steel for small diameter and cast for valves 14" up.<br />

SEAT RING (if not integral)<br />

The ring is in forged stainless steel and is part of the trim. Its outer diameter is threaded and its bore is notched to ease<br />

installation and dismantling. Special attention is given to the seating face which is ground and lapped, for a perfectly tight<br />

seal.<br />

HINGE PIN<br />

The hinge pin is part of the trim. It is forged stainless steel and it machined from round bar. The hinge pin is retained in<br />

the body by two threaded plugs and sealed by metallic gaskets. The pin can be easily removed for maintenance of the<br />

valve.<br />

COVER BOLTING<br />

The cover studs and nuts are manufactured from alloy or stainless steel to the relevant ASTM standard.<br />

17

KVC ® STAINLESS STEEL SWING CHECK VALVE - ANSI 150<br />

SPECIFICATION<br />

Bolted Cover<br />

For Horizontal or Vertical Lines (Up Flow Only)<br />

Integral Seat Ring (Standard)<br />

Welded or Threaded Seat Ring (Optional)<br />

Full Port<br />

Raised Face Flanged Ends or Butwelding Ends<br />

Parts And Material List<br />

SECTION A - A<br />

APPLICABLE STANDARDS<br />

Design: ANSI B16.34<br />

End Flange: ANSI B16.5<br />

Weld Ends: ANSI B16.25<br />

Face-to-Face : ANSI<br />

B16.10<br />

Shell and Seat Test: API<br />

No. Part Name Material ASTM Specification<br />

1 Body Stainless Steel ASTM A351 CFBM<br />

02 Cover Stainless Steel ASTM A351 CFBM<br />

04 Disc Stainless Steel ASTM A351 CFBM<br />

16 Arm Stainless Steel ASTM A351 CFBM<br />

24 Plug Bolt Stainless Steel A276 316<br />

27 Pin Stainless Steel A276 316<br />

31 Cover Bolt Stainless Steel A193 B8<br />

33 Cover Nut Stainless Steel A194 8<br />

35 Disc Nut Stainless Steel A194 8M<br />

42 Washer Stainless Steel A167 316<br />

48 Eye Bolt (6" & above) Stainless Steel A193 B8<br />

56 Gasket PTFE Sheet P#4400<br />

Ą<br />

Size<br />

Face -to-Face<br />

L<br />

Dia. of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

$ of Bolt Circle<br />

C<br />

Dimensional Data (mm)<br />

O.D. of RF<br />

g<br />

18<br />

Thk of Flange<br />

t<br />

Ht, of RF<br />

f<br />

0 o( Bolt Holes<br />

n-h<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

1/2" 108.0 12.7 88.9 60.5 35.1 11.2 1.6 4-15.8 62 3.0 2.5<br />

3/4" 117.5 19.1 98.6 69.9 42.9 11.2 1.6 4-15.8 62 3.1 3.2<br />

1" 127.0 25.4 108.0 79.2 50.8 11.2 1.6 4-15.8 74 4.1 3.7<br />

1-1/2" 165.1 38.1 127.0 98.6 73.2 14.2 1.6 4-15.8 98 4.8 7.3<br />

2" 203.2 50.8 152.4 120.7 91.9 15.7 1.6 4-19.1 113 5.6 10.9<br />

2-1/2" 215.9 63.5 177.8 139.7 104.6 17.6 1.6 4-19.1 132 5.6 17.0<br />

3" 241.3 76.2 190.5 152.4 127.0 19.1 1.6 4-19.1 143 5.6 21.5<br />

4" 292.1 101.6 228.6 190.5 157.2 23.9 1.6 8-19.1 156 6.4 34.2<br />

6" 355.6 152.4 279.4 241.3 215.9 25.4 1.6 8.22.2 210 7.1 62.4<br />

8" 495.3 203.2 342.9 298.5 269.7 28.4 1.6 8-22.2 253 8.1 98.5<br />

Wt (Kg)<br />

10" 622.3 254.0 406.4 362.0 323.9 30.3 1.6 12-25.4 300 8.6 150.0<br />

12" 698.5 304.8 482.6 431.8 381.0 31.8 1.6 12-25.4 332 9.6 225.0<br />

14" 787.4 336.6 533.4 476.3 412.8 35.1 1.6 12-28.4 403 10.4 375.0<br />

16" 863.6 387.4 596.9 539.8 469.9 36.6 1.6 16-28.4 510 11.2 465.0<br />

Non-shock pressure rating: 275 PSIG @ -20°F to 100°F per ANSI B16 34

KVC ® STAINLESS STEEL SWING CHECK VALVE - ANSI 300<br />

SPECIFICATION<br />

Bolted Cover<br />

For Horizontal or Vertical Lines (Up Flow Only)<br />

Integral Seat Ring (Standard)<br />

Welded or Threaded Seat Ring (Optional)<br />

Full Port<br />

Raised Face Flanged Ends or Butwelding Ends<br />

APPLICABLE STANDARDS<br />

Design : ANSI B16.34<br />

End Flange : ANSI B16.5<br />

Weld Ends : ANSI B16.25<br />

Face-to-Face : ANSI B16.10<br />

Shell and Seat Test : API 598<br />

Parts And Material List<br />

Fig.0333F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Cover Stainless Steel ASTM A351 CF8M<br />

04 Disc Stainless Steel ASTM A351 CF8M<br />

16 Arm Stainless Steel ASTM A351 CF8M<br />

24 Plug Bolt Stainless Steel A276 316<br />

27 Pin Stainless Steel A276 316<br />

31 Cover Bolt Stainless Steel A193 B8<br />

33 Cover Nut Stainless Steel A194 8<br />

35 Disc Nut Stainless Steel A194 8M<br />

42 Washer Stainless Steel A167 316<br />

48 Eye Bolt (6" & above) Stainless Steel A193 B8<br />

56 Gasket PTFE Sheet See Note<br />

Note : Size 8" & smaller: PTFE Sheet P#4400. Size: 10" & Larger: S.P.W. P#2301-GGO<br />

Parts And Material List<br />

Size<br />

Face -to-Face<br />

L<br />

Dia, of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

o of Bolt Circle<br />

C<br />

O.D. of RF<br />

g<br />

Thk of Flange<br />

t<br />

Ht. of RF<br />

f<br />

+of Bott Holes<br />

n-h<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

1-1/2” 241.3 38.1 155.4 114.3 73.2 20.6 1.6 4-22.2 122 4.8 11.3<br />

2” 266.7 50.8 165.1 127.0 91.9 22.2 1.6 8-19.1 136 6.4 16.4<br />

Wt (Kg)<br />

2-1/2” 292.1 63.5 190.5 149.4 104.6 25.4 1.6 8-22.2 142 6.4 24.0<br />

3 " 317.5 76.2 209.6 168.1 127.0 28.5 1.6 8-22.2 163 7.1 35.3<br />

4” 355.6 101.6 254.0 200.2 157.2 31.8 1.6 8-22.2 194 7.8 50.0<br />

6” 444.5 152.4 317.5 269.7 215.9 36.6 1.6 12-22.2 243 9.6 93.5<br />

8” 533,4 203.2 381.0 330.2 269.7 41.2 1.6 12-25.4 298 11.2 153.0<br />

10” 622.3 254.0 444.5 387.4 323.9 47.8 1.6 16-28.4 327 12.7 230.0<br />

12” 711.2 304.8 520.7 450.9 381.0 50.8 1.6 16-31.8 372 14.2 326.0<br />

14” 838.2 336.6 584.2 514.4 412.8 53.9 1.6 20-31.8 437 15.8 721.0<br />

16” 863.6 387.4 647.7 571.5 469.9 57.2 1.6 20-35.1 480 17.5 902.0<br />

18” 977.9 431.8 711.2 628.7 533.4 60.5 1.6 24-35.1 585 19.0 1002.0<br />

Non-shock pressure rating : 720 PSIG @-20 0 F to 100 0 F per ANSI B16.34<br />

19

KVC ® STAINLESS STEEL SWING CHECK VALVE - ANSI 600<br />

SPECIFICATION<br />

Bolted Cover<br />

For Horizontal or Vertical Lines (Up Flow Only)<br />

Integral Seat Ring (Standard)<br />

Welded or Threaded Seat Ring Optional)<br />

Full Port<br />

Raised Face Flanged Ends or Butwelding Ends<br />

Parts And Material List<br />

Fig. 0633F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351<br />

02 Cover Stainless Steel ASTM A351<br />

04 Disc Stainless Steel ASTM A351<br />

16 Arm Stainless Steel ASTM A351<br />

24 Plug Bolt Stainless Steel A276 316<br />

27 Pin Stainless Steel A276 316<br />

31 Cover Bolt Stainless Steel A193 B8<br />

33 Cover Nut Stainless Steel A194 8<br />

APPLICABLE STANDARDS<br />

35 Disc Nut Stainless Steel A194 8M<br />

Design: ANSI B16.34<br />

42 Washer Stainless Steel A167 316<br />

End Flange: ANSI B16.5<br />

` 48 Eye Bolt (4" & above) Stainless Steel A193 B8<br />

Weld Ends: ANSI B16.25<br />

Face-to-Face: ANSI B16.10<br />

56 Gasket Ring Joint P#1500G<br />

Shell and Seat Test: API 598<br />

Size<br />

Face -to-Face<br />

L<br />

Dia, of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

Dimensional Data (mm)<br />

o of Bolt Circle<br />

C<br />

O.D. of RF<br />

g<br />

Thk of Flange<br />

t<br />

Ht. of RF<br />

f<br />

+of Bott Holes<br />

n-h<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

2" 292.1 50.8 165.1 127.0 91.9 25.4 6.4 8-19.1 187 11.2 12.7<br />

3" 355.6 76.2 209.6 168.1 127.0 31.8 6.4 8-22.2 210 12.7 54.0<br />

Wt (Kg)<br />

4" 431.8 101.6 273.1 215.9 157.2 38.1 6.4 8-25.4 256 16.0 106.6<br />

6" 558.8 152.4 355.6 292.1 215.9 47.8 6.4 12-28.4 329 19.1 160.0<br />

8" 660.4 199.9 419.1 349.3 269-7 55.7 6.4 12-31.8 363 25.4 276.0<br />

10" 787.4 247.7 508.0 431.8 323.9 63.5 6.4 16-35.1 464 28.7 414.0<br />

Non-shock pressure rating: 1440 PSIG @ -20°F to 100°F per ANSI B16.34<br />

20

KVC ® STAINLESS STEEL SWING CHECK VALVE - ANSI 900<br />

SPECIFICATION<br />

Bolted Cover<br />

For Horizontal or Vertical Lines (Up Flow Only) Integral<br />

Seat Ring (Standard)<br />

Welded or Threaded Seat Ring (Optional) Full<br />

Port<br />

Raised Face Flanged Ends, Butwelding Ends or<br />

Ring Joint Ends<br />

APPLICABLE STANDATDS<br />

Design : ANSI B16.34<br />

End Flange : ANSI B16.5<br />

Weld Ends : ANSI B16.25<br />

Face-to-Face : ANSI B16.10<br />

Shell and Seat Test : API 598<br />

Parts And Material List<br />

FIG. 0933F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Cover Stainless Steel ASTM A351 CF8M<br />

04 Disc Stainless Steel ASTM A351 CF8M<br />

16 Arm Stainless Steel ASTM A351 CF8M<br />

24 Plug Bolt Stainless Steel A276 316<br />

25 Plug Gasket Graphite + Carbon Filler P#6610<br />

27 Pin<br />

+ C b Fill<br />

Stainless Steel A276 316<br />

31 Cover Bolt Stainless Steel A193 B8<br />

33 Cover Nut Stainless Steel A194 8<br />

35 Disc Nut Stainless Steel A194 8M<br />

42 Washer Stainless Steel A167 316<br />

42A Plug Washer Stainless Steel A276 316<br />

48 Eye Bolt (3" &<br />

b )<br />

Stainless Steel<br />

A193 B8<br />

Size<br />

Face -to-Face<br />

L<br />

Dia. of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

~ of BoR Circle<br />

C<br />

Dimensional Data (mm)<br />

O.D. of RF<br />

g<br />

Thk of Flange<br />

t<br />

Ht. of RF<br />

f<br />

0 of Bolt Holes<br />

n-h<br />

Height<br />

H<br />

Wall Thk<br />

a min<br />

2” 368.3 47.5 215.9 165.1 91.9 38.1 6.4 8-25.4 223 19.1 73.0<br />

3” 381.0 72.9 241.3 190.5 127.0 38.1 6.4 8-25.4 255 19.1 88.0<br />

Wt (Kg)<br />

4” 457.2 98.3 292.1 235.0 157.2 44.5 6.4 8-31.8 295 21.3 181.0<br />

6” 609.6 146.1 381.0 317.5 215.9 55.7 6.4 12-31.8 345 26.2 313.0<br />

8” 736.6 190.5 469.9 393.7 269.7 63.5 6.4 12-38.1 415 31.8 467.0<br />

Non-shock pressure rating: 2160 PSIG @ -20°F to 100°F per ANSI B16.34<br />

21

KVC ® STAINLESS STEEL SWING CHECK VALVE - ANSI 1500<br />

SPECIFICATION<br />

Bolted Cover<br />

For Horizontal or Vertical Lines (Up Flow Only) Integral Seat<br />

Ring (Standard)<br />

Welded or Threaded Seat Ring (Optional)<br />

Full Port<br />

Raised Face Flanged Ends, Butwelding Ends<br />

or Ring Joint Ends<br />

APPLICABLE STANDARDS<br />

Design: ANSI B16.34<br />

End Flange: ANSI B16.5<br />

Weld Ends: ANSI B16.25<br />

Face-to-Face: ANSI B16.10<br />

Shell and Seat Test: API 598<br />

Parts And Material<br />

Fig. 1533F<br />

No. Part Name Material ASTM Specification<br />

01 Body Stainless Steel ASTM A351 CF8M<br />

02 Cover Stainless Steel ASTM A351 CF8M<br />

04 Disc Stainless Steel ASTM A351 CF8M<br />

16 Arm Stainless Steel ASTM A351 CF8M<br />

24 Plug Bolt Stainless Steel A276 316<br />

25 Plug Gasket Graphite + Carbon Filler P#6610<br />

27 Pin Stainless Steel A276 316<br />

31 Cover Bolt Stainless Steel A193 B8<br />

33 Cover Nut Stainless Steel A194 8<br />

35 Disc Nut Stainless Steel A194 8M<br />

42 Washer Stainless Steel A167 316<br />

42A Plug Washer Stainless Steel A276 316<br />

48 Eye Bolt (4" & above) Stainless Steel A193 B8<br />

56 Gasket Ring Joint P#1500G<br />

Size<br />

Face -to-Face<br />

L<br />

Dia. of Bore<br />

d<br />

O.D. of Flange<br />

D<br />

Dimensional Data (mm)<br />

$ of Bolt Circle<br />

C<br />

O,D, of RF<br />

g<br />

Thk of Flange<br />

t<br />

Ht. of RF<br />

f<br />

~ of Bolt Holes<br />

n-h<br />

Height<br />

H<br />

Wall Thk<br />

a Min<br />

2" 368.3 47.5 215.9 165.1 91.9 38.1 6.4 8-25.4 223 19.1 122<br />

2-1/2" 419.1 57.2 244.3 190.5 104.6 41.2 6.4 8-28.4 265 22.4 167<br />

3" 469.9 69.9 266.7 203.2 127.0 47.8 6.4 8-31.8 325 23.9 195<br />

4" 546.1 91.9 311.2 241.3 157.2 53.8 6.4 8-34.9 350 28.7 290<br />

6" 704.9 136.4 393.7 317.5 215.9 82.6 6.4 12-38.1 370 38.1 430<br />

8" 831.9 177.8 482.6 393.7 269.7 91.9 6.4 12-44.5 405 47.8 675<br />

Wt (Kg)<br />

Non-shock pressure rating: 3600 PS IG @ -20°F to 100°F per ANSI B16.34<br />

22

ELECTRICALLY OPERATED VALVES<br />

For production of an electrically operated valve (motor operated valve),<br />

specifications such as listed below are required :<br />

1. Type or model number of motor.<br />

2. Type of construction : water-proof or explosionproof.<br />

3. Type of manual operating device.<br />

4. Open/close operating device.<br />

5. Power source.<br />

(for motor; voltage, Hz, 3-phase)<br />

(for control; voltage, Hz, single-phase)<br />

A. Type of valve.<br />

B. Primary fluid pressure: kg f/cm 2 max.<br />

C. Differential pressure of a closed valve: kg f/cm z max.<br />

D. Fluid temperature: ° C max.<br />

E. Atmospheric temperature: ° C max.<br />

GEAR OPERATED VALVES<br />

For production of a gear operated valve, specifications<br />

as listed below are required:<br />

1. Size and figure number of valve.<br />

2. Service media, Pressure and Temperature.<br />

3. Max. pressure against which valve must close.<br />

4. Any handwheel torque or rim-pull limitation.<br />

5. Limitations, if any on the type or brand of actuator.<br />

6. Other<br />

23

WELDING END DETAILS<br />

tt min<br />

2<br />

Connection Pipe Wall Thickness<br />

Larger than 7/8" size<br />

Compound Bevel<br />

Connection Pipe Wall Thickness<br />

7/8" ans smaller size<br />

A<br />

B<br />

t<br />

= Outside diameter of matching pipe, wrought or fabricated component<br />

= Nominal inside diameter<br />

= Min. wall thickness<br />

"A" Dimensions reference to ANSI 1316.25<br />

"B" Dimensions reference to ANSI B36.10<br />

Valve<br />

mm 15 20 25 40 50 65 80 100 150 200 250 300 350 400 450 500 600<br />

nominal<br />

size<br />

in 1/2 3/4 1 1-1/2 2 2-1/2 3 4 6 8 10 12 14 16 18 20 24<br />

Tolerence<br />

+ 0<br />

on A(mm) -0.8<br />

Tolerance<br />

on B(mm)<br />

±0.8 1.6 ±3.2<br />

-1.6<br />

24

REFERENCE STANDARDS AND SPECIFICATION<br />

KVCx valves are offered to meet the following Codes and Standards : Valves to BS Standard DIN Standard<br />

as well as GOST Standard are available upon request.<br />

ANSI Standards - American National Standards Institute<br />

B1.1 Unified Screw Threads<br />

B1.5 Acme Screw Threads<br />

B1.8 Stub Acme Screw Threads<br />

B1.12 Class 5 Interference - Fit Thread<br />

B2.1 Pipe Threads (Except Dryseal)<br />

B16.5 Steel Pipe Flanges, and Flanged Fittings<br />

B16.10 Face-to-Face and End-to-End Dimensions of Ferrous Valves<br />

B16.11 Forged Steel Fittings, Socket Welding and Threaded<br />

B16.20 Ring-Joint Gaskets and Grooves for Steel Pipe Flanges<br />

B16.21 Non-metallic Gaskets for Pipe Flanges<br />

B16.25 Buttwelding Ends<br />

B16.34 Steel Valves<br />

B18.2.2 Square and Hex Nuts<br />

B31.1.0 Power Piping<br />

B31.2 Fuel Gas Piping<br />

B31.3 Petroleum Refinery Piping<br />

B31.4 Liquid Petroleum Transportation Piping Systems<br />

B31.5 Refrigeration Piping Systems<br />

B31.6 Chemical Process Piping<br />

B31.7 Nuclear Power Piping<br />

B31.8 Gas Transmission and Distribution Piping Systems<br />

B36.10 Wrought-Steel and Wrought-Iron Pipe<br />

API Standards - American Petroleum Institute<br />

6A<br />

Specification for Wellhead Equipment<br />

6D<br />

Specification for Pipeline Valves<br />

597 Steel Venturi Gate Valves<br />

598 Valve Inspection and Test<br />

600 Steel Gate Valves, Flanged or Buttwelding Ends<br />

603 150-Lb, Light-Wall, Corrosion-Resistant Gate Valve for Refinery Use<br />

605 Large Diameter Carbon Steel Flanges<br />

ASTM Standards - American Society for Testing and Materials<br />

MSS Standard Practices - Manufacturers Standarisation Society of the Valve and Fittings Industry<br />

SP-6<br />

SP-9<br />

SP-25<br />

SP-42<br />

SP-44<br />

SP-45<br />

SP-53<br />

SP-54<br />

SP-55<br />

SP-61<br />

Finishes-for Contract Faces of Connection End Flanges of Ferrous Valves and Fittings<br />

MSS Spot-Facing Standard<br />

MSS Standard Making System for Valves, Fittings, Flanges and Unions<br />

MSS 150Lb Corrosion Resistant Cast Flanged Valves<br />

MSS Steel Pipe Line Flanges<br />

MSS Bypass and Drain Connection Standard<br />

Quality Standard for Steel Castings, Dry Particle Magnetic Inspection Method<br />

Quality Standard for Steel Castings, Radiographic Inspection Method<br />

Quality Standard for Steel Castings, Visual Method<br />

Hydrostatic Testing of Steel Valves<br />

25

COMPARISON LIST FOR CASTINGS AND FORGINGS<br />

General Classification<br />

Castings<br />

Forgings<br />

ASTM JIS BS ASTM JIS BS<br />

18Cr-8Ni(C 0.03) A351 - CF3 - - - F304L - SUS28 -<br />

18Cr-8Ni(C 0.08) - CFS G512 - SCS13 - - F304 - SUS27 1503 - 801<br />

18Cr-8Ni(C 0.10) - 1504 -801 - F304H - -<br />

Mr-8Ni-2Mo(C 0.03) A351 - CF3M G512 - SCS16 - - F316L G4303 -SUS33B -<br />

18Cr-8Ni-2Mo(C 0.08) - CFSM - SCS14 1632 - GRC - F316 -SUS32B 1503- 845B<br />

18Cr-8N i-2Mo(C 0.10) - - - - 316H - -<br />

18Cr-8Ni-Ti(C 0.08) - - - - F321 G4303 - SU529 -<br />

Mr-8Ni-Ti(C 0.10) - - 1504 - 821 Ti - - F321 H 1503 - 821Ti<br />

18Cr-8Ni-Cb(C 0.08) A351 - CF8C - - - F347 G4303 - SUS43B - 821 Nb<br />

18Cr-8Ni-Cb(C 0.10) - - 1504 - 821 Nb - F347H - -<br />

18Cr-8Ni-Ta-Cb(C 0.08) - - - - F348 - -<br />

18Cr-8Ni-Ta-Cb(C 0.10) - - - - F348H - -<br />

25Cr-20Ni(C 0.15) - - - - F310 - -<br />

22Cr-12Ni(C 0.08) A351 - CH18 - - - - -<br />

22Cr-12Ni(C 0.10) - CH10 - - - - -<br />

22Cr-12Ni(C 0.20) - CH20 - - - - -<br />

23Cr-19Ni(C 0.20) - CK20 - - - - -<br />

23Cr-19Ni(C 0.35) - HK30 - - - - -<br />

23Cr-19Ni(C 0.45) - HK40 - - - - -<br />

13Cr-33Ni-Mo(C 0.35) - HT30 - - - - -<br />

15Cr-13Ni-2Mo-Cb(C 0.10) CF10MC - - - - -<br />

19Cr-27Ni-2Mo-3Cu(C 0.07) - CN7M - - - - -<br />

8Cr-20Ni(C 0.20) - - - A182 - F10 - -<br />

HASTELLOY. B A494 - N-12MV - - - - -<br />

26

CHEMICAL AND PHYSICAL PROPERTIES<br />

CHEMICAL PROPERTIES<br />

Carbon<br />

Steel<br />

CASTING MATERIALS<br />

CA-15 High Temp High Temp 304-S.S. 316-S.S. Hastelloy-B 304L-S.S. 316L-S.S. Low-Temp High Temp<br />

ASTM Std A-216 A-217 A-217 A-217 A-351 A-351 A-494 A-351 A-351 A-352 A-217 A-217<br />

Grade WCB CA-15 WC6 WC9 CF8 CF8M N-12MV CF3 CF3M LCB C-5 C-12<br />

C % Max. 0.30 0.15 0.20 0.18 0.08 0.08 0.12 0.03 0.03 0.30 0.20 0.20<br />

Mn % 1.OOMax. 1.00 0.50-0.80 0.40-0.70 1.50 1.50 1.00 1.50 1.50 1.00 0.40-0.70 0.35-0.65<br />

P% Max. 0.04 0.04 0.04 0.04 0.04 0.04 0.040 0.04 0.04 0.04 0.04 0.04<br />

S% Max. 0.045 0.04 0.045 0.045 0.04 0.04 0.030 0.04 0.04 0.045 0.045 0.045<br />

Ni% 0.50 Max. 1.00 - - 8.00-11.00 9.00-12.00 Bal 8.00-12.00 9.00-13.0 - - -<br />

Cr% 0.50 Max. 11.5-14.0 1.00-1.50 2.00-2.75 18.0-21.0 18.0-21.0 1.00 17.0-21.0 17.0-21.0 - 4.0-6.50 8.00-10.00<br />

Mo°/ 0.20 Max. - 0.45-0.65 0.90-1.20 - 2.00-3.00 26.0-30.0 0.50 Max. 2.00-3.00 - 0.45-0.65 0.90-1.20<br />

Cu 0.30 Max. - - - - - - - - - - -<br />

Si 0.60 Max. 1.50 0.60 0.60 2.00 1.50 1.00 2.00 1.50 0.60 0.75 1.00<br />

Fe - - - - - - 4.0-6.0 - - - - -<br />

V - - - - - - D.2D-D.6D - - - - -<br />

PHYSICAL PROPERTIES<br />

Tensile<br />

strength Min.<br />

70-95 90-115 70-95 70-95 70 70 76 70 70 65-95 90-115 90-115<br />

KIs Mpa 485-655 620-795 485-655 485-655 485 485 525 485 485 450-620 620-795 620-793<br />

Yield Point<br />

Min-Kis Mpa<br />

Elongation in<br />

2 inch<br />

(50mm)<br />

%Min.<br />

Reduction of<br />

area % Min<br />

36 65 40 40 30 30 40 30 30 35 60 60<br />

250 450 275 275 205 205 275 205 205 240 415 415<br />

22 18 20 20 35 30 6 35 30 24 18 18<br />

35 30 35 35 - - - - - 35 35 35<br />

WROUGHT MATERIALS<br />

CHEMICAL PROPERTIES<br />

11-13%Cr<br />

Ductile<br />

Carbon<br />

Steel<br />

B-8F 321-S.S. 304-S.S. 316-S.S. 304L-S.S. 316-S.S.<br />

Hard<br />

Facing<br />

Bolts<br />

Nuts<br />

ASTM Std A-182 A-439 ASTM A-320 A-182 A-182 A-182 A-182 A-182 KLS A-193 A-194<br />

Grade F6a D,C A-105 B-8F F-321 F-304 F-316 F-304L F-316L HF-6R B7 2H<br />

C% Max. 0.15 0.29 -0.35 Max. 0.15 0.08 0.08 0.08 0.035 0.035 1.05 0.37-0.49 0.40<br />

SI % Max. 1.00 1.00-3.00 0.35 1.00 1.00 1.00 1.00 1.00 1.00 1.11 0.15-0.35 -<br />

Mn% Max. 1.00 1.80-2.4 0.60-1.05 2.00 2.00 2.00 2.00 2.00 2.00 - 0.75-1.20 -<br />

P% Max. 0.04 0.08 0.04 0.20 0.04 0.04 0.04 0.04 0.04 - 0.035 0.04<br />

S% Max. 0.03 - 0.05 0.15-0.35 0.03 0.03 0.03 0.03 0.03 - 0.04 0.05<br />

Ni% 0.50 Max. 21.0-24.0 - 8.00-10.00 9.00-12.00 8.0-11.0 10.0-14.0 8.00-13.00 10.00-15.00 - - -<br />

Cr°/ 11.5-13.5 0.50 - 17.00-19.00 17.OOMin 18.0-20.0 16.0-18.0 - 816.00-18.00 28.30 0.75-1.20 -<br />

Mo% - - - - - - 2.00-3.00 - 2.00-3.00 - 0.15-0.25 -<br />

Ti°/ - - - - C%X5-0.7 - - - - - - -<br />

Fe°/ Bal. - - - - - - - - 0.30 Bal. Bal.<br />

W% - - - - - - - - - 4.20 - -<br />

Co°/ - - - - - - - - - Bal. - -<br />

PHYSICAL PROPERTIES<br />

Tensile<br />

strength Min. 85 58 70 75 75 75 75 70 70 -<br />

125<br />

Kis Mpa 586 400 483 517 517 517 517 483 483<br />

862<br />

Yield Point<br />

55 28 36 30 30 30 30 25 25<br />

-<br />

105<br />

Min-Kis Mpa 379 193 248 207 207 207 207 172 172<br />

724<br />

Elongation in<br />

2 inch<br />

(50mm)<br />

%Min.<br />

Reduction of<br />

area % Min<br />

18 20 22 35 30 30 30 30 30 - 16 -<br />

35 - 30 50 50 50 50 50 50 - 50 -<br />

175<br />

-<br />

27

ANSI 1316.5 1981<br />

ANSI Class 150 RF to 600 RF<br />

STEEL PIPE FLANGES<br />

Class 150 Steel Pipe Flanged Dimensions<br />

Nominal Size A B C D E Bolt<br />

in mm in mm m mm in mm in mm in mm No Dia<br />

2 50 6.00 152 4.75 120.5 3.62 92 0.75 19.1 0.75 19 4 5/8<br />

2.1/2 65 7.00 178 5.50 139.5 4.12 105 0.88 22.3 0.75 19 4 5/8<br />

3 80 7.50 190 6.00 152.5 5.00 127 0.94 23.9 0.75 19 4 5/8<br />

4 100 9.00 229 7.50 190.5 6.19 157 0.94 23.9 0.75 19 8 5/8<br />

6 150 11.00 279 9.50 241.5 8.50 216 1.00 25.4 0.88 22 8 ¾<br />

8 200 13.50 343 11.75 298.5 10.62 270 1.12 28.6 0.88 22 8 ¾<br />

10 250 16.00 406 14.25 362.0 12.75 324 1.19 30.2 1.00 25 12 7/8<br />

12 300 19.00 483 17.00 432.0 15.00 381 1.25 31.8 1.00 25 12 7/8<br />

14 350 21.00 533 18.75 476.0 16.25 413 1.38 25.0 1.12 29 12 1<br />

16 400 23.50 597 21.25 539.5 18.50 470 1.44 36.6 1.12 29 16 1<br />

18 450 25.00 635 22.75 578.0 21.00 533 1.56 39.7 1.25 32 1 1.1/8<br />

6<br />

20 500 27.50 698 25.00 635.0 23.00 584 1.69 42.9 1.25 32 2 1.1/8<br />

24 600 32.00 813 29.50 ~ 749.5 27.25 692 1.88 47.7 1.38 35 1<br />

0<br />

1.1/4<br />

ANSI B16.47 Series A ( MSS SP-44 )<br />

6<br />

38.75 984.2 36.00 914.4 33.75 857.2 2.94 74.7 1.38 35 28 1.1/4<br />

30 750<br />

ANSI B16.47 Series B ( API STD 605)<br />

34.94 887.4 33.31 846.1 32.00 812.8 1.75 44.4 0.88 22.23 44 ¾<br />

Class 300 Steel Pipe Flanged Dimensions<br />

Nominal Size A B C D E Bolt<br />

in mm in mm in mm in mm in Mm in mm No Dia<br />

2 50 6.50 165 5.00 127.0 3.62 92 0.88 22.3 0.75 19 8 5/8<br />

2.1/2 65 7.50 190 5.88 149.0 4.12 105 1.00 25.4 0.88 22 8 ¾<br />

3 80 7.25 210 6.62 168.0 5.00 127 1.12 28.6 0.88 22 8 ¾<br />

4 100 10.00 254 7.88 200.0 6.19 157 1.25 31.8 0.88 22 8 ¾<br />

6 150 12.50 318 10.62 270.0 8.50 216 1.44 36.6 0.88 22 12 ¾<br />

8 200 15.00 381 13.00 330.0 10.62 270 1.62 41.3 1.00 25 12 7/8<br />

10 250 17.50 444 15.25 387.5 12.75 324 1.88 47.7 1.12 29 16 1<br />

12 300 20.50 521 17.75 451.0 15.00 381 2.00 50.8 1.25 32 16 1.1/8<br />

14 350 23.00 584 20.25 514.5 16.25 413 2.12 54.0 1.25 32 20 1.1/8<br />

16 400 25.50 648 22.50 571.5 18.50 470 2.25 57.2 1.38 35 20 1.1/4<br />

18 450 28.00 711 24.75 628.5 21.00 533 2.38 60.4 1.38 35 24 1.1/4<br />

20 500 30.50 775 27.00 686.0 23.00 584 2.50 63.5 1.38 35 24 1.1/4<br />

24 600 36.00 914 32.00 813.00 27.25 692 2.75 69.9 1.62 41 24 1.1/2<br />

Class 600 Steel Pipe Flanged<br />

Nominal Size A B C D E Bolt<br />

in mm in mm in mm in mm in mm in mm No Dia<br />

2 50 6.50 165 5.00 127.0 3.62 92 1.00 25.4 0.75 19 8 5/8<br />

2.1/2 65 7.50 190 5.88 149.0 4.12 105 1.12 28.6 0.88 22 8 ¾<br />

3 80 8.25 210 6.62 168.0 5.00 127 1.25 31.8 0.88 22 8 ¾<br />

4 100 10.75 273 8.50 216.0 6.19 157 1.50 38.1 1.00 25 8 7/8<br />

6 150 14.00 356 11.50 292.0 8.50 216 1.88 47.7 1.12 29 12 1<br />

8 200 16.50 491 13.75 349.0 10.62 270 2.19 55.6 1.25 32 12 1.1/8<br />

10 250 20.00 508 17.00 432.0 12.75 324 2.50 63.5 1.38 35 16 1.1/4<br />

12 300 22.00 559 19.25 489.0 15.00 381 2.62 66.7 1.38 35 20 1.1/4<br />

14 350 23.75 603 20.75 527.0 16.25 413 2.75 69.9 1.50 38 20 1.3/8<br />

16 400 27.00 686 23.75 603.0 18.50 470 3.00 76.2 1.62 41 20 1.1/2<br />

18 450 29.25 743 25.75 654.0 21.00 533 3.25 82.6 1.75 45 20 1.5/8<br />

20 500 32.00 813 28.50 724.0 23.00 584 3.50 88.9 1.75 45 24 1.5/8<br />

24 600 37.00 940 33.00 838.0 27.25 692 4.00 102 0 2.00 51 24 1.7/8<br />

28

ANSI 1316.5 1981<br />

ANSI Class 900 RF to 2500 RF<br />

STEEL PIPE FLANGES<br />

Class 900 Steel Pipe Flanged Dimensions<br />

minal Size A B C D E Bolt<br />

in mm in mm in mm in mm in mm in mm No. Dia<br />

2 50 8.50 216 6.50 165.00 3.62 92 1.50 38.1 1.00 25 8 7/8<br />

2.1/2 65 9.62 244 7.50 190.50 4.12 105 1.62 41.2 1.12 29 8 1<br />

3 80 9.50 241 7.50 190.50 5.00 127 1.50 31.8 1.00 25 8 7/8<br />

4 100 11.50 292 11.50 235.00 6.19 157 1.75 44.5 1.25 32 8 1.1/8<br />

6 150 15.00 381 15.00 317.50 8.50 216 2.19 55.7 1.25 32 12 1.1/8<br />

8 200 18.50 470 18.50 393.50 10.62 270 2.50 63.5 1.50 38 12 1.3/8<br />

10 250 21.50 546 21.50 470.00 12.75 324 2.75 69.9 1.50 38 16 1.3/8<br />

12 300 24.00 610 24.00 533.50 15.00 381 3.12 79.3 1.50 38 20 1.3/8<br />

14 350 25.25 641 25.25 559.00 16.25 413 3.38 85.9 1.62 41 20 1.1/2<br />

16 400 27.75 705 27.75 616.00 18.50 470 3.50 88.9 1.75 45 20 1.5/8<br />

18 450 31.00 787 31.00 686.00 21.00 533 4.00 101.6 2.00 51 20 1.7/8<br />

20 500 33.75 857 33.75 749.50 23.00 584 4.25 108.0 2.12 54 20 2<br />

24 600 41.00 1041 41.00 901.50 27.25 692 5.50 139.7 2.62 67 20 2.1/2<br />

Class 1500 Steel Pipe Flanged Dimensions<br />

minal Size A B C D E Bolt<br />

in mm in mm in mm in mm in mm in mm No. Dia<br />

2 50 8.50 216 6.50 165.0 3.62 92 1.50 38.1 1.00 25 8 7/8<br />

2.112 65 6.62 244 7.50 190.5 4.12 105 1.62 41.2 1.12 29 8 1<br />

3 80 10.50 267 8.00 203.0 5.00 127 1.88 47.8 1.25 32 8 1.1/8<br />

4 100 12.25 311 9.50 241.5 6.19 157 2.12 53.9 1.38 35 8 1.114<br />

6 150 15.50 394 12.50 317.5 8.50 216 3.25 82.6 1.50 38 12 1.3/8<br />

8 200 19.00 483 15.50 393.5 10.62 270 3.62 92.0 1.75 45 12 1.5/8<br />

10 250 23.00 584 19.00 482.5 12.75 324 4.25 108.0 2.00 51 12 1.7/8<br />

12 300 26.50 673 22.50 571.5 15.00 381 4.88 24.0 2.12 54 16 2<br />

14 350 29.50 749 25.00 635.0 16.25 413 5.25 133.4 2.38 60 16 2.1/4<br />

16 400 32.50 826 27.75 705.0 18:50 470 5.75 146.1 2.62 67 16 2.1/2<br />

18 450 36.00 914 30.50 774.5 21.00 533 6.38 162.1 2.88 73 16 2.3/4<br />

20 500 38.75 984 32.75 832.0 23.00 584 7.00 177.8 3.12 79 16 3<br />

24 600 46.00 1168 39.00 990.5 27.25 692 8.00 203.2 3.62 92 16 3.1/2<br />

Class 2500 Steel Pipe Flanged Dimensions<br />

minal Size A B C D E Bolt<br />

in mm in mm In mm in mm in mm in mm No. Dia<br />

2 50 9.25 235 6.75 171.5 3.62 92 2.00 50.80 1.12 29 8 1<br />

2.1/2 65 10.50 267 7.75 197.0 4.12 105 2.25 57.20 1.25 32 8 1.1/8<br />

3 80 12.00 305 9.00 228.5 5.00 127 2.62 66.50 1.38 35 8 1.1/4<br />

4 100 14.00 356 10.75 273.0 6.19 157 3.00 76.20 1.62 41 8 1.1/2<br />

6 150 19.00 483 14.50 368.5 8.50 216 4.25 108.00 2.12 54 8 2<br />

8 200 21.75 552 17.25 438.0 10.62 270 5.00 127.00 2.12 54 12 2<br />

10 250 26.50 673 21.25 540.0 12.75 324 6.50 165.10 2.62 67 12 2.3/4<br />

12 300 30.00 762 24.38 629.5 15.00 381 7.25 184.20 2.88 73 12 2.3/4<br />

V A L V E W A L L<br />

Class 150 & 300<br />

29<br />

For Class 600 & Larger

VALVE WALL THICKNESS<br />

Light Wall (ANSI B16.34)<br />

ANSI Rating 150 300 600 900 1500<br />

Nominal Size IN MM IN MM IN MM IN MM IN MM<br />

1/2" 0.11 3.0 0.12 3.1 0.13 3.4 0.16 4.1 0.19 4.8<br />

3/4" 0.12 3.1 0.15 3.8 0.16 4.1 0.18 4,6 0.23 5.8<br />

1" 0.16 4.1 0.19 4.8 0.19 4.8 0.22 5.6 0.25 6.6<br />

1-1/4" 0.19 4.8 0.19 4.8 0.19 4.8 0.25 6.4 0.31 7.8<br />

1-1/2" 0.19 4.8 0.19 4.8 0.22 5.6 0.28 7.1 0.38 9.6<br />

2" 0.22 5.6 0.25 6.4 0.25 6.4 0.31 7.9 0.44 11.2<br />

2-1/2" 0.22 5.6 0.25 6.4 0.28 7.1 0.34 8 6 0.50 12.7<br />

3" 0.22 5.6 0.28 7.1 0.31 7.9 0.41 10.4 0.62 15.7<br />

4" 0.25 6.4 0.31 7.8 0.38 9.6 0.50 12.7 0.75 19.0<br />

6" 0.28 7.1 0.38 9.6 0.50 12.7 0.72 18.3 1.09 27.7<br />

8" 0.31 8.1 0.44 11.2 0.62 15.8 0.88 22.4 1.41 35.8<br />

10" 0.34 8.6 0.50 12.7 0.75 19.0 1.06 26.9 1.72 43.7<br />

12" 0.38 9.6 0.56 14.2 0.91 23.1 1.25 31.8 2.00 50.8<br />

14" 0.41 10.4 0.62 15.8 0.97 24.6 1.38 35.0 2.19 55.6<br />

16" 0.44 11.2 0..69 17.5 1.09 27.7 1.56 39.6 2.50 63.5<br />

18" 0.47 11.9 0.75 19.0 1.22 31.0 1.75 44.4 2.81 71.4<br />

20" 0.50 12.7 0.81 20.6 1.34 34.0 1.91 48.5 3.12 79.2<br />

24" 0.57 14.5 0.94 23.9 1.59 40.4 2.28 57.9 3.72 94.5<br />

Heavy Wall (API 600)<br />

ANSI Rating 150 300 600 900 1500<br />

Nominal Size IN MM IN MM IN MM IN MM IN MM<br />

1/2" - - - - - - - - - -<br />

3/4" - - - - - - - - - -<br />

1" 0.25 6.4 0.25 6.4 0.31 7.9 0.50 12.7 0.50 12.7<br />

1-1/4" 0.25 6.4 0.25 6.4 0.34 8.6 0.56 14.2 0.56 14.2<br />

1-1/2" 0.25 6.4 0.31 7.9 0.37 9.4 0.59 15.0 0.59 15.0<br />

2" 0.34 8.6 0.38 9.7 0.44 11.2 0.75 19.1 0.75 19.1<br />

2-1/2" 0.38 9.7 0.44 11.2 0.47 11.9 0.88 22.4 0.88 22.4<br />

3" 0.41 10.4 0.47 11.9 0.50 12.7 0.75 19.1 0.94 23.9<br />

4" 0.44 11.2 0.50 12.7 0.63 16.0 0.84 21.3 1.13 28.7<br />

6" 0.47 11.9 0.63 16.0 0.75 19.1 1.03 26.2 1.50 38.1<br />

8" 0.50 12.7 0.69 17.5 1.00 25.4 1.25 31.8 1.88 47.8<br />

10" 0.56 14.2 0.75 19.1 1.13 28.7 1.44 36.6 2.25 57.2<br />

12" 0.63 16.0 0.81 20.6 1.25 31.8 1.66 42.2 2.63 66.8<br />

14" 0.66 16.8 0.88 22.4 1.38 35.1 1.81 46.0 2.75 69.9<br />

16" 0.69 17.5 0.94 23.9 1.50 38.1 2.06 52.3 3.13 79.5<br />

18" 0.72 18.3 1.00 25.4 1.63 41.4 2.25 57.2 3.50 88.9<br />

20" 0.75 19.1 1.06 26.9 1.75 44.5 2.50 63.5 3.88 98.6<br />

24" 0.81 20.6 1.19 30.2 2.00 50.8 2.88 73.2 4.50 114.3<br />

30

PRESSURE - TEMPERATURE RATING<br />

Materials<br />

A 182 F304 A.312 TP304 A 358 304 A 430 FP304H<br />

A182 F304H A 312 TP304H A 376 TP304 A 479 304<br />

A 240 304 A 351 CF3 (0 A 376 TP304H A 479 304H<br />

A 240 304H A 351 CF8 A 430 FP304<br />

Note: (f) Not to be used over 800°F (427°C)<br />

Temperature<br />

Working pressure by ANSI rating<br />

150 300 600 900 1500<br />

°C °F Psig Kgf/cm 2 g Psig Kgf/cm 2 g Psig Kgf/cm 2 g Psig Kgf/cm 2 g Psig Kgf/cm 2 g<br />

-29 to - 38 -20 to 100 275 19.3 720 50.6 1440 101.2 2160 151.9 3600 253.1<br />