bellow sealed valves - Federal International (2000) Ltd

bellow sealed valves - Federal International (2000) Ltd

bellow sealed valves - Federal International (2000) Ltd

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

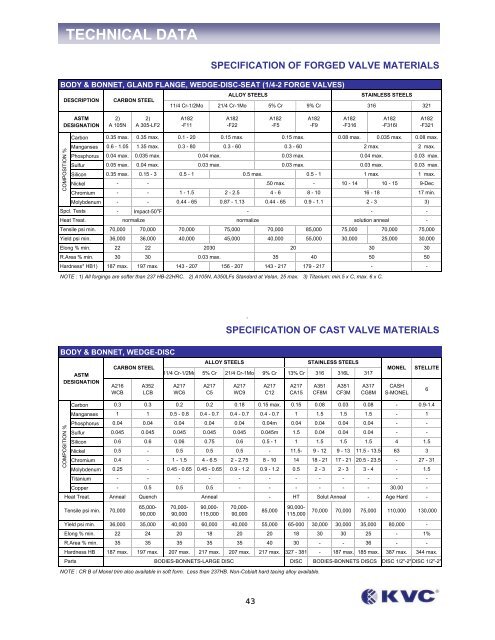

TECHNICAL DATA<br />

SPECIFICATION OF FORGED VALVE MATERIALS<br />

BODY & BONNET, GLAND FLANGE, WEDGE-DISC-SEAT (1/4-2 FORGE VALVES)<br />

ALLOY STEELS<br />

STAINLESS STEELS<br />

DESCRIPTION CARBON STEEL<br />

11/4 Cr-1/2Mo 21/4 Cr-1Mo 5% Cr 9% Cr 316 321<br />

ASTM<br />

DESIGNATION<br />

2)<br />

A 105N<br />

2)<br />

A 305-LF2<br />

A182<br />

-F11<br />

A182<br />

-F22<br />

A182<br />

-F5<br />

A182<br />

-F9<br />

A182<br />

-F316<br />

A182<br />

-F316l<br />

A182<br />

-F321<br />

COMPOSITION %<br />

Carbon<br />

Manganses<br />

Phosphorus<br />

Sulfur<br />

Silicon<br />

Nickel<br />

Chromium<br />

Molybdenum<br />

0.35 max. 0.35 max. 0.1 - 20 0.15 max. 0.15 max. 0.08 max. 0.035 max. 0.08 max.<br />

0.6 - 1.05 1.35 max. 0.3 - 80 0.3 - 60<br />

0.3 - 60<br />

2 max. 2 max.<br />

0.04 max. 0.035 max. 0.04 max. 0.03 max. 0.04 max. 0.03 max.<br />

0.05 max. 0.04 max. 0.03 max. 0.03 max.<br />

0.03 max. 0.03 max.<br />

0.35 max. 0.15 - 3 0.5 - 1 0.5 max. 0.5 - 1 1 max. 1 max.<br />

- - .50 max.<br />

- 10 - 14 10 - 15 9-Dec<br />

- - 1 - 1.5 2 - 2.5<br />

4 - 6 8 - 10 16 - 18 17 min.<br />

- - 0.44 - 65 0.87 - 1.13 0.44 - 65 0.9 - 1.1 2 - 3<br />

3)<br />

Spcl. Tests - Impact-50 o F<br />

-<br />

- -<br />

Heat Treat. normalize normalize solution anneal -<br />

Tensile psi min. 70,000 70,000 70,000 75,000 70,000 85,000 75,000 70,000 75,000<br />

Yield psi min. 36,000 36,000 40,000 45,000 40,000 55,000 30,000 25,000 30,000<br />

Elong % min. 22 22 2030 20 30 30<br />

R.Area % min. 30 30 0.03 max.<br />

35 40 50 50<br />

Hardness* HB1) 187 max. 197 max. 143 - 207 156 - 207 143 - 217 179 - 217 -<br />

-<br />

NOTE : 1) All forgings are softer than 237 HB-22HRC. 2) A105N, A350LFs Standard at Velan, 25 max. 3) Titanium: min.5 x C, max. 6 x C.<br />

`<br />

SPECIFICATION OF CAST VALVE MATERIALS<br />

BODY & BONNET, WEDGE-DISC<br />

ASTM<br />

DESIGNATION<br />

CARBON STEEL<br />

A216<br />

WCB<br />

A352<br />

LCB<br />

11/4 Cr-1/2Mo<br />

A217<br />

WC6<br />

ALLOY STEELS<br />

5% Cr 21/4 Cr-1Mo 9% Cr 13% Cr<br />

A217<br />

C5<br />

A217<br />

WC9<br />

A217<br />

C12<br />

A217<br />

CA15<br />

STAINLESS STEELS<br />

316 316L 317<br />

A351<br />

CF8M<br />

A351<br />

CF3M<br />

A317<br />

CG8M<br />

MONEL<br />

CASH<br />

S-MONEL<br />

STELLITE<br />

6<br />

COMPOSITION %<br />

Carbon<br />

Manganses<br />

Phosphorus<br />

Sulfur<br />

Silicon<br />

Nickel<br />

Chromium<br />

Molybdenum<br />

Titanium<br />

Copper<br />

Heat Treat. Anneal Quench Anneal<br />

Tensile psi min. 70,000<br />

0.3 0.3 0.2 0.2 0.18 0.15 max. 0.15 0.08<br />

1 1 0.5 - 0.8 0.4 - 0.7<br />

0.04 0.04 0.04 0.04<br />

0.045 0.045 0.045 0.045<br />

0.6 0.6 0.06 0.75<br />

0.5 - 0.5 0.5<br />

0.4 - 1 - 1.5 4 - 6.5<br />

0.25 - 0.45 - 0.65 0.45 - 0.65<br />

- - - -<br />

- 0.5 0.5 0.5<br />

65,000-<br />

90,000<br />

70,000-<br />

90,000<br />

90,000-<br />

115,000<br />

0.4 - 0.7 0.4 - 0.7 1 1.5<br />

0.04 0.04m 0.04 0.04<br />

0.045 0.045m 1.5 0.04<br />

0.6 0.5 - 1 1 1.5<br />

0.5 - 11.5- 9 - 12<br />

2 - 2.75 8 - 10 14 18 - 21<br />

0.9 - 1.2 0.9 - 1.2 0.5 2 - 3<br />

- - - -<br />

- - - -<br />

70,000-<br />

90,000<br />

- HT Solut Anneal -<br />

Yield psi min. 36,000 35,000 40,000 60,000 40,000 55,000 65-000 30,000 30,000 35,000 80,000 -<br />

Elong % min. 22 24 20 18 20 20 18 30 30 25 - 1%<br />

R.Area % min. 35 35 35 35 35 40 30 - - 36 - -<br />

Hardness HB 187 max. 197 max. 207 max. 217 max. 207 max. 217 max. 327 - 381 - 187 max. 185 max. 387 max. 344 max.<br />

Parts BODIES-BONNETS-LARGE DISC DISC BODIES-BONNETS DISCS DISC 1/2"-2" DISC 1/2"-2"<br />

85,000<br />

90,000-<br />

115,000<br />

NOTE : CR B of Monel trim also available in soft form. Less than 237HB. Non-Cobialt hard tacing alloy available.<br />

0.03 0.08 - 0.9-1.4<br />

1.5 1.5 - 1<br />

0.04 0.04 - -<br />

0.04 0.04 - -<br />

1.5 1.5 4 1.5<br />

9 - 13 11.5 - 13.5 63 3<br />

17 - 21 20.5 - 23.5 - 27 - 31<br />

2 - 3 3 - 4 - 1.5<br />

- - - -<br />

- - 30.00 -<br />

70,000 70,000 75,000 110,000<br />

Age Hard -<br />

130,000<br />

43