- Page 1 and 2:

SSANGYONG Cutting Tools Ssangyong M

- Page 3 and 4:

High Productivity SSANGYONG Cuttin

- Page 5 and 6:

A Inserts Grade Infomation A 4 Appl

- Page 7 and 8:

Turning & Milling Turning & Milling

- Page 9 and 10:

Turning & Milling Turning & Milling

- Page 11 and 12:

Application Index CERAMIC Applicati

- Page 13 and 14:

Turning & Milling IDENTIFICATION SY

- Page 15 and 16:

Ceramic Inserts Turning Roll Turnin

- Page 17 and 18:

Turning Inserts CERAMIC Turning Ins

- Page 19 and 20:

Turning Inserts CERAMIC Turning Ins

- Page 21 and 22:

Turning Inserts CERAMIC Turning Ins

- Page 23 and 24:

Turning Inserts CERAMIC Turning Ins

- Page 25 and 26:

Turning Inserts CERAMIC Turning Ins

- Page 27 and 28:

Turning Inserts CERAMIC Turning Ins

- Page 29 and 30:

Roll Turning Inserts CERAMIC Roll T

- Page 31 and 32:

Roll Turning Inserts CERAMIC Groovi

- Page 33 and 34:

Milling Inserts CERAMIC Milling Ins

- Page 35 and 36:

Milling Inserts CERAMIC Milling Ins

- Page 37 and 38:

Wiper(ZZ) Inserts CERAMIC Wiper(ZZ)

- Page 39 and 40:

Special Inserts CERAMIC Special Ins

- Page 41 and 42:

Cermet Inserts Turning Milling Spec

- Page 43 and 44:

Turning Inserts CERMET Turning Inse

- Page 45 and 46:

Turning Inserts CERMET Turning Inse

- Page 47 and 48:

Turning Inserts CERMET Turning Inse

- Page 49 and 50:

Milling Inserts CERMET Milling Inse

- Page 51 and 52:

Special Inserts CERMET Special Inse

- Page 53 and 54:

PCBN.PCD Inserts PCBN PCD Mini Tip

- Page 55 and 56:

Turning Inserts PCBN Turning Insert

- Page 57 and 58:

Turning Inserts PCBN Turning Insert

- Page 59 and 60:

Turning Inserts PCD Turning Inserts

- Page 61 and 62:

Turning Inserts PCD Turning Inserts

- Page 63 and 64:

Turning Inserts MINI TIP Turning In

- Page 65:

Endmills PCBN/PCD Special PCBN/PCD

- Page 102 and 103:

Tool Holders APPLICATION INDEX CCLN

- Page 104 and 105:

Tool Holders IDENTIFICATION SYSTEM

- Page 106 and 107:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 108 and 109:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 110 and 111:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 112 and 113:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 114 and 115:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 116 and 117:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 118 and 119:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 120 and 121:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 122 and 123:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 124 and 125:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 126 and 127:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 128 and 129:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 130 and 131:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 132 and 133:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 134 and 135:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 136 and 137:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 138 and 139:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 140 and 141:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 142 and 143:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 144 and 145:

Tool Holders EXTERNAL TOOLHOLDER Tu

- Page 146 and 147:

Tool Holders SPECIAL TOOLHOLDER Tur

- Page 148 and 149:

Tool Holders SPECIAL TOOLHOLDER Tur

- Page 150 and 151:

B End Mill High Hardened & High Spe

- Page 152 and 153:

2F ZAMUS END MILL Endmill & Drill 5

- Page 154 and 155:

High Hardened & High Speed Machinin

- Page 156 and 157:

High Hardened & High Speed Machinin

- Page 158 and 159:

High Hardened & High Speed Machinin

- Page 160 and 161:

High Hardened & High Speed Machinin

- Page 162 and 163:

High Hardened & High Speed Machinin

- Page 164 and 165:

High Hardened & High Speed Machinin

- Page 166 and 167:

High Hardened & High Speed Machinin

- Page 168 and 169:

High Hardened & High Speed Machinin

- Page 170 and 171:

High Hardened & High Speed Machinin

- Page 172 and 173:

High Hardened & High Speed Machinin

- Page 174 and 175:

High Hardened & High Speed Machinin

- Page 176 and 177:

High Hardened & High Speed Machinin

- Page 178 and 179:

End Mill for Difficult-to-Cut Mater

- Page 180 and 181:

End Mill for Difficult-to-Cut Mater

- Page 182 and 183:

End Mill for Non-Ferrous Material R

- Page 184 and 185:

Diamond Coating End Mill 2F DIAMOND

- Page 186 and 187:

Standard End Mill 4F BALL END MILL

- Page 188 and 189:

Standard End Mill 4F END MILL-BRAZE

- Page 190 and 191:

Standard End Mill for Export 2F END

- Page 192 and 193:

Standard End Mill for Export 3F END

- Page 194 and 195:

Standard End Mill for Export 4F END

- Page 196 and 197:

Standard End Mill for Export 2F BAL

- Page 198 and 199:

Standard End Mill for Export 2F END

- Page 200 and 201:

Standard End Mill for Export 3F 45H

- Page 202 and 203:

Standard End Mill for Export 2F BAL

- Page 204 and 205:

Standard End Mill for Export 2F BAL

- Page 206 and 207:

Standard End Mill for Export ROUGHI

- Page 208 and 209:

Technical Data RECOMMENDATION FOR E

- Page 210 and 211: Technical Data RECOMMENDATION FOR E

- Page 212 and 213: Technical Data RECOMMENDATION FOR E

- Page 214 and 215: Technical Data RECOMMENDATION FOR E

- Page 216 and 217: Technical Data RECOMMENDATION FOR E

- Page 218 and 219: Standard Drill SOLID DRILL-LONG End

- Page 220 and 221: Standard Drill POWER DRILL-MEDIUM E

- Page 222 and 223: Standard Drill POWER DRILL-MEDIUM /

- Page 224 and 225: Standard Drill Endmill & Drill 149B

- Page 226 and 227: Standard Drill POWER MAX DRILL-STUB

- Page 228 and 229: Standard Drill Standard Drill POWER

- Page 230 and 231: Standard Drill Standard Drill POWER

- Page 232 and 233: Standard Drill Standard Drill POWER

- Page 234 and 235: Solid Standard Series etc. SOLID CE

- Page 236 and 237: Solid Standard Series etc. HELICAL

- Page 238 and 239: Technical Data Endmill & Drill 177B

- Page 240 and 241: Technical Data Endmill & Drill 181B

- Page 242 and 243: C Chuck Products information C 2 Hy

- Page 244 and 245: Chuck PRODUCTS INFORMATION Chuck PR

- Page 246 and 247: Chuck HYDRAULIC EXPANSION CHUCK Chu

- Page 248 and 249: Chuck HYDRAULIC EXPANSION CHUCK Chu

- Page 250 and 251: Chuck HYDRAULIC EXPANSION CHUCK Chu

- Page 252 and 253: Chuck HYDRAULIC COLLET Chuck SPECIA

- Page 254 and 255: Chuck MILLING CHUCK Chuck MILLING C

- Page 256 and 257: Technical Data Technical Data Techn

- Page 258 and 259: Technical Data Technical Data Techn

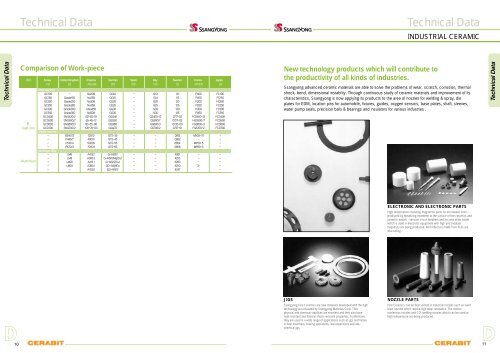

- Page 262 and 263: Technical Data Technical Data INDUS

- Page 264 and 265: Index Turning & Milling SNMG..SG CE

- Page 266 and 267: Memo Memo