14000 SERIES INPAC UNIT â MODEL 14300 - Specific Systems

14000 SERIES INPAC UNIT â MODEL 14300 - Specific Systems

14000 SERIES INPAC UNIT â MODEL 14300 - Specific Systems

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>14000</strong> <strong>SERIES</strong> <strong>INPAC</strong> <strong>UNIT</strong> – <strong>MODEL</strong> <strong>14300</strong><br />

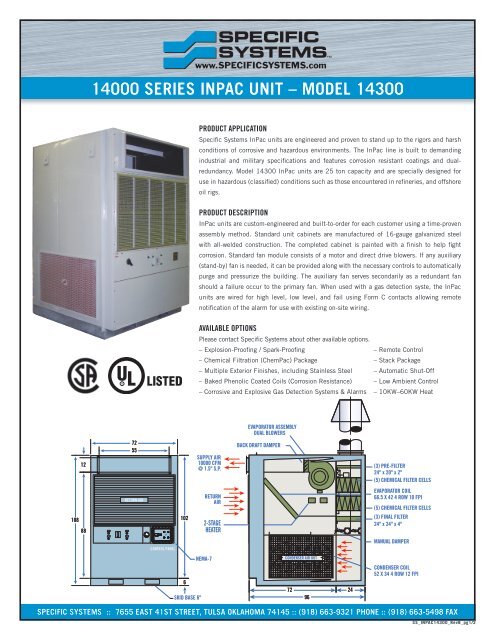

PRODUCT APPLICATION<br />

<strong>Specific</strong> <strong>Systems</strong> InPac units are engineered and proven to stand up to the rigors and harsh<br />

conditions of corrosive and hazardous environments. The InPac line is built to demanding<br />

industrial and military specifications and features corrosion resistant coatings and dualredundancy.<br />

Model <strong>14300</strong> InPac units are 25 ton capacity and are specially designed for<br />

use in hazardous (classified) conditions such as those encountered in refineries, and offshore<br />

oil rigs.<br />

PRODUCT DESCRIPTION<br />

InPac units are custom-engineered and built-to-order for each customer using a time-proven<br />

assembly method. Standard unit cabinets are manufactured of 16-gauge galvanized steel<br />

with all-welded construction. The completed cabinet is painted with a finish to help fight<br />

corrosion. Standard fan module consists of a motor and direct drive blowers. If any auxiliary<br />

(stand-by) fan is needed, it can be provided along with the necessary controls to automatically<br />

purge and pressurize the building. The auxiliary fan serves secondarily as a redundant fan<br />

should a failure occur to the primary fan. When used with a gas detection syste, the InPac<br />

units are wired for high level, low level, and fail using Form C contacts allowing remote<br />

notification of the alarm for use with existing on-site wiring.<br />

AVAILABLE OPTIONS<br />

Please contact <strong>Specific</strong> <strong>Systems</strong> about other available options.<br />

– Explosion-Proofing / Spark-Proofing – Remote Control<br />

– Chemical Filtration (ChemPac) Package – Stack Package<br />

– Multiple Exterior Finishes, including Stainless Steel – Automatic Shut-Off<br />

– Baked Phenolic Coated Coils (Corrosion Resistance) – Low Ambient Control<br />

– Corrosive and Explosive Gas Detection <strong>Systems</strong> & Alarms – 10KW–60KW Heat<br />

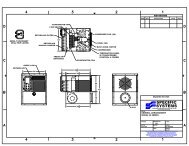

EVAPORATOR ASSEMBLY<br />

DUAL BLOWERS<br />

12<br />

72<br />

55<br />

SUPPLY AIR<br />

10000 CFM<br />

@ 1.5" S.P.<br />

BACK DRAFT DAMPER<br />

(3) PRE-FILTER<br />

24" x 20" x 2"<br />

(5) CHEMICAL FILTER CELLS<br />

108<br />

88<br />

RETURN AIR<br />

102<br />

RETURN<br />

AIR<br />

2-STAGE<br />

HEATER<br />

EVAPORATOR COIL<br />

66.5 X 42 4 ROW 10 FPI<br />

(5) CHEMICAL FILTER CELLS<br />

(3) FINAL FILTER<br />

24" x 24" x 4"<br />

MANUAL DAMPER<br />

CONTROL PANEL<br />

6<br />

SKID BASE 6"<br />

NEMA-7<br />

CONDENSER AIR OUT<br />

72<br />

96<br />

24<br />

CONDENSER COIL<br />

52 X 34 4 ROW 12 FPI<br />

SPECIFIC SYSTEMS :: 7655 EAST 41ST STREET, TULSA OKLAHOMA 74145 :: (918) 663-9321 PHONE :: (918) 663-5498 FAX<br />

SS_<strong>INPAC</strong><strong>14300</strong>_RevB_pg1/2

<strong>14000</strong> <strong>SERIES</strong> <strong>INPAC</strong> <strong>UNIT</strong> – <strong>MODEL</strong> <strong>14300</strong><br />

Electrical <strong>Specific</strong>ations for Standard Units<br />

Electric Power<br />

460/480V<br />

3Φ–60Hz<br />

415V<br />

3Φ–50Hz<br />

380V<br />

3Φ–50Hz<br />

Evaporator Fan Motor FLA 12.4 11.9 13.0 10.3<br />

575V<br />

3Φ–60Hz<br />

Condenser Motor FLA 2.5 (10) 2.4 (9.6) 2.6 (10.4) 2.1 (8.4)<br />

Compressor Motor RLA 25.6 (51.2) 24.6 (49.2) 26.8 (53.7) 21.2 (42.4)<br />

Heat 40KW, Amps (Actual KW) 52.0 (43.2) 59.6 (42.9) 59.4 (39.1) 46.5 (46.3)<br />

Heat 30KW, Amps (Actual KW) 38.9 (32.4) 44.9 (32.3) 41.0 (27.0) 31.1 (31.0)<br />

Heat 20KW, Amps (Actual KW) 26.0 (21.6) 29.8 (21.4) 29.7 (19.5) 23.3 (23.2)<br />

Heat 15KW, Amps (Actual KW) 18.5 (15.4) 22.4 (16.1) 20.6 (13.5) 15.6 (15.5)<br />

Heat 10KW, Amps (Actual KW) 13.0 (10.8) 16.0 (11.5) 14.7 (9.6) —<br />

Total FLA,<br />

Cooling<br />

10–40 KW<br />

Heat<br />

w/o Auxiliary Fan 73.6 76.4 77.1 61.1<br />

w/Auxiliary Fan 86.0 89.2 90.1 71.4<br />

MCA w/o Aux Fan 80.0 76.9 83.7 66.4<br />

MOP w/o Aux Fan 105.6 101.5 110.5 87.6<br />

MCA w/Aux Fan 92.4 88.8 96.7 76.7<br />

MOP w/Aux Fan 118.0 113.4 123.5 97.9<br />

Unit LRA* 202 AMP 194 AMP 211 AMP 167 AMP<br />

Operating Range 432V–506V 342V–418V 373V–456V 517V-600V<br />

LRA - Lock Rotor Amps, defined as evaporator fan, condenser fan, and compressor operating at full load and one compressor at LRA; MCA - Minimum Circuit Ampacity; MOP Maximum Overcurrent Protection; To size circuit breaker, select between MCA value and MOP value<br />

Model CFM @ 0.50 SP BTUH@95° AMB 80 DB / 67 WB<br />

<strong>14300</strong> 10000 @ 60 Hz<br />

8300 @ 50 Hz<br />

300,000 NOM<br />

250,000 NOM<br />

Refrigeration Charge<br />

Std. 28 lbs ea.<br />

w/Receivers 68 lbs ea.<br />

Actual Capacity @ 60 Hz, 80 DB / 67 WB Entering Evap. Coil<br />

Ambient Condition Sensible Capacity Total Capacity<br />

75°F (24°C) 256,020 BTUH 363,260 BTUH<br />

85°F (29°C) 249,090 BTUH 346,360 BTUH<br />

95°F (35°C) 242,150 BTUH 329,300 BTUH<br />

105°F (41°C) 232,310 BTUH 302,700 BTUH<br />

115°F (46°C) 224,880 BTUH 283,600 BTUH<br />

SPECIFIC SYSTEMS :: 7655 EAST 41ST STREET, TULSA OKLAHOMA 74145 :: (918) 663-9321 PHONE :: (918) 663-5498 FAX<br />

SS_<strong>INPAC</strong><strong>14300</strong>_RevB_pg2/2