AirPak - Specific Systems

AirPak - Specific Systems

AirPak - Specific Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5 – 20 Ton CapacityIndustrial and General PurposePackaged Air Conditioners

easons to choose <strong>Specific</strong> <strong>Systems</strong>Durability.<strong>Specific</strong> <strong>Systems</strong> is committed to building the best environmental control systems in the industry.Our engineering expertise and experience gained over 35 years in business enables us to designand build systems that will perform reliably in virtually any application. You can always depend on<strong>Specific</strong> <strong>Systems</strong>’ equipment for durability and performance.Engineering Excellence.At <strong>Specific</strong> <strong>Systems</strong>, our teams of engineers stand ready to work with you in evaluating and designingan environmental system suited to your specific application. We assign a lead engineer to overseeyour project and serve as liaison between you and our specialists. It is this person’s responsibilityto work one-on-one with you to develop the most suitable product for your application. Ourengineering capabilities are something you can always depend on at <strong>Specific</strong> <strong>Systems</strong>.Minimal Down Time.With <strong>Specific</strong> <strong>Systems</strong>’ standard modular environmental units, you can practically eliminate costlydown time. Our engineers have designed a modular product line that offers dual redundancy, fast,easy, on-site repair, and simplified parts replacement. You can depend on <strong>Specific</strong> <strong>Systems</strong> modularconcept to save substantial time and money.Flexibility.<strong>Specific</strong> <strong>Systems</strong> is committed to meeting your needs. Our standard modular product line can beconfigured in horizontal, vertical, slim line or split configurations and the same standard modules areused in each configuration. We offer complete capabilities for the manufacture of customized units,designed for your particular application. Whatever your requirements, you can depend on <strong>Specific</strong><strong>Systems</strong> to develop the best system for your unique situation.Quality.<strong>Specific</strong> <strong>Systems</strong> takes pride in manufacturing top quality environmental control equipment. Fromthe initial stages of planning, throughout production, and into the final stages of assembly, ouremployees maintain a high standard of quality control. At <strong>Specific</strong> <strong>Systems</strong>, you can depend on ourquality every step of the way.Service.Our goal is to work with you in a timely, professional manner to get the results you need. We’ll alwaysbe available to answer your questions and provide you with the necessary technical information. Ourtechnicians will monitor the performance of your system following installation to ensure maximumoperating performance. You can depend on <strong>Specific</strong> <strong>Systems</strong> service before, during and after theinstallation of your system.2 <strong>Specific</strong> <strong>Systems</strong> – 7655 East 41st Street, Tulsa, OK 74145

4 ApplicationsStandard Features68Commitment,Reliability, andExcellenceElectrical & Capacity DataSince 1974, <strong>Specific</strong> <strong>Systems</strong>, LTD.has held strong to a commitment17 HVAC Request Formdepend on <strong>Specific</strong> <strong>Systems</strong> to18 Nomenclature perform to full capacity.8 APK-60 (5 ton)of reliability, service and design9 APK-90 (7.5 ton)excellence in special purposeenvironmental air-conditioning,10 APK-120 (10 ton)heating, ventilating and pressurization11 APK-150 (12.5 ton)systems. This has been accomplishedthrough proven engineering and12 APK-180 (15 ton)design principles, combined with adedication to continued improvements13 APK-240 (20 ton)in our standard modular products.With this strong engineering focus,14 Optional Features<strong>Specific</strong> <strong>Systems</strong> leads the industryin modular environmental control16 Exterior Dimensionssystem technology. You can always(918) 663-9321 – (918) 663-5498 fax – www.<strong>Specific</strong><strong>Systems</strong>.com 3

Standard Features:• To-the-wall mounting• Redundant refrigeration circuits• 16-ga powdercoated galvanizedsteel cabinets• Expertly loomed electrical connections• Capacities from 5 to 20 tons• UL 508A electrical panels• Freezestats• Hot gas bypass• Crankcase Heaters• CSA / UL ApprovedOptional Features and Available Options:• Reverse air flow• Full indoor serviceability• Vertical discharge blowers• Heating elements• Multiplexor: Panel capable of operatingup to four separate units• All copper coils• Custom color powdercoating• Stainless steel cabinet• Low ambient controls• Corrosion-resistant coils• Economizer• Additional filtration• Condenser air deflector• DualPac 2-unit V plenumAll-in-one.<strong>Specific</strong> <strong>Systems</strong> engineered the <strong>AirPak</strong> units to be easy to installand operate. To ensure this, all <strong>AirPak</strong> units feature standard to-thewallmounting. This requires only two small cutouts to be made orconstructed into the mounting wall, minimizing the chances for airleakage. The supplied Myers® hubs on the sides of each unit allow quickconnection to existing wiring and help limit electrical entry points intothe building.All standard <strong>AirPak</strong> cabinets are manufactured using 16-gaugegalvanized steel that has been powdercoated for extra corrosionresistance. The same powdercoating is used on the internal 12-gaugesteel components.Unlike competing products which employ ‘birds nest wiring’, <strong>Specific</strong><strong>Systems</strong>' employees take great care to precisely loom and label eachelectrical connection for ease of identification during maintenance orinstallation. The electrical panels are UL recognized under standard508A and are CSA approved.Also standard on all <strong>AirPak</strong> units are freezestats and crankcase heatersfor the compressors. Freezestats help prevent coils from freezing over.Often, this is caused by decreased airflow (from dust, debris, etc) or froma low refrigerant charge. Crankcase heaters help keep the refrigerantfrom condensing too early and adsorbing oil. Adsorption such as thiscauses the oil to leave the compressor, and can cause gradual or instantfailure of the compressor.<strong>Systems</strong> range in capacities from 5 to 20 tons (60,000 to 240,000 BTUH),and have many available options and accessories.Built-in Backup.The most distinguishing factor of the <strong>AirPak</strong> units, when comparedto competing systems, is the dual refrigeration circuit. This redundantcircuit allows <strong>Specific</strong> <strong>Systems</strong>' units to provide our clients with minimaldowntime, thereby increasing profits through fewer repairs.6 <strong>Specific</strong> <strong>Systems</strong> – 7655 East 41st Street, Tulsa, OK 74145

Optional Features and Accessories.A commonly ordered option is heating, availabile from 10KW to40KW. Additionally, coils can be coated with several types of corrosionprotection including Esgard, Heresite, Thermoguard, Electrofin E-Coat,and Technicoat.Another popular option is the alternating panel, or multiplexor. ThisNEMA 4 rated panel is capable of controlling up to four separate unitsand alternating the load between the individual units. See pg 15.Along with freezestats and crankcase heaters, <strong>AirPak</strong>s are available withLow Ambient Controls. This package includes a receiver and a headpressure control valve (see notes at right).To further prevent corrosion, all copper coils are optional, as is astainless steel cabinet (304 or 316). Reverse air flow (drawing air throughthe evaporator instead of pushing it through) is especially useful in dustyapplications. These options give substantial protection when used in aharsh environment. Additional filtration is available via an addon unitsuch as a sand or higher grade paper filter. Filters for <strong>AirPak</strong> units may beutilized to improve indoor air quality in buildings occupied by personnel.If the unit is designed to blow into existing ductwork, <strong>AirPak</strong> units canbe engineered with ductmate flanges, vertical discharge blowers, andeven plenums sized to meet the specifications of your application.Head Pressure Control Valveand Receiver:Operate to maintain minimumcompressor discharge pressure atoutdoor temperatures down to-10 °F. (R-407c: 180 psi; R-410A:295 psi). This is accomplished bymetering the liquid refrigerant storedin the receiver into the condenser coilThis effectively reduces the operatingsize of the coil, which raises thedischarge pressure, allowing thesystem to operate at design capacityeven at low ambient conditions.(918) 663-9321 – (918) 663-5498 fax – www.<strong>Specific</strong><strong>Systems</strong>.com 7

5 Ton(60,000 BTUH)Electric Power 230/240V1Φ–60Hz200V1Φ–50Hz460/4803Φ–60Hz230/2403Φ–60Hz415V3Φ–50Hz380V3Φ-50Hz200V3Φ–50HzEvaporator Fan Motor FLA 8.7 8.5 2.5 5.0 2.3 2.6 4.9 2.1Condensor Motor FLA 10.7 10.6 3.1 6.2 2.8 3.2 6.0 2.6575V3Φ–60HzCompressor Motor RLA 18.8 (37.6) 22.5 (45.0) 5.4 (10.8) 10.8 (21.6) 4.9 (9.8) 5.6 (11.2) 13.0 (26.0) 4.5 (9.0)Heat 20KW, Amps (Actual KW) 92.2 (21.2) 95.5 (19.1) 26.0 (21.6) 53.2 (21.2) 29.8 (21.4) 29.7 (19.5) 55.0 (19.1) 23.3 (23.2)Heat 15KW, Amps (Actual KW) 65.2 (15.0) 68.5 (13.7) 18.5 (15.4) 37.7 (15.0) 22.4 (16.1) 20.6 (13.5) 39.5 (13.7) 15.6 (15.5)Heat 10KW, Amps (Actual KW) 46.1 (10.6) 40.0 (8.0) 13.0 (10.8) 26.6 (10.6) 16.0 (11.5) 14.7 (9.6) 23.1 (8.0) —Total Cooling FLA 57.0 64.1 16.4 32.8 14.9 17.0 36.9 13.720 KW Heat15 KW Heat10 KW HeatMCA — — 35.6 72.8 40.1 40.4 74.9 31.8MOP — — 61.0 124.7 69.4 69.4 128.7 54.5MCA — — 26.3 53.4 30.9 29.0 55.5 22.1MOP — — 31.8 89.8 52.7 49.0 93.8 37.2MCA 68.5 69.7 19.4 39.5 22.9 21.6 40.1 —MOP 112.4 92.2 31.8 64.9 38.3 35.7 53.1 —Unit LRA* 151 177 43 87 39 45 102 36Operating Range 216V–253V 180V–220V 432V–506V 216V–253V 373V–456V 342V–418V 180V–220V 517V–600VActual Capacity @ 60 Hz, 80° DB / 67° WB Entering Evaporator CoilAmbient Condition Sensible Capacity Total Capacity75°F (24°C) 45,850 BTUH 71,884 BTUH85°F (29°C) 44,402 BTUH 68,380 BTUH95°F (35°C) 40,632 BTUH 59,772 BTUH110°F (43°C) 38,376 BTUH 54,268 BTUH120°F (49°C) 36,764 BTUH 50,268 BTUHCFM @ ESP (Wet Coil, 60Hz)Unit Dimensions0.10 0.20 0.30 Filter Size (#) Width Depth Height Weight1720 1650 1600 18 × 20 × 2 (1) 42" 28" 85" 820 lbs16 × 20 × 2 (1) Full dimensions shown on page 168 <strong>Specific</strong> <strong>Systems</strong> – 7655 East 41st Street, Tulsa, OK 74145

7.5 Ton(90,000 BTUH)Electric Power 230/240V1Φ–60Hz200V1Φ–50Hz460/4803Φ–60Hz230/2403Φ–60Hz415V3Φ–50Hz380V3Φ-50Hz200V3Φ–50HzEvaporator Fan Motor FLA 12.8 15.4 3.7 7.4 3.6 3.9 8.9 3.0Condensor Motor FLA 12.1 14.5 3.5 7.0 3.4 3.7 8.4 2.8575V3Φ–60HzCompressor Motor RLA 28.4 (56.8) 34.1 (68.2) 8.2 (16.4) 16.4 (32.8) 7.9 (15.8) 8.6 (17.2) 19.7 (39.4) 6.6 (13.2)Heat 20KW, Amps (Actual KW) 92.2 (21.2) 95.5 (19.1) 26.0 (21.6) 53.2 (21.2) 29.8 (21.4) 29.7 (19.5) 55.0 (19.1) 23.3 (23.2)Heat 15KW, Amps (Actual KW) 65.2 (15.0) 68.5 (13.7) 18.5 (15.4) 37.7 (15.0) 22.4 (16.1) 20.6 (13.5) 39.5 (13.7) 15.6 (15.5)Heat 10KW, Amps (Actual KW) 46.1 (10.6) 40.0 (8.0) 13.0 (10.8) 26.6 (10.6) 16.0 (11.5) 14.7 (9.6) 23.1 (8.0) —Total Cooling FLA 81.7 98.1 23.6 47.2 22.8 24.8 56.7 19.020 KW Heat15 KW Heat10 KW HeatMCA 131.3 138.6 37.1 75.8 41.8 42.0 79.9 32.9MOP 220.3 230.3 62.2 127.1 70.7 70.7 132.6 55.4MCA 97.5 106.6 27.8 56.4 32.5 30.6 61.6 23.3MOP 159.5 140.7 45.3 92.2 54.0 50.3 81.3 38.1MCA 88.8 106.6 25.7 51.3 24.8 27.0 61.6 20.7MOP 117.2 140.7 33.9 67.7 32.7 35.6 81.3 27.3Unit LRA* 224 269 65 130 62 68 155 52Operating Range 216V–253V 180V–220V 432V–506V 216V–253V 373V–456V 342V–418V 180V–220V 517V–600VActual Capacity @ 60 Hz, 80° DB / 67° WB Entering Evaporator CoilAmbient Condition Sensible Capacity Total Capacity75°F (24°C) 86,454 BTUH 113,804 BTUH85°F (29°C) 84,184 BTUH 108,040 BTUH95°F (35°C) 82,506 BTUH 102,348 BTUH110°F (43°C) 78,840 BTUH 93,264 BTUH120°F (49°C) 68,380 BTUH 86,138 BTUHCFM @ ESP (Wet Coil, 60Hz)Unit Dimensions0.10 0.20 0.30 Filter Size (#) Width Depth Height Weight3900 3745 3625 24 × 20 × 2 (1) 48" 28" 94" 1000 lbs20 × 20 × 2 (1) Full dimensions shown on page 16Shown with Technicoat coil coating and Carboline coated condenser section(918) 663-9321 – (918) 663-5498 fax – www.<strong>Specific</strong><strong>Systems</strong>.com 9

10 Ton120,000 BTUH)Electric Power 230/240V1Φ–60Hz200V1Φ–50Hz460/4803Φ–60Hz230/2403Φ–60Hz415V3Φ–50Hz380V3Φ-50Hz200V3Φ–50HzEvaporator Fan Motor FLA 12.8 15.4 3.7 7.4 3.6 3.9 8.9 3.0Condensor Motor FLA 12.1 14.5 3.5 7.0 3.4 3.7 8.4 2.8575V3Φ–60HzCompressor Motor RLA 33.9 (67.8) 40.7 (81.4) 9.8 (19.6) 19.6 (39.2) 9.4 (18.8) 10.3 (20.6) 23.5 (47.0) 7.8 (15.6)Heat 20KW, Amps (Actual KW) 92.2 (21.2) 95.5 (19.1) 26.0 (21.6) 53.2 (21.2) 29.8 (21.4) 29.7 (19.5) 55.0 (19.1) 23.3 (23.2)Heat 15KW, Amps (Actual KW) 65.2 (15.0) 68.5 (13.7) 18.5 (15.4) 37.7 (15.0) 22.4 (16.1) 20.6 (13.5) 39.5 (13.7) 15.6 (15.5)Heat 10KW, Amps (Actual KW) 46.1 (10.6) 40.0 (8.0) 13.0 (10.8) 26.6 (10.6) 16.0 (11.5) 14.7 (9.6) 23.1 (8.0) —Total Cooling FLA 92.7 111.3 26.8 53.6 25.8 28.2 64.3 21.420 KW Heat10–15 KW HeatMCA 131.3 138.6 37.1 75.8 41.8 42.0 79.9 32.9MOP 220.3 230.3 62.2 119.7 70.7 70.7 132.6 55.4MCA 101.2 121.5 29.3 58.5 28.2 30.8 70.2 23.4MOP 135.1 162.2 39.1 78.1 37.6 41.1 93.7 31.2Unit LRA* 262 315 76 152 73 80 182 61Operating Range 216V–253V 180V–220V 432V–506V 216V–253V 373V–456V 342V–418V 180V–220V 517V–60 0VActual Capacity @ 60 Hz, 80° DB / 67° WB Entering Evaporator CoilAmbient Condition Sensible Capacity Total Capacity75°F (24°C) 97,290 BTUH 143,048 BTUH85°F (29°C) 94,344 BTUH 135,968 BTUH95°F (35°C) 89,372 BTUH 122,776 BTUH110°F (43°C) 84,702 BTUH 111,806 BTUH120°F (49°C) 81,750 BTUH 104,278 BTUHCFM @ ESP (Wet Coil, 60Hz)Unit Dimensions0.10 0.20 0.30 Filter Size (#) Width Depth Height Weight3900 3745 3625 24 × 20 × 2 (1) 48" 28" 94" 1000 lbs20 × 20 × 2 (1) Full dimensions shown on page 1610 <strong>Specific</strong> <strong>Systems</strong> – 7655 East 41st Street, Tulsa, OK 74145

12.5 Ton(150,000 BTUH)Electric Power 460/4803Φ–60Hz230/2403Φ–60Hz415V3Φ–50Hz380V3Φ-50Hz200V3Φ–50Hz575V3Φ–60HzEvaporator Fan Motor FLA 2.0 (4.0) 4.0 (8.0) 1.9 (3.8) 2.1 (4.2) 4.8 (9.6) 1.6 (3.2)Condensor Motor FLA 3.5 7.0 3.4 3.7 8.4 2.8Compressor Motor RLA 15.7 (31.4) 31.4 (62.8) 15.1 (30.2) 16.5 (33.0) 37.7 (75.4) 12.6 (25.2)Heat 20KW, Amps (Actual KW) 26.0 (21.6) 53.2 (21.2) 29.8 (21.4) 29.7 (19.5) 55.0 (19.1) 23.3 (23.2)Heat 15KW, Amps (Actual KW) 18.5 (15.4) 37.7 (15.0) 22.4 (16.1) 20.6 (13.5) 39.5 (13.7) 15.6 (15.5)Heat 10KW, Amps (Actual KW) 13.0 (10.8) 26.6 (10.6) 16.0 (11.5) 14.7 (9.6) 23.1 (8.0) —Total Cooling FLA 38.9 77.8 37.4 40.9 93.4 21.710–20 KW HeatMCA 42.8 85.7 41.2 45.0 102.8 33.1MOP 58.2 117.1 56.3 61.5 140.5 47.0Unit LRA* 117 235 113 123 282 61Operating Range 216V–253V 180V–220V 432V–506V 216V–253V 373V–456V 517V–600VActual Capacity @ 60 Hz, 80° DB / 67° WB Entering Evaporator CoilAmbient Condition Sensible Capacity Total Capacity75°F (24°C) 123,058 BTUH 185,162 BTUH85°F (29°C) 119,484 BTUH 178,630 BTUH95°F (35°C) 114,934 BTUH 169,660 BTUH110°F (43°C) 109,656 BTUH 155,860 BTUH120°F (49°C) 104,910 BTUH 145,352 BTUHCFM @ ESP (Wet Coil, 60Hz)Unit Dimensions0.10 0.20 0.30 Filter Size (#) Width Depth Height Weight5200 5000 4825 24 × 20 × 2 (1) 48" 28" 94" 1100 lbs20 × 20 × 2 (1) Full dimensions shown on page 16(918) 663-9321 – (918) 663-5498 fax – www.<strong>Specific</strong><strong>Systems</strong>.com 11

15 Ton(180,000 BTUH)Electric Power 460/4803ø–60Hz230/2403ø–60Hz415V3Φ–50Hz380V3Φ-50Hz200V3Φ–50HzEvaporator Fan Motor FLA 8.3 16.6 8.0 8.7 19.9 6.9575V3ø–60HzCondensor Motor FLA 3.5 (7.0) 7.0 (14.0) 3.4 (6.8) 3.7 (7.4) 8.4 (16.8) 2.8 (5.6)Compressor Motor RLA 15.7 (31.4) 31.4 (62.8) 15.1 (30.2) 16.5 (33.0) 37.7 (75.4) 12.6 (25.2)Heat 40KW, Amps (Actual KW) 52.0 (43.2) 104.4 (41.6) 59.6 (42.9) 59.4 (39.1) 120.8 (41.7) 46.5 (46.3)Heat 30KW, Amps (Actual KW) 38.9 (32.4) 78.3 (31.2) 44.9 (32.3) 41.0 (27.0) 90.8 (31.4) 31.1 (31.0)Heat 20KW, Amps (Actual KW) 26.0 (21.6) 52.2 (20.8) 29.8 (21.4) 29.7 (19.5) 60.4 (20.8) 23.3 (23.2)Heat 15KW, Amps (Actual KW) 18.5 (15.4) 37.7 (15.0) 22.4 (16.1) 20.6 (13.5) 39.5 (13.7) 15.6 (15.5)Heat 10KW, Amps (Actual KW) 13.0 (10.8) 26.6 (10.6) 16.0 (11.5) 14.7 (9.6) 23.1 (8.0) —Total Cooling FLA 46.7 93.4 45.0 49.1 112.1 37.840 KW Heat30 KW Heat10–20 KW HeatMCA 60.3 — 84.5 85.1 — 66.7MOP 125.3 — 142.1 142.4 — 141.5MCA 47.2 118.6 66.1 62.1 138.4 47.4MOP 95.8 192.8 117.6 101.0 224.2 16.9MCA 50.6 101.2 48.8 53.2 121.5 40.9MOP 66.3 132.7 63.9 69.7 159.2 53.5Unit LRA* 125 250 121 132 301 100Operating Range 216V–253V 180V–220V 432V–506V 216V–253V 373V–456V 517V–600VActual Capacity @ 60 Hz, 80° DB / 67° WB Entering Evaporator CoilAmbient Condition Sensible Capacity Total Capacity75°F (24°C) 133,164 BTUH 200,408 BTUH85°F (29°C) 129,220 BTUH 191,076 BTUH95°F (35°C) 115,376 BTUH 170,840 BTUH110°F (43°C) 110,132 BTUH 157,812 BTUH120°F (49°C) 106,092 BTUH 148.552 BTUHShown in ANSI dark grey with reverse air flowCFM @ ESP (Wet Coil, 60Hz)Unit Dimensions0.10 0.20 0.30 Filter Size (#) Width Depth Height Weight5700 5475 5300 24 × 20 × 2 (1) 60" 37 7 ⁄ 8" 94" 1150 lbs16 × 20 × 2 (2) Full dimensions shown on page 1612 <strong>Specific</strong> <strong>Systems</strong> – 7655 East 41st Street, Tulsa, OK 74145

20 Ton(240,000 BTUH)Electric Power 460/4803ø–60Hz415V3Φ–50Hz380V3Φ-50HzEvaporator Fan Motor FLA 8.3 8.0 8.7 6.9575V3ø–60HzCondensor Motor FLA 3.5 (7.0) 3.4 (6.8) 3.7 (7.4) 2.8 (5.6)Compressor Motor RLA 16.3 (32.6) 15.6 (31.2) 17.1 (34.2) 13.5 (27.0)Heat 40KW, Amps (Actual KW) 52.0 (43.2) 59.6 (42.9) 59.4 (39.1) 46.5 (46.3)Heat 30KW, Amps (Actual KW) 38.9 (32.4) 44.9 (32.3) 41.0 (27.0) 31.1 (31.0)Heat 20KW, Amps (Actual KW) 26.0 (21.6) 29.8 (21.4) 29.7 (19.5) 23.3 (23.2)Heat 15KW, Amps (Actual KW) 18.5 (15.4) 22.4 (16.1) 20.6 (13.5) 15.6 (15.5)Heat 10KW, Amps (Actual KW) 13.0 (10.8) 16.0 (11.5) 14.7 (9.6) —Total Cooling FLA 47.9 46 50.3 39.540 KW Heat30 KW Heat10–20 KW HeatMCA 60.3 84.5 85.1 66.7MOP 125.3 142.1 142.4 111.5MCA 52.0 66.1 62.1 47.4MOP 68.3 117.6 101.0 76.9MCA 52.0 49.9 54.6 42.9MOP 68.3 65.5 71.7 56.4Unit LRA* 129 124 136 107Operating Range 432V–506V 342V–418V 373V–456V 517V–600VActual Capacity @ 60 Hz, 80° DB / 67° WB Entering Evaporator CoilAmbient Condition Sensible Capacity Total Capacity75°F (24°C) 167,152 BTUH 264,600 BTUH85°F (29°C) 161,680 BTUH 251,824 BTUH95°F (35°C) 155,814 BTUH 238,962 BTUH110°F (43°C) 147,826 BTUH 219,090 BTUH120°F (49°C) 141,380 BTUH 204,718 BTUHCFM @ ESP (Wet Coil, 60Hz)Unit Dimensions0.10 0.20 0.30 Filter Size (#) Width Depth Height Weight5700 5475 5300 24 × 20 × 2 (2) 72" 42" 94" 1275 lbs20 × 20 × 2 (1) Full dimensions shown on page 16(918) 663-9321 – (918) 663-5498 fax – www.<strong>Specific</strong><strong>Systems</strong>.com 13

• Multiplexor• Dehumidification (Only avail. w/heat)• Low Ambient Controls• Water-Cooled Condenser• Chilled-Water Evaporator• Economizer• High Pressure Alarm• Heat• R-410A, R-134A, or R-407C Refrigerant• Custom Color Cabinet• DualPac Two Unit PlenumEasily CustomizedLike all <strong>Specific</strong> <strong>Systems</strong> units, <strong>AirPak</strong> units are modular in construction,and can be easily adapted to suit the needs of individual app;lications.Reverse air flow is a common option, and by reordering the modulesinside the base cabinet, this is a modification that is easily adaptedwithout extending the lead time of your unit. Call us to discover the bestoptions for your <strong>AirPak</strong> system.For buildings on raised platforms or piers, we offer full indoorserviceability. This option gives service technicians a through-the-wallmounting that can be fully serviced from inside, eliminating the needfor scaffolding or a man lift, thereby ncreasing safety and decreasingmaintenance downtime.Applications situated in cooler climates will certainly benefit from theheater option. With several heat capacities available (depending on unitsize and customer specification), <strong>Specific</strong> <strong>Systems</strong>' heater option willimprove the comfort level of personnel and help maintain a set humidityin the conditioned area. Additionally, a low ambient option is availablethat includes receivers and head pressure controls, along with thestandard crankcase heaters.Corrosive environments could benefit from one of the popularcoil coating options. With choices including Esgard, Technicoat, LuvataE-Coat, Heresite, or Thermoguard, <strong>Specific</strong> <strong>Systems</strong> offers corrosionprotection that is an exact fit for your application.Powder coating is standard on all <strong>Specific</strong> <strong>Systems</strong> units, and thestandard colors are shown below. Custom colors are also available atyour request.WHITE LIGHT GREY DARK GREY DESERT TAN CUSTOM COLOR14 <strong>Specific</strong> <strong>Systems</strong> – 7655 East 41st Street, Tulsa, OK 74145

Alternating Control PanelThe Multiplexor control panel is an option provided for applicationsthat require multiple systems to be installed in a conditioned area. Thisprovides an additional redundancy, often desired for unattended sites,and provides several standard services.The multiplexor is a microprocessor-based PLC control panel forcontrolling multiple <strong>Specific</strong> <strong>Systems</strong> units. If a failure of the main unitoccurs (determined through use of multiple sensors inside each unit),the multiplexor automatically energizes another system to keep thearea conditioned and provides visible local alarms (and dry contacts forremote alarms) to notify personnel of the failure. Override of the mainunit can also be caused by a power-failure of the main unit or a high/low temperature alarm. All multiplexors include the ability to manuallyoverride and lockout main unit. Multiplexors are enclosed in hinged6" deep NEMA 4 enclosures from 16"× 14" to 20" × 24". These panelsare shipped ready for remote mounting and remote monitoring fromanother location.As mentioned on page six, <strong>Specific</strong> <strong>Systems</strong><strong>AirPak</strong> units are available with many additionaloptions. The most common are listed below:• Economizer – As the ambient air temperaturefalls, so falls the need for the compressors towork as much. The economizer option addsan automatic damper with controls to allowcool outside air to condition the inside space.This adds what is termed 'free cooling' to theunit, extends the life of the compressors, andconserves power – thereby saving money.• Vertical discharge blowers – For applicationswith existing overhead ductwork, <strong>AirPak</strong> unitscan be ordered with vertical discharge supplyair fans that direct the air into a plenum thatcan then be tied into the ductwork.• Auto-sequencing between systems, based on 24 hr timer• Manual selection of any HVAC system in the circuit• Automatic dual-unit operation – High or low temperature condition• High temperature alarm – Form C dry contacts• Carboline coated condenser section – For theultimate in corrosion protection, fan blades andlabels are masked off, and the entire condensersection is sprayed with a heavy coating ofCarboline. This coating is extremely resistantto the chemicals in manufacturing plants andrefineries, and reduces maintenance and repairson the units.(918) 663-9321 – (918) 663-5498 fax – www.<strong>Specific</strong><strong>Systems</strong>.com 15

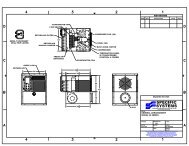

AB2" flashing on 3 sidesDSUPPLYECRETURNG F JDHModel #AUnit WidthDimensional data for basic model, inches (cm). Some external options may alter sizes.BCDEFGSupply/Return Supply Air Return Air Supply, DistUnit Depth Unit Height Air Width HeightWidth from bottomHReturn, Distfrom bottomJCondenser GrillHeightAPK-60 42" (106.68) 28" (71.12) 85" (215.90) 30" (76.20) 10" (25.40) 16" (40.64) 72 7 ⁄8" (185.10) 27" (106.68) 30"APK-90 48" (121.92) 28" (71.12) 94" (238.76) 43" (109.22) 16" (40.64) 22" (55.88) 76½" (194.31) 28½" (121.92) 42½"APK-120 48" (121.92) 28" (71.12) 94" (238.76) 43" (109.22) 16" (40.64) 22" (55.88) 76½" (194.31) 28½" (121.92) 42½"APK-150 60" (152.40) 37 7 ⁄ 8" (96.20) 94" (238.76) 55" (139.70) 16" (40.64) 22" (55.88) 76½" (194.31) 28½" (152.40) 42½"APK-180 72" (182.88) 42" (106.68) 94" (238.76) 55" (139.70) 16" (40.64) 22" (55.88) 76½" (194.31) 26½" (182.88) 32"APK-240 72" (182.88) 42" (106.68) 94" (238.76) 55" (139.70) 16" (40.64) 22" (55.88) 76½" (194.31) 26½" (182.88) 32"16 <strong>Specific</strong> <strong>Systems</strong> – 7655 East 41st Street, Tulsa, OK 74145

HVAC Request FormDate: _____________________________ Project: _______________________________To: _____________________________ Contractor: _______________________________Attn: _____________________________ Engineer: _______________________________Reference: _____________________________ Prepared by: _______________________________Based on the information below, we recommend the following:Quantity: __________ Capacity (Tons): __________Model: __________ Heating: __________Building DescriptionBuilding Size:__________ H × __________ W × __________ LInsulation Factor:__________ Roof __________ Walls __________ FloorEquipment Heat Load, Sensible:__________ BTU/KW/HrEquipment Heat Load, Latent:__________ BTULighting Heat Load:__________ BTU/KW/HrNumber of Building Personnel:__________Location of Building:________________________________________Avg. Design Temp, Outside: DB/WB: __________ Winter; __________ SummerAvg. Design Humidity: __________ Winter; __________ SummerAvg. Design Temp, Inside: DB/WB: __________ Winter; __________ SummerVoltage: __________ V __________ PhaseNumber of Air Changes: __________, __________ Building Pressure RequirementNotes:________________________________________________________________________________________________________________________________________________________Building SketchThis form can be faxed to <strong>Specific</strong> <strong>Systems</strong> at (918) 663-5498 or folded and mailed. An electronic version is also available for download on our web site.7355 East 41st Street, Tulsa, OK 74145-3229 :: (918) 663-9321 – 1-800-848-5126 – www.<strong>Specific</strong><strong>Systems</strong>.com

Product NomenclatureThe nomenclature shown on the opposite page is the <strong>AirPak</strong> only sectionof our entire product line. Using a common nomenclature allows usflexibility in design and ease of recall when service parts are ordered.Please call us with any questions regarding the <strong>AirPak</strong> product line, orany of our other products, including our industrial and explosion proof,mobile, or military products.18 <strong>Specific</strong> <strong>Systems</strong> – 7655 East 41st Street, Tulsa, OK 74145

APK 240 – A – WHD – X – G – B – 15 – TB1 – G61 – R410A – N – N – N – L1 2 3 4 5 6 7 8 9 10 11 12 13 14123456CAPACITY60 – 5 ton90 – 7.5 ton120 – 10 ton150 – 12.5 ton180 – 15 ton240 – 20 tonAPK designates <strong>AirPak</strong>VOLT / PHASE / HzA – 230–240 / 1 / 60B – 230–240 / 3 / 60C – 460–480 / 3 / 60E – 415–380 / 3 / 50F – 200 / 1 / 50G – 200 / 3 / 50H – 575 / 3 / 60K – 440 / 3 / 50CONFIGURATIONWHD – Wall Mount, Horiz DischargeWUB – Wall Mount, Up BlastEXTRA OPTIONX – Option Not AvailableCABINET AND INTERIOR CONST.G – Standard GalvanizedS – Stainless Steel (304)S1 – Stainless Steel (316)CIRCUIT BREAKERX – No Circuit BreakerB – Circuit Breaker789KW HEAT00 – No Heat10 – 10 KW15 – 15 KW20 – 20 KW40 – 40 KWCOILSX – No CoatingBB – Blygold : Both CoilsBC – Blygold : CondenserCoilBE – Blygold: Evaporator CoilC – CopperEB – Esgard : Both CoilsEC – Esgard : Condenser CoilEE – Esgard : Evaporator CoilGB – Thermoguard : Both CoilsGC – Thermoguard : Condenser CoilGE – Thermoguard : Evaporator CoilHB – Heresite : Both CoilsHC – Heresite : Condenser CoilHE – Heresite : Evaporator CoilIB – Iridite : Both CoilsIC – Iridite : Condenser CoilIE – Iridite : Evaporator CoilLB – E-Coat : Both CoilsLC – E-Coat : CondenserCoilLE – E-Coat : Evaporator CoilTB – Technicoat : Both CoilsTC – Technicoat : Condenser CoilTE – Technicoat : Evaporator CoilCOLOR OPTIONW – White : Powder CoatG61 – Light Grey : Powder CoatG70 – Dark Grey : Powder CoatT – Desert Tan : Powder CoatN – No PaintS – SPECIAL OPTIONNote : Stainless steel cabinets are notpainted as standard1011121314REFRIGERANTR134AR407CR410AEXTRA OPTIONN – Option Not AvailableEXTRA OPTIONN – Option Not AvailableEXTRA OPTIONN – Option Not AvailableOPTIONSX – No OptionsA – Alternating Panelwith Dual UnitTRI – Triplexing PanelQ – Quadruplexor PanelD – Dehumidification(Must Have Heat)L – Low Ambient(Receivers and HeadPressure Control)W – Water-CooledCondenserCHW – Chilled WaterEvaporatorE – EconomizerHA – High TemperatureAlarmNote: Other electrical optionsto be detailed underSpecial Options(918) 663-9321 – (918) 663-5498 fax – www.<strong>Specific</strong><strong>Systems</strong>.com 19

CustomSeries<strong>Specific</strong> <strong>Systems</strong> Modular Technology isNumber OneSince 1974, <strong>Specific</strong> <strong>Systems</strong>, ltd. has held strong to a commitment of reliability,service, and design excellence in special purpose environmental air conditioning,heating, ventilating, and pressurization systems. This has been accomplishedthrough proven engineering and design principles, combined with a dedicationto continued improvements in our standard modular products. With this strongengineering focus, <strong>Specific</strong> <strong>Systems</strong> leads the industry in modular environmentalcontrol technology.Through the years, <strong>Specific</strong> <strong>Systems</strong> has designed and manufactured a full rangeof specialized products, including custom environmental control packages,filtration systems, massive mobile cooling centers, and other HVAC systems. Ourcustom engineering services are available on a contract basis for special designand development programs.7655 East 41st St., Tulsa, OK 74145 :: (918) 663-9321 :: (918) 663-5498 fax<strong>AirPak</strong>The <strong>AirPak</strong> line of wall-mounted A/C unitsare available in capacities from 5–20tons. The units are designed for use inheavy-duty commercial and industrialapplications such as telecommunications,instrumentation, control, and electricalpowerhouse shelter assemblies.MacOur Military product line, available inMilSpec configuration with capacitiesfrom 1–10 tons. The Mac series is oftenchosen for use in highly mobile electronicshelter applications.InPacA broad product line of explosion proofA/C, purge & pressurization, and heatingequipment for the petroleum and processindustries. Available in sizes from 1–50tons, InPacs are designed with redundantsystems for use in highly corrosive andexplosive atmospheres.TrakThe Trak Series mobile air conditioningunits are available in capacity rangesfrom 5–75 tons with local electric powersupplies or on onboard diesel generator.High mobility makes the Trak Seriesparticularly suited for emergency spotcooling needs for office buildings andmanufacturing plants, as well as meetingconstruction requirements at refineries,airports, and shipyards.<strong>Specific</strong> <strong>Systems</strong>, Ltd. reserves the right to update its products, and to discontinue or change designs or specifications at any time and without notice © 2009 <strong>Specific</strong> <strong>Systems</strong>, Ltd.