Tectite Push Fit Solutions - Pegler Yorkshire

Tectite Push Fit Solutions - Pegler Yorkshire

Tectite Push Fit Solutions - Pegler Yorkshire

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

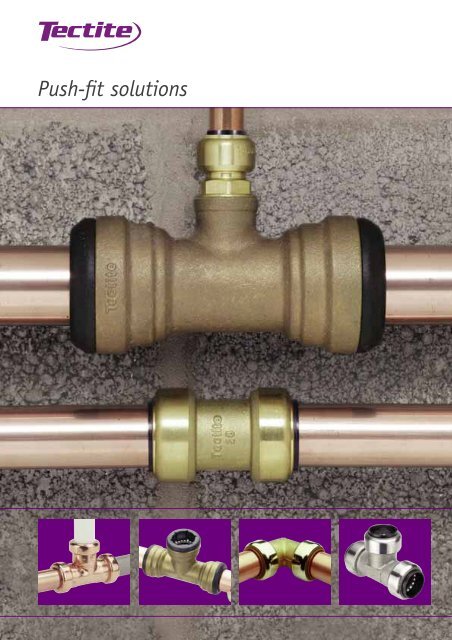

<strong>Push</strong>-fit solutions<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 1

<strong>Pegler</strong> <strong>Yorkshire</strong><br />

Unrivalled quality, innovation,<br />

customer service and long-term<br />

value for money<br />

As part of the global Aalberts Industries NV Group,<br />

<strong>Pegler</strong> <strong>Yorkshire</strong> is one of Britain’s largest and most<br />

respected manufacturers of innovative products for the<br />

demanding and diverse plumbing and heating industries.<br />

<strong>Pegler</strong> <strong>Yorkshire</strong> – a unique story<br />

It was in the late 19th century when two<br />

separate and altruistic companies set out on<br />

the long road to satisfying the needs of<br />

prospective customers and, of course, to<br />

profit in the process. Coincidentally located<br />

just 30 miles apart, each was driven by the<br />

same vision and ideals of a no-compromise<br />

culture. Cutting corners was never an option<br />

and only the best could ever be good enough.<br />

These two companies were <strong>Pegler</strong> and<br />

<strong>Yorkshire</strong> <strong>Fit</strong>tings. Although in meeting all the<br />

challenges of the 20th and 21st centuries<br />

each has changed a great deal, the business<br />

ethos common to both never has. And now<br />

these two like minds have come together as<br />

<strong>Pegler</strong> <strong>Yorkshire</strong> – a single source of proven,<br />

flow control solutions for installers,<br />

specifiers and engineers in the domestic,<br />

public and commercial markets.<br />

Reputable and established brands<br />

Just as <strong>Pegler</strong> and <strong>Yorkshire</strong> have endured<br />

over such a long period, many of the brand<br />

names they have created over time are<br />

similarly very well established, in many cases<br />

as market leaders in their respective categories.<br />

The very extensive <strong>Pegler</strong> <strong>Yorkshire</strong> product<br />

range now comprises more than 15,000 lines<br />

– without rival for the choice and coverage<br />

it offers and for the number and scope of<br />

applications it satisfies.<br />

A mind for innovation<br />

Brands which endure and are not easily<br />

displaced must by definition be the product<br />

of innovative thinking and technology that<br />

continually stand the test of time. <strong>Pegler</strong><br />

<strong>Yorkshire</strong>’s no-compromise philosophy will<br />

always put new product development high<br />

on the agenda, based on not only meeting<br />

the needs of today’s markets, but also<br />

anticipating and meeting customers’<br />

future needs.<br />

The true value of knowledge<br />

As well as the benefit of unparalleled<br />

experience of the flow control market and<br />

its growth over many decades, <strong>Pegler</strong><br />

<strong>Yorkshire</strong> has strong associations with<br />

major industry bodies such as those<br />

responsible for determining product and<br />

performance standards.<br />

The result is a comprehensive store of<br />

knowledge and reference which is invaluable<br />

in the key areas of research, development and<br />

dealing efficiently and accurately with<br />

customer enquiries – particularly with regard<br />

to product application and suitability.<br />

A charter for the best<br />

in customer service<br />

With so diverse a product range and customer<br />

base, <strong>Pegler</strong> <strong>Yorkshire</strong>’s no-compromise<br />

standards of quality, reliability and value<br />

for money naturally go hand in hand with<br />

the principle of delivering the best in<br />

customer service.<br />

Green awareness<br />

and responsibilities<br />

Developing products which reduce the carbon<br />

footprint by saving water and energy is only<br />

one side of the green issues coin. <strong>Pegler</strong><br />

<strong>Yorkshire</strong> is also increasingly committed to<br />

recycling key production materials (such as<br />

brass), eliminating the need for excessive<br />

packaging wherever possible, and looking for<br />

new ways in which the company’s day-to-day<br />

operations can be improved to reduce waste<br />

and minimise the impact on the environment.<br />

Likewise, social responsibilities such as<br />

supporting employee and local community<br />

welfare are aspects of the very fabric and<br />

philosophy upon which both <strong>Pegler</strong> and<br />

<strong>Yorkshire</strong> were founded.<br />

Standards<br />

<strong>Pegler</strong> <strong>Yorkshire</strong> are dedicated to designing,<br />

developing and manufacturing products of<br />

the highest quality. We are members of<br />

numerous standards committees and take an<br />

active part in their development. Our products,<br />

where applicable, comply with the relevant<br />

British, European and International standards.<br />

Whatever the latest developments, we<br />

guarantee that our products will always<br />

meet the latest and highest standards.<br />

Trade bodies<br />

<strong>Pegler</strong> <strong>Yorkshire</strong> is pleased to be associated<br />

with several influential industry organisations:<br />

Association of<br />

Plumbing and<br />

Heating Contractors<br />

Brass<br />

The Brass Page<br />

for specifiers,<br />

designers, engineers<br />

and manufacturers<br />

The Copper<br />

Development<br />

Association<br />

Heating and<br />

Ventilating<br />

Contractors<br />

Association<br />

The Bathroom<br />

Manufacturers<br />

Association<br />

pec<br />

CERTIFICATION LTD<br />

British Plumbing<br />

Employers Council<br />

The UK<br />

Copper Board<br />

Thermostatic<br />

Mixing Valve<br />

Manufacturers<br />

Association<br />

Construction<br />

Products<br />

Association<br />

Builders Merchants<br />

Federation<br />

Institute of<br />

Plumbing<br />

Scottish and<br />

Northern Ireland<br />

Plumbing Employers<br />

Federation<br />

2

<strong>Push</strong>-fit solutions<br />

This data book has been produced in clearly defined<br />

sections to help the user to find relevant information<br />

quickly and easily. At the foot of each page there is a reminder<br />

of the brochure sections with the relevant page numbers.<br />

Section 1<br />

Product range overview<br />

Introduction to <strong>Tectite</strong> 4<br />

Key features and benefits 6-8<br />

<strong>Tectite</strong> Sprint 6<br />

<strong>Tectite</strong> Classic 6<br />

<strong>Tectite</strong> Pro 7<br />

<strong>Tectite</strong> 316 7<br />

<strong>Tectite</strong> Advance 8<br />

<strong>Tectite</strong> quarter turn 8<br />

ball valves<br />

<strong>Tectite</strong> service valves 8<br />

<strong>Tectite</strong> flexible hose 8<br />

connectors<br />

<strong>Tectite</strong> accessories 8<br />

Standards, approvals and guarantees 9<br />

Section 2<br />

Product range details<br />

Sizes, dimensional details 10-49<br />

and product codes<br />

Section 3<br />

Technical Data<br />

<strong>Fit</strong>ting and tube compatibility 50<br />

<strong>Fit</strong>ting applications 50<br />

Materials specifications 51<br />

Manufacturing standards 51<br />

Working temperatures 52<br />

and pressures<br />

Tubes, pipe and 53-54<br />

their compatibility<br />

System design considerations 55-57<br />

and tube expansion<br />

Section 4<br />

Installation instructions<br />

Socket depths 58<br />

Preparation 58<br />

Preliminaries – 10mm to 28mm sizes 58<br />

Copper, chrome plated copper,58<br />

Stainless steel System and<br />

carbon steel System tube<br />

PB and PEX pipe 59<br />

Plastic coated carbon steel 59<br />

System tube<br />

Jointing 60<br />

Preliminaries – 35mm to 54mm sizes 61<br />

Demounting 62<br />

Disassembly 63<br />

3

<strong>Push</strong>-fit solutions<br />

The complete range<br />

<strong>Tectite</strong> fittings from <strong>Pegler</strong> <strong>Yorkshire</strong> makes jointing easier, faster and more cost<br />

effective than other jointing methods – a fittings system which simply pushes<br />

together in seconds to create a perfect joint, every time.<br />

<strong>Tectite</strong> push-fit<br />

benefits<br />

A completely heat-free system offering the<br />

following benefits:<br />

Improved installation time over<br />

traditional methods<br />

No naked flames (improved safety)<br />

Perfectly clean internal bore<br />

(less finishing/cleaning required)<br />

No localised annealing from high<br />

temperature working.<br />

No carbon deposits (less risk of corrosion)<br />

System does not need to be “dry” for<br />

effective jointing<br />

Time-saving and<br />

cost-saving<br />

installation<br />

Time-saving and cost-saving installation of<br />

many types of plumbing and heating<br />

services – for commercial, domestic and<br />

public utility applications – including:<br />

All above-ground hot and cold domestic<br />

and commercial water services<br />

Heating and chilled water services<br />

(potable and non-potable)<br />

Low-temperature hot water and heating<br />

Smallbore or minibore central heating<br />

systems<br />

Pressurised, vented and unvented<br />

heating systems<br />

Renowned <strong>Pegler</strong><br />

<strong>Yorkshire</strong> quality<br />

and reliability<br />

Renowned <strong>Pegler</strong> <strong>Yorkshire</strong> quality and<br />

reliability – with some <strong>Tectite</strong> products<br />

offering the bonus of an enhanced<br />

30-year warranty. <strong>Pegler</strong> <strong>Yorkshire</strong> also<br />

operates a Quality Management System for<br />

the development, manufacture and supply<br />

of fittings, tube, valves and accessories<br />

which complies with the requirements<br />

of BS EN ISO 9001:2000.<br />

Key to symbols<br />

Products in this brochure are accompanied by<br />

symbols intended to aid the reader by stating<br />

their ideal environments. These symbols are:<br />

Versatility and choice<br />

A wide range of<br />

fittings for use with<br />

many different types<br />

of materials,<br />

including copper<br />

tube, PEX and PB<br />

pipe, and a variety of steel including<br />

stainless and carbon.<br />

Choice of demountable or non-demountable<br />

fittings.<br />

The perfect solution<br />

all round<br />

A heat-free, time saving jointing method<br />

which guarantees uncontaminated<br />

installation. Ideal for applications as<br />

diverse as domestic maintenance and<br />

refurbishment, new build and large-scale<br />

public sector projects.<br />

Heat free<br />

Demountable<br />

Non-demountable<br />

Potable water applications<br />

Not suitable for potable water<br />

applications<br />

Gas installation applications<br />

Not suitable for gas installation<br />

applications<br />

Chilled water services<br />

Closed circuit heating<br />

Electrical continuity<br />

Hot water services<br />

Reduced requirement for flushing<br />

Galvanised or nickel plated<br />

No tools required<br />

Saves installation time<br />

Easy to insulate<br />

Easy to install in confined areas<br />

Can be rotated<br />

4 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 5<br />

1

<strong>Push</strong>-fit solutions<br />

Product overview<br />

<strong>Tectite</strong> Sprint non-demountable fittings<br />

are ideal for fast and efficient heat free<br />

jointing, offering a visually appealing, low<br />

profile design which can be easily installed<br />

in confined spaces. They are also easy to<br />

insulate.<br />

Features<br />

Available in sizes 10mm to 28mm<br />

Manufactured from copper or machined<br />

DZR brass<br />

Can be used with copper tube, PB and<br />

PEX pipe (with liners) or chrome plated<br />

copper tube<br />

Suitable for use on hot and cold water<br />

services, heating and chilled water<br />

applications and low temperature hot<br />

water services<br />

Provides electrical continuity<br />

WRAS approved*<br />

The original <strong>Tectite</strong> fitting and proven in<br />

the field for over 15 years, <strong>Tectite</strong> Classic<br />

can be used for similar applications to<br />

<strong>Tectite</strong> Sprint but where a demountable<br />

fitting is required.<br />

Features<br />

Demountable<br />

Available in sizes 10mm to 28mm<br />

Manufactured from gunmetal, A-metal or<br />

DZR brass<br />

Can be used with copper tube, PB and<br />

PEX pipe (with liners) or chrome plated<br />

copper tube<br />

Suitable for use on hot and cold water<br />

services, heating applications and low<br />

temperature hot water services<br />

WRAS approved*<br />

*On certain sizes<br />

6 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

<strong>Push</strong>-fit solutions<br />

Product overview<br />

1<br />

<strong>Tectite</strong> Pro demountable fittings have been<br />

specially developed to meet the rigorous<br />

demands of the mechanical services sector.<br />

<strong>Tectite</strong> Pro offers enhanced performance<br />

over an extended size range and is WRAS<br />

approved. 15mm to 54mm fittings feature a<br />

stainless steel grab ring.<br />

Features<br />

Demountable<br />

Available in sizes 15mm to 54mm<br />

Manufactured from gunmetal, A-metal or<br />

DZR brass<br />

Provides electrical continuity<br />

Can be used with copper tube, PB and<br />

PEX pipe, chrome plated copper tube or<br />

carbon steel tube<br />

Designed for use in the mechanical<br />

services sector on hot and cold services,<br />

heating and chilled water applications and<br />

low temperature hot water services<br />

Provides enhanced performance<br />

WRAS approved<br />

<strong>Tectite</strong> 316 is a stainless steel option<br />

which has been developed for use with<br />

316 System tube for potable water<br />

applications where water quality and<br />

hygiene are key considerations. The <strong>Tectite</strong><br />

316 range incorporates a stainless steel<br />

grab ring which has been specifically<br />

developed to grip stainless steel tube<br />

without the need to for it to be scribed.<br />

Features<br />

Demountable<br />

Available in sizes 15mm to 54mm<br />

Manufactured from 316 stainless steel<br />

Provides electrical continuity<br />

Can be used with 316 System tube<br />

Designed for use for potable water<br />

services in the food processing and<br />

pharmaceutical industries<br />

WRAS approved<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 7

<strong>Push</strong>-fit solutions<br />

Product overview<br />

Designed for use in conjunction with<br />

XPress carbon steel System tube, the nondemountable<br />

<strong>Tectite</strong> Advance System is five<br />

times quicker to install than a traditional<br />

screwed steel installation*. With installed<br />

cost savings of up to 70%, borne out in an<br />

independent industry report, <strong>Tectite</strong><br />

Advance can help to deliver projects on<br />

time and within budget.<br />

*Research carried out in conjunction with<br />

Leeds College of Building, February 2007.<br />

Features<br />

Available in sizes from 15mm to 54mm<br />

Manufactured from galvanised carbon steel<br />

Provides electrical continuity<br />

Can be used with XPress carbon steel<br />

System tube and plastic coated XPress tube<br />

Light weight and easy to fit<br />

Designed for use with unvented closed<br />

circuit heating and chilled water services<br />

(closed loop)<br />

<strong>Tectite</strong> Pro quarter turn ball valves<br />

<strong>Tectite</strong> Pro quarter turn ball valves are a<br />

safe, reliable and cost effective way to<br />

control the flow of water.<br />

Features<br />

Available in sizes from 15mm to 22mm<br />

Manufactured from brass with nickel<br />

plated finish<br />

Designed for use with hot and cold water<br />

services and heating systems<br />

<strong>Tectite</strong> Classic and <strong>Tectite</strong> Pro<br />

servicing valves<br />

<strong>Tectite</strong> Pro servicing valves allow sections<br />

of pipework to be isolated for repair or<br />

maintenance without the need to drain<br />

down the system. They incorporate a simple<br />

open/shut mechanism which can be<br />

operated with a screwdriver or coin.<br />

Features<br />

Available in 15mm sizes<br />

Manufactured from brass with a chrome<br />

plated finish<br />

Provides electrical continuity<br />

Designed for use in hot and cold<br />

water services<br />

Ideal for use with terminal taps and<br />

float valves<br />

<strong>Tectite</strong> flexible hose connectors<br />

<strong>Tectite</strong> flexible hose connectors are suitable<br />

for use in areas where space is limited and<br />

the fitting of rigid tube is difficult.<br />

Features<br />

Available in 15mm sizes<br />

Manufactured with high quality stainless<br />

steel braided EPDM hose<br />

Designed for use in hot and cold water<br />

services and on fan coils<br />

WRAS approved<br />

<strong>Tectite</strong> accessories<br />

The <strong>Tectite</strong> range is complemented by a<br />

variety of accessories. These include<br />

deburring/scribe tools, disconnecting tools<br />

and clips, pipe clips, demounting end caps,<br />

grab rings and lubricant.<br />

8 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

<strong>Push</strong>-fit solutions<br />

Standards, approvals<br />

and guarantees<br />

1<br />

It’s <strong>Pegler</strong> <strong>Yorkshire</strong>’s policy to provide a range of products and services which meet,<br />

or exceed, the requirements of our customers in respect of quality, cost and delivery.<br />

Standards and<br />

approvals<br />

WRAS All <strong>Tectite</strong> Sprint, <strong>Tectite</strong> Classic,<br />

<strong>Tectite</strong> Pro and <strong>Tectite</strong> 316 fittings are listed<br />

and comply with the requirements of the<br />

United Kingdom Water Regulations/Byelaws<br />

(Scotland).<br />

DVGW <strong>Tectite</strong> Classic and <strong>Tectite</strong> 316 fittings<br />

have been approved by the German approval<br />

authority. They comply with DVGW Arbeitsblatt<br />

W534, which covers fittings and joints for<br />

tubes in potable water installations.<br />

<strong>Tectite</strong> Classic fittings are also approved by<br />

KIWA (Dutch certification), SITAC (Norway,<br />

Sweden and Finland certification) and CSTB<br />

(French certification). <strong>Tectite</strong> 316 fittings are<br />

also approved by SVGW (Swiss certification).<br />

<strong>Tectite</strong>-PEX barrier pipe<br />

is kitemark approved<br />

The <strong>Tectite</strong> range has<br />

been certified by the<br />

WRAS and is audited periodically.<br />

Applicable <strong>Tectite</strong> products<br />

are DVGW approved for the<br />

European market.<br />

ISO is achieved through the<br />

continuous improvement of<br />

our Quality Management System<br />

in line with the requirements of<br />

BS EN ISO9001: 2000.<br />

PRODUCT APPROVALS<br />

Product WRAS CSTB KIWA DVGW ETA ACS Sintef Sitac SVGW OVGW<br />

<strong>Tectite</strong> Sprint ✔ – – – – – ✔ ✔ – –<br />

<strong>Tectite</strong> Classic ✔ ✔ ✔ ✔ ✔ ✔ – – – –<br />

<strong>Tectite</strong> Pro ✔ – – – – – – – – –<br />

<strong>Tectite</strong> 316 ✔ – – ✔ – – – – ✔ ✔<br />

<strong>Tectite</strong> Advance – – – – – – – – – –<br />

Guarantees<br />

25 YEAR GUARANTEE<br />

Where <strong>Tectite</strong> Sprint, <strong>Tectite</strong> Classic, <strong>Tectite</strong><br />

Pro and <strong>Tectite</strong> 316 fittings, <strong>Tectite</strong>-PEX<br />

barrier pipe and 316 System tube are<br />

installed in pipelines with other products, all<br />

are guaranteed against all manufacturing<br />

defects for 25 years.<br />

<strong>Tectite</strong> fittings, tube and accessories<br />

Guarantee period (years)<br />

5 10 25 30<br />

<strong>Fit</strong>tings – – ✔ –<br />

<strong>Fit</strong>tings with Yorkex* copper tube and/or<br />

<strong>Tectite</strong>-PEX pipe<br />

– – – ✔<br />

<strong>Fit</strong>tings – – ✔ –<br />

<strong>Fit</strong>tings with Yorkex* copper tube and/or<br />

<strong>Tectite</strong>-PEX pipe<br />

– – – ✔<br />

<strong>Fit</strong>tings – – ✔ –<br />

<strong>Fit</strong>tings with Yorkex* copper tube and/or<br />

<strong>Tectite</strong>-PEX pipe<br />

30 YEAR GUARANTEE<br />

Where pipelines are<br />

constructed exclusively<br />

using <strong>Tectite</strong> fittings<br />

and recommended<br />

tubes, the resulting<br />

installations will be deemed <strong>Tectite</strong> Systems<br />

and as such qualify for a 30 year guarantee<br />

against all manufacturing defects.<br />

– – – ✔<br />

<strong>Fit</strong>tings with XPress carbon steel System tube – ✔ – –<br />

<strong>Fit</strong>tings – – ✔ –<br />

<strong>Fit</strong>tings and stainless steel 316 System tube – – – ✔<br />

<strong>Fit</strong>tings with XPress carbon steel System tube – ✔ – –<br />

<strong>Fit</strong>tings ✔ – – –<br />

<strong>Fit</strong>tings with XPress carbon steel System tube – ✔ – –<br />

<strong>Tectite</strong> Pro quarter turn ball valves – – ✔ –<br />

<strong>Tectite</strong> Classic and <strong>Tectite</strong> Pro servicing valves – – ✔ –<br />

<strong>Tectite</strong> flexible hose connectors – ✔ – –<br />

To qualify for guarantees, all products must be installed in accordance with our instructions in specified applications.<br />

*Yorkex is a brand name of <strong>Yorkshire</strong> Copper Tube.<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 9

<strong>Push</strong>-fit for copper and plastic<br />

Manufactured from copper and DZR brass, <strong>Tectite</strong> Sprint is ideal for use<br />

on hot and cold-water services, in low-temperature hot water and heating.<br />

System PEX Pipe<br />

TP520 Barrier pipe. Straight lengths<br />

Size Finish Order code<br />

15mm x 3m White plastic 60029<br />

15mm x 6m White plastic 60030<br />

22mm x 3m White plastic 60037<br />

22mm x 6m White plastic 60038<br />

28mm x 3m White plastic 60041<br />

28mm x 6m White plastic 60042<br />

Suitable for:<br />

TP525 Barrier pipe. Coil<br />

Size Finish Order code<br />

12mm x 50m White plastic 60020<br />

12mm x 100m White plastic 60021<br />

15mm x 25m White plastic 60024<br />

15mm x 50m White plastic 60025<br />

15mm x 100m White plastic 60026<br />

22mm x 25m White plastic 60033<br />

22mm x 50m White plastic 60034<br />

Suitable for:<br />

<strong>Push</strong>-fit fittings<br />

TT1 Straight coupling<br />

Za<br />

a<br />

Size a Za Order code<br />

10mm 34 2 75500<br />

12mm 36 2 75660<br />

14mm 37 2 75661<br />

15mm 36 2 75501<br />

16mm 36 2 75662<br />

18mm 37 2 75663<br />

22mm 38 2 75502<br />

28mm 40 2 75503<br />

Suitable for:<br />

10 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

For jointing plain and chrome plated copper tube to BS EN 1057,<br />

PEX - including <strong>Tectite</strong> PEX - and PB plastic pipes to BS 7291<br />

Guaranteed for 30 years against manufacturing defects when installed<br />

exclusively with <strong>Tectite</strong> PEX or Yorkex Copper Tube from <strong>Yorkshire</strong> Copper Tube<br />

Ltd, or for 25 years when used with other products 2<br />

TT1R Reducing coupling<br />

Size a Za Order code<br />

15 x 10mm 41 8 75504<br />

14 x 12mm 38 5.5 75664<br />

15 x 12mm 39 7 75665<br />

16 x 12mm 40 7.5 75666<br />

16 x 14mm 37.5 5.5 75667<br />

18 x 15mm 37.5 5.5 75668<br />

18 x 16mm 37 5.5 75669<br />

22 x 15mm 42 8 75505<br />

22 x 16mm 42 9.5 75670<br />

22 x 18mm 41.5 7.5 75671<br />

a<br />

Za<br />

Suitable for:<br />

TT2 Straight female connector<br />

S<br />

Size a Za S Order code<br />

10mm x 1 /2" 35.5 6.5 25 75672<br />

12mm x 1 /2" 35.5 6.5 25 75673<br />

14mm x 3 /8" 33 5.5 20 75674<br />

14mm x 1 /2" 35.5 6.5 25 75675<br />

15mm x 1 /2" 34 17 24.5 75510<br />

16mm x 1 /2" 35 6.5 25 75676<br />

18mm x 1 /2" 35.5 6 25 75677<br />

22mm x 3 /4" 37 19 30 75511<br />

28mm x 1" 41 3 38 75678<br />

Za<br />

a<br />

Suitable for:<br />

TT3 Straight male connector<br />

S<br />

Size a Za S Order code<br />

10mm x 3 /8" 32 17 22 75679<br />

10mm x 1 /2" 34.5 19.5 22 75680<br />

12mm x 3 /8" 32 16.5 22 75681<br />

12mm x 1 /2" 34.5 19 22 75682<br />

14mm x 3 /8" 32.5 17 22 75683<br />

14mm x 1 /2" 34 18.5 22 75684<br />

15mm x 1 /2" 37 20 21 75515<br />

16mm x 1 /2" 34 19 22 75685<br />

18mm x 3 /4" 38.5 22 27 75687<br />

22mm x 3 /4" 39.5 21.5 26 75516<br />

28mm x 1" 43.5 24.5 32 75518<br />

Suitable for:<br />

Za<br />

a<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 11

<strong>Push</strong>-fit for copper and plastic<br />

S<br />

TT5 Tank connector<br />

b<br />

Size a Za S b Order code<br />

Za<br />

a<br />

15mm x 1 /2" 42 25 22 34.8 75520<br />

22mm x 3 /4" 46 28 28 42 75521<br />

Suitable for:<br />

TT6 Reducer<br />

Za<br />

a<br />

Size a Za Order code<br />

15 x 10mm 37 21 75523<br />

15 x 12mm 37 21.5 75524<br />

18 x 15mm 39 23.5 75520<br />

22 x 14mm 46 30.5 75688<br />

22 x 15mm 39 22 75525<br />

28 x 15mm 43 26 75526<br />

28 x 22mm 44 26 75527<br />

Suitable for:<br />

TT12 Elbow<br />

a<br />

Za<br />

Size a Za Order code<br />

Za<br />

a<br />

10mm 28 12 75530<br />

12mm 32 15.5 75689<br />

14mm 34.5 18.5 75690<br />

15mm 35 18 75531<br />

16mm 37 21.5 75691<br />

18mm 37.5 22 75692<br />

22mm 44.5 26.5 75532<br />

28mm 52.5 33.5 75533<br />

Suitable for:<br />

TT12S Street elbow<br />

a<br />

Za<br />

b<br />

Size a b Za Order code<br />

10 x 10mm 28 44 12 75535<br />

10 x 15mm 28 45 12 75536<br />

12 x 12mm 32.5 33.5 16.5 75693<br />

14 x 14mm 35 35 19 75694<br />

15 x 15mm 35 35 18 75537<br />

16 x 16mm 37 37 21.5 75695<br />

18 x 18mm 37.5 42.5 22 75696<br />

22 x 22mm 52.5 50 33.5 75538<br />

Suitable for:<br />

12 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TT13 Male elbow<br />

Size a b Za Order code<br />

15mm x 1 /2" 25.5 29 8.5 75540<br />

a<br />

Za<br />

Suitable for:<br />

b<br />

TT14 Female elbow<br />

Size a b Za Zb Order code<br />

14mm x 1 /2" 26 26.5 9.5 14 75697<br />

15mm x 1 /2" 27 25 10 10 75545<br />

16mm x 1 /2" 25 26.5 9.5 14 75698<br />

b<br />

Zb<br />

Za<br />

a<br />

Suitable for:<br />

TT15 Backplate elbow<br />

Size a b c Za Zb Order code<br />

a<br />

Za<br />

12mm x 1 /2" 43.5 26 17 9.5 14 75548<br />

14mm x 1 /2" 43.5 26 17 9.5 14 75699<br />

15mm x 1 /2" 41.5 27 17.5 10 10 75550<br />

c<br />

Zb<br />

b<br />

Suitable for:<br />

TT21 Obtuse elbow<br />

r<br />

Size a Za Order code<br />

12mm 26.5 10 75701<br />

14mm 27.5 11 75702<br />

15mm 27.5 12 75551<br />

16mm 28 12.5 75703<br />

18mm 33 14 75704<br />

22mm 34 17 75552<br />

28mm 40 21.5 75553<br />

a<br />

Za<br />

Za<br />

a<br />

b<br />

Suitable for:<br />

TT21S Obtuse street elbow<br />

b<br />

Size a Za Order code<br />

r<br />

12mm 27.5 10 75705<br />

14mm 28 11.5 75706<br />

15mm 28 12 75585<br />

16mm 28.5 12.5 75707<br />

18mm 30.5 14 75708<br />

22mm 34 17 75586<br />

28mm 40 21.5 75587<br />

a<br />

Za<br />

c<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 13

<strong>Push</strong>-fit for copper and plastic<br />

TT24 Equal tee<br />

b<br />

Za<br />

Size a b Za Order code<br />

Za<br />

a<br />

Za<br />

10mm 46.5 23 7 75555<br />

12mm 52 25.5 9 75709<br />

14mm 52.5 26 10 75710<br />

15mm 52.5 26 9 75556<br />

16mm 59.5 29.7 14 75711<br />

18mm 57.5 28.5 13 75712<br />

22mm 62.5 31 13 75557<br />

28mm 72.5 36 17 75558<br />

Suitable for:<br />

3<br />

TT25 Tee, reduced branch<br />

b<br />

Zb<br />

1<br />

Za<br />

a<br />

Za<br />

2<br />

Size (1 x 2 x 3) a b Za Zb Order code<br />

14 x 14 x 12mm 50 26.5 8.5 10 75713<br />

15 x 15 x 10mm 48 25 7 9 75565<br />

15 x 15 x 12mm 49 27.5 8.5 11 75714<br />

16 x 16 x 12mm 49 27.5 8.5 11 75715<br />

16 x 16 x 14mm 50 26.5 9.5 10 75716<br />

18 x 18 x 12mm 50 29.5 8 13 75717<br />

18 x 18 x 14mm 51 28.5 9 12 75718<br />

18 x 18 x 15mm 54 27.5 10 12 75719<br />

22 x 22 x 10mm 50 29.5 7 13.5 75566<br />

22 x 22 x 14mm 57 30.5 11 14 75720<br />

22 x 22 x 15mm 54 30.5 9 13.5 75567<br />

22 x 22 x 16mm 60 31.5 12.5 16 75721<br />

22 x 22 x 18mm 60 31.5 12.5 15 75722<br />

28 x 28 x 15mm 56 34.5 9 17.5 75568<br />

28 x 28 x 18mm 63 34.5 12.5 18 75723<br />

28 x 28 x 22mm 65 35.5 13.5 17.5 75569<br />

Suitable for:<br />

3<br />

TT26 Tee, one end reduced<br />

b<br />

Zb 2<br />

1<br />

Za Zc<br />

a<br />

Size (1 x 2 x 3) a b Za Zb Zc Order code<br />

15 x 12 x 15mm 60 28 12.5 15.5 12.5 75724<br />

18 x 12 x 18mm 65 31.5 13 19 15 75725<br />

18 x 15 x 18mm 64 30.5 13 18 14 75726<br />

22 x 15 x 22mm 68.5 31.5 13.5 13.5 20 75573<br />

22 x 18 x 22mm 68.5 32.5 14 15 20 75727<br />

28 x 15 x 28mm 77.5 36.5 17.5 17.5 24 75574<br />

28 x 22 x 28mm 78.5 36.5 17.5 17.5 24 75575<br />

Suitable for:<br />

14 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TT27 Tee, one end and branch reduced<br />

3<br />

Size (1 x 2 x 3) a b Za Zb Zc Order code<br />

a<br />

Zb<br />

16 x 14 x 14mm 54 26.5 12.5 10 10 75728<br />

22 x 15 x 15mm 63.5 30 12 13 13.5 75582<br />

22 x 18 x 18mm 65 33 13.5 16.5 17.5 75729<br />

28 x 18 x 18mm 73 36.5 13.5 20 24 75730<br />

28 x 22 x 22mm 70 34 17.5 15 15.5 75584<br />

1<br />

Za<br />

a<br />

Zc<br />

2<br />

Suitable for:<br />

TT61 Stop end<br />

Size a Order code<br />

10mm 16 75590<br />

12mm 18 75731<br />

14mm 18 75732<br />

15mm 17 75591<br />

16mm 17 75733<br />

18mm 19 75734<br />

22mm 18 75592<br />

28mm 19 75593<br />

a<br />

Suitable for:<br />

TT62 Tap connector<br />

Size a Za Order code<br />

10mm x 1 /2" 33 17 75600<br />

12mm x 3 /8" 34.5 18 75736<br />

12mm x 1 /2" 36.5 20 75735<br />

14mm x 3 /8" 37 21 75738<br />

14mm x 1 /2" 34 18 75737<br />

15mm x 1 /2" 34 17 75601<br />

16mm x 1 /2" 36 20.5 75739<br />

16mm x 3 /4" 35.5 20 75740<br />

18mm x 1 /2" 36 20 75741<br />

18mm x 3 /4" 36 20 75742<br />

22mm x 3 /4" 38.5 20.5 75603<br />

a<br />

Za<br />

Suitable for:<br />

TT63 Bent tap connector<br />

Size a b Za Order code<br />

10mm x 1 /2" 36 24 20 75604<br />

12mm x 1 /2" 32.5 24 16 75743<br />

15mm x 1 /2" 37 24 20 75605<br />

18mm x 1 /2" 40.5 32 24 75744<br />

a<br />

Za<br />

b<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 15

Demountable push-fit<br />

for copper and plastic<br />

System PEX pipe<br />

TP520 Barrier pipe. Straight lengths<br />

Size Finish Order code<br />

15mm x 3m White plastic 60029<br />

15mm x 6m White plastic 60030<br />

22mm x 3m White plastic 60037<br />

22mm x 6m White plastic 60038<br />

28mm x 3m White plastic 60041<br />

28mm x 6m White plastic 60042<br />

Suitable for:<br />

TP525 Barrier pipe. Coil<br />

Size Finish Order code<br />

12mm x 50m White plastic 60020<br />

12mm x 100m White plastic 60021<br />

15mm x 25m White plastic 60024<br />

15mm x 50m White plastic 60025<br />

15mm x 100m White plastic 60026<br />

22mm x 25m White plastic 60033<br />

22mm x 50m White plastic 60034<br />

Suitable for:<br />

Za<br />

a<br />

Demountable push-fit fittings<br />

T1 Straight coupling<br />

Size a Za Order code<br />

10mm 49 1 45108<br />

12mm 49 1 45110<br />

14mm 49 1 45112<br />

15mm 49 1 45114<br />

16mm 49 1 45116<br />

18mm 49 1 45118<br />

20mm 59 1 45120<br />

22mm 59 1 45121<br />

28mm 65 1 45123<br />

Suitable for:<br />

16 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

T1R Reducing coupling<br />

Size a Za Order code<br />

12 x 10mm 49 1 45155<br />

14 x 12mm 49 1 45157<br />

15 x 10mm 49 1 45159<br />

15 x 12mm 49 1 45161<br />

16 x 12mm 49 1 45163<br />

16 x 14mm 49 1 45165<br />

18 x 15mm 49 1 45167<br />

20 x 18mm 54 1 45168<br />

22 x 10mm 54 1 45170<br />

22 x 15mm 54 1 45172<br />

22 x 18mm 54 1 45174<br />

28 x 22mm 62 1 45178<br />

a<br />

Za<br />

Suitable for:<br />

T2 Straight female connector<br />

S<br />

Size a Za S Order code<br />

10mm x 3 /8" 39 2 22 45190<br />

10mm x 1 /2" 40 2 26 45192<br />

12mm x 3 /8" 39 2 25 45194<br />

12mm x 1 /2" 40 2 25 45196<br />

14mm x 3 /8" 39 2 22 45200<br />

14mm x 1 /2" 40 2 25 45202<br />

15mm x 3 /8" 39 2 22 45204<br />

15mm x 1 /2" 40 3 25 45206<br />

15mm x 3 /4" 40 1 25 45208<br />

18mm x 1 /2" 40 3 25 45210<br />

18mm x 3 /4" 43 3 32 45212<br />

22mm x 1 /2" 45 2 32 45220<br />

22mm x 3 /4" 47 3 32 45222<br />

22mm x 1" 49 2 38 45223<br />

28mm x 3 /4" 51 3 32 45224<br />

28mm x 1" 53 1 37 45225<br />

a<br />

Za<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 17

Demountable push-fit<br />

for copper and plastic<br />

S<br />

T3 Tapered male connector<br />

a<br />

Za<br />

Size a Za S Order code<br />

10mm x 3 /8" 39 15 22 45250<br />

10mm x 1 /2" 42 18 23 45252<br />

12mm x 3 /8" 39 15 20 45254<br />

12mm x 1 /2" 40 16 25 45256<br />

15mm x 3 /8" 39 16 20 45265<br />

15mm x 1 /2" 40 16 22 45267<br />

18mm x 1 /2" 43 19 24 45286<br />

18mm x 3 /4" 43 19 28 45288<br />

22mm x 1 /2" 44 16 28 45290<br />

22mm x 3 /4" 46 18 28 45292<br />

22mm x 1" 49 20 34 45294<br />

28mm x 1" 53 21 37 45296<br />

Suitable for:<br />

S<br />

T3P Straight male connector<br />

a<br />

Za<br />

b<br />

Size a Za b S Order code<br />

12mm x 3 /8" 37 13 30 22 45350<br />

14mm x 3 /8" 37 13 30 22 45354<br />

14mm x 1 /2" 37 14 32 24 45356<br />

15mm x 1 /2" 40 17 27 21 45358<br />

15mm x 3 /4" 47 23 50 42 45360<br />

16mm x 1 /2" 38 14 32 24 45362<br />

22mm x 1 /2" 42 14 32 26 45364<br />

22mm x 3 /4" 44 15 35 28 45366<br />

22mm x 1" 45 16 42 28 45368<br />

28mm x 1" 48 16 42 32 45370<br />

Suitable for:<br />

S<br />

T5 Tank connector<br />

a<br />

Za<br />

b<br />

Size a Za b S Order code<br />

15mm x 1 /2" 49 25 35 22 45390<br />

22mm x 1 /2" 53 24 42 28 45394<br />

28mm x 1" 56 24 48 32 45396<br />

Suitable for:<br />

18 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

T6 Reducer<br />

Size a Za Order code<br />

12 x 10mm 45 21 45410<br />

14 x 12mm 46 22 45414<br />

15 x 10mm 48 24 45416<br />

15 x 12mm 46 22 45418<br />

16 x 12mm 46 22 45420<br />

16 x 14mm 46 22 45421<br />

18 x 12mm 46 22 45423<br />

18 x 15mm 46 22 45424<br />

22 x 12mm 52 28 45425<br />

22 x 15mm 52 28 45426<br />

22 x 18mm 52 28 45430<br />

28 x 15mm 55 31 45435<br />

28 x 18mm 55 31 45437<br />

28 x 22mm 56 27 45438<br />

Suitable for:<br />

Za<br />

a<br />

T12 Elbow<br />

Size a Za Order code<br />

10mm 30 6 45510<br />

12mm 31 7 45512<br />

14mm 33 9 45514<br />

15mm 33 9 45516<br />

16mm 33 9 45518<br />

18mm 34 10 45520<br />

20mm 40 12 45522<br />

22mm 40 12 45524<br />

28mm 49 17 45526<br />

a<br />

Za<br />

Za<br />

a<br />

Suitable for:<br />

T12S Street elbow<br />

Size a b Za Order code<br />

10mm 30 42 6 45490<br />

12mm 31 42 7 45492<br />

10 x 15mm 33 42 9 45494<br />

15mm 33 44 9 45496<br />

18mm 34 48 10 45498<br />

22mm 41 48 12 45500<br />

28mm 49 57 17 45502<br />

a<br />

Za<br />

b<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 19

Demountable push-fit<br />

for copper and plastic<br />

T12SNP Street elbow (nickel plated)<br />

a<br />

Za<br />

b<br />

Size a b Za Order code<br />

10mm 30 42 6 45491<br />

10 x 15mm 33 42 9 45495<br />

15mm 33 44 9 45497<br />

Suitable for:<br />

T13 Male elbow<br />

a<br />

Za<br />

b<br />

Size a b Za Order code<br />

10mm x 3 /8" 30 24 6 45550<br />

10mm x 1 /2" 30 29 6 45552<br />

12mm x 3 /8" 32 24 7 45554<br />

12mm x 1 /2" 33 29 7 45556<br />

14mm x 1 /2" 33 29 9 45560<br />

15mm x 1 /2" 33 29 9 45561<br />

16mm x 1 /2" 34 29 10 45563<br />

16mm x 3 /4" 36 36 13 45564<br />

18mm x 1 /2" 34 29 10 45569<br />

18mm x 3 /4" 34 36 10 45570<br />

22mm x 3 /4" 41 34 12 45576<br />

28mm x 1" 49 42 17 45578<br />

Suitable for:<br />

T14 Female elbow<br />

a<br />

Za<br />

Zb<br />

b<br />

Size a b Za Zb Order code<br />

10mm x 3 /8" 34 23 10 13 45590<br />

10mm x 1 /2" 34 23 10 11 45592<br />

12mm x 3 /8" 34 24 10 13 45594<br />

12mm x 1 /2" 34 25 10 11 45596<br />

14mm x 1 /2" 34 25 10 11 45600<br />

15mm x 1 /2" 34 25 10 11 45606<br />

16mm x 1 /2" 34 25 9 12 45608<br />

16mm x 3 /4" 39 32 16 14 45609<br />

18mm x 1 /2" 36 25 12 11 45614<br />

18mm x 3 /4" 40 33 16 18 45615<br />

22mm x 3 /4" 42 33 13 18 45620<br />

28mm x 1" 49 37 17 21 45622<br />

Suitable for:<br />

20 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

T15 Backplate elbow<br />

Size a b c Za Zb Order code<br />

a<br />

Za<br />

10mm x 1 /2" 44 34 20 11 11 45630<br />

12mm x 1 /2" 45 34 20 11 11 45638<br />

14mm x 1 /2" 45 35 20 12 11 45640<br />

15mm x 1 /2" 45 35 20 11 11 45646<br />

16mm x 1 /2" 45 35 20 10 12 45648<br />

18mm x 1 /2" 45 34 20 13 11 45650<br />

18mm x 3 /4" 51 40 20 9 11 45652<br />

22mm x 3 /4" 54 40 21 18 12 45654<br />

c<br />

Zb<br />

b<br />

Suitable for: Flow chart: Figure 00, page 00<br />

T21 Obtuse elbow<br />

Size a Za Order code<br />

12mm 33 5 45531<br />

14mm 33 5 45533<br />

15mm 33 5 45535<br />

16mm 33 5 45536<br />

18mm 34 5 45537<br />

22mm 41 6 45538<br />

28mm 49 7 45539<br />

a<br />

Za<br />

Za<br />

a<br />

Suitable for:<br />

T21S Obtuse street elbow<br />

Size a b Za Order code<br />

12mm 33 36 5 45528<br />

14mm 33 37 5 45529<br />

15mm 33 37 5 45542<br />

16mm 33 37 5 45543<br />

18mm 34 38 5 45544<br />

22mm 41 42 6 45545<br />

28mm 49 48 7 45546<br />

a<br />

Za<br />

b<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 21

Demountable push-fit<br />

for copper and plastic<br />

b<br />

Zb<br />

Za<br />

a<br />

Za<br />

T24 Equal tee<br />

Size a b Za Zb Order code<br />

10mm 59 30 6 6 45660<br />

12mm 62 31 7 7 45662<br />

14mm 65 33 8 9 45664<br />

15mm 65 34 9 10 45666<br />

16mm 68 34 10 10 45668<br />

18mm 68 34 10 10 45670<br />

20mm 80 41 14 12 45674<br />

22mm 81 41 12 12 45676<br />

28mm 97 49 16 15 45678<br />

Suitable for:<br />

b<br />

Zb<br />

Za<br />

a<br />

Za<br />

T25 Tee, reduced branch<br />

Size a b Za Zb Order code<br />

12 x 12 x 10mm 60 32 7 7 45700<br />

14 x 14 x 12mm 62 33 8 9 45710<br />

15 x 15 x 10mm 59 32 6 8 45715<br />

15 x 15 x 12mm 63 33 8 9 45717<br />

16 x 16 x 12mm 66 33 8 9 45719<br />

16 x 16 x 14mm 67 34 10 10 45722<br />

18 x 18 x 14mm 67 35 10 11 45724<br />

20 x 20 x 16mm 75 36 9 12 45726<br />

22 x 22 x 10mm 70 38 6 14 45730<br />

22 x 22 x 14mm 75 38 9 14 45736<br />

22 x 22 x 15mm 75 38 9 14 45737<br />

22 x 22 x 16mm 75 38 9 14 45739<br />

22 x 22 x 18mm 78 36 10 12 45742<br />

28 x 28 x 15mm 84 40 10 16 45744<br />

28 x 28 x 18mm 87 39 10 15 45745<br />

28 x 28 x 22mm 91 44 12 15 45746<br />

Suitable for:<br />

b<br />

Zb<br />

Za<br />

a<br />

Zc<br />

T26 Tee, one end reduced<br />

Size a b Za Zb Zc Order code<br />

15 x 10 x 15mm 65 34 9 10 9 45780<br />

22 x 15 x 22mm 78 41 9 13 17 45786<br />

22 x 18 x 22mm 78 41 9 13 17 45788<br />

28 x 15 x 28mm 88 48 12 16 25 45790<br />

28 x 18 x 28mm 88 48 11 16 24 45792<br />

28 x 22 x 28mm 92 48 11 15 20 45793<br />

Suitable for:<br />

22 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

T27 Tee, one end and branch reduced<br />

Size a b Za Zb Zc Order code<br />

15 x 10 x 10mm 63 32 8 9 8 45810<br />

15 x 12 x 12mm 62 33 9 9 7 45812<br />

16 x 14 x 14mm 66 33 10 9 9 45815<br />

22 x 18 x 18mm 71 36 9 12 11 45819<br />

22 x 15 x 15mm 73 36 9 13 10 45820<br />

28 x 18 x 18mm 80 41 10 17 10 45821<br />

28 x 22 x 22mm 89 44 15 16 15 45822<br />

b<br />

Zb<br />

Za<br />

a<br />

Zc<br />

Suitable for:<br />

T30 Female branch tee<br />

Size a b Za Zb Order code<br />

b<br />

Zb<br />

12 x 12mm x 1 /2" 69 24 11 8 45823<br />

15 x 15mm x 1 /2" 69 25 11 12 45840<br />

16 x 16mm x 1 /2" 71 25 12 13 45825<br />

22 x 22mm x 1 /2" 78 27 10 14 45845<br />

22 x 22mm x 3 /4" 78 30 13 12 45846<br />

Za<br />

a<br />

Za<br />

Suitable for:<br />

T61 Stop end<br />

Size a Order code<br />

10mm 24 45860<br />

12mm 24 45862<br />

14mm 24 45864<br />

15mm 24 45866<br />

16mm 24 45868<br />

18mm 24 45870<br />

20mm 29 45872<br />

22mm 29 45874<br />

28mm 32 45876<br />

a<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 23

Demountable push-fit<br />

for copper and plastic<br />

T61RV Air release stop end<br />

a<br />

Size a Order code<br />

10mm 24 45890<br />

12mm 24 45891<br />

15mm 24 45892<br />

18mm 24 45893<br />

22mm 29 45894<br />

28mm 32 45895<br />

Suitable for:<br />

a<br />

Za<br />

T62 Tap connector<br />

Size a Za Order code<br />

10mm x 1 /2" 40 16 45900<br />

15mm x 1 /2" 43 19 45902<br />

15mm x 3 /4" 42 18 45171<br />

22mm x 3 /4" 52 24 45903<br />

Suitable for:<br />

T62S Tap connector<br />

a<br />

Size a Order code<br />

15mm x 1 /2" 39 45910<br />

15mm x 3 /4" 45 45912<br />

22mm x 3 /4" 49 45914<br />

Suitable for:<br />

T63 Bent tap connector<br />

a<br />

Za<br />

b<br />

Size a b Za Order code<br />

10mm x 1 /2" 34 42 11 45920<br />

15mm x 1 /2" 33 45 9 45922<br />

22mm x 3 /4" 40 47 12 45924<br />

Suitable for:<br />

24 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

T68FF Flat faced union adaptor<br />

Size a Za Order code<br />

15mm x 3 /4" 34 11 40759<br />

Suitable for:<br />

a<br />

Za<br />

Classic Flexifit<br />

TF90 Flexible connector<br />

Size a Order code<br />

15mm 300 45983<br />

22mm 400 45984<br />

Suitable for:<br />

a<br />

TF92 Flexible tap connector<br />

Size a Order code<br />

15mm x 1 /2" 300 45985<br />

22mm x 3 /4" 400 45986<br />

a<br />

Suitable for:<br />

Classic push-fit manifolds<br />

TM80 Manifold<br />

Size a b c Za Zb Order code<br />

Zb<br />

b<br />

22 x 22 x 10mm 75 37 38 47 12 45940<br />

Suitable for:<br />

a<br />

Za<br />

c<br />

TM81 Manifold<br />

Size a b c Za Zb Order code<br />

22 x 22 x 10 x 10mm 75 37 38 47 12 45942<br />

Suitable for:<br />

Za<br />

a<br />

c<br />

Zb<br />

Zb<br />

b<br />

b<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 25

Enhanced performance<br />

demountable push-fit fittings<br />

Za<br />

a<br />

TX1 Straight coupling<br />

Size a Za Order code<br />

15mm 49 1 65114<br />

22mm 59 1 65121<br />

28mm 65 1 65123<br />

35mm 115 1 45126<br />

42mm 125 1 45128<br />

54mm 139 1 45130<br />

Suitable for:<br />

a<br />

TX1 Slip straight coupling, slip pattern<br />

Size a Order code<br />

15mm 49 65141<br />

22mm 59 65143<br />

28mm 65 65144<br />

35mm 115 45145<br />

42mm 125 45146<br />

54mm 139 45147<br />

Suitable for:<br />

S<br />

TX2 Straight female connector<br />

a<br />

Za<br />

Size a Za S Order code<br />

15mm x 1 /2" 40 3 25 65206<br />

22mm x 3 /4" 47 3 32 65222<br />

22mm x 1" 49 2 38 65223<br />

28mm x 1" 53 1 37 65225<br />

35mm x 1 1 /4" 84 5 48 45230<br />

42mm x 1 1 /2" 89 4 54 45232<br />

54mm x 2" 101 4 66 45234<br />

Suitable for:<br />

26 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TX3 Tapered male connector<br />

Size a Za S Order code<br />

15mm x 1 /2" 40 16 22 65267<br />

22mm x 3 /4" 46 18 28 65292<br />

22mm x 1" 49 20 34 65294<br />

28mm x 1" 53 21 37 65296<br />

35mm x 1 1 /4" 83 26 43 45310<br />

42mm x 1 1 /2" 88 26 50 45312<br />

54mm x 2" 100 31 61 45314<br />

Suitable for:<br />

a<br />

S<br />

Za<br />

TX3P Straight male connector<br />

S<br />

Size a b Za S Order code<br />

15mm x 1 /2" 40 27 17 21 65358<br />

22mm x 3 /4" 44 35 15 28 65366<br />

22mm x 1" 45 42 16 28 65368<br />

28mm x 1" 48 42 16 32 65370<br />

Suitable for:<br />

a<br />

Za<br />

b<br />

TX6 Reducer<br />

Size a Za Order code<br />

22 x 15mm 52 28 65426<br />

28 x 15mm 55 31 65435<br />

28 x 22mm 56 27 65438<br />

35 x 15mm 81 57 45450<br />

35 x 22mm 83 54 45452<br />

35 x 28mm 87 58 45454<br />

42 x 15mm 86 62 45456<br />

42 x 22mm 88 59 45458<br />

42 x 28mm 92 60 45460<br />

42 x 35mm 116 59 45462<br />

54 x 15mm 94 70 45464<br />

54 x 22mm 95 66 45466<br />

54 x 28mm 100 68 45468<br />

54 x 35mm 124 67 45470<br />

54 x 42mm 129 67 45472<br />

Suitable for:<br />

Za<br />

a<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 27

Enhanced performance<br />

demountable push-fit fittings<br />

TX12 Elbow<br />

a<br />

Za<br />

Za<br />

a<br />

Size a Za Order code<br />

15mm 33 9 65516<br />

22mm 40 12 65524<br />

28mm 49 17 65526<br />

35mm 76 19 45530<br />

42mm 85 23 45532<br />

54mm 98 29 45534<br />

Suitable for:<br />

TX12S Street elbow<br />

a<br />

Za<br />

b<br />

Size a b Za Order code<br />

15mm 33 44 9 65496<br />

22mm 41 48 12 65500<br />

28mm 49 57 17 65502<br />

Suitable for:<br />

TX13 Male elbow<br />

a<br />

Za<br />

b<br />

Size a b Za Order code<br />

15mm x 1 /2" 29 33 9 65561<br />

22mm x 3 /4" 34 41 12 65576<br />

28mm x 1" 42 49 17 65578<br />

Suitable for:<br />

TX14 Female elbow<br />

a<br />

Za<br />

Zb<br />

b<br />

Size a b Za Zb Order code<br />

15mm x 1 /2" 34 26 10 11 65606<br />

22mm x 3 /4" 42 25 13 18 65620<br />

28mm x 1" 49 37 17 21 65622<br />

Suitable for:<br />

28 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TX15 Backplate elbow<br />

Size a b c Za Zb Order code<br />

a<br />

Za<br />

15mm x 1 /2" 45 35 20 11 11 65646<br />

Suitable for:<br />

c<br />

Zb<br />

b<br />

TX21 Obtuse elbow<br />

Size a Za Order code<br />

15mm 33 9 65535<br />

22mm 41 12 65538<br />

28mm 49 17 65539<br />

35mm 76 19 45540<br />

42mm 85 23 45541<br />

54mm 98 29 45558<br />

a<br />

Za<br />

Za<br />

a<br />

Suitable for:<br />

TX21S Obtuse street elbow<br />

Size a b Za Order code<br />

15mm 33 37 9 65542<br />

22mm 41 42 12 65545<br />

28mm 49 48 17 65546<br />

35mm 56 94 10 45547<br />

42mm 75 106 13 45548<br />

54mm 83 114 14 45549<br />

a<br />

Za<br />

b<br />

Suitable for:<br />

TX24 Equal tee<br />

Size a b Za Zb Order code<br />

b<br />

Zb<br />

15mm 65 34 9 10 65666<br />

22mm 81 41 12 12 65676<br />

28mm 97 49 16 15 65678<br />

35mm 152 76 20 20 45680<br />

42mm 170 85 23 23 45682<br />

54mm 196 98 29 29 45684<br />

Za<br />

a<br />

Za<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 29

Enhanced performance<br />

demountable push-fit fittings<br />

3<br />

TX25 Tee, reduced branch<br />

b<br />

Zb<br />

Size (1 x 2 x 3) a b Za Zb Order code<br />

1<br />

Za Za<br />

a<br />

2<br />

22 x 22 x 15mm 75 38 9 14 65737<br />

28 x 28 x 15mm 84 40 10 16 65744<br />

28 x 28 x 22mm 91 44 12 15 65746<br />

35 x 35 x 15mm 135 67 11 44 45750<br />

35 x 35 x 22mm 148 74 17 45 45752<br />

35 x 35 x 28mm 148 78 17 46 45753<br />

42 x 42 x 15mm 159 82 18 58 45754<br />

42 x 42 x 22mm 159 76 18 47 45756<br />

42 x 42 x 28mm 159 81 18 49 45758<br />

54 x 54 x 15mm 175 89 19 65 45760<br />

54 x 54 x 22mm 175 84 19 55 45762<br />

54 x 54 x 28mm 175 87 19 55 45764<br />

54 x 54 x 35mm 177 86 21 29 45765<br />

Suitable for:<br />

3<br />

TX26 Tee, one end reduced<br />

b<br />

Zb<br />

Size (1 x 2 x 3) a b Za Zb Zc Order code<br />

1<br />

Za<br />

a<br />

Zc<br />

2<br />

22 x 15 x 22mm 78 41 9 13 17 65786<br />

28 x 15 x 28mm 88 48 12 16 25 65790<br />

28 x 22 x 28mm 92 48 11 15 20 65793<br />

Suitable for:<br />

30 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TX27 Tee, one end and branch reduced<br />

3<br />

Size (1 x 2 x 3) a b Za Zb Zc Order code<br />

22 x 15 x 15mm 73 36 9 13 10 65820<br />

28 x 22 x 22mm 89 44 15 16 15 65822<br />

b<br />

Zb<br />

1<br />

Za<br />

a<br />

Zc<br />

2<br />

Suitable for:<br />

TX30 Female branch tee<br />

3<br />

Size a b Za Zb Order code<br />

b<br />

Zb<br />

15 x 15mm x 1 /2" 69 25 11 12 65840<br />

22 x 22mm x 1 /2" 78 27 10 14 65845<br />

35 x 35mm x 1 /2" 135 38 11 21 65848<br />

42 x 42mm x 1 /2" 147 41 12 25 65850<br />

1<br />

Za<br />

a<br />

Za<br />

2<br />

Suitable for:<br />

TX61 Stop end<br />

Size a Order code<br />

15mm 24 65866<br />

22mm 29 65874<br />

28mm 32 65876<br />

35mm 57 45878<br />

42mm 62 45880<br />

54mm 69 45882<br />

a<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 31

Enhanced performance<br />

demountable push-fit fittings<br />

TX61RV Air release stop end<br />

a<br />

Size a Order code<br />

15mm 24 65892<br />

22mm 29 65894<br />

28mm 32 65895<br />

Suitable for:<br />

TX62 Tap connector<br />

a<br />

Za<br />

Size a Za Order code<br />

15mm x 1 /2" 43 19 65902<br />

15mm x 3 /4" 42 18 65171<br />

22mm x 3 /4" 52 24 65903<br />

Suitable for:<br />

TX63 Bent tap connector<br />

a<br />

Za<br />

b<br />

Size a b Za Order code<br />

15mm x 1 /2" 33 45 9 65922<br />

22mm x 3 /4" 40 47 12 65924<br />

Suitable for:<br />

TX68FF Flat faced union adaptor<br />

a<br />

Za<br />

Size a Za Order code<br />

15mm x 3 /4" 34 11 65759<br />

Suitable for:<br />

32 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TX68S Cylinder union<br />

Size a Order code<br />

22mm x 1" 48 65930<br />

Suitable for:<br />

a<br />

Pro Flexifit<br />

TXF90 Flexible connector<br />

Size a Order code<br />

15mm 300 65983<br />

22mm 400 65984<br />

a<br />

Suitable for:<br />

TXF92 Flexible tap connector<br />

Size a Order code<br />

15mm x 1 /2" 300 65985<br />

22mm x 3 /4" 400 65986<br />

a<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 33

Stainless steel push-fit fittings<br />

for stainless steel tube<br />

316 System Tube<br />

SS610 316 System tube<br />

Size Finish Order code<br />

15mm x 6m Stainless steel 25010<br />

18mm x 6m Stainless steel 25012<br />

22mm x 6m Stainless steel 25014<br />

28mm x 6m Stainless steel 25016<br />

35mm x 6m Stainless steel 25018<br />

42mm x 6m Stainless steel 25020<br />

54mm x 6m Stainless steel 25022<br />

Suitable for:<br />

Za<br />

a<br />

316 push-fit fittings<br />

TS1 Straight coupling<br />

Size a Za Order code<br />

15mm 49 1 25114<br />

18mm 49 1 25118<br />

22mm 59 1 25121<br />

28mm 69 1 25123<br />

35mm 115 1 25126<br />

42mm 125 1 25128<br />

54mm 139 1 25130<br />

Suitable for:<br />

S<br />

TS2 Straight female connector<br />

a<br />

Za<br />

Size a Za S Order code<br />

15mm x 1 /2" 40 4 25 25206<br />

18mm x 1 /2" 40 4 25 25210<br />

18mm x 3 /4" 44 5 32 25212<br />

22mm x 1 /2" 45 4 32 25220<br />

22mm x 3 /4" 47 4 32 25222<br />

28mm x 1" 54 5 37 25225<br />

35mm x 1 1 /4" 84 6 48 25230<br />

42mm x 1 1 /2" 89 6 54 25232<br />

54mm x 2" 100 6 66 25234<br />

Suitable for:<br />

34 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TS3 Tapered male connector<br />

Size a Za S Order code<br />

15mm x 1 /2" 43 19 24 25267<br />

18mm x 1 /2" 43 19 24 25286<br />

18mm x 3 /4" 44 20 28 25288<br />

22mm x 3 /4" 46 17 28 25292<br />

28mm x 1" 54 20 36 25296<br />

35mm x 1 1 /4" 83 26 43 25310<br />

42mm x 1 1 /2" 88 26 50 25312<br />

54mm x 2" 100 31 61 25314<br />

Suitable for:<br />

a<br />

S<br />

Za<br />

TS6 Reducer<br />

Size a Za Order code<br />

18 x 15mm 46 22 25424<br />

22 x 15mm 52 30 25426<br />

22 x 18mm 52 28 25430<br />

28 x 15mm 55 31 25435<br />

28 x 18mm 55 31 25437<br />

28 x 22mm 56 27 25438<br />

35 x 22mm 83 54 25452<br />

35 x 28mm 87 53 25454<br />

42 x 22mm 87 58 25458<br />

42 x 28mm 92 58 25460<br />

42 x 35mm 116 59 25462<br />

54 x 35mm 124 67 25470<br />

54 x 42mm 129 67 25472<br />

Suitable for:<br />

Za<br />

a<br />

TS12 Elbow<br />

Size a Za Order code<br />

15mm 33 9 25516<br />

18mm 35 11 25520<br />

22mm 41 12 25524<br />

28mm 49 15 25528<br />

35mm 76 19 25530<br />

42mm 85 23 25532<br />

54mm 98 29 25534<br />

a<br />

Za<br />

Za<br />

a<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 35

Stainless steel push-fit fittings<br />

for stainless steel tube<br />

a<br />

Za<br />

b<br />

TS12S Street elbow<br />

Size a b Za Order code<br />

15mm 32 44 8 25496<br />

18mm 35 48 11 25498<br />

22mm 41 50 12 25500<br />

28mm 49 57 15 25502<br />

Suitable for:<br />

TS13 Male elbow<br />

b<br />

Size a b Za Order code<br />

a<br />

Za<br />

15mm x 1 /2" 33 29 9 25561<br />

18mm x 1 /2" 35 33 11 25569<br />

22mm x 3 /4" 41 34 12 25576<br />

28mm x1" 49 41 15 25578<br />

Suitable for:<br />

TS14 Female elbow<br />

a<br />

Za<br />

Zb<br />

b<br />

Size a b Za Zb Order code<br />

15mm x 1 /2" 34 25 10 12 25606<br />

18mm x 1 /2" 36 25 12 12 25614<br />

18mm x 3 /4" 40 25 16 11 25615<br />

22mm x 3 /4" 42 33 13 18 25620<br />

28mm x 1" 49 37 15 21 25622<br />

Suitable for:<br />

TS15 Backplate elbow<br />

Za<br />

a<br />

Size a b c Za Zb Order code<br />

b<br />

Zb<br />

c<br />

15mm x 1 /2" 44 35 19 11 13 25646<br />

18mm x 1 /2" 44 35 19 11 13 25650<br />

22mm x 3 /4" 53 43 21 14 17 25654<br />

Suitable for:<br />

36 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TS21 Obtuse elbow<br />

Size a Za Order code<br />

15mm 33 9 26043<br />

18mm 33 9 26045<br />

22mm 39 10 26047<br />

28mm 49 15 26048<br />

35mm 77 20 26049<br />

42mm 85 23 26050<br />

54mm 98 29 26051<br />

a<br />

Za<br />

Za<br />

a<br />

Suitable for:<br />

TS21S Obtuse street elbow<br />

Size a b Za Order code<br />

15mm 33 36 9 26063<br />

18mm 33 37 9 26065<br />

22mm 39 42 10 26067<br />

28mm 46 48 12 26068<br />

35mm 66 93 9 26069<br />

42mm 75 106 13 26070<br />

54mm 83 114 14 26071<br />

a<br />

Za<br />

b<br />

Suitable for:<br />

TS24 Equal tee<br />

Size a b Za Zb Order code<br />

15mm 66 33 9 9 25666<br />

18mm 66 33 9 9 25670<br />

22mm 78 39 10 10 25676<br />

28mm 92 46 12 12 25678<br />

35mm 154 77 20 20 25680<br />

42mm 170 85 23 23 25682<br />

54mm 196 98 29 29 25684<br />

Suitable for:<br />

b<br />

Zb<br />

Za<br />

a<br />

Za<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 37

Stainless steel push-fit fittings<br />

for stainless steel tube<br />

3<br />

TS25 Tee, reduced branch<br />

b<br />

Zb<br />

Size a b Za Zb Order code<br />

1<br />

Za<br />

a<br />

Za<br />

2<br />

18 x 18 x 15mm 60 31 6 7 25725<br />

22 x 22 x 15mm 71 35 6 11 25737<br />

22 x 22 x 18mm 75 35 8 11 25742<br />

28 x 28 x 15mm 79 39 6 15 25744<br />

28 x 28 x 18mm 82 41 7 17 25745<br />

28 x 28 x 22mm 86 43 9 14 25746<br />

35 x 35 x 15mm 137 63 11 39 25750<br />

35 x 35 x 22mm 148 73 17 49 25752<br />

35 x 35 x 28mm 148 76 17 42 25753<br />

42 x 42 x 22mm 159 76 17 47 25756<br />

42 x 42 x 28mm 159 79 17 45 25758<br />

54 x 54 x 22mm 176 77 19 48 25762<br />

54 x 54 x 28mm 176 85 19 51 25764<br />

54 x 54 x 35mm 178 86 20 29 25765<br />

54 x 54 x 42mm 184 91 23 29 25766<br />

Suitable for:<br />

TS30 Female branch tee<br />

b<br />

Zb<br />

Size a b Za Zb Order code<br />

Za<br />

a<br />

Za<br />

15 x 15mm x 1 /2" 68 25 10 12 25840<br />

18 x 18mm x 1 /2" 74 28 13 15 25843<br />

22 x 22mm x 1 /2" 78 27 10 14 25845<br />

22 x 22mm x 3 /4" 80 30 11 15 25846<br />

28 x 28mm x 1 /2" 86 32 9 19 25847<br />

35 x 35mm x 1 /2" 136 49 11 36 25848<br />

42 x 42mm x 1 /2" 147 52 12 27 25850<br />

Suitable for:<br />

38 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TS61 Stop end<br />

Size a Order code<br />

15mm 24 25866<br />

18mm 24 25870<br />

22mm 29 25874<br />

28mm 34 25876<br />

35mm 57 25878<br />

42mm 62 25880<br />

54mm 69 25882<br />

a<br />

Suitable for:<br />

TS62 Tap connector<br />

Size a Za Order code<br />

15mm x 1 /2" 43 19 25902<br />

22mm x 3 /4" 52 24 25903<br />

Suitable for:<br />

a<br />

Za<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 39

Carbon steel push-fit fittings<br />

System tubes<br />

SC640 Carbon steel system tube<br />

Size Finish Length Order code Length Order code<br />

15mm x 1.2mm* Galvanised steel 6m 45080 3m 25080<br />

18mm x 1.2mm* Galvanised steel 6m 45081 3m 25081<br />

22mm x 1.5mm* Galvanised steel 6m 45082 3m 25082<br />

28mm x 1.5mm* Galvanised steel 6m 45083 3m 25083<br />

35mm x 1.5mm* Galvanised steel 6m 45084 3m 25084<br />

42mm x 1.5mm* Galvanised steel 6m 45085 3m 25085<br />

54mm x 1.5mm* Galvanised steel 6m 45086 3m 25086<br />

Suitable for:<br />

SC660 Plastic coated carbon steel system tube<br />

Size Finish Order code<br />

15mm x 2.2mm* x 6m Galvanised steel 25060<br />

18mm x 2.2mm* x 6m Galvanised steel 25061<br />

22mm x 2.5mm* x 6m Galvanised steel 25062<br />

28mm x 2.5mm* x 6m Galvanised steel 25063<br />

35mm x 2.5mm* x 6m Galvanised steel 25064<br />

42mm x 2.5mm* x 6m Galvanised steel 25065<br />

54mm x 2.5mm* x 6m Galvanised steel 25066<br />

Suitable for:<br />

Za<br />

a<br />

b<br />

Advance push-fit fittings<br />

TA1 Straight coupling<br />

Size a b Za Order code<br />

15mm 40 23 3 76000<br />

18mm 42 26 4 76001<br />

22mm 42 31 4 76002<br />

28mm 46 38 6 76003<br />

35mm 67 46 7 76004<br />

42mm 74 55 7 76005<br />

54mm 78 67 7 76006<br />

Suitable for:<br />

*Supplied and priced from the XPress Stainless range.<br />

40 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TA2 Straight female connector<br />

Size a b Za Order code<br />

15mm x 1 /2" 39 27 3 76007<br />

18mm x 1 /2" 38 30 2 76008<br />

22mm x 3 /4" 42 36 5 76010<br />

28mm x 1" 47 41 4 76011<br />

Suitable for:<br />

Za<br />

a<br />

b<br />

TA3 Tapered male connector<br />

Size a b Za Order code<br />

15mm x 1 /2" 39 27 21 76013<br />

18mm x 1 /2" 40 30 22 76014<br />

22mm x 3 /4" 42 36 24 76016<br />

28mm x 1" 48 46 26 76017<br />

35mm x 1 1 /4" 60 52 29 76018<br />

42mm x 1 1 /2" 62 63 30 76019<br />

54mm x 2" 69 78 34 76020<br />

Suitable for:<br />

b<br />

a<br />

Za<br />

TA6 Reducer<br />

Size a b Za Order code<br />

18 x 15mm 42 18 25 76021<br />

22 x 15mm 45 22 27 76022<br />

22 x 18mm 48 22 30 76023<br />

28 x 15mm 51 28 34 76024<br />

28 x 18mm 51 28 32 76025<br />

28 x 22mm 52 28 32 76026<br />

35 x 15mm 67 35 48 76110<br />

35 x 18mm 65 35 47 76111<br />

35 x 22mm 62 35 43 76027<br />

35 x 28mm 64 35 43 76028<br />

42 x 22mm 71 42 53 76112<br />

42 x 28mm 68 42 48 76113<br />

42 x 35mm 77 42 46 76029<br />

54 x 22mm 84 54 65 76030<br />

54 x 28mm 81 54 61 76031<br />

54 x 35mm 84 54 54 76114<br />

54 x 42mm 86 54 54 76032<br />

Suitable for:<br />

a<br />

Za<br />

a<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 41

Carbon steel push-fit fittings<br />

TA12 Elbow<br />

a<br />

Za<br />

Za<br />

a<br />

r<br />

b<br />

Size a b Za r Order code<br />

15mm 35 23 17 18 76033<br />

18mm 40 26 21 22 76034<br />

22mm 46 31 26 27 76035<br />

28mm 55 38 35 34 76036<br />

35mm 73 46 42 42 76037<br />

42mm 83 55 51 50 76038<br />

54mm 101 68 64 65 76039<br />

Suitable for:<br />

b<br />

TA12S Street elbow<br />

a<br />

Za<br />

r<br />

c<br />

Size a b c Za r Order code<br />

15mm 35 23 52 17 18 76040<br />

18mm 40 26 52 21 22 76041<br />

22mm 46 31 58 26 27 76042<br />

28mm 55 38 68 35 34 76043<br />

35mm 73 46 93 42 42 76044<br />

42mm 83 55 105 51 50 76045<br />

54mm 101 68 117 65 65 76046<br />

Suitable for:<br />

TA21 Obtuse elbow<br />

a<br />

Za<br />

Za<br />

r<br />

a<br />

b<br />

Size a b Za r Order code<br />

15mm 25 23 7 18 76047<br />

18mm 27 26 9 22 76048<br />

22mm 30 31 11 27 76049<br />

28mm 35 38 15 34 76050<br />

35mm 48 46 17 42 76051<br />

42mm 54 55 21 50 76052<br />

54mm 63 68 26 65 76053<br />

Suitable for:<br />

42 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TA21S Obtuse street elbow<br />

Size a b c Za r Order code<br />

b<br />

r<br />

15mm 25 23 37 7 18 76054<br />

18mm 27 26 39 9 22 76055<br />

22mm 30 31 42 11 27 76056<br />

28mm 35 38 48 15 34 76057<br />

35mm 48 46 68 17 42 76058<br />

42mm 54 55 76 21 50 76059<br />

54mm 63 68 86 26 65 76060<br />

a<br />

Za<br />

c<br />

Suitable for:<br />

TA24 Equal tee<br />

b<br />

Size a b c Za Zc Order code<br />

15mm 59 23 30 12 12 76061<br />

18mm 63 26 31 14 13 76062<br />

22mm 67 31 34 16 16 76063<br />

28mm 78 38 38 21 20 76064<br />

35mm 109 47 55 24 24 76065<br />

42mm 120 55 61 27 28 76066<br />

54mm 141 68 71 40 35 76067<br />

c<br />

Zc<br />

Za<br />

a<br />

Za<br />

Suitable for:<br />

TA25 Tee, reduced branch<br />

Size a b c Za Zc Order code<br />

18 x 18 x 15mm 60 26 30 12 13 76068<br />

22 x 22 x 15mm 62 31 32 13 14 76069<br />

22 x 22 x 18mm 63 31 34 13 16 76070<br />

28 x 28 x 15mm 66 38 37 13 19 76071<br />

28 x 28 x 18mm 68 38 37 14 19 76072<br />

28 x 28 x 22mm 71 38 37 16 17 76073<br />

35 x 35 x 15mm 83 47 41 11 24 76074<br />

35 x 35 x 18mm 86 47 42 12 24 76075<br />

35 x 35 x 22mm 90 47 42 14 22 76076<br />

35 x 35 x 28mm 96 47 45 17 25 76077<br />

42 x 42 x 22mm 99 55 45 18 25 76078<br />

42 x 42 x 28mm 105 55 47 21 27 76079<br />

42 x 42 x 35mm 120 55 60 28 29 76080<br />

54 x 54 x 22mm 106 68 51 16 31 76081<br />

54 x 54 x 28mm 112 68 53 19 33 76082<br />

54 x 54 x 35mm 125 68 66 31 35 76083<br />

54 x 54 x 42mm 136 68 70 31 38 76084<br />

c<br />

Zc<br />

Za<br />

a<br />

Za<br />

b<br />

Suitable for:<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 43

Carbon steel push-fit fittings<br />

c<br />

Za<br />

a<br />

Za<br />

b<br />

TA30 Female branch tee<br />

Size a b c Za Order code<br />

15 x 15mm x 1 /2" 59 23 47 12 76085<br />

18 x 18mm x 1 /2" 63 26 45 14 76086<br />

22 x 22mm x 1 /2" 67 31 55 16 76087<br />

28 x 28mm x 1 /2" 71 38 56 16 76088<br />

35 x 35mm x 1 /2" 90 47 70 14 76089<br />

42 x 42mm x 1 /2" 99 55 64 18 76090<br />

54 x 54mm x 1 /2" 106 68 70 16 76091<br />

Suitable for:<br />

TS61 Stop end<br />

b<br />

a<br />

Size a Order code<br />

15mm* 24 25866<br />

18mm* 24 25870<br />

22mm* 29 25874<br />

28mm* 34 25876<br />

35mm* 57 25878<br />

42mm* 62 25880<br />

54mm* 69 25882<br />

Suitable for:<br />

TA69 Straight male union connector<br />

b<br />

a<br />

Za<br />

Size a b Za Order code<br />

15mm x 1 /2" 72 32 53 76092<br />

18mm x 1 /2" 72 32 53 76094<br />

22mm x 3 /4" 78 38 59 76097<br />

28mm x 1" 86 48 65 76099<br />

35mm x 1 1 /4" 97 53 66 76100<br />

42mm x 1 1 /2" 104 67 71 76101<br />

54mm x 2" 124 67 88 76102<br />

Suitable for:<br />

*Supplied and priced from the <strong>Tectite</strong> 316 range.<br />

44 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

<strong>Tectite</strong> accessories<br />

DT Disconnecting tool<br />

Size<br />

Order code<br />

10mm 45970<br />

12mm 45971<br />

14mm 45972<br />

15mm 45973<br />

16mm 45974<br />

18mm 45975<br />

22mm 45977<br />

28mm 45978<br />

DC Disconnecting clip<br />

Size<br />

Order code<br />

10mm 46100<br />

12mm 46101<br />

14mm 46102<br />

15mm 46103<br />

16mm 46104<br />

18mm 46105<br />

22mm 46107<br />

28mm 46108<br />

DTX Disconnecting tool<br />

Size Order code<br />

35-54mm 46145<br />

T66 PEX Liner<br />

Size<br />

Order code<br />

10mm 60100<br />

15mm 60103<br />

22mm 60105<br />

28mm 60106<br />

T67 Copper liner<br />

Size Order code<br />

10mm 60144<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 45

Accessories<br />

T110 Deburring/scribe tool<br />

Size Order code<br />

10-28mm 46132<br />

T115 <strong>Tectite</strong> Sprint deburring/scribe tool<br />

Size Order code<br />

10-28mm 75640<br />

T120 Pipe clips - nail in<br />

Size<br />

Order code<br />

10mm 60110<br />

15mm 60111<br />

22mm 60112<br />

28mm 60113<br />

T125 Bend former<br />

Size Order code<br />

15mm 60130<br />

T140 Pipe cutter-ratchet<br />

Size Order code<br />

10-28mm 60120<br />

TCX End cap<br />

Size<br />

Order code<br />

35mm 46180<br />

42mm 46181<br />

54mm 46182<br />

46 1 Range overview 2 Product details 3 Technical data 4 Installation instructions

2<br />

TDX Demounting end cap<br />

Size<br />

Order code<br />

35mm 46146<br />

42mm 46151<br />

54mm 46156<br />

TX100 Replacement ‘O’ ring<br />

Size<br />

Order code<br />

35mm 46147<br />

42mm 46148<br />

54mm 46149<br />

TX105 Replacement grab ring<br />

Size<br />

Order code<br />

35mm 46135<br />

42mm 46136<br />

54mm 46137<br />

TX106 Replacement grab ring for <strong>Tectite</strong> 316<br />

Size<br />

Order code<br />

35mm 46183<br />

42mm 46184<br />

54mm 46185<br />

S122 Tube preparation kit<br />

Size Order code<br />

35-54mm 39233<br />

S130 Silicone lubricant grease<br />

Size Order code<br />

100g tub 39219<br />

1 Range overview 2 Product details 3 Technical data 4 Installation instructions 47

Quarter-turn ball valves<br />

and servicing valves<br />

TX480 Servicing valve<br />

Za<br />

a<br />

Size a Za Order code<br />

15mm 69 21 65950<br />

Suitable for:<br />

a<br />

Za<br />

TX481 Servicing valve<br />

Size a Za Order code<br />

10mm x 1 /2" 74 50 45952<br />

15mm x 1 /2" 70 46 65954<br />

Suitable for:<br />

TX490L Quarter-turn ball valve<br />

Za<br />

a<br />

Size a Za Order code<br />

15mm 83 35 65962<br />

22mm 94 36 65964<br />

Suitable for:<br />

a<br />

Za<br />

TX495 Quarter-turn ball valve<br />