DG Technical Information - International Greenhouse Company

DG Technical Information - International Greenhouse Company

DG Technical Information - International Greenhouse Company

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

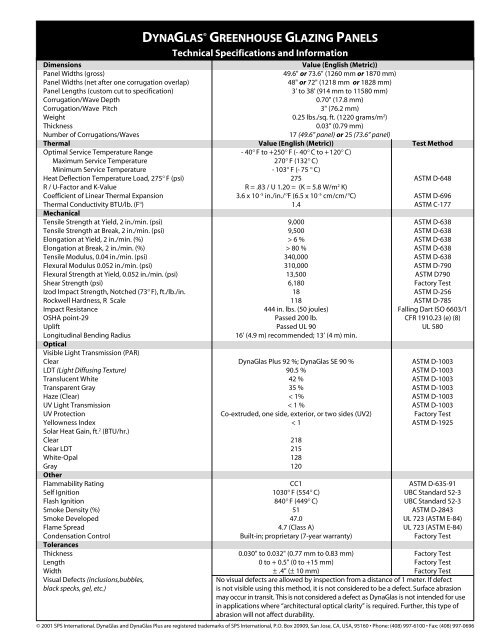

DYNAGLAS ® GREENHOUSE GLAZING PANELS<br />

<strong>Technical</strong> Specifications and <strong>Information</strong><br />

Dimensions<br />

Value (English (Metric))<br />

Panel Widths (gross)<br />

49.6" or 73.6" (1260 mm or 1870 mm)<br />

Panel Widths (net after one corrugation overlap)<br />

48" or 72" (1218 mm or 1828 mm)<br />

Panel Lengths (custom cut to specification)<br />

3' to 38' (914 mm to 11580 mm)<br />

Corrugation/Wave Depth<br />

0.70" (17.8 mm)<br />

Corrugation/Wave Pitch<br />

3" (76.2 mm)<br />

Weight 0.25 lbs./sq. ft. (1220 grams/m 2 )<br />

Thickness<br />

0.03" (0.79 mm)<br />

Number of Corrugations/Waves<br />

17 (49.6” panel) or 25 (73.6” panel)<br />

Thermal Value (English (Metric)) Test Method<br />

Optimal Service Temperature Range - 40° F to +250° F (- 40° C to + 120° C)<br />

Maximum Service Temperature 270° F (132° C)<br />

Minimum Service Temperature - 103° F (- 75 ° C)<br />

Heat Deflection Temperature Load, 275° F (psi) 275 ASTM D-648<br />

R / U-Factor and K-Value R = .83 / U 1.20 = (K = 5.8 W/m 2 K)<br />

Coefficient of Linear Thermal Expansion 3.6 x 10 -5 in./in./°F (6.5 x 10 -5 cm/cm/°C) ASTM D-696<br />

Thermal Conductivity BTU/lb. (F°) 1.4 ASTM C-177<br />

Mechanical<br />

Tensile Strength at Yield, 2 in./min. (psi) 9,000 ASTM D-638<br />

Tensile Strength at Break, 2 in./min. (psi) 9,500 ASTM D-638<br />

Elongation at Yield, 2 in./min. (%) > 6 % ASTM D-638<br />

Elongation at Break, 2 in./min. (%) > 80 % ASTM D-638<br />

Tensile Modulus, 0.04 in./min. (psi) 340,000 ASTM D-638<br />

Flexural Modulus 0.052 in./min. (psi) 310,000 ASTM D-790<br />

Flexural Strength at Yield, 0.052 in./min. (psi) 13,500 ASTM D790<br />

Shear Strength (psi) 6,180 Factory Test<br />

Izod Impact Strength, Notched (73° F), ft./lb./in. 18 ASTM D-256<br />

Rockwell Hardness, R Scale 118 ASTM D-785<br />

Impact Resistance 444 in. lbs. (50 joules) Falling Dart ISO 6603/1<br />

OSHA point-29 Passed 200 lb. CFR 1910.23 (e) (8)<br />

Uplift Passed UL 90 UL 580<br />

Longitudinal Bending Radius<br />

16' (4.9 m) recommended; 13’ (4 m) min.<br />

Optical<br />

Visible Light Transmission (PAR)<br />

Clear DynaGlas Plus 92 %; DynaGlas SE 90 % ASTM D-1003<br />

LDT (Light Diffusing Texture) 90.5 % ASTM D-1003<br />

Translucent White 42 % ASTM D-1003<br />

Transparent Gray 35 % ASTM D-1003<br />

Haze (Clear) < 1% ASTM D-1003<br />

UV Light Transmission < 1 % ASTM D-1003<br />

UV Protection Co-extruded, one side, exterior, or two sides (UV2) Factory Test<br />

Yellowness Index < 1 ASTM D-1925<br />

Solar Heat Gain, ft. 2 (BTU/hr.)<br />

Clear 218<br />

Clear LDT 215<br />

White-Opal 128<br />

Gray 120<br />

Other<br />

Flammability Rating CC1 ASTM D-635-91<br />

Self Ignition 1030° F (554° C) UBC Standard 52-3<br />

Flash Ignition 840° F (449° C) UBC Standard 52-3<br />

Smoke Density (%) 51 ASTM D-2843<br />

Smoke Developed 47.0 UL 723 (ASTM E-84)<br />

Flame Spread 4.7 (Class A) UL 723 (ASTM E-84)<br />

Condensation Control Built-in; proprietary (7-year warranty) Factory Test<br />

Tolerances<br />

Thickness 0.030" to 0.032" (0.77 mm to 0.83 mm) Factory Test<br />

Length 0 to + 0.5" (0 to +15 mm) Factory Test<br />

Width ± .4" (± 10 mm) Factory Test<br />

Visual Defects (inclusions,bubbles,<br />

No visual defects are allowed by inspection from a distance of 1 meter. If defect<br />

black specks, gel, etc.)<br />

is not visible using this method, it is not considered to be a defect. Surface abrasion<br />

may occur in transit. This is not considered a defect as DynaGlas is not intended for use<br />

in applications where “architectural optical clarity” is required. Further, this type of<br />

abrasion will not affect durability.<br />

© 2001 SPS <strong>International</strong>. DynaGlas and DynaGlas Plus are registered trademarks of SPS <strong>International</strong>, P.O. Box 20909, San Jose, CA, USA, 95160 • Phone: (408) 997-6100 • Fax: (408) 997-0696

Other <strong>Technical</strong> Notes<br />

Light Transmission<br />

Recent test results utilizing a Licor LI-1800 Spectroradiometer confirm the above indicated light transmission values in an<br />

actual greenhouse environment. These tests also confirm that DynaGlas Plus, since it eliminates the millions of condensate<br />

droplets that would otherwise reflect sun light back into the atmosphere, transmits 30% more PAR light and 45% more<br />

infrared energy than corrugated polycarbonate panels without an effective condensate control mechanism. DynaGlas Plus’<br />

condensate control feature has been proven to control condensation in full-scale commercial greenhouses for more than 5<br />

years — without any loss of effectiveness!<br />

Compared to Polycarbonate Structured Sheet<br />

One of the primary disadvantages of polycarbonate structured, or double-skinned, sheet is its relatively low level of light<br />

transmission, about 78% - 80% when new. Additionally, structured sheet requires rafter support every four or six feet,<br />

depending on panel width. This results in further light transmission loss of about 4%, resulting in a net light transmission<br />

factor of about 74%. And this value further diminishes as a result of eventual dust and/or algae build-up in the panel cavities.<br />

U-Factor<br />

The insulating characteristics of glazing materials is a complex subject, involving much more than simple U-factors. Typical U-<br />

factors for some glazing materials are: Fiberglass, 1.25; DynaGlas Plus, 1.20; Glass, 1.16; Structured Sheet, .64. However, a glass<br />

greenhouse suffers additional heat loss through conduction at the metal glazing rafters and through infiltration at glass laps,<br />

especially under windy conditions.<br />

It is important to note that DynaGlas Plus incorporates two important features which result in heat gain:<br />

(1) A built-in proprietary condensate control mechanism, and (2) a heat- and strength-enhancing surface contour which<br />

reduces the reflection of solar energy. DynaGlas Plus’ efficient condensate control mechanism eliminates the millions of<br />

droplets which would otherwise reflect away solar energy. Test results show that, during peak periods, DynaGlas Plus<br />

transmits up to 45% more heat energy than panels without an effective condensate control mechanism.<br />

DynaGlas Plus’ contoured shape reduces the problem of the reflection of solar energy on flat surfaces due to the low angle at<br />

which the sun’s rays strike these surfaces during early morning and evening hours, especially during the colder months. With<br />

DynaGlas Plus, many of these rays strike the panels perpendicular to the slanted vertical corrugation walls, facilitating their<br />

transmission into the greenhouse interior.<br />

Finally, the ideal greenhouse in terms of energy conservation is a DynaGlas Plus house fitted with an SPS ThermaShade <br />

Curtain System. While the installed cost of this combination is very comparable to that of structured sheet construction<br />

without a curtain, its insulating effect is far superior. Depending on the type of material selected, annual energy savings of up<br />

to 50% may be realized. And there is the additional important benefit of being able to shade the greenhouse, on a very<br />

selective basis, at no additional cost.<br />

Panel Weight<br />

Prospective users of corrugated polycarbonate panels should be aware that some brand panels weigh<br />

as little as .205 lbs/sq. ft. This results in a directly proportional reduction of about 20% in panel strength and rigidity.<br />

3" (76 mm)<br />

DynaGlas Plus Panel Configuration and Dimensions<br />

Panel center<br />

1" (25 mm)<br />

.625" (16 mm)<br />

Gross panel width: 49.6" (1260 mm) or 73.6" (1860 mm)<br />

Net coverage after one (1) corrugation overlap: 48" (1220 mm) or 72" (1830 mm)