Small Scale Foundries for Developing Published by: Intermediate ...

Small Scale Foundries for Developing Published by: Intermediate ...

Small Scale Foundries for Developing Published by: Intermediate ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Choice of Moulding Method<br />

The method of moulding to be used must be<br />

related to the type of castings to be produced<br />

and to the skills and equipment available in<br />

the foundry.<br />

<strong>Small</strong> castings are usually produced in<br />

sand tnoulds, <strong>by</strong> hand if the quantities are<br />

not large, or on moulding machines <strong>for</strong><br />

repetition work. Larger castings may also be<br />

made with moulding machines, although<br />

large machines are expensive. It will be<br />

necessary to handle large moulds with a<br />

crane, whether these are made <strong>by</strong> machine<br />

or <strong>by</strong> hand.<br />

Running and feeding<br />

The choice of the moulding method must<br />

also be related to the methods used to introduce<br />

the molten metal into the casting cavity<br />

through the runner system.<br />

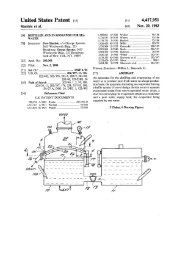

A typical runner system consis;? .3f a<br />

basin, <strong>for</strong>med in the top of the mouid, to<br />

receive the metal as it is poured from the<br />

ladle. From this basin a vertical channel,<br />

called a downsprue, leads to the mould joint<br />

level, wnere horizontal channels known as<br />

runner bars lead to the casting cavity. The<br />

metal flows into the casting cavity from the<br />

runner bars through entry positions known<br />

as ingates.<br />

As the metal in the casting cools and<br />

solidifies, it contracts. Unless more liquid<br />

metal is able to flow in to keep the cavity<br />

full, the casting will solidify with empty<br />

spaces or porosity. The additional liquid<br />

metal is prcvided <strong>by</strong> the use of feeders.<br />

Feeders are masses of metal, larger in section<br />

than the casting, joined to the ingate,<br />

and calculated to remain liquid until after<br />

the casting is completely solid.<br />

7<br />

Much of the skill of casting production<br />

lies in the way in which the runner and feeder<br />

systems are designed. The metal must flow<br />

freely hito the thinnest sections of the casting,<br />

without scouring and washing away the<br />

sand. Slag and dirt should be prevented<br />

from enter’:lg the casting. Porosity and<br />

shrir,h.lge must be avoided, <strong>by</strong> carp j<br />

design of the solidification process, I ;-<br />

feeders (and in some cases chins, whit:<br />

metal inserts i- ;he mould to accelerate cooling<br />

lticaliy). P,“,I the same time the vie! 1 of the<br />

weight of cas”n,+ to the weight of runner<br />

system h. s to be kept as high as po&ole tc<br />

minimise meltir :; c,)sts.<br />

Different metals, different casting designs,<br />

different mo!ltding methods, and<br />

different pattern-m;,.\.ng methods require<br />

different ::rpes c unner system design.<br />

Methods correct i ,)I one foundry may not be<br />

suitable <strong>for</strong> another foundry.<br />

There are no fixed rules, the best methods<br />

being developed <strong>by</strong> experience and trial and<br />

error.<br />

Some foundries rely upon moulders to<br />

design the runner system, whilst in other<br />

foundries this is the responsibility of the<br />

pattern designer or the manager.<br />

Even in the small scale foundry, much<br />

time, ef<strong>for</strong>t and cost can be saved if experienced<br />

advice can be obtained in the field of<br />

runner system design.<br />

Moulding Boxes<br />

To produce most types of mould, prepared<br />

moulding sand is rammed around the<br />

pattern. Usually the pattern is set in a frame<br />

or moulding box. Moulding boxes may be<br />

made of iron, steel or wood. Moulding<br />

boxes must be accurately constructed, par-