Un ed States Patent

Un ed States Patent

Un ed States Patent

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

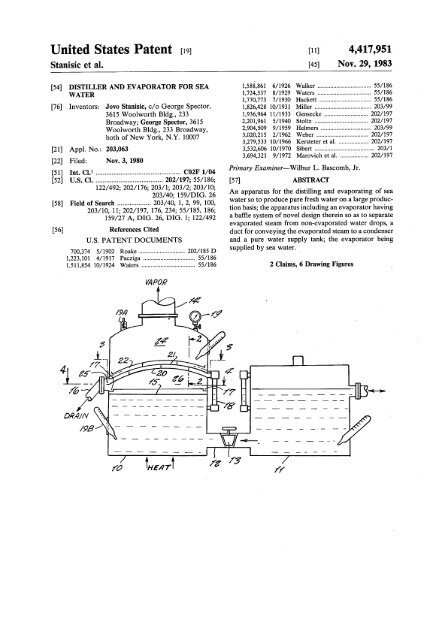

<strong>Un</strong> <strong>ed</strong> <strong>States</strong> <strong>Patent</strong>S~c et al.Ill] 4,417,951~ Nov. 2~ 1983[54] DISTILLER AND EVAPORATOR FOR SEA I~8~861 6/1926 Walker ...............................55/186WATER1fl2~5378/1929Waters...............................55/1861fl7~7737/1930Hackett..............................55/186[76] Inventors: Jovo Stani~ c/o George SpectoL 1~2~42810/193! Miller ...............................203/993615 Woolworth Bldg., 2331)3~96411/1933Gensecke............................202/197Broadway; George Spectoh 3615~201~61 5/1940Stoltz...............................202/197Woolworth Bldg., 233 Broadway, ~90~509 9/1959Helmers..............................203/99both of New York, N.Y. 100073~2~215 2/1962Weber...............................202/1973,279,533 10/1966Kersteteret al ....................202/197[21]Appl. No.: 20a,0633,532,606 10/1970Sibert...............................203/1~69~3219/1972Marovichet al ...................202/197[22] Fil<strong>ed</strong>: Nov. 3, 1980Prima~ Examiner--Wilb~ L. B~com~ J~[51] InL Cl) ................................................C02F 1/04[52] U.S. Cl .......................................202/197; 55/18~ABSTRACT122/492; 202/17~ 203/1; 203/2; 203/10;An appar~us ~r the ~stilhng and evap~ating of sea203/40; 159/DIG. 26water so ~ produce pu~ ff~h w~er on a large produ~[58] Field of Search ................... 203/40, 1, 2, 99, 100,fion bails; the appar~us ~u~ng an evapor~or hav~g203/10, 11; 202/197, 17~ 234; 55/185, 18~159/27 A, DIG. 2~ DIG. I; 122/492a ba~e sy~em of novd defign ther~n so as to separateevapor~<strong>ed</strong> steam from nomevapor~<strong>ed</strong> water drop~ a[56] References Cit<strong>ed</strong>du~ ~r conve~ng the evapom~d ~eam ~ a conden~rU.S. PATENT DOCUMENTSand a pure water sup~y ~n~ the evapor~or bring700~74 5/1902 Roake .............................202/185 Dsupp<strong>ed</strong> by ~a w~e~1~2~I01 4/1917 Pac~ga .................................55/1861,511,854 10/1924 W~ers ..................................55/1864

U.S. <strong>Patent</strong>Nov. 29, 1983 4,417,951

4,417,951DISTILLER AND EVAPORATORFOR S~drMns water from the evapormor when ff~becomesheavily saturat<strong>ed</strong> with brin~ Another drainpipe 16 withWATER ’ a colMction canM 17 ~ a ring plme 15 colMc~ nonevaporM<strong>ed</strong>brine water droplets. ~ :T~s ~vem~n r~es g~em~y m eq~pmem ~r ~e 5 The evaporator ~ provid<strong>ed</strong> wffh a water Mv~ gauge~ation and ~~ ~ ~a w~ ¯ 18, vacuum gauge 1~ a manom~er 19A and a s~om~It h wall known that ~th inc~as~g ~p~ the~ te~ , ~ ....is an ~c~g ~n~m~ of drin~ng w~er, and In the evaporator, the steam space 24 g ~NMd withwkh a g~ ~fi~z~o~ ~e ~ a h~ amoum baffles 2~,21 and 22, for the evapora~d ~eam. The10 purpose of the baffles N to separNevaporat<strong>ed</strong> steamof pure water ~q~d ~ various en~rg<strong>ed</strong> and newph~es of manu~ufing W~u~. Accor~n~% ~om non-evapor~<strong>ed</strong> water drops wh~h are not asthere ~ ~ a more ne<strong>ed</strong> to find other sources of jet-pure as distilMd ~eam. Each baffle 2~ and 21 aspu~ w~ than ~ pr~enfly b~ng o~n<strong>ed</strong> from ~k~, shown in FIG. 2, has ope~ngs 23 of diffuser shape.rivers and the 1~ pa~u~fly ~ ~ew that more and Such diffuser-shap<strong>ed</strong> openings acc~r~e the separ~nmore of k ~ ~ p~l~<strong>ed</strong> due to chem~s of l~ of saturat<strong>ed</strong> ~eam. The last component baffle 22 forms~du~ and w~te of mod~n ~v~g b~ng dump<strong>ed</strong>~ d~oy~g the n~ur~ puny of such waterbo~. It i~ ~e~, n~ur~ ~ a~enfion ~ nowa Nst barrier for non~vaporat<strong>ed</strong> water drops and fordisti~<strong>ed</strong> geam before entering steam space 2& Thebaffle surNce N equM ~ area to the ~Nde transverseb~ng ~ven to obt~n pur~ flesh w~ o~ of s~y ~a area of the evapor~or, and is arcuate for more effectivew~ ~ ~ me~ ~e p~nt day ~q~me~s. In ~me 20 separ~ion of distill<strong>ed</strong> ~eam. The lowermo~ baffle 2~countries flesh water ~ ration<strong>ed</strong> pa~afly ~ dry or has the Nrge~ surNc~ and on ~s peripherN <strong>ed</strong>ge has ahot season~colMcting vault 25 in which non-evapor~<strong>ed</strong> waterAccor~n~ ~ ~ a prin~p~ o~e~ of the w~em drops colMct and are convey<strong>ed</strong> to the drNn canM 17 ~~vem~n ~ prov~e an ~W~ ~s~Mr and evapor~tot ~r converting sea w~ ~ pure ff~h w~. 25 througri hng plat~h~5~iffuseE rVap°ratesh dape~teao mpeNnf~s°m2;reaand2~hePnAnther o~e~ h to pin,de a distiller and evaporator~r ~a w~ w~ch ~ one pa~uhr deign can be ~g coupe and b~ng partly dives~d of water drop~#nge on the second component baffle 21 while changus<strong>ed</strong>aboard a sh~ whe~ ~ t~s time there ~ a gre~ After g~ng through the openings 23 of the secondwa~e of he~ by ~e exhau~ g~ of ~e large en~n~baffle 21 pure steam and non-evaporat<strong>ed</strong> water dropspas~ng out of the s~p ~nnd and ~to the ~mosphe~, 30 are separ~<strong>ed</strong>, the pure ~eam then Maving ~eam spaceand wh~n t~s w~d heat ~ the ~nnd can be h~ness<strong>ed</strong>to produce ~ of the s~s ~q~mem of ~h24 through outlet pipe 14 to the condenseLTwo or more baffles ~ a same evapormor may bewater during an ocean voyag~ ~t any ad~fion~expens~ The ~a w~ us<strong>ed</strong> ~ co~ ~e en~n~ can beemploye~ as may be req~r<strong>ed</strong> for ma~mum effect.us<strong>ed</strong> as ~ ~ ~ready p~e~<strong>ed</strong> ~ to 45 degrees cen~ 35 In FIG. ~ a mottle design of ~ffuser opening 23 ~grad~ so it ~ ready ~r ~o~n.provid<strong>ed</strong> by a diffuser 30 of Venturi shape wffh dectriccontac~ 31 and 32 on 0ppo~te ~des so thin ~rge w~erO~ o~ec~ are to pro~de a distiller and evaporator~r ~a w~ w~ch ~ ~m~e in deign, inexpensiv<strong>ed</strong>rops entering the same will dose an dectric~c~t~ manu~ rugg<strong>ed</strong> in con~ru~ easy to use andthat will thus cause a spark thin will vaporize the w~ereffl~em ~ ~.40 drop. Thus preventing water drop passage therethrough.Contact 31 ~ ~ationary whim contact 32 isThese and ~~s ~1 be ready e~dem upona ~udy of the ~l~w~g ~e~fic~n and the accomp~ slidable closer ~her~o where ~eam pre~ure ~de arean~ng ~a~ wh~n26 is increas<strong>ed</strong>, at wh~h time there are Mrger concentrationof w~er drops so that they must be vaporiz<strong>ed</strong>.FIG. 1 ~ a ~mmm~c ~de vMw of a sy~em of the~em ~venfion.45 T~s ~ accomplish<strong>ed</strong> by a hollow accordian shap<strong>ed</strong>,FIG. 2 ~ an e~g<strong>ed</strong> det~ ~ cross section of ~e expandable case 33 interconnect<strong>ed</strong> to area 2~ andim~r baffle co~u~n ~e ~o~ t~ ~ong which pushes a #votabM lever 34 connect<strong>ed</strong> to slide 35section 2--2 of FIG. 1.which carries contact 32.FIG. 3 ~ a ~p ~ew ~ ~e baffle con~rucfion ~de While various changes may be made in the d~ilthe evapor~o~ as ~ew<strong>ed</strong> ~ direction 3--3 of FIG. 1. 50 construction, ff ~ unde~tood that such changes will beFIG. 4 ~ a cross secfion~ew on fi~ 4--4 of FIG. within the s#rit and scope of the present ~vention as ~1. defin<strong>ed</strong> by the append<strong>ed</strong>Mms.FIG. 5 is an e~g<strong>ed</strong> cross secfion~ ~ew on fine The following ~ dMme~5--5 of FI~ ~ ~o~ a peripher~ dr~nage can~. 1. A Sea water distiller comprising a sea w~er supplyFIG. 6 ~ a mo~ficafion of the ~venfion show~g a 55 tank connect<strong>ed</strong> by a conduito the bottom of an evaporatorwith heating mean~ ~duding a ring plmecross section ~rough a mottl<strong>ed</strong> ~se~. The proem ~vent~n is ~own ~ FIG. 1 to ~ude mount<strong>ed</strong> around the ~de periphery of sMd evaporatoran evapor~or 10 and a sea water sup~y water tank 11 at a pr<strong>ed</strong>~erm~<strong>ed</strong> levd, s~d ring pl~e ~u~ng aw~ch are ~onne~<strong>ed</strong> by a sup~y ~pe 12 ha~ng a pefipher~ dr~nage can~ ~ com~nation with a pluralsup~yv~ve 1~ w~ch ~ a~om~c~y ~g~<strong>ed</strong> by 60 Ry of spac<strong>ed</strong> venally curvate baffles above s~d pl~¯ e water Mvd ~t~n the evaporato~ The ~p of the the lowermo~ of s~d baffles having a peripher~ <strong>ed</strong>geevapor~or ~ connect<strong>ed</strong> w~h a condenser ~ot show~ portion<strong>ed</strong> above and l~er~ly adjacent s~d can~by a ~pe 14 ~r ~u~ ~o~ steam ~to ~econdenser whe~ a vacuum ~ o~n<strong>ed</strong> by vacuum ~e~whereby moi~ure ~ direct<strong>ed</strong> and dron<strong>ed</strong> from s~dbaffle to s~d can~, ~ fu~her combination with a dr~ntor~~ ~ow~. Condens<strong>ed</strong> water from a condens<strong>ed</strong>65 age pipe having an inl~ ~ commu~c~n wffh s~dsuction pump ~ show~ ~k~ wa~r and discharges k~ drin~ng w~er mn~ ~ ~ow~. A dr~n ~pe ~show~ ~ the b~mm of the evapor~or periodicallycanM for drayage purposes, sMd baffles having upwardorient<strong>ed</strong> diffusers and an upper solid baffle superimpos<strong>ed</strong>over sMd baffles with the diffuser~ sMd upper2

3baffle having an outer <strong>ed</strong>ge spac<strong>ed</strong> from evaporator~ner sur~ce whereby deflect<strong>ed</strong> ~eam vapor ~ direc~dpefipher~ly to the s~d <strong>ed</strong>ge and to a ~eam space aboves~d upper baffle ~duding a ~eam outlet above s~d~eam space wheron s~d diffusers ~duding means forvafia~y restrict~g water drops from pas~ng therethroughcompiling a Vemufi sect~n in s~d diffusers4,417,9514wi~ O~c~ m~ns ~ ~e Ve~ufi ~n ~r v~ofiz-~g water drops upon con~ of sa~ de~fic~ meanswith water drop~2. A ~sfil~r ~ ~ clam 1 wh~n s~d de~fic~means include ~e~fic con~ vafia~y spac<strong>ed</strong> respon-~ve to steam pressure.10152o253O355055

<strong>Un</strong> <strong>ed</strong> <strong>States</strong> <strong>Patent</strong>EII~ J~Ill]<strong>Patent</strong> Number:~ Date of PatenUWATER DEGASIFICATION AND3,479,949 11/1969Reynoldset al ......................99/295DISTILLATION APPARATUSL53L60610/1970Sibert...............................202/180L83E016 9/1974Powers...............................~ Invento~202/181John ~ EIH~ J~ 1084 P~m~ Ave, L935,0771/1976Dennison............................202/180LarchmonL N.Y. 10538~081~31 3/1978Weiss................................202/181~1] Ap~. N~: 48~767~13L984 1/1979Kirschmann..........................202/83~17~84212/1979Vitous...............................99/295~ ~l<strong>ed</strong>: Ap~ 2~ 1983~18~150 2/1980Rich............................203/DIG. 16~24L369 1/1981Bean................................202/181Rd~<strong>ed</strong> ~ A~ ~~25~616 2/1981Glazer...............................202/181~261fl964/1981Lemoine.............................202/181C~u~a~ ~ ~ No. 26~88~ Ju~ 3, 1981, ~269~63 5/1981McFee................................202/202Pa~ N~ ~3~.~41~95111/1983Stanisicet al .......................202/197~42~37412/1983Ellis................................202/176~1] InL ~? ...........................B01D 3/0~ ~2F 1~[5~ ~ ~ .....................................~ 202/18~FOREIGN PATENT DOCUMENTS202/181; 202/185.5; 2~/188; 202/19~202/197; 202/202; 202/23~ ~2~ ~203/1~ 203~ 203/2~ 203/DIG. 16;109551 1/1940 Amtmha .............................202/196Prima~ Examiner~Wiibur B~comb~ 22 Attorney, Agen~ or Firm--Eugene E Geoffre~ JL~ ~fld of Seth ..................... 202/188, 185.5, 17~ABSTRACT202/19~ 2~ 19~ 181, 18~ 83, 19~ 19~ 19~195, 202; ~. 17, 1~ I1, DIG. 2~ 2~ W~er deg~ific~n and ~stillation apparatus ha~ng aDIG. 16; 99/295 cont~ner ~r wa~er to be dega~fi<strong>ed</strong> and ~still<strong>ed</strong>, a~ R~ ~t<strong>ed</strong>~lativ~y small boiler a~ng s~d container and ha~~g a first condor e~en~ng ~to the cont~ner so thin a~S. PATENT DOCUMENTSs~e~<strong>ed</strong> wmer ~v~ ~ ~e confiner will fill s~d boiler284~II 8/1883Her~ck .......................~3~ 17 to a s~ec~d h~ght, a condenser w~n the con~er771,832 I~19~ R~ ..............................~I~ and immer~d ~ the water contain<strong>ed</strong> there,, a second851,~5 ~1907 ~ck ................................20~/196 cond~t e~en~ng ~om the space above the water ~9~9,6259/1910Ho~et ~ .....................2~/I~ s~d b~r to the ~t of the condense, an outlet on theI~I~508 2/1911 ~Cu~ ..............................202/196 condenser ex~n~ng ~rough a cont~ner w~] for ~~13~8 10/1938 Kess~ .................................202/1892~75~82 7/1949~em~s ..............................202/194char~ng dega~fi<strong>ed</strong> and ~s~d water and heating3~2~214 2/1962B<strong>ed</strong>uhn e~ ~ ....................203~0 X means m s~d boiler for heating the water therei~3~2~215 2/1962W~er ...............................203~ X3~4~305 ~1966 W~|~m~n .....................202/19~ X

U.S. Patem s~ 1~ 1~6 ~t3 ~S 4~12~90

U.S. <strong>Patent</strong> se~ 16, 1986 She~ 4 of 8 4,612,090

U.S. <strong>Patent</strong> se~ 1~ 1986 She~5 of 8 4,612,090

~S. Patem sev 16, 1986 S~ 6 ~8 4~12~900 o 0

-U.S. Palm s~ 16, 1986 S~ 7 a8 4~12~900

U.S. <strong>Patent</strong> se~ 16, 1986 She~ 8 of 8 4,612,090

~61~090A s~l ~h~ o~e~ of the invention re,des ~ theWATER DEGA~CA~ON AND D~LLA~ON prov~ion of a novd and ~ wm~ d~c~APPARATUSand d~t~n apparatus char~ri~d by ~s ~m~ff~ ~ ~~ and mMn~nance and r~mi~y ~wTMs ap~m~n ~ a continuation-in~a~ cf applic~ 5 cos~tion Se~ N~ 269,880 ~<strong>ed</strong> June 3, 1981 entitl<strong>ed</strong> "Wmer A s~l ~h~ o~e~ of the ~vention ~Nd~ ~ theDegasification and D~tillm~n Apparatus" now U.S. provM~ ~ a ~vd ~d ~pro~d b~ ~r ~e ~s~Pro. No. ~42~37~fion of water wNch mi~m~ ~e accum~ation ofTh~ ~vention r~a~s to d~ng apparmus and mo~ ~am ~ the b~er caus<strong>ed</strong> by sNt~ d~e~ and otherspe~ficflly to novd and improv<strong>ed</strong> water ~fl~tion10 water ~ma~ms wMch can ~nm~ the waterapparatus.bNng ~s~&Known ~sti~ng apparmus generally ~v~ve ~eutil~m~n of a dos<strong>ed</strong> boiler and means ~r continuoufly ~c~dan~ ~ ~e ~v~fion ~ud~ a ~n~r ~~e~ng wmer to the boiler. As the wmer ~ the boil~ m m~ ~d ~ ~c~ ~e wm~ ~ ~ ~s~d. A ~heat<strong>ed</strong> to produce wmer vapor or ~eam, v~ati~ cherub15 b~Mr ha~ng he~ng demems mourn<strong>ed</strong> ~on ~ p~Gc~ componen~ of water ha~ng boiling p~nts ~wer e~ secur<strong>ed</strong> to one ~de of the rank and a fl~d condMtcou#~ ~e bMMr ~ ~e rank ~ ~ ~e l~d Mvdthan the wmer will boil off and combine with the steam.The steam tog~her with the v~a~e vaporiz<strong>ed</strong> chemic~compone~s will then be condens<strong>ed</strong> ~ a s~tab~m ~e b~ ~H be conffdMd by ~e fiq~d Mvd ~ ~econdenser so that the ~sdm~ ~s~ wffi cont~n the 20 a__condense~ ank" A ~eam~o~ly~and ~ap°r ~d°Ufl~ ~ ~nthe b~er~ ~mkeou#<strong>ed</strong> tov~a~e chemic~ In ca~s wher~n ~e wmer has a outlet of the conden~r ex~nds ~rough the w~ of th<strong>ed</strong>isagreeable odor produc<strong>ed</strong> by s~phur compounds and tanZ The conden~r may be ~ ~ such a mann~~m ~e hq~d ~ ~e mk ~H ~r pm ~ ~ ~ ~ethe ~k~ known apparatus ~nds to concentra~ the odorcondenseL ~ ~ a~mm and wffh the heatersanp drior u.sm āke th;a~WateNr~ eve4, n33~30m 7°~fUlg "ran~d j~yApN~ant’l s3, 1982 25 ~ ~e bMMr ~g ~ ~e ~uM ~ ~e ~r ~Hen~tl<strong>ed</strong>: "D~tillm~u Apparmuf’ dNcloses distiNng heat Mmo~ ~anmneoufly and ~em ~H be ~ outappar~us embod~ng upper and ~wer chambers with ¯rough the condenseL As the p~e wff~ thethe condenNng coil ~spo~d ~ the upper chamber b~er exce<strong>ed</strong>s the capm~ of the outlet to rec~vewMch N normally fill<strong>ed</strong> wi~h w~er and graduNly ~d steam or water v~oL p~u~ will ~e water in theinto the ~wer chamber wNch N heat<strong>ed</strong> by a s~tab~means ~ order to prodnce geam. The steam g then ~d~ ~ ~& wm~ ~H ~Mn ~w ~o ~e b~upwardly through a condenser ~ the upper chamberand ~ then discharg<strong>ed</strong> ~om the condenser as a ~q~& ~ of the d~ apparatus. ~nee hot wmer ~By opiating the apparmus ~r a sho~ period of time 35 b~ c~smfly ~d ~ ~e mk and ~ ~m ~prior to the co~ection of the ~<strong>ed</strong> wate~ the condens~w~ ~cre~e ~e ~mperature of the wa~r ~ thecon~anfly ~mov<strong>ed</strong> ~om the c~m~ by ~e w~er~t~n ~e tanL ~e w~ wi~ ~e tank w~ ~e~eupper chamber ~nd bNl off vMa~e chemicN comp~ ~ mm~e and b~ off ~M ~e~c~ ~nent~tMn<strong>ed</strong> ~ ~e wm~ prior m ~s~lm~n ~e~o~ C~dTh~ ~vention constitutes an improvement over prior~ water ~ ~r~y ~d to ~e mk at ~e ~Mt to theknown ~stilling apparatus ~u~ng the apparmus d~dos<strong>ed</strong>~ apN~ant’s prior U~d Stat~ pment ~ Ihm ~ time ~e b~ ~ ~M~ Means may M~ be pro~d~b~ler so that the boiler wiB ree~ve cold wmer ~hembod~s a novd and improv<strong>ed</strong> smNI bNler ~ud~g ~ a~o~afion w~h the rank ~r ~e~ng condens<strong>ed</strong> ~instantaneous ~eating mean~ a conden~r ~nd a re~b ~Md ~d ~g~d ~ ~m ~e~ ~s ~rvNr wNch pro~d~ ~n a~omatic supNy ef wm~ to the 45 ma~ng co~ tea or merdy pro~de hot wmer ~rbN~r and may Nnction to con the condenser. With other pu~th~ arrangement, lhe water ~ the ~rvN~ ~ w~ be The ~ove and other ~ec~ and advanmg~ of theshowm ~rcMm~ m and from the boiler to repeme~y ~v~ti~ w~ become mo~ appa~m ~m the ~w-~rrupt boiling and hem thus impal<strong>ed</strong> lo the wmer ~ ~g ~ri~ and ~mpan~ d~ ~rm~g¯ e re~rvNr tog~her w~h ~e hem m ~t pa~ of ~ pa~ of t~s ~#c~.wMch may be impal<strong>ed</strong> by the condenser wffi heat thewater in the ~rvNr to a ~mperatu~ that w~ effectivdyboil off chemicN constituents of the water and FI~ 1 ~ a ~agmemary p~ ~w ~e m~mm~ ~E D~N~the time req~d for operation of the ~stil~r ~ order ~ ~ d~g ~m ~ ~e ~h ~ ~to produce a ~stillate free of the m~als and undesirab~ 55 tio~odors ~ mmeriN~ r<strong>ed</strong>uc<strong>ed</strong>.FIG. 2 ~ a ~o~ ~ctionM ~ew of FIG. 1 ~ ~Another o~ect of the ~vention reNdes ~ the provi- the ~ne 2--2 ~e~o~~on of novd and improv<strong>ed</strong> wmer dgtiHation apparmus FIG. 3 ~ a cro~ ~ctionM ~ew of FIG. 1 token MongwNch not o~y avNds co~rM means for fe<strong>ed</strong>~g wm~ the ~ne 3--3 ~e~and ~t~ ~ ~cd~ meansfrom a re~rvoir ~o a bNler but also embodi~ an arrangeme~and orga~zation of ~ements wher~n all FIG. 4 ~ a cro~ sectionM ~ew of the b~er and a60 cam<strong>ed</strong> by the comMne~potions of both the reservoir and boiler are readily ~agmemary po~on ~ the tank token ~ong the l~eacc~s~ for ~ea~ng and m~ntenanc~~ thereof of FIG. ~A still N~her o~e~ of the ~vention reNdes ~ the FIG. ~ ~ a ~de d~M ~ew of a mottl<strong>ed</strong> emprovisionof hot ~stil~d and sub~antially odobffee65 bo~mem of ~e ~vem~n ~r produ~ng d~Md wm~water ~r the brewing of coffee and ~a ~ well as for use ~r ~e and other ~od~~n the preparation of other ~ods such as soups and the FIG. 6 ~ a cro~ ~ctionM ~ew of FIG. 3 token Mong~k~the ~e a--6 m~eo~2

3~61~090FIG. 7 ~ a fide devafionfl ~ew ~ parti~ section of 41 and the boiler can be readily disassem~<strong>ed</strong> for deaning.The heating dements 13 and 14 in the ~ant em-the water tank and b~Mr of FIG. 5;FIG. 8 ~ a cross ~ction~ew of FIG. 5 taken ~ong bo~ment of the ~vention are carri<strong>ed</strong> by the w~141 andthe line 8--8 thereo~are connect<strong>ed</strong> in series by a lead 44 connecting oneFIG. 9 ~ a cro~ sectional ~ew ~ pe~pective of a 5 ~rmin~ of one heater to one term~ of the othermo~fi<strong>ed</strong> embo~ment of a d~fiNer ~ accordance wkh heate~ The power ~ne 45 has one lead 46 connect<strong>ed</strong> tothe invenfio~the other ~rm~ of the he~er 14 while the second leadFIG. 10 ~ a fragmentary crcss ~ction~ew of still 47 ~ connect<strong>ed</strong> through a thermo~ 48 to the otheranother embo~ment of the ~ventio~termin~ of the heater 13. The thermo~ is moun~d onFIG. 11 ~ an dev~ion~ ~ew of the water Mvd 10 a bracket 49 ~ dose pro~mky to the heater 13 and incontrol of FIG. 1~the even the heater 13 reaches a ~mperature above theFIG. 12 ~ an devation~ ~ew ~ partifl section taken norm~ operat~g ~mperatur~ the thermo~at will operateto open the drc~t and d~energ~e both heaters 13~ong the Nne 12--12 of FIG. 1~FIG. 13 is a cross sectionfl ~ew of FIG. 12 taken and 1~ R ~ evident however that heaters 13 and 14flong the l~e 13--13 thereo~15 cord be arrang<strong>ed</strong> for paralld operation or ~ the ~te~FIG. 14 ~ a cross section~ew of FIG. 13 taken nativ~ a ~ngle he~er may be employ<strong>ed</strong> provid<strong>ed</strong> howeverk drivers the quantky of heat necessary for oper~~ong the fine 14--14 thereo~ andFIG. 15 ~ a top ~ew ~ parti~ section of the boiler tion of the apparatu~shown ~ FIG. 10.If de,r<strong>ed</strong>, the tank or cont~ner 10 may be prov~<strong>ed</strong>Re~rring now to the drawings and more sp<strong>ed</strong>fic~ly 20 with a convention~ cover having openings therdn or ~to FIGS. 1 through ~ the ~g apparatus ~ acco~ the ~ternative may util~e forc<strong>ed</strong> ~r Orculation meansdance with the ~vention compds~ a cylindric~ tank or for the remov~ of unde~rable vapo~ Hbera~d from thecont~ner 10 ha~ng a p~r of handMs 11 secur<strong>ed</strong> to the Nquid w~hin the tank 10 during the course of the d~tillationprocess. One embodiment of air circulating meansfide thereo£ A boiler 12 ha~ng in~antaneous heatingdements 13 and 14 ther~n ~ affix<strong>ed</strong> to the fide of the25 ~ illustrat<strong>ed</strong> in FIG. & The ~r drculating means ifidudesan ~ve~<strong>ed</strong> dish<strong>ed</strong> cover gener~ly denot<strong>ed</strong> bytank 10 by the fl~d connectors 15 and 1~ The fl~dconnector 15 ~dud~ an ~bow 17 ha~ng a sho~der 18 the numer~ 50 which ~dudes a flat upper wall 51, anand a thread<strong>ed</strong> shank e~en~ng through cooperm~g upwardly extending pefipher~ wall 52 and a downwardlycurv<strong>ed</strong> peripher~ w~l 53. The lower peripher~ope~ngs ~ the wall 19 of the b~Mr 12 and the wM1 ofthe tank 10. A nut 20 engages the shank of the fitting 15 30 <strong>ed</strong>ge of the wMl 53 carries three or more angularlyand tog~her with a resilMnt w~her 21 pro~d~ a wv dispos<strong>ed</strong> rolM~ 54 each having space discs 55 rota~~r-tight seM for both the tank 10 and the b~ler 12. A ably carri<strong>ed</strong> by a sha~ ~ The discs 55 engage thewmer i~ tube 22 ~ fixe~y cou#<strong>ed</strong> to the fitting 13 by rolMd <strong>ed</strong>ge 10’ of the tank 10 and accordin~y providemeans of a nut 23 so that water wren the tank 10 will an annular vent b~ween the cover 15 and the <strong>ed</strong>ges ofbe automaticaNy ~d ~to the b~Mr 12 until the water35 the tank 10.levd wff~n the b~ler co~esponds to the wmer levd ~ The wall 51 of the ~r drculat~g means shown ~the tanL ~ w~ Mso be observ<strong>ed</strong> thin the wmer Mvd ~ FIG. 3 includes a motor gener~ly denot<strong>ed</strong> by the numer~57 which has a sha~ 58 extending through thethe tank ~ pre~raMy mMntMn<strong>ed</strong> m a Mvd to effe~ |olMor ~ Mast sub~antiM immerfion of the heating dements perforat<strong>ed</strong> wall 51 and carries a fan 59. Power ~ f<strong>ed</strong> to13 and ~4 ~ the wmer wff~n the boiler.40 the motor 57 by a ca~e 60 connect<strong>ed</strong> in a convention~The ~eam outlet fltt~g 16 ~ of conventionM con- manner to the moto~ If des~<strong>ed</strong>, sw~ch means may be~ruction and ~dud~ an outlet #pc 24, a thread<strong>ed</strong> provid<strong>ed</strong> for operation of the fan. The fan motor ~shank 2~ ex~nd~g through the walls of the tank and cover<strong>ed</strong> by a dome~hap<strong>ed</strong> houfing 61 securdy fi~<strong>ed</strong> tothe boiler and secur<strong>ed</strong> thereto by a nut 25. A sealing the cover 53 and secur<strong>ed</strong> thereto by any s~ta~e means.w~her 26 ~ d~po~d b~ween 1he tank and the boiler Io45 In the in~ant embodiment of lhe ~vention, the domeshap<strong>ed</strong>houfing 61 ~ adapt<strong>ed</strong> to frictionally engage thepro~de a w~evtight connection. The condenser 27 ~the ~ant embo~ment of the ~vention ~ ~ the form of peripher~ wall 52 of the cover 50. In operation, ~r ~a c~Md tube of m~M such as ~M~s ~<strong>ed</strong>, copper or drawn in through an opening 62 and the perforat<strong>ed</strong> wallthe Nke and has the ~Mt end potion 28 seMably connect<strong>ed</strong>to the fitting 16 wit~n the tank 10. The oufl~ 29 50 in the container and d~charg<strong>ed</strong> through the annular51 whereupon k ~ direct<strong>ed</strong>ownwardly over the w~erof the condenser 27 has a fitt~g 30 ex~nd~g through opening between the container 10 and cover 50.the wall cf the tank 10 and pro~d~ the fl~d oufl~ 31. In the operation of the di~ill~ion apparatus d~The tank fu~her ~dud~ ~n overflow p~e 22 w~ch ~ scrib<strong>ed</strong> abov~ the tank 10 and boiler 12 are fir~ filMdconnect<strong>ed</strong> to a fitt~g 33 seal<strong>ed</strong> to the wMl of the tank 10 with water to a Mvd at Mast substantially covering theand a drMn cock 34 for drM~ng l~d from the tanL A 55 heating dements 13 and 14 as wi~ be observ<strong>ed</strong> morew~er ~Mt vMve 34 ~ card<strong>ed</strong> m the upper potion of the deafly in FIG. 2. R will be observ<strong>ed</strong> th~ when fill~gtank or contMner 10 and has an inlet 3~ an outlet 37 the tank 10, water wi~ automatically flow through conduit22 ~to the boiler so that the Mvd of the water inwithin the tank and a hand-wheal 38 for reg~ating thewmer sup#y ~ order to mMntMn substantially constant lhe lank will be lhe same as the wa~r Mvd in the boile~Mvd of lhe w~er wff~n the tank.60 Energy ~ then suppN<strong>ed</strong> to the heating demen~ 13 andThe boiler ~ shown more deafly ~ FIG. 4 and confi~sof two hous~g demen~ 39 and 40. A drc~ar wMl boiler 12. S~am ~om lhe boiler win emerge through14 which win function to boil the water wkhin theor partition 41 ~ ~spos<strong>ed</strong> b~ween the houfing demen~ the outlet 24 and then flow through the condenser 1739 and 40 and ~dudes a p<strong>ed</strong>pherM seM 42 w~ch ~ and the condens<strong>ed</strong> ~eam will then be d~charg<strong>ed</strong> as ardeasably damp<strong>ed</strong> b~ween the outer alms of the hou~ 65 Hq~d ~om the outlet 31. When initi~ly operating this~g dements 39 and 40 by clips 43 about the periphery apparatu~ k ~ gener~ly defirabM to discard the d~tillateuntil the water within the tank 10 has attun<strong>ed</strong> aof the boiler 12. T~s arrangement com~etely ~Ms thechamber form<strong>ed</strong> by the hous~g posen 39 and the wall normally operat<strong>ed</strong> ~mperature which ~ ra~dly ~-4

5~61Z090tin<strong>ed</strong> in the following manne~ HeMers 13 and 14 are fion a ~m~ircd~ brackm 84 of L6hap<strong>ed</strong> section ~rdefign<strong>ed</strong> to hem the water wit~n the boiler at a rate ¯ dably recoving a basket 85 ~u~ramd ~ brokendines~ster than the condenser 27 can accommodMe the ~ FIG. 5 wMch may normally h~d a fi~er and groundsteam produc<strong>ed</strong>. Accordin~ pressure ~ devdop<strong>ed</strong> coffee. A base 86 engages and suppo~s the Z-shap<strong>ed</strong>within the boiler 12 and will force ~q~d ~om the boiler5 brack~ 72 and ~Oud~ a convenfionM de.fie heatingthrough the tube 22 back ~to the ~nk 1~ As soon as the dement 8% The heating dement 87 ~ prodd<strong>ed</strong> wffhpressure ~ reliev<strong>ed</strong> w~n the boile~ water w~ ag~n suitabl ener#zing conducmn and swim~ng means not~ow through the tube 22 back ~to the b~r w~h the shown so that ff may be turn<strong>ed</strong> on and off as defi~&resdt that there w~ be a perio~c reve~ of water The space b~ween ~e b~mm of ~e basket 85 and ~eflow through the tube 22. T~s action resu~s ~ a sub-10 top of the heating demem 87 ~ of ~ffident magnitude~anti~ ~crease ~ temperature of the wa~r w~n Ihe to ~cdve a s~m~e ~cepm~e 88 ~r ~c~ng b~wCd~nk 10 and contributes to the he~ impal<strong>ed</strong> to the coffee. It ~ ob~o~ ~om ~e ~g~ng d~cus~on thMwMer ~ the ~nk 10 by the action of the condenser 2~ the basket 85 may be a~ang<strong>ed</strong> to aceommodMe teaThe ~mper~ure of the w~er tank 10 however ~ ~- ~aves ~r the brewing of tea or ~ the ~rnative theways brow the boiling ~mperature and shodd pre~ra-15 distill<strong>ed</strong> water ~om the fittMg 83 can be f<strong>ed</strong> ~ctly~y be ~ the range of 180’ F. to 19& ~ ~ order to be ~to ~e ~ce~ac~ 88 ~r making soup or any otherce~n that undesirab~ componen~ ~ the water are purple ~r w~ch purifi<strong>ed</strong> ~s~l<strong>ed</strong> w~ may be ~-boil<strong>ed</strong> off prior to a~u~ d~tiH~n.q~&In one form of the ~vention utilizing a tank 10 hating The cont~ner 70 ~dud~ a ~sh<strong>ed</strong> cover gener~lya v~ume ~f 1 to 2 gallons of w~e~ a b~lCr 12 h~d~g20 denot<strong>ed</strong> by the num~ 89 wMch may be affix<strong>ed</strong> ~ theappro~m~dy 16 ounces of wate~ heating dements contMner 70 by any s~tab~ mean~ The cover 89 ~-deign<strong>ed</strong> to d~fipMe from 1,500 to ~000 wMt~ ~ wffi ~udes an ope~ng 90 for ~e~ng wMer ~to the cont~ner70 and a cooperat~g rid 91. Forc<strong>ed</strong> Mr O~-take appro~m~dy 15 minu~s of operM~n for thewater ~ the ~nk to reach a ~mperature of approxim~dy18~ ~ lo 19& F. and the b~r wffi normally25 ri<strong>ed</strong> on the top ~de of the cover 91 and ~dud~ an~g means general~ denot<strong>ed</strong> by the nume~l 92 ~ ca~hem tap water above the boiling p~nt wit~n about 45 de~ric m~or and ~n subs~ntially ~mil~ ~ ~M ~u~second~ W~h t~s a~angement and after the warm-up tm~d and describ<strong>ed</strong> m connection wi~ FIG. & The airperiod, subsmnfi~ly all v~atile chem~s ~ the wa~r circ~ating means ~dud~ an air inl~ opening 93 on theare boil<strong>ed</strong> off prior lo ~stil~tion with the resdthM the mp ~de ~eof and appropriMe ope~ngs not shownd~tiHMe ~ subs~nfi~ly odorless and bee of all unde~ 30 a~ ~rm<strong>ed</strong> ~ the top of the cover 89 ~ permk theab~ component~ In actu~ te~ ~ has been found that ~oduction of ~r ~to the space defin<strong>ed</strong> by the cont~ner70 and Hd 8~ The ~r ~ exhau~<strong>ed</strong> from one orw~h distillation apparatus as describ<strong>ed</strong> abov~ distill<strong>ed</strong>w~er w~ be produc<strong>ed</strong> ~ the rate of on~h~f to thre~ mo~ oufle~ 94 ~ the cover and an dectdc cab~ 95 ~quarters of a gallon per hou~utiliz<strong>ed</strong> ~r en~ng ~e ~n and may ~dude appro-A mottl<strong>ed</strong> form of the ~vention ~ ~ustra~d ~ 35 prime swish mean~FIGS. 5 through 8. Th~ form of the ~vention m m- The operation of ~e apparat~ illu~t<strong>ed</strong> ~ FIGS. ~tend<strong>ed</strong> for the brewing of coffee and for the production ¯rough 8 ~ mb~anti~ly ~e~ to thM describ<strong>ed</strong> ~of hot d~til~d wMer for other purposesuch as the connection wi~ the p~ce~ng embo~me~ of the m-brewing of te~ ma~ng of soups and the ~ke.ventiom Howeve~ ~nce the defice ~ not a~ang<strong>ed</strong>,~ w~ become apparent ~om the following descriptionof FIGS. ~ through 8 of the drawings thM the ~ ~e com~ner ~ initiMly ~d wi~ w~ ~o ~ ~e~ ~ough k may b~ ~r the continuous ~ffiation of w~operation cf the brewer ~ substantially ~entic~ to lhe ~vd ~ ju~ brow the portion of ~e ~1~ 81 of theoperation of the form of the invention shown ~ FIGS. condenser 80. g ~e container 70 ~ of mffidet s~ |he1 through & More speOfic~l~ the brewer comprises a d~lation proce~ can continue until the vessd 88 hastank or cont~ner 70 having an outwardy form<strong>ed</strong> pe-4ripherM ~p 71. The conta~er ~ suppos<strong>ed</strong> by a p~r of q~ ad~tion~ wMer can be add<strong>ed</strong> through thebeen ~d. If ~rger amounts of ~s~d wM~r are re-Z-shap<strong>ed</strong> brack~s 72 cou~<strong>ed</strong> by a transverse dement ope~ng 90 as may be ~q~d ~ order ~ m~nt~n the72 w~ch m~nt~ns the two brack~s 72 ~ spac<strong>ed</strong> rdafions~p.The confiner 70 ~ suppos<strong>ed</strong> by the upper cause ~e heating dements ~ the boiler 74 ~ be M ~ast~vd of ~e wM~ ~ ~e container M a h~g~ ~M w~horizont~ bracket potions 73 w~ch engage ~e peripher~p71 on the ~des of the cont~ner 70. A b~r Re~rring now to ~e ~rms of the ~venfion shown ~50 ~a~ially covere&74 substantially ~entic~ to the boiler 12 shown on FIG. FIG. 9 and FIG~ 10 ~rough 1~ ~ has been ~und th~4 ~ affix<strong>ed</strong> to one end of the confiner 7~ ~nce the improv<strong>ed</strong> results can be obtain<strong>ed</strong> by ~<strong>ed</strong>ing the wat~boiler functions ~ the same manner as the b~ler 12 and sup~y controll<strong>ed</strong> by lhe wM~ inl~ v~ve 35 as sho~n~ substantially ~entic~er~ a fu~her description ~ 55 ~r ~s~nce ~ FIG. 1, ~rough an dongat<strong>ed</strong> tube 37tot deem<strong>ed</strong> necessary.w~ch ~rm~ates adj~ng lhe bo:l~ i~ 22’. TheThe boiler 74 ~ cou~<strong>ed</strong> to the confiner 70 by a wM~ inl~ tube ~7’ ~ p~rab~ a~ang<strong>ed</strong> ~ swivd ~fitt~g 75 having a w~er inlet 76 secur<strong>ed</strong> to one ~de ~dicat<strong>ed</strong> ~ FIG. 9 so ~ ~ can ~e rais<strong>ed</strong> ~ ~cilita~lhereof and a w~er out~t 77 d~pos<strong>ed</strong> w~n the boiler a~u~mem of ~e w~ ~<strong>ed</strong> ~ just main~ ~e defi<strong>ed</strong>74. A second fitting 78 extends through the walls of the60 wMer ~vd ~ the cont~ner 10 as de~rib<strong>ed</strong> ~ connectionw~h FIGS. 1 and ~ It w~ be observ<strong>ed</strong> ~ thecont~ner 70 and boiler 74 and card~ a ~ream outlet 79on one end thereo~ WitCh the confiner, the ~t end water inlet 22’ to ~e boiler ~ a ~rmght tube ~a~ng81 of the condenser 80 ~ affix<strong>ed</strong> to the fitting 78 and the ¯ ~etly ~ ~e ~w~ po~icn of ~e b~r and ~ atilt!on~ ~c~ng c~d ~let wM~ ~ctly from ~e ~beoutlet end 82 of the condenser ~ secur<strong>ed</strong> to a fitting 83extend~g through an ope~ng ~ the bottom of the65 3T, ~e tube 22’ ~ ea~ ~ ~e~n as w~ be ~d ~cont~ner 70.more detail m connection with FIGS. 10 ~rough 15.The underfide of the cont~ner 70 as shown ~ FIGS. It has been ~und ~ ~e ~s~fion of wM~ ~M ~e5 and 8 ~dudes ~ the ~stant embodiment of the ~ve~ presence of s~, de~rgen~ and o~ ~mil~ chemicals6

~61L090~nd m cause the generat~n of foam in the boiler wh~h ing 10~ As v~w<strong>ed</strong> in FIGS. 10 and 13, the baffle whichadve~dy affects the dfimate distilhm and Mso neces~tatesmore ~equent dea~ng of the apparatus to attMn to the left so that the L-shap<strong>ed</strong> steam outlet 118 which~ of ~rc~ar configuration ~ inclin<strong>ed</strong>ownwardly andoptimum resets. A ~ructure for achieving lhes ends is ~ coupl<strong>ed</strong> to the fitting 16 ~es to the left of the baffle asillustrat<strong>ed</strong> in FIGS. 10 through 15 wheron the contMnerfor recoving the water sup#y ~ generally de-right ~de of the baffl~ The baffle ~ hid in place by a5 view<strong>ed</strong> in these figures while the heaters 111 are on thenot<strong>ed</strong> by the numerM lff while the b~Mr ~ generMly b~t 119 carri<strong>ed</strong> by the wall 103’ of the boiler sectiondenot<strong>ed</strong> by the numerM 12~ The boiMr 12’ ~ secur<strong>ed</strong> to 103 and extending through an opening in the baffle 117the contMner lff in the same manner as describ<strong>ed</strong> in to recove a cooperating nut 120 to hold the baffle inconnection wffh FIGS. I and 2 in thin lower and upper10 position. The baffle Mso includes a centrMly d~pos<strong>ed</strong>seM<strong>ed</strong> fittings 15 and 16 secure the boiler to the contMnerand at the same time provide a lower water inMt portion 122 extending inwardly ~om the fitting 15 pre-ope~ng 121 to recove the end of a water inlet tubeand an upper ~eam outleL The end of the fitting 16 viou~y describ<strong>ed</strong>. The ~eam outl~ tube as view<strong>ed</strong> ind~pcs<strong>ed</strong> wffh the contMner 10 ~ coupl<strong>ed</strong> to the inlet cf FIG. 12 preferably l~s b~ween 30° and 50* to the le~ ofcondenser 29 and the outlet of condenser 29 ~ con-1nect<strong>ed</strong> to an outlet fitting 30 which in~udes d~till<strong>ed</strong> holes 123 dispos<strong>ed</strong> wall to the right cf the center line ofverticM and the baffle 117 includes a plurMity of smallwater d~charge means having a pipe 31, an rusticoupling100 and an elbow 101 to facilffme collection of the generat<strong>ed</strong> principMly on the heater ~de of the baffle 117the boiMr 103. W~h this arrangemenL foam will b<strong>ed</strong>istilMd water in a suitabM receptaO~ The inl~ pipe 2T with the resulthat the baffle will tend to confine theextends through the fitting 15 and into the b~Mr in a 20 foam with only the ~eam or water vapor pas~ngmanner to be describ<strong>ed</strong> in connection with the succe<strong>ed</strong>ingfigures.thermor ~nce the ~eam outlet 118 ~ angularly d~-through the openings 123 to the ~eam outlet 118. FurRe~rring now to FIG~ 12 through 15, the boiler ~ pos<strong>ed</strong> r~ative to the openings 123, foam which mayform<strong>ed</strong> of two ~uncat<strong>ed</strong> hem~phericM or bowllike pos~bly pa~ through the openings 123 will not reachportions 102 and 103 having integrally form<strong>ed</strong> ~os<strong>ed</strong>25 the ~eam outlet 118 easily and accordingly only thebottom portions 10T and 103’ respectively. The boiler ~eam will pa~ through the ~eam outleL This actionsection 102 ~ provid<strong>ed</strong> wffh a peripherM flange 104 resul~ in the ~tainment of much purer water than in thewhile the boiler section 103 ~ provid<strong>ed</strong> wffh a ~miMr case where foam can reach the steam outlet and ultim~dybe recombin<strong>ed</strong> with the d~tilMte.peripherM flange 105. The boiMr sections 102 and 103are separat<strong>ed</strong> by a separate plate or partition 106 having30 Referring agMn to FIGS. 10 and 11, the contMner 10’a diameter ju~ slightly greater than the diameter of the includes an overflow control assembly generMly denol<strong>ed</strong>by the numerM 124. This a~embly inOudes aperipherM flanges 104 and 105. An annular U-shap<strong>ed</strong>gask~ 107 ~ fi~<strong>ed</strong> about the <strong>ed</strong>ge of the partition 106 fitting 12~ extending through the wall of the containerand a plurMffy of clips 108 engage the peripherM flanges 10’ and carrying an L-shap<strong>ed</strong> tube 126 rotatably dis-104 and 105 to secure the boiler portions one to the35 pos<strong>ed</strong> within the fitting. A hou~ng portion 127 rota~other and at the same time seM the boiler 103. For convenienceof assembly, the pa~ifion 106 wffh the gasket having soft and hard pos~ions as illustrat<strong>ed</strong> moreably recoves the tube 126 and suppo~s a fix<strong>ed</strong> scMe 128107 ~ secur<strong>ed</strong> in position rdative to the boiler section ~eafly in FIG. 11. A shaft 129 extends ~om the hou~ng102 by an dongat<strong>ed</strong> screw 109 extending through the 127 and ~ mechanicMly coupl<strong>ed</strong> to the tubular memberend wM1 102’ of the boiMr section 102 and through a 40 126 so that rotation of the shaft 129 will rotate the tubecen~M opening in the pa~ition and ~ secur<strong>ed</strong> in place 126 to move the angularly d~pos<strong>ed</strong> end potion 126’ ofby a s~tabM nut 110 and sealing washer 11ff.the tube 1264o Other a horizontM position or a verticMA pMr of heaters 111 idenficM to the heaters 13 and 14 position as illustrat<strong>ed</strong>. A knob 130 having a point<strong>ed</strong>of FIGE I and 2 are carri<strong>ed</strong> [y the pa~ition 106 and are portion 131 ~ carri<strong>ed</strong> by the shaft 129 and ~O~tesdispos<strong>ed</strong> slightly brow the central axis cf lhe boileL As 45 rotation of the shafto one or the other of the positions.shown in FIG. 1~ each hemer includes ffs individuM Wffh this arrangement, should lhe water be relativdythermostat 112 with each heater and thermo~at being hard, the pointer 130 ~ mov<strong>ed</strong> to the horizontal positionconnect<strong>ed</strong> in seriem The series connect<strong>ed</strong> heaters wffh to ~mit the quantity of water deliver<strong>ed</strong> to the boilertheir assodat<strong>ed</strong> thermostats are then connect<strong>ed</strong> in parMldas shown in FIG. 14 so that ~ne voltage ~ appli<strong>ed</strong> to 50 deliver<strong>ed</strong> to the boiler ~ increas<strong>ed</strong>. The verticM posi-while at the verticM positio~ the quantity of watereach heater and each heater ~ individually protect<strong>ed</strong> tion ~ us<strong>ed</strong> when rdatively soft water ~ encounter<strong>ed</strong>agMn~ overheating. The heating dements of ~ach of ~nce the verticM position will provide increas<strong>ed</strong> waterthe heaters 111 ~ dispos<strong>ed</strong> wffhin the boiler section 103 to the boiler and greater output without any adverseand ~ en~os<strong>ed</strong> by a w~er impervious hou~ng 111’ affect on the distilMte. The horizontM portion resul~ inwh~h not only protects the heating dement but Mso 55 a r<strong>ed</strong>uction of the quantity ~f distillate produc<strong>ed</strong>. It ~ toseMs the heater agMn~ the pa~ition 10& The heaters be underwood that the lower water Mvd will Mwaysare energiz<strong>ed</strong> by a power cabM 112 having three conducto~113, 114 and 115. The conductor 114 ~ a In order to avoi damage to the gasket 107 surround-produce the superior d~tiHat~ground conductor and ~ connect<strong>ed</strong> to the grounding ing the pa~ition 106 in the event pressure shouldescrew116 while the conductors 113 and 115 are con-6nect<strong>ed</strong> to the heating dements as illu~rat<strong>ed</strong> in FIG. l& sur~ a plug 132 form<strong>ed</strong> of plastic materiM ~ loosdyvdop wffhin the boiler 103 exce<strong>ed</strong>ing the de,r<strong>ed</strong> pres-As previou~y point<strong>ed</strong> ouL water for drinking and inse~<strong>ed</strong>a cooperming opening at the top of the boiMrother Furposes often contains relatively large quantitiesas will be observ<strong>ed</strong> more ~eady in FIGS. 10 and 13.of salt~ detergents and other chem~Ms wh~h produce The pre~ure requir<strong>ed</strong> to di~odge the plug 132 ~ exsubstantlMquantities of foam during the distilling pro-6ce~ and ff ~ of course desirabM to preventhe foam of rupturing the boiler 103 or even dislodging the resil-~emdy small so th~ there ~ no poss~ility whatsoever~om entering the condenser 29. For this purpose, a ~nt sealing member 107. In the event one or both of thebaffle 117 ~ angularly d~pos<strong>ed</strong> within the boiler hou~ heating dements 111 shodd become damag<strong>ed</strong> or

9the case may be so that the water w~ com~dy or~61~090burn<strong>ed</strong> ouL the section 102 ~g~h~ wRh the ~tion and a readily accesfible cover ~ate ~movably se~<strong>ed</strong> to106 can ready be ~m~ ~m ~e bA~r ~r ~ac~ s~d open fide ~r ready access to the bA~nmere ~ ~p~n ~ ~e same tim~ it ~ q~e ob~o~ ~ Z Water degafification and ~stiHation apparatusby ~ason of the umque a~n~ and con~ruction accor~ng to d~m 1 wh~n s~d cont~ner ~dud~ a~ ~e d~il~r ~ ~c~d~ ~ ~e ~, ~ ~ 5 cover and ~r ~ating means card<strong>ed</strong> by sfid covehpotions are ready acc~e ~r dean~&In the ~ of the d~tiller ~ ~eo~ w~hthe ~vention ~dud~g the ~rms of the ~ventionshown ~ FIGS. 1 and 2 as w~ as FIGS. 10 and 13, thes~d ~r ~rc~g means ~g ~r ~to s~d conminerand s~d cover ~dud~g means ~r dightings~d ~r from s~d conm~er whe~by vapo~ produc<strong>ed</strong>w~n s~d container are d~charg<strong>ed</strong> ~to the atmosphere.baler is portion<strong>ed</strong> rdative to the cont~ner 10 or lff as 10clemens ~nction to heat the water very m~y ~d asa ~s~t c~e a ~m~ ~ ~e bA~r w~ch ~the water ~t ~e b~ ~d b~k ~ ~e cont~ne~ 15In FIGS. 1 ~d 2 ~nce the hot water ~11 rise ~t~n the~n~r 1~ ~ w~ ~ ~ ~ ~d b~k ~m ~ebAMr but ~ the meantime b~ng has been com#~dym~up~d. ~ FIG~ 10 and 13 w~e the water doesnot e~rdy e~ose the hem~s when d~charg<strong>ed</strong> from 20the b~eL upon ~e~ng of cad water from the ~Mt#~ ~’ ~y m ~e ~ ~’ m ~e b~ ~e c~dwm~ w~ ~rm~e b~g ~ M~t momentarywhe~upon ~e ~ ~d d~ process ~ ~Mn 25~pe~e& H h~ b~n ~und ~ both ~s of the ~nventionthin exce<strong>ed</strong>~#y pure water ~ ~d wMch ~n~ o~M~bM wffh ~y ~h~ known de~c~ ~ compv~le fize and r~e of ~H~. In the ~ of the~vention shown ~ FIGS. 10 and 13, when the waterMvd ~ a~u~<strong>ed</strong> to the Mw Mv~ the pure~ water ~~n~M w~M at the ~gh Mv~ the w~er will meetp~db<strong>ed</strong> ~s ~r ~s~Md wmeL The ~gh Mvd~ prodd<strong>ed</strong> pa~ady ~r use wffh wmer ha~ng lowtotM ~v<strong>ed</strong> s~s and other impudt~s fince the 35~ w~ d~ver as much as three qua~e~ of ag~on of d~ti~<strong>ed</strong> water per hour w~M the apparatuswffh wm~ m ~e ~w Mvd w~ dd~ on~hMf a gM~nper houLW~M o~y ce~n e~m~ of the invention ~have been illustrat<strong>ed</strong> ~d describ<strong>ed</strong>, ff ~ apparent thatM~mtiom, changes and m~c~s may be madewffhom ~ng ~ the ~ue scope and s#~thereo~W~t ~ dMm~ ~: ~1. Wmer ~~ ~d ~11~ apparatuscomprising a contMner ~r h~ng w~er to be dega~fi<strong>ed</strong> and ~ a condenser ~ sMd comMn~ ha~ng~ ~ ~d oufleL ab~ ~vdy ~ v~um~ aMw~ wm~ ~ on sMd b~ ~d commu~c~g ~wffh sMd container at a pare s~y below theMvd of ~e w~ ~ sMd conm~ ~r ~e~ng w~ff<strong>ed</strong>y to ~d ~m sMd b~eL sMd bAMr bong point<strong>ed</strong>~ m ~d ~n~r m ~y mMmMn ap~d~d wamr Mvd ~t~n sMd b~eL an upper 55oufl~ on sMd b~er ~ove sMd ~e~M~ wmerMvd and ~mm~ wAh the ~Mt of sMd condenseLand means ~r being water ~ sMd bAMr andperio~cM~ ~e~ng ff ~effom ~Oud~g a he~ngdemem ~ sMd b~ ~d g~m~g h~t ~ a ~mp~v ~ture ~t to produce steam at a g~ rate thansMd ~eam can ~ ~ha~ from sMd upper omMt~e~ a pressure m sMd b~er ~em to ~rcewmer ~ sMd b~er ba~ ~to sMd contMner ~mugh~d Mw~ w~ ~ ~ ~e ~e~e ~ ~d b~ ~ ~r~ and b~ng ime~up~d wh~eupon w~ w~agMn flow ~m sMd b~ m sMd ~~d Mv~sMd bAMr bring ~<strong>ed</strong> of a fin#e opem~d<strong>ed</strong> hou~ng10& Wa|er deg~ification and ~stiHation apparatusaccording to d~m 2 wh~n s~d cov~ h~ a convexconfiguration, s~d ~r ~g means ~ m the ~rmof an de~ric ~n ha~ng a ~n motor c~fi<strong>ed</strong> by s~dcover and ~n ~ades a~x<strong>ed</strong> to the motor shaft, s~dcover ~du~ng opemngs ~r the admission of fir andmeans about the <strong>ed</strong>ge thereof ~r enga~ng s~d conminerand h~ng ~e <strong>ed</strong>ge of s~d cover ~ spac<strong>ed</strong>rdation~ m sfid container m pro~de ~r ~e ~charge of ~r ~rc~<strong>ed</strong> by s~d ~n.¢ W~er dega~fic~n and ~il~tion appar~maecor~ng to ~m 1 ~dud~g means ~r supportings~d conm~ above a ~pporting sur~c~ and s~dcondenser oufl~ emend~g ~rough the boRom wMl ofm~ cont~ner whereby a vessd may be d~pos<strong>ed</strong> b~neath s~d cont~ner and ~ hne w~h s~d condenseroufl~ m ~c~ve ~e ~s~d w~eL5. W~ degas~cation and d~lation ~pp~accord~g to d~m 4 ~dud~g means on the undersideof s~d container and mrroun~ng s~d condens~ oufl~~r supposing a b~k~ hav~g an ope~ng ~ ~e b~mmthereof ~r ~c~ng and h~ng a ~r eontaimngground coffe~ ~a or the ~ke whe~by s~d d~tiH<strong>ed</strong>w~ w~ first flow ~ said ba~ and ~ence ~ ~aidvessel.~ W~ deg~ification and ~stillation appallsaccording m d~m 1 whe~ said boiler ~ ~rm<strong>ed</strong> of ahollow, ~tantially hemi~he~c~ housing ha~ng aperipheral flange e~en~ng ~om ~e open end potionand pofition<strong>ed</strong> ~ a verfic~ ~an~ ~id cov~ ~e co~~rm~g ~ ~e fize and configuration of said flange anda g~k~ ~<strong>ed</strong> b~ween s~d bA~r and ~e andmeam ~mova~y ~curing s~d ~e and gasket ~ s~dflang~~ Water degafification and ~sti~n app~uscompdfing a coma~ ~r hA~ng w~ ~ te degasifi<strong>ed</strong>and d~till<strong>ed</strong>, a bA~r of ~latively sm~l vAum~ a~wer water inlet on s~d boiler and communicatingwi~ said ¢o~ner ~r ~e~ng w~ m said boiler, saidbA~r b~ng pofition<strong>ed</strong> ~tive to s~d conm~ tonormally m~m~n a pr<strong>ed</strong>eterm~<strong>ed</strong> water ~vd w~ns~d boile~ a condense~ an upper o~t on s~d bA~rabove said pr<strong>ed</strong>etermin<strong>ed</strong> wa~er ~vel and commun~at-~g w~h ~e inl~ of s~d condense~ and heating means~ said boil~ and gen~ating heat ~ a ~mperatu~ sufficfe~~ produce steam ~ a great~ m~ ~an said steamcan be d~charg<strong>ed</strong> from s~d upper oufl~ ~e~g ap~ure m s~d bA~r suffident m ~e w~ ~ s~dbAkr back into s~d container ~rough m~ ~wer waterinl~ un~ ~e p~u~ m s~d boil~ ~ ~ev<strong>ed</strong> whe~uponw~er w~ ag~n flow ~to s~d boiler to s~d p~de~rmin<strong>ed</strong>~vel, s~d bA~r b~ng ~rm<strong>ed</strong> of a fin~eopen-sid<strong>ed</strong> houfing and a ~adi~ accesfib~ cover ~e~movably sefl<strong>ed</strong> to s~d open fide ~r ready access ~¯ e boiler, sfid bA~r bring ~rm<strong>ed</strong> of a hollow, sub~antifllyhem~ph<strong>ed</strong>c~ houfing ha~ng a pefipherfl flangee~en~ng from ~e open end potion and position<strong>ed</strong> ~a v~tic~ ~n~ said cover plate con~rm~g m ~e fize

114,612,090and conflgurm~n of sMd flange and a gask~ ~spos<strong>ed</strong> ~upt<strong>ed</strong> whereupon w~er will agMn flow ~to s~d boilerb~ween sMd b~Mr and #me and means removably to s~d pr<strong>ed</strong>~erm~<strong>ed</strong> lev~, sMd boiler b~ng form<strong>ed</strong> ofsecuring sMd ~me and gask~ to sMd fiang~ sMd he~- a ~n~e open-~d<strong>ed</strong> housing and a readily acce~ible~g means bring an de~ric hemer carri<strong>ed</strong> by sMd ~me cover ~me ~mova~y seM<strong>ed</strong> to sMd open ~de ~r readywith the dectricM connections therefor ~spos<strong>ed</strong> on the 5 acce~ to the boile~ s~d b~Mr ~ud~g a battle ~douter~de of sMd #me and a second h~low, sub~antiallyhemisphericM housing ~du~ng a peripherM outlet d~pos<strong>ed</strong> on one ~de thereof and s~d heating~g sMd boiler into two portions with s~d upper steamflange endoMng sMd decU~M connections and sMd means and ~wer water inlet on the other ~de thereofhou~ngs with sMd cover #me bring removably ~cur<strong>ed</strong> and s~d baffle ~ud~ m Mast one upper ope~ng anguoneto the other~10 lady ~splac<strong>ed</strong> from sMd upper ~eam outl~.8. W~er dega~fication and ~m~n apparatus 10. Water dega~fication and ~stiHation apparatuscompri~ng a contMner for h~ng w~er to be degasifi<strong>ed</strong>and di~ille~ a conden~r ~ sMd container ha~ng h~Mw, subsmntiMly hemisphericM hou~ng ha~ng aaccord~g to ~Mm 1 wher~n sMd b~Mr ~ form<strong>ed</strong> of aan inl~ and outleL a b~Mr of rdativdy small v~um~ a peripherM flange ex~n~ng from the open end, sMdlower wmer ~Mt on sMd boiler and commu~cming15 boiler bring affix<strong>ed</strong> lo the eu~r sMe of said containerwith sMd contMner at a p~nt sub~antiMly bdow the with ~ Mast sMd ~wer w~er inl~ e~en~ng throughMvd of the w~er ther~n for ~e~ng wmer fre~y m and sMd houfing and contMneL a ~<strong>ed</strong> wmer inlet carri<strong>ed</strong> byfrom said boiler, said boiler being position<strong>ed</strong> rd~Ne to sMd contMner for ~e~ng water to sMd contMner ~ thesMd contMner to normally mMnmin a pr<strong>ed</strong>etermin<strong>ed</strong> ~dnity ~f the b~ler wmer ~let, and a wmer cver£owwater levi wit~n sMd boile~ an upper outlet on sMd 20 outlet carri<strong>ed</strong> by sMd contMner to mMnmin a con~antboiler above sMd pr<strong>ed</strong>eterm~<strong>ed</strong> water Mvd and commu~catingwith the ~Mt of sMd condenseL and means 11. Water degasification and ~stilMtion apparatuswater Mvd ~ sMd contMneLfor heating wmer ~ sMd boiler and period~Mly ~ecfing comprising a contMner for h~ng wmer to ~e degasifi<strong>ed</strong>and ~still<strong>ed</strong>, a boiler of relativdy small vMum~ ait therefrom ~dud~g a heating ~ement ~ sMd bMl~and generating hem m a ~mpermure suffidem to pro-2duce ~eam at a gremer rate than sMd ~eam can be with said contMner for ~e~ng wmer to sMd b~ML sMdMwer wmer ~Mt on sMd boiler and commu~cm~gd~charg<strong>ed</strong> from sMd upper outl~ creating a pressure in boiler bring posffion<strong>ed</strong> r~ative to sMd container tosMd b~Mr suffident lo force w~er ~ sMd b~Mr back normally mMntMn a p~<strong>ed</strong>e~rm~<strong>ed</strong> w~er levi wff~n~to sMd contMner through sMd Mwer ~Mt until the sMd boile~ a condenseL an upper outl~ on sMd b~lerpre~ure ~ said boiler ~ rdMv<strong>ed</strong> and boil~g interrupt<strong>ed</strong> 20 above sMd pr<strong>ed</strong>etermin<strong>ed</strong> wmer Mvd and commu~cmwhereuponwmer w~ agMn flow ~to sMd boiler to sMd ~g wffh the inlet of sMd condenseL sMd heating meanspr<strong>ed</strong>~erm~<strong>ed</strong> Mvel, said boiler being form<strong>ed</strong> of a sin#e ~ sMd boiler and generating heat m a ~mperature suffidentto produce steam at a greater rate than said steamopen-sid<strong>ed</strong> hou~ng and a readily acce~ible cover #meremovably seM<strong>ed</strong> to sMd open ~de for ready acce~ to can be d~charg<strong>ed</strong> from sMd upper outl~ creating athe boileL said boiler being form<strong>ed</strong> of hollow, sub~anfiallyhemisphericM hou~ng ha~ng a peripherM flange boiler back ~to said confiner through said lower wmer35 pressure ~ sMd boiler suffident to force water ~ sMdex~nd~g from the open end potion and portion<strong>ed</strong> ~ inl~ until the pre~ure ~ sMd boiler ~ reliev<strong>ed</strong> wher~a ve~M #an~ and sMd cover #me conform~g to the upon w~er w~ ag~n flow ~to s~d boiler to sMd pr~~ze and configurm~n of sfid flange and a gaskm ~ de~rmin<strong>ed</strong> levi, sMd b~Mr bring form<strong>ed</strong> of a ~n#epos<strong>ed</strong> b~ween sMd boiler and #me and means remov-4ably ~curing sMd #me and g~km to sMd flang~ sMd removably seM<strong>ed</strong> to sMd open ~de for ready access toopen-sid<strong>ed</strong> hou~ng and a readily accessible cover #mehollow, substantially hemisphericM hou~ng ~dud~g the b~M~ said boiler being form<strong>ed</strong> of a hollow, ~u~s~nfiMlyhemisphericM hou~ng ha~ng a pefipherM flangean ~clin<strong>ed</strong> baffle with sMd ~eam outlet l~ng on one~de of the baffle and sMd heating means on the other e~en~ng from the open en~ s~d boiler bring affix<strong>ed</strong> to~de of the baffl~ sMd water inlet ~e~ng water to the45 the outer ~de of s~d contMner wffh at M~t sMd lowerheater ~de of sMd baffle and sMd baffle fu~her ~dud- water inlet ex~nd~g through sMd housing and containeLa ~<strong>ed</strong> water inlet carri<strong>ed</strong> by sMd container for~g m lea~ one ope~ng a~M~ng the top <strong>ed</strong>ge andang~ar spac<strong>ed</strong> from the ~eam oufleL~e~ng water to sMd contMner ~ the ~dnity of the¯ Water dega~fication and ~stilMt~n apparatus b~Mr w~er inlet, and a wmer overflow outlet ca~i<strong>ed</strong>compris~g a contMner for hM~ng wmer to be degasi-5fl<strong>ed</strong> and ~stilM~ a condenser ~ s~d contMner ha~ng sMd contMneL sMd wa~r overflow oufl~ compd~ng aby sMd contMner to mMntMn a constant water levi inan inl~ and outlet, a boiler of relatively smM1 vol~m~ a horizontally d~pos<strong>ed</strong> wmer d~charge tube rotmablylower wmer ~Mt on sMd b~Mr and commu~cm~g carri<strong>ed</strong> by a fitt~g e~en~ng through the wall of sMdwffh sMd contMner m a p~nt substantially bdow the containeL the ~ner end of sMd tube bring anguMriyMvd of the w~er there~ for ~e~ng w~er ~<strong>ed</strong>y to and55 ~spos<strong>ed</strong> rdmNe to the rema~der of the tub~ means onfrom sMd b~ML sMd boiler bring position<strong>ed</strong> rdative to the outride of sMd contMner and cou#<strong>ed</strong> to sMd tubesMd contMner to normally mMntMn a pr<strong>ed</strong>etermin<strong>ed</strong> for rotation thereof whereby the Mvd of the water ~w~er Mvd wff~n sMd boileL an upper oufl~ on sMd sMd contMner can be chang<strong>ed</strong> by ang~ady po~fio~ngboiler above sMd pr<strong>ed</strong>etermin<strong>ed</strong> water Mv~ and commu~c~gwith the inl~ of sMd condenseL and means60 12. Water dega~fication and ~m~n apparatusthe ~ner end of sMd tube.for heating wmer ~ said boiler and perio~cMly ~e~g compri~ng a contMner for h~ng water to be degafif<strong>ed</strong>and ~stiH<strong>ed</strong>, a b~Mr of relativdy smM1 v~um~ a~ therefrom ~du~ng a heating ~ement ~ sMd b~Mrand generating he~ ~ a ~mFer~ure suffident lo producesteam at a gremer rate than sMd steam can be wffh sMd contMner for ~<strong>ed</strong>~g wmer to sMd boile~ sMd~wer water inlet on sMd boiler and commu~cating¯ scharg<strong>ed</strong> from sMd upper oufl~ creating a pr~sure ~ 65 boiler bring poskion<strong>ed</strong> rdafive to sMd contMner tosMd b~Mr suffident to force wmer ~ sMd boiler back normally mMntMn a pr<strong>ed</strong>~ermin<strong>ed</strong> w~er Mvd withininto said container through said ~wer wmer inl~ until sMd boileL a condenseL an upper outlet on sfid boilerthe pressure ~ sMd b~Mr ~ reliev<strong>ed</strong> and boiling ~ter- above sMd pr<strong>ed</strong>~erm~<strong>ed</strong> wmer lev~ and commu~cm-12

~61L090~g wffh the ~Mt of sMd condenses and heating means pfis~ at Ma~ one w~erproof de~ric heater carri<strong>ed</strong> by~ sMd boiler and generatMg hem ~ a ~mperMure suffl- sMd #~e wi~ ~e de~ric mrm~Ms ~spo~d on theOem m produce s~am ~ a gre~er r~e lhan sMd ~eam outer fide of sMd #m~can be d~charg<strong>ed</strong> ~om sMd upper oufl~ creating a 1~ Water degafification and distillation apparatuspre~ure ~ sMd boiler suffl~ento force wmer ~ sMd 5 according to dMm 13 wheron sMd boiler houfing indud~a baffle ~fid~g sMd housing M~ two ~para~boiler back ~to said container through said ~wer w~er~Mt until the pressure ~ sMd boiler ~ rehev<strong>ed</strong> whe~uponwmer w~ agMn flow ~to sMd b~Mr to to sMd fide of sMd baffl~ sMd heating means ~spos<strong>ed</strong> on thechamb~s wi~ sMd upper oml~ bong ~spos<strong>ed</strong> on onepr<strong>ed</strong>~erm~<strong>ed</strong> Mv~, sMd b~Mr b~ng form<strong>ed</strong> ofa sin#e other fide of sMd baffle and sMd ~wer w~er inlet ~<strong>ed</strong>open-s~<strong>ed</strong>houfing and a really accesfiMe cover #me10 ~g w~er to the heater fide ofsMd baffle and sMd baffleremovaMy seM<strong>ed</strong> to sMd open fide for ready acce~ to ~du~ng at lea~ one ope~ng near the upper <strong>ed</strong>gethe boileL sMd b~ler comprifing a sub~antiMly round the~of and angu~fly posff~n<strong>ed</strong> ~tive ~ s~d upperbowl6hap<strong>ed</strong> hou~ng ha~ng an omwar~y ex~nd~g ~eam oufleLflang<strong>ed</strong> rim and a flatten<strong>ed</strong> bottom dispos<strong>ed</strong> ~ a vertical 15. Water degafification and ~still~n apparatus#ane and smMler ~ ~ammer than sMd tim, sMd ~wer 15 according to dMm 14 where~ sMd condenser ~ ~water inlet ex~nds through sMd bosom, sMd upper pos<strong>ed</strong> wit~n sMd conmineL sMd b~Mr houfing m s~outlet extends through sMd bosom and carries a tube cur<strong>ed</strong> to the ou~r wall of sMd contMner wffh ~e upperwit~n sMd b~Mr hou~ng curv<strong>ed</strong> upwar~y and m an outl~ and ~wer ~l~ e~en~ng through the wMl ofsMdan#e rdafive to a ve~icM #ane normM to sMd bottom container, means ~r ~e~ng wmer to said container andand a #me conform~g to sMd flange secur<strong>ed</strong> ~ seM<strong>ed</strong>20 a container overflow to mMntMn a wamr Mvd ~ sMdrelationsh~ to sMd flang<strong>ed</strong> rim.contMner th~ will cause sMd boiler houfing to be nov13. Water degasiflcation and distillation apparatus mally ~l<strong>ed</strong> ~ sMd pr<strong>ed</strong>etermin<strong>ed</strong> Mvd.accord~g to OMm 12 wheron sMd heating means com-2514355565

<strong>Un</strong>it<strong>ed</strong> <strong>States</strong> <strong>Patent</strong>EIHs, Jr.I ll[lllllgll lllflll llllllllllllllHlllIHUS~0A[11] <strong>Patent</strong> Numbe~ 5,203,970~q Date of Paten~ Apr. 20, 1993METHOD FOR WATER DEGASIFICATIONAND DISTILLATION~ Invento~ John C. Elfi~ Jr., 1084 PMmer Av~,Larchmont, N.Y. 10538~1] Ap~. No.: 48~228~ Fil<strong>ed</strong>: Feb. 28, 1990FOREIGN PATENT DOCUMENTS8~8 12/1988 World Int. Prop. ~ .~ma~ Exam~er--V~nia Man~aranAttorn~ Ageng or Firm~We~eL Can~ Muter &Hayer~1] InL Ci.5 ........................B01D 3/0~ B01D 19/02; A m~hod ~r w~er d~on and distillation ~ anC02F 1/04 ~ratus ~v~g a conm~er ~r a reservo~ of w~er ~~ U~. Ci ...........................203/1~ 202/175; ~ ~g~d and distill<strong>ed</strong>, a rdafivdy sm~ b~r adj~ng~e con~ner ~d ha~ng a ~<strong>ed</strong> water cond~t202/17@ 202/180; 202/202; 202/203; 202/265;203/4; 203/22; 203/DIG. 18; 203/DIG. 22 co~e~ the con~ner and b~ler so that a s~ec~d~ Fi~ of Search ............ 202/175, 17G 203, 185.5, water ~vd ~ the conm~er w~ ~1 the ~fler to the202/265, 180, 202, 181, 188, 19~ 203/IK G 1, ~e ~v~ a coil~ tu~ condenser whh~ ~e con~er2, 2K DIG. 18, DIG. 22; 55/36 ~mer~d ~ ~e w~er ~ere~ the condenser coil hav-~g a ve~c~y ~spos<strong>ed</strong> ~n~u~n~ a~s, a secondReCreates Cit<strong>ed</strong>condor in the b~r conne~ the space above theU.S. PATENT DOCUMENTSwater levd ther~n to the ~et of the condenser so thatsteam flows ~om ~e ~r m the condenser, ~ oufl~567,434 9/1896Young.................................202/175on the condenser emen~ng ~rough a conm~er w~841,401/1907Hope...................................202/1751,30~508 6/1919Meakinet al .......................202/175~r ~schar~ng the condens<strong>ed</strong> steam as dega~fi<strong>ed</strong> ~sd~dw~eh a he~er ~ the b~er ~r being the water2,77~7231/1957Prymek...............................202/1653fl94,566 2/1974Raal.....................................202/202 ¯ erd~ and a m~or driven silver a~y ~ ~e c~L891~95 6/1975Winkler...............................159/901 tube condenser ~r gener~g a sw~g movemem of3,980,526 9/1976Kirschmann........................202/234 the reservoir water w~h ~on of steam bubbles4,045,293 8/1977Cooksley...............................203/10 therdm4,08%7505/1978Kirschmanet al ...................203/104,214,454 7/1980Taylor...................................203/10 O~on~% an over~z<strong>ed</strong> ~ter ~ mourn<strong>ed</strong> at the outlet4,26~6635/1981McFee..................................203/10 of the condense~4,34L6238/1982Loeffler................................203/104,61Z0909/1986Elli~Jr .................................203/102 Ci~ms, 2 Dra~ S~e~I004

U.S. <strong>Patent</strong> Apr. 20, 1993 Sheet 1 of 2 5,203,970tt5I00 ~38I I J ’ 1oo4

U.S. <strong>Patent</strong> Apr. 20, 1993 Sheet 2 of 2 ~203~70

5,203,970In the p~<strong>ed</strong> embo~mem of the ~vention herin ating the ~s~Mtion apparmus, it ~ generally defirabMillustrat<strong>ed</strong> a forc<strong>ed</strong> Mr ckculation means asd~s removM to ~scard the ~stilM~ produ~ until the water ~deof ~eam and undesiraWe vapo~ ~b~m<strong>ed</strong> fom He reserverwater with~ reservok container 10. The Mr ~mpermu~ w~ch Fre~raWy ~ 18~-19~ F. (w~chreservMr container 10 h~ retain<strong>ed</strong> a normM operat~gd~c~ating means w~ch ~ shown ~ FIG. 3 compri~s5 ra#~y mtMn<strong>ed</strong>). Heme~ 13 and 14 are d~n<strong>ed</strong> to heman ~vene d~h<strong>ed</strong> cover generally denot<strong>ed</strong> by the numerM~0 over re~rv~r container 10 w~ch ~dudes a condenser coil 27 can accommodme the ~eam pro-the water witch the boiler at a rate f~ter than thefiat upper wall $1 thin ~ perfora~dapenure~ an duc<strong>ed</strong>. Accor~n#% a head of ~eam ~ devdop<strong>ed</strong>upward~ emen~ng peripher~ wall 52 and a doww wit~n the boiler 12 and the steam pressure w~ forcewarty curv<strong>ed</strong> peripher~ wall ~3. The ~wer peripheral 10 hq~d fore the boiler back through the cond~t 22 ~to<strong>ed</strong>ge of the wall $3 carries three or more d~gon~ly the re~rv~r container 10 thereby reliev~g the ~teamdispos<strong>ed</strong> r~ 54 each ha~ng spac<strong>ed</strong> ~scs $~ romtablycarri<strong>ed</strong> by a sha~ 56. The ~scs $~ engage the ~ reliev<strong>ed</strong>, water will again flow through the conduit 22pressure. As soon as the steam pressure within the boilerroll<strong>ed</strong> <strong>ed</strong>ge 10’ of the reserver container 10 and accord- back ~to the boiler w~h the rese thin there will be a~y pro~de an ann~ r veto b~ween the cover $0 and 15 period~versal of wmer flow through the condu~ 22.the top <strong>ed</strong>ge of the re~rv~r container 10.Th~ pulsating action res~u ~ a mcre ~a#d ~crease ~The flat apenur<strong>ed</strong> wall ~1 of the air circulating means ~mpermure of the reservok wmer with~ the conm~ersupports an dectric motor gener~ denot<strong>ed</strong> by the 10 by contribut~g hem over and above the heat impal<strong>ed</strong>to the reservok wmer by the action of the con-numerM ~7 w~ch powers a shaft ~$ ex~n~ng throughthe perform<strong>ed</strong> w~l ~1. The ~n $9 ~ mount<strong>ed</strong> on sha~ 20 den~r c~l 27. The ~mperature of the reservo~ wmeL$$. Power ~ f<strong>ed</strong> tothe motor 57 by a cable 60 connect<strong>ed</strong> howeveL ~ Mwavs below the boil~g ~mperature (of~ a convention~ manner to the moto~ If d<strong>ed</strong>re~ the water ~ boiler 1~ so that ~me will be condens<strong>ed</strong>in condenser 27. Pre~raWy the reserver waterswitch means may be prov~<strong>ed</strong> for operation of the ~n.The ~n motor 57 is cover<strong>ed</strong> by a vent<strong>ed</strong> dom~shap<strong>ed</strong> sho<strong>ed</strong> be ke~ ~ the range of 18~ F. to 190" F. Thishou~ng 61 thin ~ securdy fia<strong>ed</strong> to the cover ~0 and ~ 25 ~mpermure Mvd w~ boil off undesirable componentsattach<strong>ed</strong> thereto by any s~tab~ means. In the ~us- from the reviver wmer (prior to actuM ~ation~at<strong>ed</strong> embo~ment of the ~ventio~ the dom~shap<strong>ed</strong> thereo0, and Mso serves to operme condenser 27 adequmdy.To mMnmin proper operation cf the apparmus,hou~ng 61 fri~ionally engages the peripher~ wall 52 ofthe cover ~0.a sub~antiM propo~ion of the ~<strong>ed</strong> water w~ch entersIn one mode of ~n operation, Mr ~ drawn ~to the Mr 30 m the ~1~ 37 ~timmdy ~ ~scharg<strong>ed</strong> as overflowdrcdating means ~mWy through an ope~ng 62 ~ through tube 32 and outlet 35.the dome~hap<strong>ed</strong> housing 61 and then down through Operm~n of ~krer Wades 102 mmeriMly changes thethe per~r~<strong>ed</strong> wall 51 whereupon it is direct<strong>ed</strong>ownwartyover the ~rv~r wm~ ~ re~rv~r contMner 102 generate a w~rling turb~ent motion of wmer ~-dynamics of the distillation apparatus. The sti~er blad~10 and therea~er is ~scharg<strong>ed</strong> through the ann~ar35 ~de cylindricM space 100 thereby improv~g heat exchangeconm~ b~ween the reservok water and theope~ng b~ween the ~rv~r contMner 10 and hscover $0. In the reverse mode of ~n operation the ~n tuMng of condenser coil 27. In addit~ motion of the59 draws Mr ~ through He ann~ opemng b~ween stirrer Wades generme ca~mtion w~ch ~ the d~t~vre~rv~r contMner 10 and ~s cover 50 up through pe~ don apparmus of th~ invention constitutes formation offora~d w~l ~1 and ope~ng out through vent 62 ~ 40 ~eam bubWes beneath the sur~ce of the wmer. Typicall%the bubWes contMn both ~eam and v~atil~<strong>ed</strong>motor hou~ng 61.As may be seen ~ FIG. 3, a stirrerod 101 extends gases and vapor~fom an integrM conne~n whh motor sha~ ~8 at the The ra#d romtionM movement of the sti~er Madeshub cf fan 59 pre~mWy but n~ necessarily axially of 102 genermes loca~z<strong>ed</strong> pressure ~fferentials ~ the rewthe cylindric~ re~rv~ re,on 100 ~dde of condenser 45 erv~r wmer cau~ng an increas<strong>ed</strong> (and super-atmospheri~pressure on the up,ream ~ce of the Mades andc~l 27 and ~rm~m~ ~ the stirrer Wades 102 immer~d~ lhe ~rv~r w~e~ The depth of immersion for a decreas<strong>ed</strong> relativdy negative Ond sub-mmospheriOstirrer Wades 102 is n~ critical, bm p~raWy, they are pre~ure on the down,ream ~ce of the Wades. S~cenot deeper than the bottom of coil condenser 27. In the the water ~ the reservoir ~ hot, desirably at betweenmode ~u~m~d hero~ the stirrer rod w~ position<strong>ed</strong> 50 18~-19~ F., generation of locM~<strong>ed</strong> sub-mmosphericmodestly off-center |o avid ~r~rence wi~h the cutletbend 29 of condenser coil 27, see FIGS. 1 and 2. w~ch steam flashes off fom the hot water (form~gpre~ure re#ons ~ the water creates a v~d space ~toIn the operat~n of the d~tiHation appara~s of t~s thereby the bubble~. Ev~v<strong>ed</strong> Mong with the ~eam, ~~vention, the reservoir container 10 and boiler 12 are any Mr still d~solv<strong>ed</strong> ~ the water and any volati~zabMfir~ fil<strong>ed</strong> wkh water to a levi at ~a~ substantially 55 components still present ~ the wmer. Moreover, as thecovering the heating dements 13 and 14 as may be bubWes pass up through the re~rv~r water to escape atobserv<strong>ed</strong> mo~ ~eady ~ FIG. 2. It will be observ<strong>ed</strong> thin the water suffac~ they scavenge Mr and v~mfl~abMwhen filling re~rv~r container 10, wmer w~l automaticallyflow through condor 22 ~to the boiler so that Thu~ mecha~cM ~ring of lhe hot re~rv~r wmercomponen~ fom the wm~.~fimmdy the ~vd of the water ~ the reservoir con-6miner 10 wi~ be the same ~ the wmer levi m the boiler remov~g M1 v~mfl~able components th~efom beforeasfis~ greatly ~ dea~m~g the re~rv~r water and ~12. When energy ~ then supp<strong>ed</strong> to the heating d~ wmer from the reservoir enters the boiler 12 to be ~men~ 13 and 14 they will function to boil the water till<strong>ed</strong> ~her~n. In ad~tio~ mecha~cM mkring ~cilimteswit~n the boiler 12. Steam fom the b~r will enter mMntenance of a good heat bMance witch the resevthe ~t 24 and then flow through the condenser coil 27 ~ v~L~o be condens<strong>ed</strong> therein. The condens<strong>ed</strong> steam will then In operm~n of the ~stilMtion apparatus, the heatdischarge ~rough filter 115 as the ~me Oiq~d) impal<strong>ed</strong> m b~Mr 12 ty the heating dements 13 and 14product fom the conden~r oufl~ 31. When firm opev can leave the ~fion app~mus o~y ~ the hem6

75,203,970energy content of the hot (condens<strong>ed</strong> ~eam) d~tiHate pipe 32 ~ r<strong>ed</strong>uc<strong>ed</strong> substantially by indu~on of ~rerprodu~ or of the hot reserver wmer discard<strong>ed</strong> through 102 ~ the distillation apparmus.overflow ~pe 32 or as the hem energy in the (heat<strong>ed</strong>) A ~m vernon mode of the distillation apparmus fllu~~r and vapor vent<strong>ed</strong> by fan 59 ~hrough ~ther the trat<strong>ed</strong> her~n was made and test<strong>ed</strong> wkhou the ~rer inann~ar ven~ in cover 50 or the opening 62 in motor5 opermion (reservoir depth 5½’3. Convection was reli<strong>ed</strong>hou~ng 61 depending on how ~n 59 ~ operm<strong>ed</strong>). To upon for stirrin& The ~mper~ure m the bottomof thethe extenth~ ~rer 102 causes cavitation and generationof ~eam bubbles in the reservoir water which bub-the reservo~ was 180" F. The temperature of the d~fibreservoir was 160" F. The temperature ~ lhe surface ofbles in turn escape the reservoir water to become late product was 200* F., and an appr<strong>ed</strong>able amount ofvente~ the proportion of boiler hem vent<strong>ed</strong> to the a~ 10 steam was being produc<strong>ed</strong> ~ong w~h the distillate.mosphere ~ increas<strong>ed</strong>. This increase ~ substanti~. Co~ About 2.5 g~lons of cooling water per gallon cf distilrespon~ngl%the quantity of heat<strong>ed</strong> reservo~ water ~te product was being us<strong>ed</strong>. Then, when the stirrer wasthat mug be discharg<strong>ed</strong> through overflow pipe 32 to operat<strong>ed</strong> the tempermure of the distillate rapidly becamer<strong>ed</strong>uc<strong>ed</strong> to below about 155" F. The~ ~o r~se them~ntain a proper heat b~ance in the reservoir watermay be and is r<strong>ed</strong>uc<strong>ed</strong>.15 tempermure in the reservo~ to above 180" F. the ratioAs a pra~ mm~L operation of stirrer blades 102 of cooling water to distil~te was r<strong>ed</strong>uc<strong>ed</strong> ~om the Z5di~inctly increases the ~mpermure differenti~ between to 1 to about 1.2 to 1. The distil~ temperature rose tothe ~eam in,de condenser coil 27 and the water in above 190" F. Then, operation of the sti~er was discontinu<strong>ed</strong>,whereupon the outlet of the condenser ~eam<strong>ed</strong>reservoir container 10 adjacent condenser coil 27. hsho<strong>ed</strong> be appr<strong>ed</strong>m<strong>ed</strong> that ~though the decreas<strong>ed</strong> pres-2sure zones on the down,ream ~ces of stirrer 102 are ~ystem return<strong>ed</strong> ~o normS.profusely. Then, the ~irrer was turn<strong>ed</strong> on again and thelocat<strong>ed</strong> and are trandent in nature, more ~ not ne<strong>ed</strong><strong>ed</strong> As has ~ready been point<strong>ed</strong> cut, a mechan~ exp<strong>ed</strong>ient~o facilita~ m~ntenance of a di~tin~ tempermureto create a bubble wher~n pan of the hem<strong>ed</strong> reservoirwater flashes into ~eam, concurrently dgnificantly across the condenser coil tubing ~ illustrat<strong>ed</strong> in FIG. 5.cooling the reservoir wmer adjacent the bubble25 Shown there ~ an charg<strong>ed</strong> pa~i~ cross-section of condensercoil tubing. In,de the tu~ng ~ a deflector 77~hrough Io~ there~om of the hem of vaporizmion forthe steam). ~nce the steam bub~e and the hct reserver whose purpose ~ to generate spir~ flow movement ofwater can coe~ at the sub-mmosphefic pre~ure ~vd steam and condensa~ to the tube wa~. Also, flow becomesmore turbulenthereby haling hem exchangegenerm<strong>ed</strong> by the stirrer 102, the buboes form readilyand do not collapse imm<strong>ed</strong>imdy when norm~ pressure30 across the tube wall. A ~ke deflector 79 may be provid<strong>ed</strong>in the cond~t connecting reservoir container 10~ re~or<strong>ed</strong>. Mostly, the ~eam bubbles escape over headof the reserv~and boiler 12 ~ee FIG. 6). The purpose of deflector 77Of cou~ the stirrer ~ in constant motion, mi~ng the is, of cours~ to create turbulent mi~ng of the water soreserver wmer q~te thoroughly so thin distin~ zones as to avid any ~mpermure ~r~iflcm~n ~lher in rese~of ~mpermure differences never can become e~ab-35 voir container 10 or in boiler 12.Hsh<strong>ed</strong> in the reservoir wmer. HoweveL generation of An addition~ option~ exp<strong>ed</strong>ient which has beenlhe ~eam ~om the locat<strong>ed</strong> (and ~anfitory) r<strong>ed</strong>uc<strong>ed</strong> found advantageous in practice of this invention ~ thepre~ure zones is ~nu~ly in~antaneou~ Once the bubbleis form<strong>ed</strong>, its collapse, however, ~ not instantaneouscondenseroufl~ 31. In the embodiment illustrat<strong>ed</strong>provision ofa fil~ pre~ra~y an over~z<strong>ed</strong> filte~ at theso th~ the bubbles la~ long enough to rise up through 40 her~n the over,zeal filter 115 is a carbon filter.the reservoir water and escape through the sur~ce FiRer 115 absorbs any orga~c mmeri~s thin are carri<strong>ed</strong>over with the condensate. ~ polishes the conden-thereo£ Since the reservoir wmer ~ hot, des~a~y in the180"-190 ° F. range, a sub~anti~ pa~i~ pre~ure of sat~ so to speak but ~so ~ achieves a superior aermionsteam e~s, which ~ to say, that the stirrer generates for the condensate.many ~eam bubbles and in tot~ the ~eam bubbles re-4move a condderable quantity of hem energy ~om the r~us of this ~vention opermes in a pulsating fashionAs has ~ready been poin~d out the d~tillation appa-reserver wmer.cau~ng water to flow through the connecting cond~tThus, generating a micro environment of tran~tory 22 back and fo~h b~ween boiler 12 and reservo~ 12.sub-mmosphefic pressure zones at the down,ream ~ce The same pulsmions affect condenser 27. A p~se ofof the stirrer 102 genermes a ~g~ficant change in the50 (steam) pressure ~om boiler 12 passes through the condensertubing in a forwar d~ection during a ~eammacro en~ronment of the reservo~. The ~mpermureof the water in the reservoir as a wh~e ~ r<strong>ed</strong>uc<strong>ed</strong> by genermion pulse, sending condensate out through filterthe flashing of ~eam to form the bubbles. Although 115. Then during the ~ eve~e suct~n prise, ~r ~ drawnonly the wmer adjacent the buboes becomes cooler, the into the filter 115, and even into the outlet end of conra~dswirling water movement caus<strong>ed</strong> by stirrer 10255 denser 27. Thu~ the filter 115 acts as much to filter ~rm~es the w~er ~most imm<strong>ed</strong>iatdy so (hm the ~mpe~ drawn into the condenser tubin~ as it does to filterature of the reservoir water over~1 has been r<strong>ed</strong>uc<strong>ed</strong>. distiH~e ~aving the condenser tubing.Moreove~ the coole reservoir water ~ adjacenthe Ma~festl% the p~ses are not equ~ in thor effect.condenser coil tubing. Thus, a better ~mpermure diffeb Steam ~ being generm<strong>ed</strong> in boiler 12, then ~ condens<strong>ed</strong>enti~ b~ween the condenser coil and the reservoir 60 in condenser coil 27. The d~tillme ~ discharg<strong>ed</strong> m thewater ~ generat<strong>ed</strong> and m~ntain<strong>ed</strong> by the stirring improvingthereb~ the opermion of condenser 27. movement of ~stil~d wmer through filter 115 res~.oufl~ 31 through filer 115. A n~ movement outflowAnother important overall pra~ effect of the At the same fim~ a small net inflow of~r into fil~r 115~fing to remove more of the baler he~ overhead of and condenser 27 result. The distiH~ ~g., atthe reserver ~ to save wate~ Le~ of the boiler hem65 190°-195 * F., is hot enough to heat filter 115 and preven~m~ro~ contaminmion of the fil~ Th~ meansmu~ be remov<strong>ed</strong> by d~carding w~er through overflowpipe 32. The proportion of the ~<strong>ed</strong> wmer in the distill~ that ~r which enters over,zeal filter 115 during thetion apparmus thin mu~ be discard<strong>ed</strong> through overflow su~n p~ses is ret~n<strong>ed</strong> ther~n and becomes ~eril~<strong>ed</strong>8