phvac Dec 2006.qxd - Plumbing & HVAC

phvac Dec 2006.qxd - Plumbing & HVAC

phvac Dec 2006.qxd - Plumbing & HVAC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Refrigeration<br />

Working with induction motors<br />

By Ed Gravelle<br />

An induction motor<br />

(IM) is a type of<br />

alternating current<br />

(AC) motor where<br />

power is supplied to the<br />

rotating device by<br />

means of electromagnetic induction.<br />

The other commonly used name is<br />

“squirrel cage motor,” due to the fact<br />

that the rotor bars with short circuit<br />

rings resemble a squirrel cage (hamster<br />

wheel).<br />

An electric motor converts electrical<br />

power to mechanical power in its<br />

rotor (rotating part). There are several<br />

ways to supply power to the rotor.<br />

In a direct current (DC) motor, this<br />

power is supplied to the armature<br />

directly from a DC source, while in an<br />

AC motor this power is induced in the<br />

rotating device.<br />

An induction motor is sometimes<br />

called a rotating transformer because<br />

the stator (stationary part) is essentially<br />

the primary side of the transformer and<br />

the rotor (rotating part) is the secondary<br />

side. Induction motors are widely<br />

used, especially polyphase induction<br />

motors, which are frequently used in<br />

industrial drives. (Wikepedia)<br />

Rotating magnetic field<br />

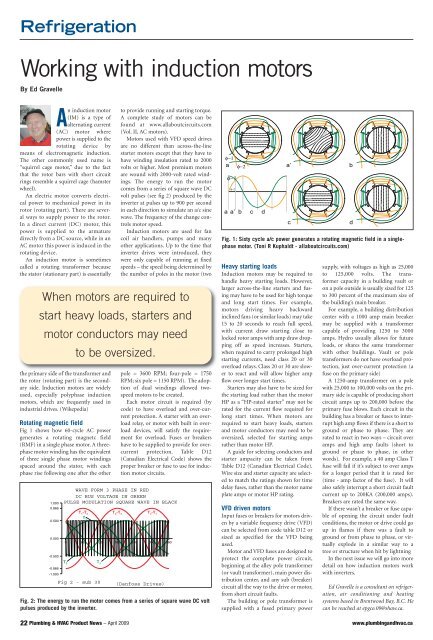

Fig 1 shows how 60-cycle AC power<br />

generates a rotating magnetc field<br />

(RMF) in a single phase motor. A threephase<br />

motor winding has the equivalent<br />

of three single phase motor windings<br />

spaced around the stator, with each<br />

phase rise following one after the other<br />

to provide running and starting torque.<br />

A complete study of motors can be<br />

found at www.allaboutcircuits.com<br />

(Vol. II, AC motors).<br />

Motors used with VFD speed drives<br />

are no different than across-the-line<br />

starter motors except that they have to<br />

have winding insulation rated to 2000<br />

volts or higher. Most premium motors<br />

are wound with 2000-volt rated windings.<br />

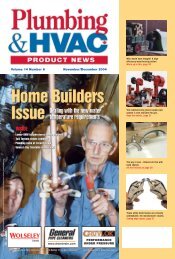

The energy to run the motor<br />

comes from a series of square wave DC<br />

volt pulses (see fig 2) produced by the<br />

inverter at pulses up to 900 per second<br />

in each direction to simulate an a/c sine<br />

wave. The frequency of the change controls<br />

motor speed.<br />

Induction motors are used for fan<br />

coil air handlers, pumps and many<br />

other applications. Up to the time that<br />

inverter drives were introduced, they<br />

were only capable of running at fixed<br />

speeds – the speed being determined by<br />

the number of poles in the motor (two<br />

When motors are required to<br />

start heavy loads, starters and<br />

motor conductors may need<br />

to be oversized.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

pole = 3600 RPM; four-pole = 1750<br />

RPM; six pole = 1150 RPM). The adoption<br />

of dual windings allowed twospeed<br />

motors to be created.<br />

Each motor circuit is required (by<br />

code) to have overload and over-current<br />

protection. A starter with an overload<br />

relay, or motor with built in overload<br />

devices, will satisfy the requirement<br />

for overload. Fuses or breakers<br />

have to be supplied to provide for overcurrent<br />

protection. Table D12<br />

(Canadian Electrical Code) shows the<br />

proper breaker or fuse to use for induction<br />

motor circuits.<br />

WAVE FORM 3 PHASE IN RED<br />

DC BUS VOLTAGE IN GREEN<br />

PULSE MODULATION SQUARE WAVE IN BLACK<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Fig 2 - sub 30<br />

(Danfoss Drives)<br />

Fig. 2: The energy to run the motor comes from a series of square wave DC volt<br />

pulses produced by the inverter.<br />

φ−1<br />

a<br />

φ−1<br />

φ−2<br />

φ−2<br />

a a’ b c d<br />

Heavy starting loads<br />

Induction motors may be required to<br />

handle heavy starting loads. However,<br />

larger across-the-line starters and fusing<br />

may have to be used for high torque<br />

and long start times. For example,<br />

motors driving heavy backward<br />

inclined fans (or similar loads) may take<br />

15 to 20 seconds to reach full speed,<br />

with current draw starting close to<br />

locked rotor amps with amp draw dropping<br />

off as speed increases. Starters,<br />

when required to carry prolonged high<br />

starting currents, need class 20 or 30<br />

overload relays. Class 20 or 30 are slower<br />

to react and will allow higher amp<br />

flow over longer start times.<br />

Starters may also have to be sized for<br />

the starting load rather than the motor<br />

HP as a “HP-rated starter” may not be<br />

rated for the current flow required for<br />

long start times. When motors are<br />

required to start heavy loads, starters<br />

and motor conductors may need to be<br />

oversized, selected for starting amps<br />

rather than motor HP.<br />

A guide for selecting conductors and<br />

starter ampacity can be taken from<br />

Table D12 (Canadian Electrical Code).<br />

Wire size and starter capacity are selected<br />

to match the ratings shown for time<br />

delay fuses, rather than the motor name<br />

plate amps or motor HP rating.<br />

VFD driven motors<br />

Input fuses or breakers for motors driven<br />

by a variable frequency drive (VFD)<br />

can be selected from code table D12 or<br />

sized as specified for the VFD being<br />

used.<br />

Motor and VFD fuses are designed to<br />

protect the complete power circuit,<br />

beginning at the alley pole transformer<br />

(or vault transformer), main power distribution<br />

center, and any sub (breaker)<br />

circuit all the way to the drive or motor,<br />

from short circuit faults.<br />

The building or pole transformer is<br />

supplied with a fused primary power<br />

a’ b<br />

c<br />

Fig. 1: Sixty cycle a/c power generates a rotating magnetic field in a singlephase<br />

motor. (Toni R Kuphaldt - allaboutcircuits.com)<br />

d<br />

supply, with voltages as high as 25,000<br />

to 125,000 volts. The transformer<br />

capacity in a building vault or<br />

on a pole outside is usually sized for 125<br />

to 300 percent of the maximum size of<br />

the building’s main breaker.<br />

For example, a building distribution<br />

center with a 1000 amp main breaker<br />

may be supplied with a transformer<br />

capable of providing 1250 to 3000<br />

amps. Hydro usually allows for future<br />

loads, or shares the same transformer<br />

with other buildings. Vault or pole<br />

transformers do not have overload protection,<br />

just over-current protection (a<br />

fuse on the primary side)<br />

A 1250-amp transformer on a pole<br />

with 25,000 to 100,000 volts on the primary<br />

side is capable of producing short<br />

circuit amps up to 200,000 before the<br />

primary fuse blows. Each circuit in the<br />

building has a breaker or fuses to interrupt<br />

high amp flows if there is a short to<br />

ground or phase to phase. They are<br />

rated to react in two ways – circuit over<br />

amps and high amp faults (short to<br />

ground or phase to phase, in other<br />

words). For example, a 40 amp Class T<br />

fuse will fail if it’s subject to over amps<br />

for a longer period that it is rated for<br />

(time - amp factor of the fuse). It will<br />

also safely interrupt a short circuit fault<br />

current up to 200KA (200,000 amps).<br />

Breakers are rated the same way.<br />

If there wasn’t a breaker or fuse capable<br />

of opening the circuit under fault<br />

conditions, the motor or drive could go<br />

up in flames if there was a fault to<br />

ground or from phase to phase, or virtually<br />

explode in a similar way to a<br />

tree or structure when hit by lightning<br />

In the next issue we will go into more<br />

detail on how induction motors work<br />

with inverters.<br />

Ed Gravelle is a consultant on refrigeration,<br />

air conditioning and heating<br />

systems based in Brentwood Bay, B.C. He<br />

can be reached at epgco.09@shaw.ca.<br />

22 <strong>Plumbing</strong> & <strong>HVAC</strong> Product News – April 2009 www.plumbingandhvac.ca