Aluminium Recycling in Europe: the Road to High

Aluminium Recycling in Europe: the Road to High

Aluminium Recycling in Europe: the Road to High

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

metal for future use, and alum<strong>in</strong>ium<br />

oxide. The alum<strong>in</strong>ium oxide is <strong>the</strong>n used<br />

<strong>in</strong> a variety of applications, such as<br />

<strong>the</strong> production of cement. Filter dust<br />

(~8 kg/<strong>to</strong>nne alum<strong>in</strong>ium3)) is recycled or<br />

discarded <strong>in</strong><strong>to</strong> specially designed facilities.<br />

Skimm<strong>in</strong>gs (~120kg/<strong>to</strong>nne alum<strong>in</strong>ium3)) and, <strong>in</strong> some cases, furnace l<strong>in</strong><strong>in</strong>g<br />

(~2 kg/<strong>to</strong>nne alum<strong>in</strong>ium3)) are recycled<br />

with<strong>in</strong> <strong>the</strong> alum<strong>in</strong>ium recycl<strong>in</strong>g <strong>in</strong>dustry.<br />

Measur<strong>in</strong>g <strong>the</strong> <strong>Recycl<strong>in</strong>g</strong><br />

Performance of <strong>the</strong> <strong>Alum<strong>in</strong>ium</strong><br />

Industry<br />

The recycl<strong>in</strong>g performance of <strong>the</strong><br />

alum<strong>in</strong>ium <strong>in</strong>dustry can be described by<br />

different <strong>in</strong>dica<strong>to</strong>rs, namely <strong>the</strong> overall<br />

and <strong>the</strong> end-of-life recycl<strong>in</strong>g efficiency<br />

rate (see frequently ask questions).<br />

The recycl<strong>in</strong>g performance of <strong>the</strong><br />

alum<strong>in</strong>ium <strong>in</strong>dustry is determ<strong>in</strong>ed first of<br />

all by how much alum<strong>in</strong>ium metal is lost<br />

with<strong>in</strong> <strong>the</strong> <strong>in</strong>dustry. Usually, ref<strong>in</strong>ers and<br />

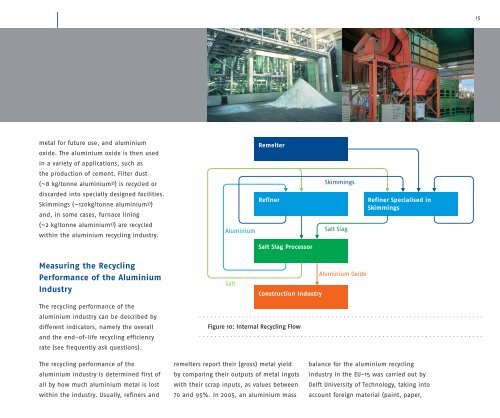

<strong>Alum<strong>in</strong>ium</strong><br />

Salt<br />

Remelter<br />

Ref<strong>in</strong>er<br />

Salt Slag Processor<br />

Construction Industry<br />

Figure 10: Internal <strong>Recycl<strong>in</strong>g</strong> Flow<br />

remelters report <strong>the</strong>ir (gross) metal yield<br />

by compar<strong>in</strong>g <strong>the</strong>ir outputs of metal <strong>in</strong>gots<br />

with <strong>the</strong>ir scrap <strong>in</strong>puts, as values between<br />

70 and 95%. In 2005, an alum<strong>in</strong>ium mass<br />

Skimm<strong>in</strong>gs<br />

Salt Slag<br />

<strong>Alum<strong>in</strong>ium</strong> Oxide<br />

Ref<strong>in</strong>er Specialised <strong>in</strong><br />

Skimm<strong>in</strong>gs<br />

balance for <strong>the</strong> alum<strong>in</strong>ium recycl<strong>in</strong>g<br />

<strong>in</strong>dustry <strong>in</strong> <strong>the</strong> EU-15 was carried out by<br />

Delft University of Technology, tak<strong>in</strong>g <strong>in</strong><strong>to</strong><br />

account foreign material (pa<strong>in</strong>t, paper,<br />

15