Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

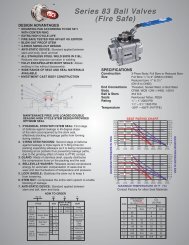

<strong>Series</strong> <strong>77</strong> <strong>Ball</strong> <strong>Valves</strong><br />

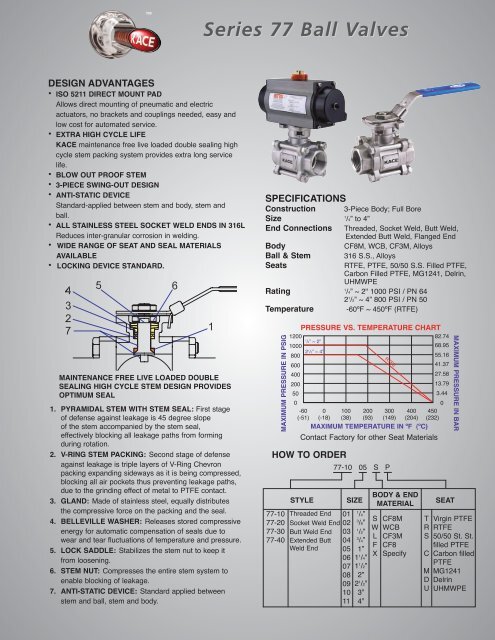

DESIGN ADVANTAGES<br />

• ISO 5211 DIRECT MOUNT PAD<br />

Allows direct mounting of pneumatic and electric<br />

actuators, no brackets and couplings needed, easy and<br />

low cost for automated service.<br />

• EXTRA HIGH CYCLE LIFE<br />

<strong>KACE</strong> maintenance free live loaded double sealing high<br />

cycle stem packing system provides extra long service<br />

life.<br />

• BLOW OUT PROOF STEM<br />

• 3-PIECE SWING-OUT DESIGN<br />

• ANTI-STATIC DEVICE<br />

Standard-applied between stem and body, stem and<br />

ball.<br />

• ALL STAINLESS STEEL SOCKET WELD ENDS IN 316L<br />

Reduces inter-granular corrosion in welding.<br />

• WIDE RANGE OF SEAT AND SEAL MATERIALS<br />

AVAILABLE<br />

• LOCKING DEVICE STANDARD.<br />

MAINTENANCE FREE LIVE LOADED DOUBLE<br />

SEALING HIGH CYCLE STEM DESIGN PROVIDES<br />

OPTIMUM SEAL<br />

1. PYRAMIDAL STEM WITH STEM SEAL: First stage<br />

of defense against leakage is 45 degree slope<br />

of the stem accompanied by the stem seal,<br />

effectively blocking all leakage paths from forming<br />

during rotation.<br />

2. V-RING STEM PACKING: Second stage of defense<br />

against leakage is triple layers of V-Ring Chevron<br />

packing expanding sideways as it is being compressed,<br />

blocking all air pockets thus preventing leakage paths,<br />

due to the grinding effect of metal to PTFE contact.<br />

3. GLAND: Made of stainless steel, equally distributes<br />

the compressive force on the packing and the seal.<br />

4. BELLEVILLE WASHER: Releases stored compressive<br />

energy for automatic compensation of seals due to<br />

wear and tear fluctuations of temperature and pressure.<br />

5. LOCK SADDLE: Stabilizes the stem nut to keep it<br />

from loosening.<br />

6. STEM NUT: Compresses the entire stem system to<br />

enable blocking of leakage.<br />

7. ANTI-STATIC DEVICE: Standard applied between<br />

stem and ball, stem and body.<br />

SPECIFICATIONS<br />

Construction 3-Piece Body; Full Bore<br />

Size 1<br />

/4” to 4”<br />

End Connections Threaded, Socket Weld, Butt Weld,<br />

Extended Butt Weld, Flanged End<br />

Body<br />

CF8M, WCB, CF3M, Alloys<br />

<strong>Ball</strong> & Stem 316 S.S., Alloys<br />

Seats<br />

RTFE, PTFE, 50/50 S.S. Filled PTFE,<br />

Carbon Filled PTFE, MG1241, Delrin,<br />

UHMWPE<br />

Rating 1<br />

/4” ~ 2" 1000 PSI / PN 64<br />

2 1 /2” ~ 4” 800 PSI / PN 50<br />

Temperature -60ºF ~ 450ºF (RTFE)<br />

MAXIMUM PRESSURE IN PSIG<br />

HOW TO ORDER<br />

<strong>77</strong>-10<br />

<strong>77</strong>-20<br />

<strong>77</strong>-30<br />

<strong>77</strong>-40<br />

PRESSURE VS. TEMPERATURE CHART<br />

1200<br />

82.74<br />

1<br />

/4” ~ 2”<br />

1000<br />

68.95<br />

800<br />

2 1 /2” ~ 4”<br />

55.16<br />

600<br />

41.37<br />

400<br />

27.58<br />

200<br />

13.79<br />

50<br />

3.44<br />

0<br />

0<br />

-60 0 100 200 300 400 450<br />

(-51) (-18) (38) (93) (149) (204) (232)<br />

MAXIMUM TEMPERATURE IN ºF (ºC)<br />

Contact Factory for other Seat Materials<br />

STYLE<br />

Threaded End<br />

Socket Weld End<br />

Butt Weld End<br />

Extended Butt<br />

Weld End<br />

<strong>77</strong>-10 05 S P<br />

SIZE<br />

01<br />

02<br />

03<br />

04<br />

05<br />

06<br />

07<br />

08<br />

09<br />

10<br />

11<br />

1<br />

/4”<br />

3<br />

/8”<br />

1<br />

/2”<br />

3<br />

/4”<br />

1”<br />

1 1 /4”<br />

1 1 /2”<br />

2”<br />

2 1 /2”<br />

3”<br />

4”<br />

BODY & END<br />

MATERIAL<br />

S<br />

W<br />

L<br />

F<br />

X<br />

RTFE<br />

CF8M<br />

WCB<br />

CF3M<br />

CF8<br />

Specify<br />

T<br />

R<br />

S<br />

C<br />

M<br />

D<br />

U<br />

SEAT<br />

MAXIMUM PRESSURE IN BAR<br />

Virgin PTFE<br />

RTFE<br />

50/50 St. St.<br />

filled PTFE<br />

Carbon filled<br />

PTFE<br />

MG1241<br />

Delrin<br />

UHMWPE

<strong>Series</strong> <strong>77</strong> <strong>Ball</strong> <strong>Valves</strong><br />

1/4" ~ 3"<br />

4"<br />

EXTENDED BUTT<br />

WELD END<br />

MATERIALS LIST<br />

NO.<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

PART NAME<br />

BODY<br />

END CAP<br />

FLANGED END CAP<br />

BALL<br />

SEAT<br />

JOINT GASKET<br />

THRUST WASHER<br />

STEM<br />

GLAND PACKING<br />

GLAND PACKING<br />

GLAND BUSH<br />

BELLEVILLE WASHER<br />

STOP WASHER<br />

STEM NUT<br />

STEM WASHER<br />

HANDLE<br />

LOCKING DEVICE<br />

HANDLE COVER<br />

BOLT<br />

BOLT NUT<br />

BOLT WASHER<br />

STOP PIN<br />

PIN NUT<br />

QTY<br />

1<br />

2<br />

2<br />

1<br />

2<br />

2<br />

1<br />

1<br />

*<br />

1<br />

1<br />

2<br />

1<br />

2<br />

1<br />

1<br />

1<br />

1<br />

#<br />

&<br />

&<br />

1<br />

1<br />

MATERIAL<br />

CF8M / WCB<br />

CF3M / WCB<br />

CF8M<br />

SS316<br />

RTFE<br />

PTFE<br />

RTFE<br />

SS316<br />

PTFE<br />

25% GLASS FIBER FILLED + PTFE<br />

SS304<br />

SS301<br />

SS304<br />

SS304<br />

SS304<br />

SS304<br />

SS304<br />

PLASTIC<br />

SS304<br />

SS304<br />

SS304<br />

SS304<br />

SS304<br />

BUTT WELD<br />

END<br />

SOCKET WELD<br />

END<br />

NPT<br />

BODY DIMENSIONS (INCHES)<br />

SIZE ø D A B C ø E ø F G L L 2 ø P H I S O 5 2 11<br />

1<br />

/4”<br />

3<br />

/8”<br />

0.45 1.65 0.34<br />

0.49 1.65 0.34<br />

5.47<br />

5.47<br />

1.41 1.65 0.35<br />

1.41 1.65 0.35<br />

2.5<br />

2.5<br />

0.92 1.81 3.07<br />

0.92 1.81 3.07<br />

F03 / F04<br />

F03 / F04<br />

1<br />

/2” 0.59 1.65 0.34 5.47 1.41 1.65 0.35 2.58 0.92 1.81 3.07 F03 / F04<br />

3<br />

/4” 0.78 1.88 0.33 5.47 1.41 1.65 0.35 2.99 1.1 2.04 3.26 F03 / F04<br />

1”<br />

1 1 /4”<br />

0.98 2.22 0.44<br />

1.25 2.39 0.44<br />

6.49<br />

6.49<br />

1.65 1.96 0.43 3.39 1.33 2.36 3.<strong>77</strong><br />

1.65 1.96 0.43 4.04 1.67 2.89 3.93<br />

F04 / F05<br />

F04 / F05<br />

1 1 /2” 1.49 3.05 0.54 8.46 1.96 2.75 0.55 4.7 2.09 3.36 4.99 F05 / F07<br />

2” 1.96 3.35 0.54 8.46 1.96 2.75 0.55 5.17 2.54 4.08 5.31 F05 / F07<br />

2 1 /2” 2.55 4.27 0.66 10.31 2.75 4.01 0.66 6.45 3.42 5.11 6.57 F07 / F10<br />

3” 3.14 4.63 0.7 4.0 2.75 4.01 0.66 7.19 3.89 6.12 6.92 F07 / F10<br />

4” 3.93 5.21 0.66 4.0 2.75 4.01 0.66 9.27 4.99 7.4 7.51 F07 / F10<br />

END CONNECTION DIMENSIONS (INCHES)<br />

SIZE<br />

1<br />

/4”<br />

3<br />

/8”<br />

1<br />

/2”<br />

3<br />

/4”<br />

1”<br />

1 1 /4”<br />

1 1 /2”<br />

2”<br />

2 1 /2”<br />

3”<br />

4”<br />

*<br />

#<br />

&<br />

For 1/4" to 2" - 2pcs, For 2-1/2" to 4" - 3pcs.<br />

For 1/4" to 3" - 4pcs, For 4" - 6pcs of bolts<br />

For 1/4" to 2" - 4pcs<br />

For 2-1/2" to 3" - 8pcs<br />

For 4" - 12pcs<br />

ø B 2 B 3 ø C L 1 L E ø G T W t . ( l b . )<br />

0.55<br />

0.69<br />

0.85<br />

1.07<br />

1.34<br />

0.39<br />

0.39<br />

0.39<br />

0.51<br />

0.51<br />

0.45 2.46<br />

0.49 2.46<br />

0.59 2.58<br />

0.78 2.99<br />

0.98 3.39<br />

8.85<br />

8.85<br />

8.85<br />

8.85<br />

9.64<br />

0.63 0.06<br />

0.68 0.06<br />

0.89 0.06<br />

1.08 0.06<br />

1.33 0.06<br />

-<br />

-<br />

1.4<br />

1.8<br />

2.75<br />

1.68 0.51 1.25 4.04 10.03 1.68 0.06 -<br />

1.91 0.51 1.49 4.7 10.23 1.91 0.06 7.25<br />

2.40 0.62 1.96 5.17 10.82 2.38 0.06 10.5<br />

2.90 0.62 2.55 6.45 13.14 3.0 0.07 20<br />

3.54 0.62 3.14 7.19 13.93 3.54 0.07 26.75<br />

4.53 0.78 3.93 9.27 4.56 0.13 -<br />

THREADED END<br />

BREAKAWAY TORQUE<br />

&<br />

Cv VALUES<br />

SIZE<br />

1<br />

/4”<br />

3<br />

/8”<br />

1<br />

/2”<br />

3<br />

/4”<br />

1”<br />

1 1 /4”<br />

1 1 /2”<br />

2”<br />

2 1 /2”<br />

3”<br />

4”<br />

BREAK AWAY<br />

TORQUE (In.Lb.)<br />

27<br />

27<br />

27<br />

62<br />

106<br />

133<br />

1<strong>77</strong><br />

204<br />

310<br />

487<br />

753<br />

Cv<br />

U.S. GPM<br />

8<br />

10<br />

12<br />

32<br />

56<br />

82<br />

120<br />

240<br />

320<br />

580<br />

1020<br />

STANDARDS<br />

ANSI / ASME: B16.34, B16.25, B1.20.1<br />

API: 6D, 598<br />

ISO: 5211/1, 5209, 5752, 7/1, 261<br />

DIN:<br />

3357, 50.049-3.1B<br />

MSS:<br />

SP25, SP72<br />

BS: 5351<br />

NACE:<br />

MR01-75<br />

<br />

<strong>KACE</strong> BALL VALVES<br />

10440 Corporate Drive<br />

Sugar Land,Texas <strong>77</strong>478<br />

Tel. 281-240-0955<br />

Fax 281-240-5619<br />

e-mail: sales@kace-valves.com<br />

http://www.kace-valves.com<br />

Distributor:<br />

05/11