Series G88 Metal Seated Ball Valves - KACE Valves

Series G88 Metal Seated Ball Valves - KACE Valves

Series G88 Metal Seated Ball Valves - KACE Valves

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

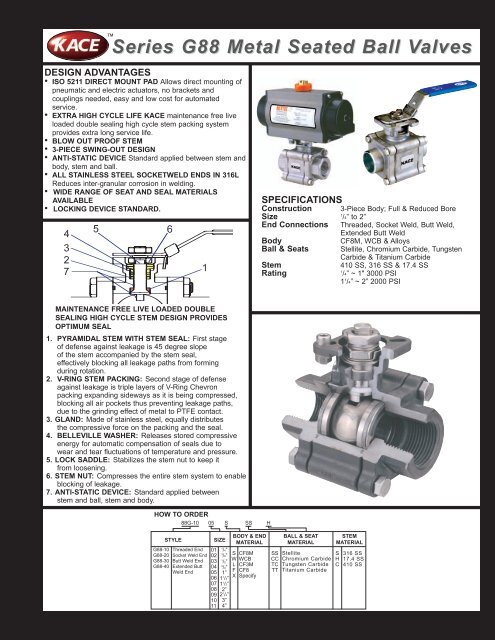

<strong>Series</strong> <strong>G88</strong> <strong>Metal</strong> <strong>Seated</strong> <strong>Ball</strong> <strong>Valves</strong>VDESIGN ADVANTAGES• ISO 5211 DIRECT MOUNT PAD Allows direct mounting ofpneumatic and electric actuators, no brackets andcouplings needed, easy and low cost for automatedservice.• EXTRA HIGH CYCLE LIFE <strong>KACE</strong> maintenance free liveloaded double sealing high cycle stem packing systemprovides extra long service life.• BLOW OUT PROOF STEM• 3-PIECE SWING-OUT DESIGN• ANTI-STATIC DEVICE Standard applied between stem andbody, stem and ball.• ALL STAINLESS STEEL SOCKETWELD ENDS IN 316LReduces inter-granular corrosion in welding.• WIDE RANGE OF SEAT AND SEAL MATERIALSAVAILABLE• LOCKING DEVICE STANDARD.SPECIFICATIONSConstructionSize 1/4” to 2”End ConnectionsBody<strong>Ball</strong> & SeatsStemRating3-Piece Body; Full & Reduced BoreThreaded, Socket Weld, Butt Weld,Extended Butt WeldCF8M, WCB & AlloysStellite, Chromium Carbide, TungstenCarbide & Titanium Carbide410 SS, 316 SS & 17.4 SS1/4” ~ 1" 3000 PSI1 1 /4” ~ 2” 2000 PSIMAINTENANCE FREE LIVE LOADED DOUBLESEALING HIGH CYCLE STEM DESIGN PROVIDESOPTIMUM SEAL1. PYRAMIDAL STEM WITH STEM SEAL: First stageof defense against leakage is 45 degree slopeof the stem accompanied by the stem seal,effectively blocking all leakage paths from formingduring rotation.2. V-RING STEM PACKING: Second stage of defenseagainst leakage is triple layers of V-Ring Chevronpacking expanding sideways as it is being compressed,blocking all air pockets thus preventing leakage paths,due to the grinding effect of metal to PTFE contact.3. GLAND: Made of stainless steel, equally distributesthe compressive force on the packing and the seal.4. BELLEVILLE WASHER: Releases stored compressiveenergy for automatic compensation of seals due towear and tear fluctuations of temperature and pressure.5. LOCK SADDLE: Stabilizes the stem nut to keep itfrom loosening.6. STEM NUT: Compresses the entire stem system to enableblocking of leakage.7. ANTI-STATIC DEVICE: Standard applied betweenstem and ball, stem and body.HOW TO ORDER88G-10 05 S SS H<strong>G88</strong>-10<strong>G88</strong>-20<strong>G88</strong>-30<strong>G88</strong>-40STYLEThreaded EndSocket Weld EndButt Weld EndExtended ButtWeld EndSIZE01020304050607080910111/4”3/8”1/2”3/4”1”1 1 /4”1 1 /2”2”2 1 /2”3”4”BODY & ENDMATERIALSWLFXCF8MWCBCF3MCF8SpecifySSCCTCTTBALL & SEATMATERIALStelliteChromium CarbideTungsten CarbideTitanium CarbideSTEMMATERIALSHC316 SS17.4 SS410 SS

++1-+18SERIES <strong>G88</strong>MATERIALS LIST101798765432115øM1øM2GL -+øX11øX211 12 14 21 13HBAEM1-+19201øCB1B160.80.21/4" ~ 2"2 1/2" ~ 4"NO.123456789101112131415161718192021PART NAMEBODYEND CAPBALLSEATJOINT GASKETSTEM SEALSTEMGLAND PACKINGGLAND BUSHSTOP WASHERSTEM NUTHANDLEHANDLE SLEEVESTEM WASHERBOLTBOLT NUTBELLEVILLE WASHERSTOP PINPIN NUTBUSHINGLOCKING DEVICENOTE: *QTY12122111112111**211111/4” ~ 2” - 4 pcs2 1 /2” ~ 4” - 6 pcsMATERIALCF8MCF3MSS316 / COATEDSS316 / COATEDGraphiteRTFE / PEEK / GRAPHITE410 SS / 316 SS / 17.4 SSGraphiteSS304SS304SS304SS304VINYLSS304SS304SS304SS301SS304SS30415% GLASS FIBER FILLED + PTFESS304A - VIEW6B - VIEWPS: 1/2" ~ 1" 2000 WOG1-1/4" ~ 2" 1500 WOG9208BUTT WELDSOCKET WELDTHREADED ENDL1 - Full PortL - Reduced PortSCH. 40 Available on RequestReduced Port Drawings Available Upon RequestOptional 3-WayConfigurationConsult FactoryBODY & MOUNTING PAD DIMENSIONS (INCHES)SIZEB1 B2 E F H L øM1 øM2 P øX1 øX2 Wt.(lb.) ISO5211F R F R F R F R F R F R F R F R F R F R F R F R F R1/4”3/8”0.250.25--1.681.68--5.475.47--0.350.35--3.083.08--2.952.95--1.421.42--1.651.65--0.120.12--0.240.24--0.240.24--1.961.94--F03 / F04F03 / F04--1/2”3/4”0.25 0.25 1.68 1.680.34 0.25 1.85 1.685.475.475.475.470.35 0.35 3.08 3.08 2.85 2.95 1.42 1.42 1.65 1.65 0.12 0.12 0.24 0.24 0.24 0.240.35 0.35 3.25 3.08 3.36 2.85 1.42 1.42 1.65 1.65 0.12 0.12 0.24 0.24 0.24 0.241.802.841.831.85F03 / F04 F03 / F04F03 / F04 F03 / F041” 0.41 0.34 2.34 1.84 6.5 5.47 0.43 0.35 3.88 3.25 4.15 3.36 1.65 1.42 1.97 1.65 0.2 0.12 0.24 0.24 0.28 0.24 4.42 3.30 F04 / F05 F03 / F041 1 /4” 0.41 0.41 2.47 2.34 6.5 6.50 0.43 0.43 4.01 3.88 4.37 4.15 1.65 1.65 1.97 1.97 0.2 0.20 0.24 0.24 0.28 0.28 6.07 4.77 F04 / F05 F04 / F051 1 /2” 0.53 0.41 3.11 2.47 8.47 6.50 0.55 0.43 5.0 4.01 5.01 4.37 1.97 1.65 2.76 1.97 0.39 0.20 0.3 0.24 0.35 0.28 9.26 9.39 F05 / F07 F04 / F052” 0.53 0.53 3.45 3.11 8.47 8.47 0.55 0.55 5.34 5.00 5.71 5.01 1.97 1.97 2.76 2.76 0.39 0.39 0.3 0.30 0.35 0.35 15.25 11.66 F05 / F07 F05 / F072 1 /2” 0.66 0.53 4.28 3.45 10.32 8.47.67/.75 0.55 6.60 5.33 7.28 5.71 2.76 1.97 4.02 2.76 0.63 0.39 0.39 0.30 0.47 0.35 26.40 14.32 F07 / F10 F05 / F073”4”.67 .670.70 0.66 4.63 4.28 10.32 10.32 /.75 /.75 6.96 6.60 8.07 7.28 2.76 2.76 4.02 4.02 0.63 0.63 0.39 0.39 0.47 0.47 35.64 26.40 F07 / F10 F07 / F10.67 .670.66 0.70 5.26 4.63 12.28 10.32 /.75 /.75 7.59 6.96 9.45 8.07 2.76 2.76 4.02 4.02 0.63 0.63 0.39 0.39 0.47 0.47 56.76 35.64 F07 / F10 F07 / F10END CONNECTION DIMENSIONS (INCHES)SIZEøA øC øD J L1 L2F R F R F R F R F R F R1/4” 0.55 - 0.45 - 0.85 - 0.13 - 2.95 - 0.39 -3/8” 0.69 - 0.5 - 0.85 - 0.11 - 2.95 - 0.39 -1/2” 0.85 0.85 0.59 0.50 0.85 0.85 0.06 0.06 2.85 - 0.39 0.393/4” 1.08 1.08 0.79 0.59 1.07 - 0.06 0.06 3.36 2.95 0.51 0.511” 1.34 1.34 0.98 0.79 1.34 - 0.06 0.06 4.15 3.54 0.51 0.511 1 /4” 1.69 1.69 1.26 0.98 1.68 - 0.06 0.06 4.37 4.31 0.51 0.511 1 /2” 1.92 1.92 1.50 1.26 1.91 - 0.06 0.06 5.01 4.50 0.51 0.512” 2.4 2.4 1.97 1.50 2.38 -5.620.06 0.06 /5.71 5.12 0.63 0.632 1 /2” 2.9 3.03 2.56 1.97 3.00 - - 7.28 5.71 0.63 0.633” 3.54 3.54 3.15 - 3.54 - - 8.07 - 0.63 0.634” 4.54 4.54 3.94 - 4.57 - - 9.45 - 0.79 0.79STANDARDSANSI / ASME: B16.34, B16.25, B1.20.1API: 6D, 598, 607ISO: 5211, 5209, 5752, 7/1, 261DIN:MSS:3357, 50.049-3.1BSP25, SP72BS: 5351, 6755-1, 6755-2NACE:MR01-75TM<strong>KACE</strong> BALL VALVES10440 Corporate DriveSugar Land,Texas 77478Tel. 281-240-0955Fax 281-240-5619e-mail: sales@kace-valves.comhttp://www.kace-valves.comDistributor:04/05