Series 33 Multi-Way Ball Valves - KACE Valves

Series 33 Multi-Way Ball Valves - KACE Valves

Series 33 Multi-Way Ball Valves - KACE Valves

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

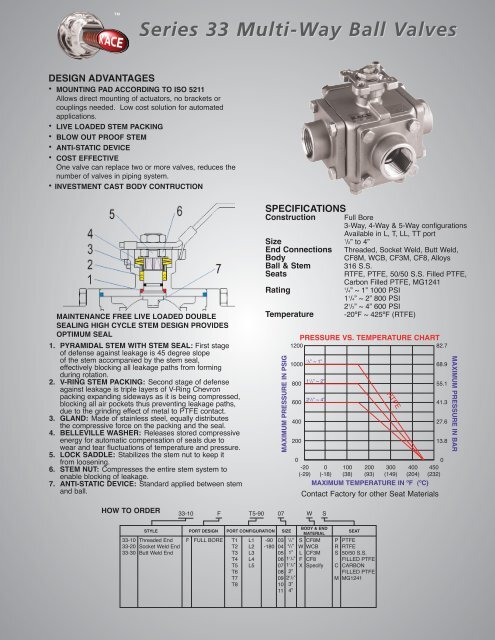

<strong>Series</strong> <strong>33</strong> <strong>Multi</strong>-<strong>Way</strong> <strong>Ball</strong> <strong>Valves</strong>DESIGN ADVANTAGES• MOUNTING PAD ACCORDING TO ISO 5211Allows direct mounting of actuators, no brackets orcouplings needed. Low cost solution for automatedapplications.• LIVE LOADED STEM PACKING• BLOW OUT PROOF STEM• ANTI-STATIC DEVICE• COST EFFECTIVEOne valve can replace two or more valves, reduces thenumber of valves in piping system.• INVESTMENT CAST BODY CONTRUCTIONMAINTENANCE FREE LIVE LOADED DOUBLESEALING HIGH CYCLE STEM DESIGN PROVIDESOPTIMUM SEAL1. PYRAMIDAL STEM WITH STEM SEAL: First stageof defense against leakage is 45 degree slopeof the stem accompanied by the stem seal,effectively blocking all leakage paths from formingduring rotation.2. V-RING STEM PACKING: Second stage of defenseagainst leakage is triple layers of V-Ring Chevronpacking expanding sideways as it is being compressed,blocking all air pockets thus preventing leakage paths,due to the grinding effect of metal to PTFE contact.3. GLAND: Made of stainless steel, equally distributesthe compressive force on the packing and the seal.4. BELLEVILLE WASHER: Releases stored compressiveenergy for automatic compensation of seals due towear and tear fluctuations of temperature and pressure.5. LOCK SADDLE: Stabilizes the stem nut to keep itfrom loosening.6. STEM NUT: Compresses the entire stem system toenable blocking of leakage.7. ANTI-STATIC DEVICE: Standard applied between stemand ball.SPECIFICATIONSConstructionFull Bore3-<strong>Way</strong>, 4-<strong>Way</strong> & 5-<strong>Way</strong> configurationsAvailable in L, T, LL, TT portSize 1/2” to 4”End Connections Threaded, Socket Weld, Butt Weld,BodyCF8M, WCB, CF3M, CF8, Alloys<strong>Ball</strong> & Stem 316 S.S.SeatsRTFE, PTFE, 50/50 S.S. Filled PTFE,Carbon Filled PTFE, MG1241Rating1/4” ~ 1” 1000 PSI1 1 /4” ~ 2” 800 PSI2 1 /2” ~ 4” 600 PSITemperatureMAXIMUM PRESSURE IN PSIG1200-20ºF ~ 425ºF (RTFE)PRESSURE VS. TEMPERATURE CHART1/4” ~ 1”10008006004002001 1 /4” ~ 2”2 1 /2” ~ 4”RTFE82.768.955.141.327.613.800-20 0 100 200 300 400 450(-29) (-18) (38) (93) (149) (204) (232)MAXIMUM TEMPERATURE IN ºF (ºC)Contact Factory for other Seat MaterialsMAXIMUM PRESSURE IN BARHOW TO ORDER<strong>33</strong>-10 F T5-90 07 W S<strong>33</strong>-10<strong>33</strong>-20<strong>33</strong>-30STYLE PORT DESIGN PORT CONFIGURATION SIZEBODY & ENDMATERIALSEATThreaded End F FULL BORE T1 L1 -90 03 1/2” S CF8M PSocket Weld EndT2 L2 -180 043/4” W WCB RButt Weld EndT3 L3 05 1” L CF3M ST4 L4 06 1 1 /4” F CF8T5 L5 07 1 1 /2” X Specify CT608 2”T709 2 1 /2”MT810 3”11 4”PTFERTFE50/50 S.S.FILLED PTFECARBONFILLED PTFEMG1241

ød2121110ød198765164213DIMENSIONS (INCHES)SIZE ø A1/4”3/8”1/2”3/4”1”1 1 /4”1 1 /2”2”2 1 /2”3”4”B13 14 15 19LBA VIEWL/2øB0.460.500.590.790.981.261.50.350.350.350.430.430.550.67/0.75NPTPTISO1.97 0.67/0.752.56 0.67/0.75 BSP2.993.940.870.87<strong>Series</strong> <strong>33</strong> <strong>Multi</strong>-<strong>Way</strong> <strong>Ball</strong> <strong>Valves</strong>C1817 22øAG E FA VIEWC5.915.915.916.510.3510.3510.3512.3213.5412.4820.08H23øC0.560.690.861.081.341.691.932.41ANSI743.544.55øB2120DLL/20.390.390.390.510.510.510.510.630.630.630.79øAø d 1 ø d 21.421.421.421.651.651.972.762.762.764.024.02øCDTHREADED ENDSOCKET WELDBUTT WELDENDEND<strong>33</strong>-10 <strong>33</strong>-20 <strong>33</strong>-30LøAEøEøAø ET37.5FL1.651.651.651.971.971.731.731.732.132.520.640.690.891.081.340.350.350.350.410.411.38 3.351.38 3.351.38 3.351.78 3.662.24 4.253.623.623.624.<strong>33</strong>5.670.060.060.060.060.062.76 3.09 1.68 0.51 2.35 5.0 5.75 0.064.024.024.023.744.04.721.912.383.000.710.710.712.85 5.983.17 6.263.81 6.976.467.249.290.060.060.084.924.925.236.463.544.570.910.914.13 7.68 10.435.18 8.89 10.590.080.14GMATERIALS LISTNO.1234567891011121314151617181920212223Consult Factory for 4/5 way DiagramsHPART NAMEBODYEND CAP - AEND CAP - BSEAT RETAINERBALLSEATSJOINT GASKETSTEM SEALSTEMGLAND PACKINGGLAND BUSHBELLEVILLE WASHERSTOP WASHERSTEM NUTSTEM WASHERRETAINER SEALHANDLEHANDLE SLEEVELOCKING DEVICEBOLT NUTPIN NUTSTOP PINO-RINGLTQTY1325155111 SET12121511120111W t . ( l b . ) I S O 5 2 113.083.082.866.1810.4712.6523.2329.5246.8863.47126.52MATERIALWCB / CF8MWCB / CF3MWCB / CF3MCF8MSS316RTFEPTFEPTFESS31625% GLASS FIBER FILLED + PTFESS304SS301SS304SS304SS304PTFESS304VINYLSS304SS304SS304SS304VITONF03/F04/F05F03/F04/F05F03/F04/F05F04 / F05F04/F04/F07F05 / F07F07 / F10F07 / F10F07 / F10F10 / F12F10 / F12StandardConfigurationT5-90ºFlow Patterns - 3 WAY T PORTOther Available ConfigurationsT4-90º T3-90º T6-90º T1-180º T2-180º T3-180º T7-180ºStandardConfigurationL2-90ºFlow Patterns - 3 WAY “L” PORTOther Available ConfigurationsL1-180º L3-180º L4-180ºConsult Factory for other port arrangementsSTANDARDSANSI / ASME:B16.34, B16.25, B1.20.1API: 6D, 598ISO: 5211/1, 5209, 5752, 7/1, 261DIN:<strong>33</strong>57, 50.049-3.1BMSS:SP25, SP72BS: 5351NACE:MR01-75Flow Patterns - 4 WAY X PORT“T” PORT “L” PORT “X” PORTT8-180º L5-180º X-90ºSIZE1/4”3/8”1/2”3/4”1”1- 1 /4”1- 1 /2”2”2- 1 /2”3”4”BREAKAWAYTORQUE (In.-Lb.)1051051151974174607501050140022002800Cv U.S. GPM(L-PORT)2.94.371227396092154210390<strong>KACE</strong> BALL VALVES10440 Corporate DriveSugar Land,Texas 77478Tel. 281-240-0955Fax 281-240-5619e-mail: sales@kace-valves.comhttp://www.kace-valves.comDistributor:05/11