Water treatment plant Steel Mill Salzgitter - PSE Engineering GmbH

Water treatment plant Steel Mill Salzgitter - PSE Engineering GmbH

Water treatment plant Steel Mill Salzgitter - PSE Engineering GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PSE</strong> <strong>Engineering</strong> <strong>GmbH</strong><br />

Pfaffenstr. 11<br />

49610 Quakenbrück, Germany<br />

Phone +49 5431 14-0<br />

Fax +49 5431 14-191<br />

E-Mail info@pse-eng.de<br />

Page 1 of 2<br />

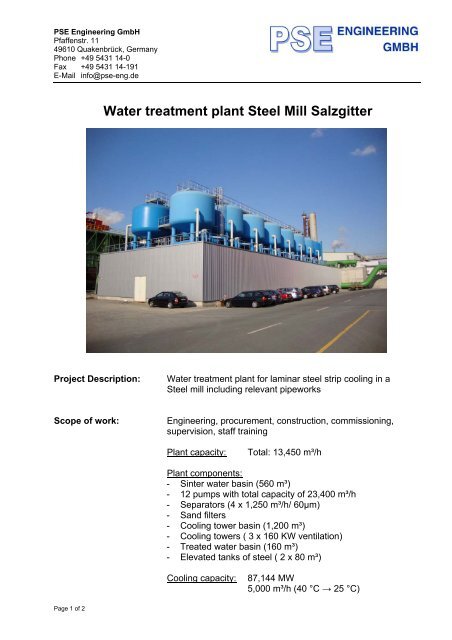

<strong>Water</strong> <strong>treatment</strong> <strong>plant</strong> <strong>Steel</strong> <strong>Mill</strong> <strong>Salzgitter</strong><br />

Project Description: <strong>Water</strong> <strong>treatment</strong> <strong>plant</strong> for laminar steel strip cooling in a<br />

<strong>Steel</strong> mill including relevant pipeworks<br />

Scope of work: <strong>Engineering</strong>, procurement, construction, commissioning,<br />

supervision, staff training<br />

Plant capacity: Total: 13,450 m³/h<br />

Plant components:<br />

- Sinter water basin (560 m³)<br />

- 12 pumps with total capacity of 23,400 m³/h<br />

- Separators (4 x 1,250 m³/h/ 60µm)<br />

- Sand filters<br />

- Cooling tower basin (1,200 m³)<br />

- Cooling towers ( 3 x 160 KW ventilation)<br />

- Treated water basin (160 m³)<br />

- Elevated tanks of steel ( 2 x 80 m³)<br />

Cooling capacity: 87,144 MW<br />

5,000 m³/h (40 °C → 25 °C)

<strong>PSE</strong> <strong>Engineering</strong> <strong>GmbH</strong><br />

Pfaffenstr. 11<br />

49610 Quakenbrück, Germany<br />

Phone +49 5431 14-0<br />

Fax +49 5431 14-191<br />

E-Mail info@pse-eng.de<br />

Page 2 of 2<br />

<strong>Water</strong> <strong>treatment</strong> <strong>plant</strong> <strong>Steel</strong> <strong>Mill</strong> <strong>Salzgitter</strong><br />

The cooling water circuit consists of pumping stations,<br />

different scale pits with oil separation, from here the water will<br />

be divided into three part streams, each part will be cleaned in<br />

a different way. First part stream goes directly to the cooling<br />

tower basin, second part stream will be treated in a settling<br />

basin with longitudinal scraper and the third part stream will be<br />

cleaned with scale separators and gravel filters. This water<br />

than will be cooled with cooling towers. In the cooling tower<br />

basin all part streams will be collected to be pumped to the hot<br />

strip rolling mill.<br />

Cooling water tanks are installed to realize a huge cooling<br />

water flow for a short while for laminar cooling.<br />

Client: <strong>Salzgitter</strong> Flachstahl <strong>GmbH</strong>, <strong>Salzgitter</strong><br />

Project Duration: 2005 – 2007<br />

Contract Amount: approx. 7 Mio. EUR