PROFI CN - Domestica

PROFI CN - Domestica

PROFI CN - Domestica

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE COMPANYBased in Offenburg, Germany, HOBART leads the worldmarket in industrial warewashing technology. We servecustomers such as hotels, restaurants and caterer,bakeries and butcheries as well as supermarkets, airlinesand cruise ships across the world.HOBART develops, produces and sells warewash, cooking,food preparation and waste treatment appliances and systems,and employs around 6,865 staff members across theworld, 903 of them in Germany. HOBART is a subsidiary of theUS Illinois Tool Works (ITW) Group, which manufactures andsells a variety of products; the group has a staff of 65,000employees in 875 autonomous companies in 49 countries.OUR VISIONWASH WITHOUT WATEROur intensive market research has shown unequivocallythat our customers require appliances that are economicaland ecological while still producing first-class results.We have addressed this demand and worked out our vision,Wash Without Water. The resulting areas of focus – innovation,economy, ecology – set the direction. Our vision meansleaving no stone unturned when it comes to reducing water,energy and detergent consumption.Utopian?Everything begins with a vision. Many of the products thatmake everyday life easier today began as the ideas of avisionary; many of these ideas would have seemed utopianat the time. There can be no progress without a vision – andthat applies to warewashing as much as anything else. Beforethe introduction of PREMAX, a dishwasher with a 50 %water saving technology would have been utopia.Today, PREMAX has set new standards, and we by nowknow that whenever the dishwasher that washes withoutwater will come, it‘ll be a PREMAX.FOCUSINNOVATIONInnovation means more than just turning an idea into reality.We at HOBART see innovation as a continuous process.In fact, we‘ve put more than 30 innovative products ontothe market since the PREMAX launch. All these innovationsshare one single goal – to generate real value added forour customers.We have a global network of more than 300 research anddevelopment engineers to make this possible, plusmarketing teams out on every continent to identify customerpreferences and requirements. We have a grouptechnology centre in the US with more than a 1,000 patentapplications a year, together with an innovation centre forwarewashing in Offenburg, Germany.EconomyAlready in the early 1980s our energy-formula set benchmarksin energy saving and recovery which are still uniquetoday. This innovative spirit found its fulfillment in the PREMAXline. The PREMAX flight-type dishwasher saves up to 50 %water, 30 % energy, and 80 % chemicals in comparison toconventional technologies, making HOBART a pioneerin terms of efficiency and economy.ECOLOGYThe HOBART environmental protection programCO 2NSEQUENT has been in existence for some time.The program includes a large number of measures thatare all related to protectingthe environment. Thesemeasures are implementedin production, purchasing,the development and saleof products and in additionalprojects. As an example, youmight like to know that allHOBART products are manufacturedusing regenerativeenergy only.CertificateGreen ElectricityHobart GmbHMichael BöddekerManaging Director, ENTEGAGeschäftskunden GmbH & Co. KGFrank GeyThiscompanyprotectstheclimate.Managing Director, ENTEGAGeschäftskunden GmbH & Co. KGWith certified greenelectricity from ENTEGARobert-Bosch-Str. 17, 77656 Offenburgdecided to obtain green electricity NATURpurfrom ENTEGA Geschäftskunden GmbH & Co. KG.The accordant consumption of electricity in the expected annualquantity of approximately 3.300.000 kWh is generated from renewableenergy. The provided green electricity is generated in identifiablehydro-electric power plants in Germany and wi l be fed in the commonelectric power system.TÜV Rheinland confirms that NATURpur green electricity (hydraulicenergy) is regeneratively produced energy according to the list ofciteria of VdTÜV bu letin 1304 (edition 02/05).In obtaining ENTEGA green electricity NATURpur Hobart GmbHannua ly avoids the development of approximately 1.716 tons of theclimate-damaging gas carbon dioxide (CO 2) and valuably contributesto environmental protection.The contract period for obtaining green electricity is from01.08.2011 bis 31.12.2013Darmstadt, 01.08.2011

WAREWASHINGRack-Type Dishwasher<strong>PROFI</strong> <strong>CN</strong>EFFICIENT – RELIABLE – INNOVATIVE1economyENERGY-MANAGEMENT EFFICIENTA conventional rack-type dishwasher loses 40 % of theenergy available in the machine via the exhaust system. Thedistribution of water and the air stream have a considerableinfluence. The new energy-management EFFICIENT reducesthe evaporation loss. The improved arrangement of thewide angle nozzles FAN and the orientation of the washarms reduce the air flow within the machine. The patentedwide angle nozzle FAN spreads out a 65 % wider and moreeven spray pattern. Therefore the recirculation of watercan be reduced for the same wash result. In order tokeep the system in balance less air/water steam has tobe exhausted. The new energy-management reduces theenergy loss of the rack-type dishwasher by up to 15 %.DETERGENT SAVING SYSTEM LOW-CHEMWith the optional detergent saving system LOW-CHEMdetergent is injected directly into the wash tank, which iscontinuously regenerated by fresh water from the rinse.Therefore detergent is added to maintain the concentrationaccording to the added regeneration volume. The enhancedLOW-CHEM detergent saving system directs only 105 liter offresh rinse water into the wash tank for regeneration. Aheadof the final rinse, detergent is flushed off the wash ware bythe RADIUS pre-rinse nozzle and diverted back into the washtank. The dosing of detergent depends on the regenerationwater volume. As a result detergent consumption is reducedby up to 70 % compared to conventional systems.HOBART HEAT RECOVERYHOBART‘s heat recovery system functions according tothe countercurrent principle, using the energy from theextracted air to heat up the incoming water. The energyexchange takes place in the HOBART high-performancecondenser. At the same time, the extracted air is cooleddown and dehumidified. The HOBART heat recovery systemreduces energy consumption by up to 6.3 kW and totalconnected load to 29.6 kW. 1) The extracted air can be leddirectly into the building‘s ventilation ducting. 2)HOBART HEAT PUMPTHE HOBART heat pump uses the residual energy in theextracted air following heat recovery. A compressor andrefrigerant are used to ensure efficient heat recovery. Theamount of recovered energy is sufficient to heat the washand rinse water. This innovative technology reduces energyconsumption by up to 10 kWh and total connected load to20.0 kW. 3) The temperature of the extracted air is reducedto approx. 20 - 24°C. 4) The extracted air can be blowndirectly into the room. 2)1)Calculation example for the <strong>PROFI</strong> <strong>CN</strong> S-A-DS, C20 compared to models withoutheat recovery2)Conditional on compliance with VDI 20523)Calculation example for the <strong>PROFI</strong> <strong>CN</strong> S-A-DS, CHP compared to models withoutheat pump4)Values in continuous operation +/-10 % depending on incoming air in the roomand inlet temperature of the fresh water (values based on 10°C incoming waterand 23°C ambient air temperature)EFFICIENT – OPTIMALECONOMICAL – EFFICIENTUp to 65 % wider andmore even spray pattern.The HOBART heat pumpuses the residual energyin the extracted air.

WAREWASHINGRack-Type Dishwasher<strong>PROFI</strong> <strong>CN</strong>EFFICIENT – RELIABLE – INNOVATIVE5 PERMANENT CLEAN The PERMANENT clean system automatically activelyPERMANENT CLEANAvailable for models with L- or S-Pre-wash Zones• No soiling spreading around the appliance• Active soiling removal from the zone• Constant high-level wash water quality• Reduction in water, energy, and chemicals consumption• Reduces refilling during operation• Convenient removal of soiling at the end of thedishwashing shiftIn busy kitchens, large amounts of dirt collecting in thepre-wash section of the flight-type dishwasher can normallynot be prevented.This increases wash water soiling and more frequent tankwater changes. Apart from that, this also has detrimentaleffect on waste water and degreasing.removes coarse soiling from the appliance in the pre-washphase using a well-designed and effective filter system.The coarse soiling in this zone is permanently filtered outand pumped into a filter drawer in the appliance to keeppre-wash results clean at all times. Food residues can thenbe conveniently removed from the drawer at the end of thedishwashing shift. This eliminates the time-consuming choreof emptying the filter basket, interrupting operation.PERMANENT clean removes soiling particles from thewashing process before they adversely affect water quality,keeping wash water quality high while reducing detergentreplenishment and eliminating the need to empty the tankduring operation. This gives you further savings in operatingcosts while automatically reducing degreaser andwaste water burden, and protecting the environment.CLEAN – ACTIVELASTING – ECOLOGICALPhase 1:Coarse soiling is removedfrom the washware early,in the pre-wash zone.Phase 3:The process wateravailable washes thecoarse soiling into thefilter drawer in theappliance intake.Phase 2:The coarse soiling washedoff is automatically andcyclically removed from thepre-wash zone.Phase 4:Convenient removal ofthe accumulated soilingresidues at the end of thedishwashing shift.

5technicaL DATARacksConveyorWater consumptionEnergy consumption**RecommendedTotal length(number/h)speed(m/min)(connected load)[kWh; (kW)]model selectionSpeed 1 Speed 2Speed 3 (l/h) (l/rack)*** with heatwith heat(in mm(as perrecoverypumpwithout dryingDINzone)10510)− 90 120 0.67 170 1.425.1(27.8)17.4(21.0)<strong>CN</strong>-A 1,350− 100 150 0.83 170 1.124.6(27.9)16.0(21.2)<strong>CN</strong>-E-A 1,850− 120 180 1.00 180 1.028.1(29.2)18.5(22.5)<strong>CN</strong>-L-A 2,000− 120 180 1.00 180 1.028.1(29.2)18.5(22.5)<strong>CN</strong>-C-A 2,375− 150 220 1.25 180 0.829.6(30.0)20.0(23.2)<strong>CN</strong>-S-A 2,250120 180 250 1.50 180 0.729.6(31.9)20.5(25.1)<strong>CN</strong>-E-S-A 2,750120 180 260 1.50 210 0.837.4(42.4)27.9(32.6)<strong>CN</strong>-L-A-A 2,950120 190 280 1.58 210 0.738.9(43.1)29.4(33.3)<strong>CN</strong>-S-A-A 3,150120 210 320 1.75 220 0.739.4(46.1)29.9(33.3)<strong>CN</strong>-E-S-A-A 3,650* Official fresh water consumption figure under optimised conditions (results may vary by customer)** Energy consumption figures in a fully loaded machine*** Ideal values

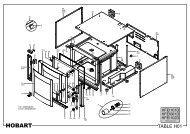

WAREWASHINGRack-Type Dishwasher<strong>PROFI</strong> <strong>CN</strong>EFFICIENT – RELIABLE – INNOVATIVE6MODULE SELECTIONPre-wash zone650Main wash zone195013503001474AR900900CDC182180014742150ARDrying zone900CDC92HEAT RECOVERY/HEAT PUMP377215019611474862150 4402049Loading width:510 mmLoading height:440 mm773

WAREWASHINGRack-Type Dishwasher<strong>PROFI</strong> <strong>CN</strong>EFFICIENT – RELIABLE – INNOVATIVEGOOD – BETTER – <strong>PROFI</strong>Under continuous high capacity conditions in hotels, restaurants, nursing homes,canteens and motorway service areas, warewashing equipment must meet the moststringent requirements in terms of quality and reliability.With its energy management system EFFICIENT and its highly effective heat recoverysystems, HOBART sets new economical standards in rack-type dishwashers, while alsoprotecting the environment by reducing consumption levels.With its perfectly hygienic wash result and practical use features, the <strong>PROFI</strong> <strong>CN</strong> stands forquality – made by HOBART.

warewashing cooking food preparation waste treatment serviceHOBART GMBHRobert-Bosch-Straße 1777656 Offenburg/GERMANYPhone +49(0)781.600-28 20Fax +49(0)781.600-28 19email: info-export@hobart.dewww.hobart-export.comEFFICIENT – RELIABLE – INNOVATIVEMember of the ITW Food Equipment Group EuropePR-0309-0212-654-K-eThe details given in this leaflet are correct as of 02/2012. We reserve the right to technical or design modifications.