5 Series Rotary Combines - Official Site for Gleaner Combines - AGCO

5 Series Rotary Combines - Official Site for Gleaner Combines - AGCO

5 Series Rotary Combines - Official Site for Gleaner Combines - AGCO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

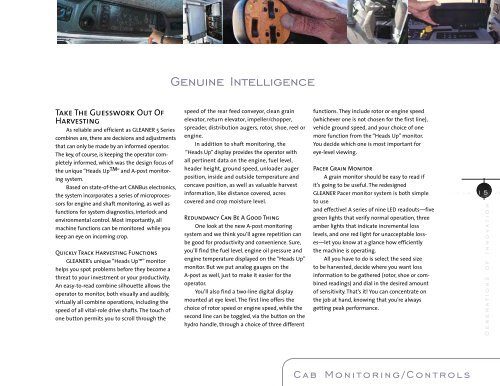

Genuine IntelligenceTake The Guesswork Out OfHarvestingAs reliable and efficient as GLEANER 5 <strong>Series</strong>combines are, there are decisions and adjustmentsthat can only be made by an in<strong>for</strong>med operator.The key, of course, is keeping the operator completelyin<strong>for</strong>med, which was the design focus ofthe unique “Heads Up TM ” and A-post monitoringsystem.Based on state-of-the-art CANBus electronics,the system incorporates a series of microprocessors<strong>for</strong> engine and shaft monitoring, as well asfunctions <strong>for</strong> system diagnostics, interlock andenvironmental control. Most importantly, allmachine functions can be monitored while youkeep an eye on incoming crop.Quickly Track Harvesting FunctionsGLEANER’s unique “Heads Up” monitorhelps you spot problems be<strong>for</strong>e they become athreat to your investment or your productivity.An easy-to-read combine silhouette allows theoperator to monitor, both visually and audibly,virtually all combine operations, including thespeed of all vital-role drive shafts. The touch ofone button permits you to scroll through thespeed of the rear feed conveyor, clean grainelevator, return elevator, impeller/chopper,spreader, distribution augers, rotor, shoe, reel orengine.In addition to shaft monitoring, the“Heads Up” display provides the operator withall pertinent data on the engine, fuel level,header height, ground speed, unloader augerposition, inside and outside temperature andconcave position, as well as valuable harvestin<strong>for</strong>mation, like distance covered, acrescovered and crop moisture level.Redundancy Can Be A Good ThingOne look at the new A-post monitoringsystem and we think you’ll agree repetition canbe good <strong>for</strong> productivity and convenience. Sure,you’ll find the fuel level, engine oil pressure andengine temperature displayed on the “Heads Up”monitor. But we put analog gauges on theA-post as well, just to make it easier <strong>for</strong> theoperator.You’ll also find a two-line digital displaymounted at eye level. The first line offers thechoice of rotor speed or engine speed, while thesecond line can be toggled, via the button on thehydro handle, through a choice of three differentfunctions. They include rotor or engine speed(whichever one is not chosen <strong>for</strong> the first line),vehicle ground speed, and your choice of onemore function from the “Heads Up” monitor.You decide which one is most important <strong>for</strong>eye-level viewing.Pacer Grain MonitorA grain monitor should be easy to read ifit’s going to be useful. The redesignedGLEANER Pacer monitor system is both simpleto useand effective! A series of nine LED readouts—fivegreen lights that verify normal operation, threeamber lights that indicate incremental losslevels, and one red light <strong>for</strong> unacceptable losses—letyou know at a glance how efficientlythe machine is operating.All you have to do is select the seed sizeto be harvested, decide where you want lossin<strong>for</strong>mation to be gathered (rotor, shoe or combinedreadings) and dial in the desired amountof sensitivity. That’s it! You can concentrate onthe job at hand, knowing that you’re alwaysgetting peak per<strong>for</strong>mance.13 14 15 16G e n e r a t i o n s o f I n n o v a t i o nCab Monitoring/Controls