Handling bauxite & alumina - Port Technology International

Handling bauxite & alumina - Port Technology International

Handling bauxite & alumina - Port Technology International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

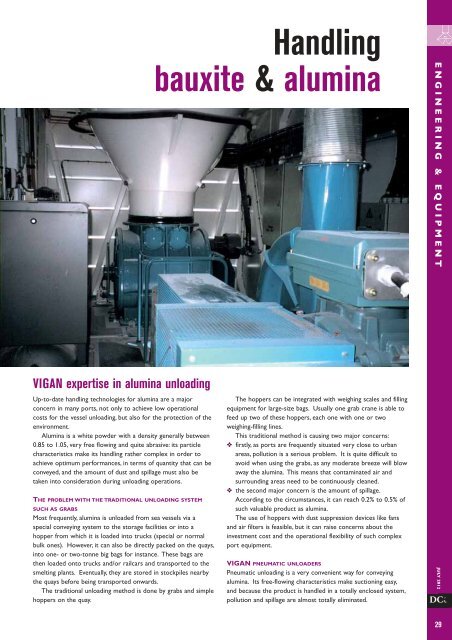

<strong>Handling</strong><strong>bauxite</strong> & <strong>alumina</strong>ENGINEERING & EQUIPMENTVIGAN expertise in <strong>alumina</strong> unloadingUp-to-date handling technologies for <strong>alumina</strong> are a majorconcern in many ports, not only to achieve low operationalcosts for the vessel unloading, but also for the protection of theenvironment.Alumina is a white powder with a density generally between0.85 to 1.05, very free flowing and quite abrasive: its particlecharacteristics make its handling rather complex in order toachieve optimum performances, in terms of quantity that can beconveyed, and the amount of dust and spillage must also betaken into consideration during unloading operations.THE PROBLEM WITH THE TRADITIONAL UNLOADING SYSTEMSUCH AS GRABSMost frequently, <strong>alumina</strong> is unloaded from sea vessels via aspecial conveying system to the storage facilities or into ahopper from which it is loaded into trucks (special or normalbulk ones). However, it can also be directly packed on the quays,into one- or two-tonne big bags for instance. These bags arethen loaded onto trucks and/or railcars and transported to thesmelting plants. Eventually, they are stored in stockpiles nearbythe quays before being transported onwards.The traditional unloading method is done by grabs and simplehoppers on the quay.The hoppers can be integrated with weighing scales and fillingequipment for large-size bags. Usually one grab crane is able tofeed up two of these hoppers, each one with one or twoweighing-filling lines.This traditional method is causing two major concerns:❖ firstly, as ports are frequently situated very close to urbanareas, pollution is a serious problem. It is quite difficult toavoid when using the grabs, as any moderate breeze will blowaway the <strong>alumina</strong>. This means that contaminated air andsurrounding areas need to be continuously cleaned.❖ the second major concern is the amount of spillage.According to the circumstances, it can reach 0.2% to 0.5% ofsuch valuable product as <strong>alumina</strong>.The use of hoppers with dust suppression devices like fansand air filters is feasible, but it can raise concerns about theinvestment cost and the operational flexibility of such complexport equipment.VIGAN PNEUMATIC UNLOADERSPneumatic unloading is a very convenient way for conveying<strong>alumina</strong>. Its free-flowing characteristics make suctioning easy,and because the product is handled in a totally enclosed system,pollution and spillage are almost totally eliminated.JULY 2012DCi29

ENGINEERING & EQUIPMENTAfter the <strong>alumina</strong> is ‘vacuumed’ from the ship hold, it isseparated from the conveying air thanks to a special large-sizeair filter before passing through a special designed valve (seepicture on pxx), down to a chain conveyor which transports the<strong>alumina</strong> to the top of the quay hopper, for instance. The end ofthis conveyor has one or two loading telescopic chute(s) with acover to provide a seal around the<strong>alumina</strong>’s entrance into the hopper(see picture above).When entering into thereceiving hopper, the <strong>alumina</strong> flowsdown gently in such a way that itwill be easily conveyed downwards.This means handling must becontrolled very carefully from thenegative to normal pressure area,in order to be continuouslyconveyed at a determined rate.VIGAN technology achievesthis control thanks to itsengineering and equipment designto precisely monitor the amountof <strong>alumina</strong> in the receiving tankand its flow down to the conveyorthrough a specially designed valve.This technology allows for theelimination of all the maintenancecosts of an airlock for instance,which often suffers significant weardue to the abrasive nature of<strong>alumina</strong>.Special sealing features ensure that no dust will escape out ofthe mechanical conveyor and the dust at transfer points iscontinuously collected thanks to a suction fan with self-cleaningfilter.Moreover, as they are self-propelled on rails or tyres, theunloaders are able to move easily along the ship and noadditional equipment (such ashoppers) must be displaced toensure quick and reliable unloadingoperations and eventual packing(see picture, left). VIGAN is alsoable to design and manufacture theentire bagging system.In all equipment, a frequencyconverter — also called a speedvariator, or an inverter — allows forthe continuous and precise controlof the suction pattern, as well assignificant energy consumptionsavings.With equipment for <strong>alumina</strong>unloading already commissioned inseveral countries such as Finland,France, Poland, China and Iran,VIGAN has gained a large amountof experience regarding this rawmaterial handling in bulk. This costeffectivetechnology for <strong>alumina</strong>unloading is a most promisingalternative for many ports and the<strong>alumina</strong> processing industry.JULY 2012DCi31