Wind influence on container handling, equipment and stacking - Port ...

Wind influence on container handling, equipment and stacking - Port ...

Wind influence on container handling, equipment and stacking - Port ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

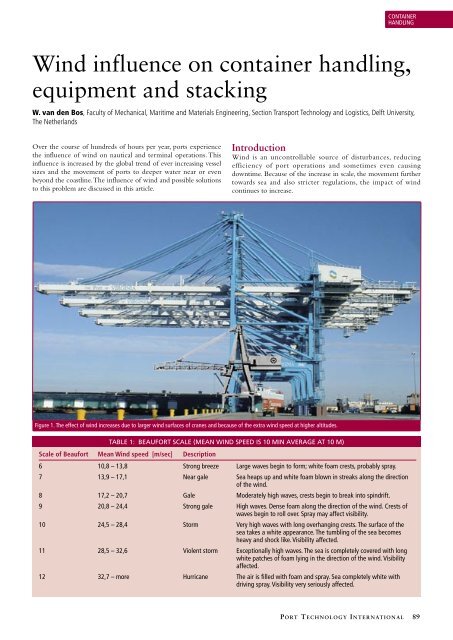

CONTAINERHANDLING<str<strong>on</strong>g>Wind</str<strong>on</strong>g> <str<strong>on</strong>g>influence</str<strong>on</strong>g> <strong>on</strong> c<strong>on</strong>tainer <strong>h<strong>and</strong>ling</strong>,<strong>equipment</strong> <strong>and</strong> <strong>stacking</strong>W. van den Bos, Faculty of Mechanical, Maritime <strong>and</strong> Materials Engineering, Secti<strong>on</strong> Transport Technology <strong>and</strong> Logistics, Delft University,The Netherl<strong>and</strong>sOver the course of hundreds of hours per year, ports experiencethe <str<strong>on</strong>g>influence</str<strong>on</strong>g> of wind <strong>on</strong> nautical <strong>and</strong> terminal operati<strong>on</strong>s. This<str<strong>on</strong>g>influence</str<strong>on</strong>g> is increased by the global trend of ever increasing vesselsizes <strong>and</strong> the movement of ports to deeper water near or evenbey<strong>on</strong>d the coastline. The <str<strong>on</strong>g>influence</str<strong>on</strong>g> of wind <strong>and</strong> possible soluti<strong>on</strong>sto this problem are discussed in this article.Introducti<strong>on</strong><str<strong>on</strong>g>Wind</str<strong>on</strong>g> is an unc<strong>on</strong>trollable source of disturbances, reducingefficiency of port operati<strong>on</strong>s <strong>and</strong> sometimes even causingdowntime. Because of the increase in scale, the movement furthertowards sea <strong>and</strong> also stricter regulati<strong>on</strong>s, the impact of windc<strong>on</strong>tinues to increase.Figure 1. The effect of wind increases due to larger wind surfaces of cranes <strong>and</strong> because of the extra wind speed at higher altitudes.TABLE 1: BEAUFORT SCALE (MEAN WIND SPEED IS 10 MIN AVERAGE AT 10 M)Scale of Beaufort Mean <str<strong>on</strong>g>Wind</str<strong>on</strong>g> speed [m/sec] Descripti<strong>on</strong>6 10,8 – 13,8 Str<strong>on</strong>g breeze Large waves begin to form; white foam crests, probably spray.7 13,9 – 17,1 Near gale Sea heaps up <strong>and</strong> white foam blown in streaks al<strong>on</strong>g the directi<strong>on</strong>of the wind.8 17,2 – 20,7 Gale Moderately high waves, crests begin to break into spindrift.9 20,8 – 24,4 Str<strong>on</strong>g gale High waves. Dense foam al<strong>on</strong>g the directi<strong>on</strong> of the wind. Crests ofwaves begin to roll over. Spray may affect visibility.10 24,5 – 28,4 Storm Very high waves with l<strong>on</strong>g overhanging crests. The surface of thesea takes a white appearance. The tumbling of the sea becomesheavy <strong>and</strong> shock like. Visibility affected.11 28,5 – 32,6 Violent storm Excepti<strong>on</strong>ally high waves. The sea is completely covered with l<strong>on</strong>gwhite patches of foam lying in the directi<strong>on</strong> of the wind. Visibilityaffected.12 32,7 – more Hurricane The air is filled with foam <strong>and</strong> spray. Sea completely white withdriving spray. Visibility very seriously affected.P O RT TECHNOLOGY INTERNAT I O N A L 89

CONTAINERHANDLINGTABLE 2. RELATION BETWEEN AVERAGE WIND SPEED OVER VARIOUS PERIODS AND MEAN SPEED (SOURCE EN 13001)Gust factorPeriod [s] 1 3 5 10 30 60 120 600(1 min) (2 min) (10 min)V(t)/Vmean [.] 1.6 1.5 1.5 1.4 1.3 1.2 1.1 1Figure 2. <str<strong>on</strong>g>Wind</str<strong>on</strong>g> map of Europe (EN 13001). Figure 3. <str<strong>on</strong>g>Wind</str<strong>on</strong>g> pressure based <strong>on</strong> gust winds (EN 13001).<str<strong>on</strong>g>Wind</str<strong>on</strong>g> characteristics<str<strong>on</strong>g>Wind</str<strong>on</strong>g> can be characterised by speed <strong>and</strong> directi<strong>on</strong>. Unfortunatelyin the working envir<strong>on</strong>ment of ports there is c<strong>on</strong>fusi<strong>on</strong> aboutBeaufort scale (Table 1) <strong>and</strong> wind speed. The wind speed ofthe Beaufort scale is ‘the average wind speed taken over theten minutes preceding the time of observati<strong>on</strong> at 10 m’(J. Weringa en P.J. Rijkoort <str<strong>on</strong>g>Wind</str<strong>on</strong>g>klimaat van Nederl<strong>and</strong>, KNMI)or mean wind. Sometimes however, a wind regime at Beaufort6 is wr<strong>on</strong>gly interpreted as gusts of wind with speeds varyingbetween 10.8 <strong>and</strong> 13.8 m/s.By definiti<strong>on</strong> of the European st<strong>and</strong>ard for Crane design(European st<strong>and</strong>ard EN13001 Cranes – general design) thegust wind is the average three-sec<strong>on</strong>d wind. Table 2 shows therelati<strong>on</strong> between the maximum wind speed <strong>and</strong> the measuretime interval. The table shows that wind speed increases withdecreasing interval time. The maximum gust wind at Beaufort 6is therefore not 13.8 but 13.8*1.5=20.7 m/s!Increase of wind velocityTo h<strong>and</strong>le vessels with deep draught the internati<strong>on</strong>al trend is toc<strong>on</strong>struct new ports closer to the sea, while older docks near citycentres become less important or are even closed. The differencein wind speed between the coast <strong>and</strong> the open sea is indicated bythe Royal Meteorological Institute of the Netherl<strong>and</strong>s (KNMI) as:“under equal circumstances ... it is c<strong>on</strong>cluded that potential wind<strong>on</strong> sea is 12% str<strong>on</strong>ger than <strong>on</strong> open terrain <strong>on</strong> shore <strong>on</strong>ly becauseof the difference in roughness. However, most experiments reveala difference of 20% or more mainly because the shore terrain isnot open but rugged.”This is also c<strong>on</strong>firmed by our own research where we foundthat 30 km off-shore the mean wind speed is up to two m/shigher than <strong>on</strong> shore, while for wind gusts, the difference canbe even four m/s. If we assume that moving five km towards sea(from Maasvlakte I to Maasvlakte II) increases mean wind speedwith <strong>on</strong>e m/s, the amount of hours with troubling winds <strong>and</strong> lossof productivity <strong>on</strong> a c<strong>on</strong>tainer terminal due to wind will double.Figure 4a) <str<strong>on</strong>g>Wind</str<strong>on</strong>g> load of crane in operati<strong>on</strong>, b) Unfavorable wind directi<strong>on</strong>s.90 P O RT TECHNOLOGY INTERNAT I O N A L www.porttechnology.org

CONTAINERHANDLINGFigure 5b. Dynamic c<strong>on</strong>tainer displacement due to wind load for both c<strong>on</strong>figurati<strong>on</strong>s.augmented because of the extra wind speed at higher altitudes.Besides the affects <strong>on</strong> vessels <strong>and</strong> cranes, high investments inquay strength are also needed, in order to support the highcorner pressures of a 110 m high stowed crane, which is exposedto storm winds (Figure 1).Figure 5a. Computer simulati<strong>on</strong> model for machine trolley vs rope trolleyc<strong>on</strong>figurati<strong>on</strong>.Increase of wind pressureThe increase in world sea trade causes an increase in port<strong>equipment</strong> <strong>and</strong> vessel size. For example, the 9500 TEU c<strong>on</strong>tainervessel commissi<strong>on</strong>ed in 2005 is almost ten times the capacity ofthe first generati<strong>on</strong> c<strong>on</strong>tainer vessels of 1962. This also affectsthe size of the cranes. The effect of wind increases due tolarger wind surfaces of cranes <strong>and</strong> vessels, but the effect is alsoStrict regulati<strong>on</strong>sOver the years society has become stricter in terms ofaccepted polluti<strong>on</strong> <strong>and</strong> hazard level. An example of thisincreased attenti<strong>on</strong> is the stricter interpretati<strong>on</strong> of windpressure due to wind gusts in the new European crane designst<strong>and</strong>ard EN13001. <str<strong>on</strong>g>Wind</str<strong>on</strong>g> pressure <strong>on</strong> cranes is now explicitlydependent <strong>on</strong> wind gusts, while previously in Nati<strong>on</strong>alSt<strong>and</strong>ards (Din 15019 teil 1 Krane, St<strong>and</strong>sicherheit; NEN2018 Hijskranen) <strong>on</strong>ly the wind categories ‘light, normal,<strong>and</strong> heavy’ were defined. Furthermore, terrain roughnessfactors account for higher coastal winds, while wind loadsno l<strong>on</strong>ger depend <strong>on</strong> countries, but rather <strong>on</strong> a wind mapwhere Europe is divided into wind regi<strong>on</strong>s (A to F) based <strong>on</strong>measured data (Figure 2).Figure 6. Trailer stability depending <strong>on</strong> gust wind velocity <strong>and</strong> trailer speed while turning.Figure 7. Straddle carrier stability.92 P O RT TECHNOLOGY INTERNAT I O N A L www.porttechnology.org

CONTAINERHANDLINGFigure 8. Risk of empty c<strong>on</strong>tainer sliding or tilting.Effects of wind<strong>Port</strong> proceduresIn general, internati<strong>on</strong>al st<strong>and</strong>ards <strong>and</strong> port or terminal authoritiesboth assume that ports are operati<strong>on</strong>al up to 6-8 Beaufort. Atterminals in the port of Rotterdam, operati<strong>on</strong>s are suspended atBeaufort 8 or when gust wind speed exceeds 25 m/s. From figure3, it can be deduced that a gust wind speed of 25 m/s signifiesa mean wind speed of 25/1.5= 17 m/s, which means that portoperati<strong>on</strong>s in practice stop at the end of Beaufort 7.Vessel mooringFor ship-shore loading <strong>and</strong> unloading, the movements of thevessel due to wind load need to be limited. We researched thedynamic resp<strong>on</strong>se of a moored Ultra Large C<strong>on</strong>tainer Vessel(ULCV) which carries 12.500 TEU <strong>on</strong> a typical wind spectrumat Beaufort scales 6 <strong>and</strong> 7. We found out that the maximummovements of the cell guides are acceptable for positi<strong>on</strong>ingc<strong>on</strong>tainers in the cell guides, but the maximum calculated forceof 150 kN in the mooring lines requires special lines <strong>and</strong> wharfbollards. For wind at Beaufort 8 or higher, storm bollards for thesevessel types are highly recommended.Crane operati<strong>on</strong>Beside vessel movement, wind also causes problems withcrane operati<strong>on</strong>s. <str<strong>on</strong>g>Wind</str<strong>on</strong>g> causes undesirable movements (mainlysway <strong>and</strong> skew) of the c<strong>on</strong>tainer in the crane (Figure 4a <strong>and</strong>b). The crane driver can correct disturbances in sway, but aneffective way to c<strong>on</strong>trol skew does not yet exist. Heavy sway isgenerated by head <strong>on</strong> winds, but the crane driver can correctthese movements. Skew is mainly generated by diag<strong>on</strong>al winds.If diag<strong>on</strong>al winds can be avoided, producti<strong>on</strong> loss due tounc<strong>on</strong>trollable skew can be reduced.The vulnerability of the c<strong>on</strong>tainer in the crane to both skew<strong>and</strong> sway depend <strong>on</strong> the type of trolley. Because a (semi) ropetrolley has a V-shape cable c<strong>on</strong>figurati<strong>on</strong> the stiffness of thec<strong>on</strong>figurati<strong>on</strong> in sway directi<strong>on</strong> is higher than with machinetrolley with vertical inner ropes. A computer simulati<strong>on</strong> of themovements of the c<strong>on</strong>tainer exposed to wind for both trolleytypes show a 40% decrease in sway for the (semi) rope trolley(Figure 5a <strong>and</strong> b).Terminal <strong>equipment</strong>Because of the relative high frame height (1.1 m) <strong>and</strong> theunlashed c<strong>on</strong>tainer load, the MTS-trailer is used to calculate themaximum wind for safe (c<strong>on</strong>tainer) transport <strong>on</strong> the terminal.Side wind reduces total trailer stability <strong>and</strong> can cause tilt of the(empty) c<strong>on</strong>tainer. The c<strong>on</strong>tainer/trailer combinati<strong>on</strong> stabilitywhile turning is sufficient during low gust winds, but at highspeed <strong>and</strong> with gust winds above 22 m/s, an empty c<strong>on</strong>tainer cantilt from the trailer frame. It is therefore recommended to drive atlower speeds during high winds (Figure 6).Another vulnerable c<strong>on</strong>tainer transportati<strong>on</strong> vehicle to wind isthe straddle carrier. Because of the high positi<strong>on</strong> of the c<strong>on</strong>tainerduring transport, these vehicles have limited maximum speed. Thestability of a straddle carrier loaded with a 45 ft empty c<strong>on</strong>tainer,as well as a straddle carrier with a maximum loaded (30 t<strong>on</strong>nes)45ft c<strong>on</strong>tainer, decreases during higher gust winds. As with MTStrailersit is recommended to lower driving speed during highgust winds (Figure 7).Empty c<strong>on</strong>tainer <strong>stacking</strong>For storage, empty c<strong>on</strong>tainers at the terminal area are stacked upto 10 high. The risk of a single c<strong>on</strong>tainer sliding, or the tiltingof a whole row of c<strong>on</strong>tainers, is calculated with wind pressureaccording to the Dutch TGB st<strong>and</strong>ard (Nen 6720). Depending <strong>on</strong>the <strong>stacking</strong> height, the risk of the total row tilting increases. Inrespect to a c<strong>on</strong>tainer sliding, a fricti<strong>on</strong> coefficient of 0.1 is taken(the lowest steel-steel c<strong>on</strong>tact fricti<strong>on</strong>). The sliding <strong>and</strong> tilting riskis calculated for several different c<strong>on</strong>tainer types, but for safetyreas<strong>on</strong>s, the wind speed at which the first c<strong>on</strong>tainer type startsto slide or tilt is plotted. The calculati<strong>on</strong>s clearly show that tilting<strong>and</strong> sliding can occur at low wind speeds near or around 10 m/s(Figure 8). Lashing down stacked empty c<strong>on</strong>tainers <strong>and</strong> reshufflingempty c<strong>on</strong>tainers in normal stack to lower positi<strong>on</strong>s is thereforenecessary at Beaufort 5 or even at lower wind regimes!Reducti<strong>on</strong> of wind <str<strong>on</strong>g>influence</str<strong>on</strong>g>Reducti<strong>on</strong> of windThe wind regime <strong>on</strong> a wind sensible terminal locati<strong>on</strong> can belowered by raising the ‘climatological’ roughness. The terminalshould be planned in the shadow of other industrial installati<strong>on</strong>sor buildings, <strong>and</strong> quay <strong>and</strong> cranes should be properly orientedto reduce the <str<strong>on</strong>g>influence</str<strong>on</strong>g> of the dominant wind directi<strong>on</strong>. As analternative, <strong>on</strong>e can also use a lashed empty c<strong>on</strong>tainer stack as aroughness increasing obstacle.94 P O RT TECHNOLOGY INTERNAT I O N A L www.porttechnology.org

CONTAINERHANDLINGFigure 9. Carrier Crane c<strong>on</strong>cept, TU Delft.<str<strong>on</strong>g>Wind</str<strong>on</strong>g> <strong>on</strong> vesselsTo avoid the breakage of mooring lines or wharf bollards at Beaufort8 or higher, severe storms bollards must be installed <strong>on</strong> the wharf.C<strong>on</strong>tainer ship-to-shore cranesThe effect of severe wind <strong>on</strong> ship-to-shore operati<strong>on</strong>s can belimited by using a rope trolley instead of a machine trolley. Anotherway of reducing wind <str<strong>on</strong>g>influence</str<strong>on</strong>g> <strong>on</strong> the load <strong>and</strong> unloading processis to change the crane cycle under stormy c<strong>on</strong>diti<strong>on</strong>s. With‘rectangular hoisting,’ combined horiz<strong>on</strong>tal <strong>and</strong> vertical movementsare avoided, which reduce sway <strong>and</strong> skew significantly, but theloading <strong>and</strong> unloading process becomes slower. Another possibilityis a new crane c<strong>on</strong>cept, the Carrier Crane, where a c<strong>on</strong>tainer ishoisted from the ship by a trolley, transported over the main cranebeam with a carrier <strong>and</strong> again, <strong>on</strong> l<strong>and</strong>, unloaded with a trolley. Thisdivisi<strong>on</strong> of the crane cycle significantly increases crane performancebecause the cycle time of each process is a lot shorter than that ofan original total load or unload cycle (Figure 9).Terminal <strong>equipment</strong>If terminal operati<strong>on</strong>s have to c<strong>on</strong>tinue at Beaufort 8, terminalmovements have to be performed by <strong>equipment</strong> other thanstraddle carriers. In order to use MTS-trailers or similartransportati<strong>on</strong> <strong>equipment</strong> at stormy c<strong>on</strong>diti<strong>on</strong>s, c<strong>on</strong>tainers needto be fixed <strong>on</strong> the frame.C<strong>on</strong>clusi<strong>on</strong><str<strong>on</strong>g>Wind</str<strong>on</strong>g> causes producti<strong>on</strong> loss, <strong>and</strong> heavy winds even causedowntime at the terminal. <strong>Port</strong> expansi<strong>on</strong>s move in the directi<strong>on</strong>of the sea, <strong>and</strong> in this perspective, more wind <strong>and</strong> additi<strong>on</strong>alwind problems for terminals can be expected. Therefore, wind<str<strong>on</strong>g>influence</str<strong>on</strong>g>s should receive proper attenti<strong>on</strong> as a design aspect fornew terminals <strong>and</strong> port expansi<strong>on</strong> programmes.<str<strong>on</strong>g>Wind</str<strong>on</strong>g> speed can be reduced by using obstacles which increasethe climatological roughness of the area. If no installati<strong>on</strong> ornatural barrier is available, an empty c<strong>on</strong>tainer stack can be usedas an obstacle.The effects of wind can also be reduced by proper orientati<strong>on</strong>of the quay to the dominant wind directi<strong>on</strong>, <strong>and</strong> use of a ropetrolley combined with the ‘rectangular hoisting’ procedurefor ship-to-shore movements. Use of new crane types, such asthe Carrier Crane, can improve producti<strong>on</strong> as well as reducevulnerability to wind.Empty c<strong>on</strong>tainers are sensitive to wind, <strong>and</strong> lashing of c<strong>on</strong>tainerstacks <strong>and</strong> reshuffling of empty c<strong>on</strong>tainers in normal stacks isnecessary even at Beaufort 5. During stormy c<strong>on</strong>diti<strong>on</strong>s, it isadvised to lock c<strong>on</strong>tainers to the transporting vehicle frame <strong>and</strong>to avoid the use of straddle carriers.ABOUT THE AUTHOR AND THE COMPANYWouter van den Bos graduated in 1998 from principles <strong>and</strong> applied engineering to design industrialDelft University in Mechanical Engineering (MSc). systems <strong>and</strong> <strong>equipment</strong> for the <strong>h<strong>and</strong>ling</strong> <strong>and</strong> transportHe is employed at the secti<strong>on</strong> Transport Technology of unit loads <strong>and</strong> bulk materials. In additi<strong>on</strong> to the<strong>and</strong> Logistic at the same university. He has carried <strong>equipment</strong> itself, aspects such as energy c<strong>on</strong>sumpti<strong>on</strong>,out various research programmes with a focus <strong>on</strong> the exchange of informati<strong>on</strong> <strong>and</strong> automati<strong>on</strong> are giventransport, cranes <strong>and</strong> load <str<strong>on</strong>g>influence</str<strong>on</strong>g>s <strong>on</strong> mechanical due c<strong>on</strong>siderati<strong>on</strong>. The functi<strong>on</strong>s to be fulfilled by thedesigns.<strong>equipment</strong> are defined <strong>on</strong> the basis of an inventory ofrequirements. The research activities are carried outThe field of ‘Transport Engineering <strong>and</strong> Logistics’ at in close cooperati<strong>on</strong> with the Netherl<strong>and</strong>s ResearchDelft University encompasses the c<strong>on</strong>trolled <strong>h<strong>and</strong>ling</strong> School for Transport, Infrastructure <strong>and</strong> Logistics,<strong>and</strong> transportati<strong>on</strong> of unit loads <strong>and</strong> bulk materials. (TRAIL), <strong>and</strong> with industrial partners, especially thoseThe research <strong>and</strong> teaching involve the use of basic located in the Rotterdam area of the Netherl<strong>and</strong>s.ENQUIRIESWouter van den BosFaculty of Mechanical, Maritime <strong>and</strong> MaterialsEngineeringSecti<strong>on</strong> Transport Technology <strong>and</strong> LogisticsMekelweg 22628 CD DelftThe Netherl<strong>and</strong>sE-mail: w.v<strong>and</strong>enbos@wbmt.tudelft.nlP O RT TECHNOLOGY INTERNAT I O N A L 95