Technology Today issue 1 2008 - Raytheon

Technology Today issue 1 2008 - Raytheon

Technology Today issue 1 2008 - Raytheon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Special Interest<br />

Continued from page 35<br />

There are three levels of PHM concurrently<br />

being developed by <strong>Raytheon</strong>:<br />

Embedded prognostic technologies<br />

Secure net-centric data communication<br />

and storage<br />

Health management data processing and<br />

control<br />

War Planner<br />

Health Mgmt.<br />

Center<br />

5<br />

Low Priority<br />

Equipment<br />

Orders Placed<br />

MISSION READINESS/SUCCESS DATA<br />

3<br />

Mission Success<br />

Report<br />

FIELD EQUIPMENT ORDERS<br />

Logistics<br />

36 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

4<br />

FIELD DATA ANALYSIS<br />

Equipment<br />

Remaining Useful<br />

Life (RUL) Report<br />

The Joint Strike Fighter program office defined<br />

health management concepts as follows:<br />

Classified<br />

Network<br />

2<br />

Pre-cursor to<br />

Failure Data<br />

Reported<br />

MISSION<br />

ASSURED<br />

EQUIPMENT DELIVERY<br />

6<br />

Equipment Delivered<br />

Before Next Mission<br />

Diagnostics: the process of determining<br />

the state of a component to perform its<br />

function(s)<br />

Prognostics: the predictive diagnostics,<br />

which include determining the remaining<br />

life or time span of proper operation of a<br />

component<br />

ENCRYPTED FIELD REPORTS<br />

Future<br />

Prognostics<br />

Scenario<br />

Field<br />

Support<br />

1<br />

Equipment<br />

Pre-cursor to Failure<br />

Data Detailed<br />

Fielded<br />

Equipment<br />

7<br />

Equipment<br />

Repaired<br />

Before Mission<br />

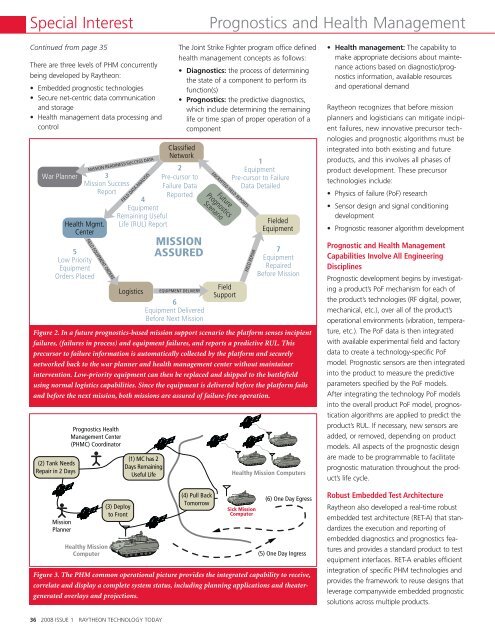

Figure 2. In a future prognostics-based mission support scenario the platform senses incipient<br />

failures, (failures in process) and equipment failures, and reports a predictive RUL. This<br />

precursor to failure information is automatically collected by the platform and securely<br />

networked back to the war planner and health management center without maintainer<br />

intervention. Low-priority equipment can then be replaced and shipped to the battlefield<br />

using normal logistics capabilities. Since the equipment is delivered before the platform fails<br />

and before the next mission, both missions are assured of failure-free operation.<br />

(2) Tank Needs<br />

Repair in 2 Days<br />

Mission<br />

Planner<br />

Prognostics Health<br />

Management Center<br />

(PHMC) Coordinator<br />

Healthy Mission<br />

Computer<br />

(3) Deploy<br />

to Front<br />

(1) MC has 2<br />

Days Remaining<br />

Useful Life<br />

(4) Pull Back<br />

Tomorrow<br />

FIELD REPAIR<br />

Healthy Mission Computers<br />

Sick Mission<br />

Computer<br />

(6) One Day Egress<br />

(5) One Day Ingress<br />

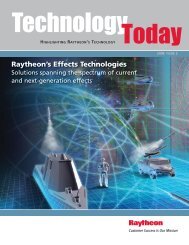

Figure 3. The PHM common operational picture provides the integrated capability to receive,<br />

correlate and display a complete system status, including planning applications and theatergenerated<br />

overlays and projections.<br />

Prognostics and Health Management<br />

Health management: The capability to<br />

make appropriate decisions about maintenance<br />

actions based on diagnostic/prognostics<br />

information, available resources<br />

and operational demand<br />

<strong>Raytheon</strong> recognizes that before mission<br />

planners and logisticians can mitigate incipient<br />

failures, new innovative precursor technologies<br />

and prognostic algorithms must be<br />

integrated into both existing and future<br />

products, and this involves all phases of<br />

product development. These precursor<br />

technologies include:<br />

Physics of failure (PoF) research<br />

Sensor design and signal conditioning<br />

development<br />

Prognostic reasoner algorithm development<br />

Prognostic and Health Management<br />

Capabilities Involve All Engineering<br />

Disciplines<br />

Prognostic development begins by investigating<br />

a product’s PoF mechanism for each of<br />

the product’s technologies (RF digital, power,<br />

mechanical, etc.), over all of the product’s<br />

operational environments (vibration, temperature,<br />

etc.). The PoF data is then integrated<br />

with available experimental field and factory<br />

data to create a technology-specific PoF<br />

model. Prognostic sensors are then integrated<br />

into the product to measure the predictive<br />

parameters specified by the PoF models.<br />

After integrating the technology PoF models<br />

into the overall product PoF model, prognostication<br />

algorithms are applied to predict the<br />

product’s RUL. If necessary, new sensors are<br />

added, or removed, depending on product<br />

models. All aspects of the prognostic design<br />

are made to be programmable to facilitate<br />

prognostic maturation throughout the product’s<br />

life cycle.<br />

Robust Embedded Test Architecture<br />

<strong>Raytheon</strong> also developed a real-time robust<br />

embedded test architecture (RET-A) that standardizes<br />

the execution and reporting of<br />

embedded diagnostics and prognostics features<br />

and provides a standard product to test<br />

equipment interfaces. RET-A enables efficient<br />

integration of specific PHM technologies and<br />

provides the framework to reuse designs that<br />

leverage companywide embedded prognostic<br />

solutions across multiple products.