Technology Today issue 1 2008 - Raytheon

Technology Today issue 1 2008 - Raytheon

Technology Today issue 1 2008 - Raytheon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

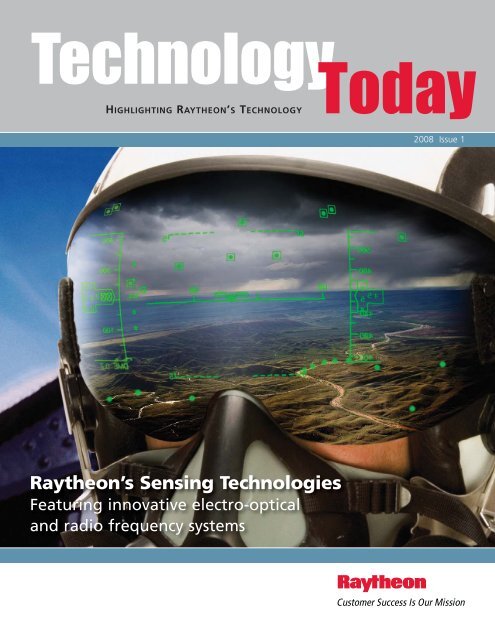

<strong>Technology</strong><br />

<strong>Today</strong><br />

HIGHLIGHTING RAYTHEON’S TECHNOLOGY<br />

<strong>Raytheon</strong>’s Sensing Technologies<br />

Featuring innovative electro-optical<br />

and radio frequency systems<br />

<strong>2008</strong> Issue 1

A Message From Dr. Taylor W. Lawrence<br />

Do you have an idea for an article?<br />

We are always looking for ways to connect<br />

with you — our Engineering, <strong>Technology</strong> and<br />

Mission Assurance professionals. If you have an<br />

article or an idea for an article regarding<br />

technical achievements, customer solutions,<br />

relationships, Mission Assurance, etc., send it<br />

along. If your topic aligns with a future <strong>issue</strong> of<br />

<strong>Technology</strong> <strong>Today</strong> or is appropriate for an online<br />

article, we will be happy to consider it and will<br />

contact you for more information.<br />

Send your article ideas to<br />

techtodayeditor@raytheon.com.<br />

2 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Vice President of Engineering, <strong>Technology</strong> and Mission Assurance<br />

Sensing is the first of <strong>Raytheon</strong>’s core markets, which is appropriate because sensing<br />

is where it all starts. Before our customers can react, shape or control their environments,<br />

they need to understand them.<br />

This is a wide market for <strong>Raytheon</strong>, both in terms of the customers we serve and<br />

the range of technologies we deploy. <strong>Raytheon</strong> sensors acquire precise situational<br />

data in the domains of air, space and water, and they span the full electromagnetic<br />

spectrum, from radio waves to gamma waves, and include many different modalities,<br />

from hyperspectral to acoustic sampling.<br />

This <strong>issue</strong> of <strong>Technology</strong> <strong>Today</strong> explores some of <strong>Raytheon</strong>’s newest capabilities in<br />

the Sensing market — from advances in high-definition infrared focal plane arrays<br />

and ladar sensors, to new applications for small, low-power RF radars. These<br />

advances in turn are providing users like pilots, warfighters and meteorologists<br />

improved speed, resolution and range to more quickly act on the information<br />

they receive.<br />

In this <strong>issue</strong>’s Leaders Corner column, we hear from Greg Alston, <strong>Raytheon</strong>’s vice<br />

president of Mission Assurance. Greg has really hit the ground running since joining<br />

us in June, and he discusses how he is developing an integrated enterprise<br />

Mission Assurance vision and strategy to drive organizational assurance and health.<br />

Lastly, I would like to congratulate our newest Excellence in Engineering and<br />

<strong>Technology</strong> Award recipients. Eighty-six outstanding <strong>Raytheon</strong> engineers and<br />

technologists were recognized in March with the company’s highest technical<br />

honor. They have achieved technological breakthroughs and demonstrated program<br />

excellence that contributed to the success of our customers and our company. The<br />

new standard of excellence they have set serves as an inspiration to us all.<br />

Until next time …<br />

Dr. Taylor W. Lawrence

View <strong>Technology</strong> <strong>Today</strong> online at:<br />

www.raytheon.com/technology_today/current<br />

<strong>Technology</strong> <strong>Today</strong> is published<br />

quarterly by the Office of Engineering,<br />

<strong>Technology</strong> and Mission Assurance.<br />

Vice President<br />

Dr. Taylor W. Lawrence<br />

Managing Editor<br />

Lee Ann Sousa<br />

Senior Editors<br />

Donna Acott<br />

Tom Georgon<br />

Kevin J. Wynn<br />

Art Director<br />

Debra Graham<br />

Photography<br />

Rob Carlson<br />

Bob Casper<br />

Dan Plumpton<br />

Bill Patterson III<br />

Website Design<br />

Joe Walch IV<br />

Publication Coordinator<br />

Dolores Priest<br />

Contributors<br />

Roopa Bhide<br />

Sue Booth<br />

Stephen Diehl<br />

Blythe Marshall<br />

Mike Nason<br />

Marcilene Pribonic<br />

Sean Price<br />

Sharon Stein<br />

Rick Steiner<br />

INSIDE THIS ISSUE<br />

Feature: <strong>Raytheon</strong>’s Sensing Technologies<br />

Electro-optical Sensors Overview 4<br />

High-Definition Infrared Focal Plane Arrays 5<br />

Next-Generation Lasers for Advanced Active EO Systems<br />

Advanced Radar Functionality at Optical Wavelengths<br />

9<br />

via Coherent Ladar 13<br />

Radio Frequency Sensors Overview<br />

Active Panel Array <strong>Technology</strong> Enables Affordable<br />

16<br />

Weather Radar 17<br />

Adaptive Land Enhanced <strong>Raytheon</strong> Radar <strong>Technology</strong> 20<br />

Leaders Corner: Q&A With Greg Alston<br />

Eye on <strong>Technology</strong><br />

21<br />

Architecture & Systems Integration 24<br />

<strong>Raytheon</strong> <strong>Technology</strong> Networks Overview 25<br />

RF Systems 26<br />

Materials & Structures 28<br />

Processing Systems<br />

Events<br />

30<br />

SEtdp Graduates 57 Systems Engineers 31<br />

2007 Excellence in Engineering and <strong>Technology</strong> Awards<br />

Special Interest<br />

<strong>Raytheon</strong> Engineers Help MathMovesU Students Design<br />

32<br />

Rescue Device<br />

Prognostics and Health Management: Enhancing Mission<br />

34<br />

Assurance as Part of System Development 35<br />

U.S. and International Patents 38<br />

EDITOR’S NOTE<br />

It’s a new year with new challenges; but one thing is constant: our commitment to<br />

delivering world-class solutions using the most innovative technologies we can bring to<br />

bear on not just meeting, but exceeding, our customer’s expectations.<br />

This year’s first two <strong>issue</strong>s will focus on two of our core technology markets, starting<br />

with sensing — from both an electro-optical and RF perspective. You’ll read about<br />

emerging high-definition focal plane array technology and its application in space<br />

surveillance systems, as well as the ALERRT portable perimeter security system now<br />

being field-tested by the U.S. Air Force.<br />

Also in this <strong>issue</strong>, you’ll learn more about our Excellence in Engineering and <strong>Technology</strong><br />

Award winners, and get an early look at <strong>Raytheon</strong>’s efforts to develop a prognostics and<br />

health management system to ensure that our delivered systems continue operating in<br />

the field to ensure mission success.<br />

Enjoy!<br />

Lee Ann Sousa<br />

RAYTHEON TECHNOLOGY TODAY <strong>2008</strong> ISSUE 1 3

Feature<br />

Electro-optical Sensors<br />

Expanding the Frontiers of<br />

Military Sensing <strong>Technology</strong><br />

Humans have always used technology to enhance their<br />

natural abilities to sense and transform the world around<br />

them. Recent technological advances have extended<br />

humans’ color vision to include other forms of electromagnetic<br />

energy (radio frequency, infrared and ultraviolet) with higher spectral<br />

resolution (multi- and hyper-spectral imaging). Active sensors —<br />

radar and ladar (laser radar) — allow us to measure distance with<br />

incredible accuracy and generate 3-D images that circumvent the<br />

diffraction limit. New sensing capabilities are on the horizon that<br />

will add a new temporal dimension to this sensing arsenal (micro-<br />

Doppler vibrometry). This <strong>issue</strong>’s electro-optical (EO) feature articles<br />

describe <strong>Raytheon</strong>’s recent advances in sensing technology for a<br />

variety of military, national and civil applications.<br />

For some, the term “night vision” conjures up images of a CNN<br />

broadcast from Baghdad, with its eerie green out-of-focus shots of<br />

anti-aircraft artillery firing blindly against a backdrop of towering<br />

minarets and onion-shaped palace domes. For others, “thermal<br />

imaging” reminds them of blurry pseudo-color thermographic<br />

maps of a house in a TV infomercial, selling them on the need for<br />

high-efficiency window glazing and insulation. Few, however,<br />

would associate either “thermal imaging” or “night vision” with<br />

the sharpness and format of a modern high-definition TV<br />

picture. Yet this is the reality of modern infrared technology<br />

described in our first feature article on the advances in infrared<br />

focal plane arrays from <strong>Raytheon</strong> Vision Systems in Goleta, Calif.<br />

In a recent article on “Benefits of Eyesafe Laser <strong>Technology</strong>”<br />

(Eye On <strong>Technology</strong>, <strong>Technology</strong> <strong>Today</strong>, Issue 2, 2007), a new lasing<br />

system was described, a system capable of efficiently extracting<br />

1.617 μm eyesafe radiation from a rod of erbium-doped yttrium<br />

aluminum garnet that is directly pumped by laser diodes. While<br />

4 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

adequate for low average power applications such as tactical ranging<br />

and telecommunications, this rod geometry is not well suited<br />

for moderate to high average power laser sources, which are needed<br />

in long-range target illumination, designation, 3-D imaging, and<br />

directed energy weapon systems. The problem is the rod’s shape,<br />

which requires that the heat generated in the lasing process flow<br />

radially from the center to the cooled barrel surface of the rod.<br />

The higher the power, the greater the temperature difference from<br />

center to edge, and the greater the attendant thermal lensing,<br />

stress birefringence (which leads to depolarization), and surface<br />

tension (which eventually leads to rod fracture). In our second<br />

feature article, we introduce a new high-aspect-ratio planar geometry<br />

for the laser gain medium that minimizes the temperature<br />

drop and guides the beam to maintain high extraction efficiency<br />

and good beam quality, even at high lasing powers.<br />

Synthetic aperture radar (SAR) imaging, one of the greatest inventions<br />

in military sensing technology at the end of the 20th century,<br />

routinely provides useful imagery for the intelligence, surveillance<br />

and reconnaissance community at substantial standoff ranges. In<br />

recent years, <strong>Raytheon</strong> has extended synthetic aperture sensing<br />

hardware and compatible image formation techniques to the optical<br />

regime, substantially improving the resolution of these venerable<br />

sensors. In solving the atmospheric phase error, platform<br />

motion, and target vibration problems at optical frequencies, our<br />

researchers have not only set the standard for synthetic aperture<br />

ladar image quality, but have opened a new realm of sensing capability:<br />

micro-Doppler vibrometry. In our third feature article, we<br />

explore these advances in coherent ladar sensors, which promise to<br />

further expand military sensing capability in the EO/IR regime.<br />

Bob Byren<br />

rwbyren@raytheon.com

High-Definition Infrared<br />

Focal Plane Arrays<br />

Enhance and Simplify<br />

Space Surveillance Sensors<br />

Feature<br />

<strong>Raytheon</strong> Vision Systems (RVS) has been providing light-sensing focal plane arrays for space applications for more than four decades,<br />

encompassing diverse applications, including weather data collection, space astronomy, Earth observation and missile surveillance.<br />

This extensive history of design and fabrication of high-performance focal plane arrays (FPA) for both tactical and strategic applications<br />

has allowed RVS to retain its position as one of the most technically advanced visible and infrared (IR) sensor houses in the country.<br />

The IR FPA consists of an infrared detector, which absorbs photons and generates a small voltage, and a readout integrated circuit (ROIC)<br />

that amplifies the voltage. These two components are hybridized together, with indium interconnects providing the electrical connection<br />

between each pixel in the array. Both the IR detectors and the ROIC are designed in-house at RVS’ Santa Barbara, Calif., facility. The detectors<br />

are fabricated with a variety of techniques and materials to provide application-specific spectral coverage over any portion of the<br />

infrared spectrum. One particular aspect of RVS’ FPA production is focused on missile surveillance for the national missile defense.<br />

A primary mission of the national missile defense is to effectively defend the United States against ballistic missile attack. This has multiple<br />

objectives, including surveillance, tracking, targeting and intercepting ballistic missiles during boost, midcourse or terminal phases. Spacebased<br />

infrared sensors provide a significant portion of the surveillance, tracking and targeting capabilities for the national missile defense.<br />

The satellite systems deploying the IR sensors have evolved over the years and have encompassed the Space Based Infrared System (SBIRS),<br />

Continued on page 6<br />

RAYTHEON TECHNOLOGY TODAY <strong>2008</strong> ISSUE 1 5

Feature<br />

Continued from page 5<br />

Space Tracking and Satellite Surveillance<br />

(STSS) system, Overhead Non-Imaging<br />

Infrared (ONIR) system, and Alternative<br />

Infrared Satellite System (AIRSS) efforts.<br />

<strong>Raytheon</strong> has worked with each of these<br />

efforts to some degree. As sensor technology<br />

matures, each generation of satellite<br />

systems incorporates the available improvements<br />

to provide increased surveillance<br />

capabilities. Advancements made in highdefinition<br />

IR FPA to recently enhance and<br />

simplify space surveillance systems are<br />

discussed here.<br />

Traditionally, FPAs for space surveillance<br />

have necessitated scanning arrays to ensure<br />

complete theater coverage. These involve<br />

complex optics and moving components to<br />

sweep the sensor field of view across a swath<br />

of the potential path of a ballistic missile.<br />

The sensor FOV is incrementally adjusted<br />

until the entire target area has been<br />

encompassed, then the sensor is returned<br />

to the starting configuration and the scan<br />

is repeated. This scan must be completed<br />

within a timeframe adequate to detect rapidly<br />

moving missile threats. Until recently,<br />

the use of scanning arrays was the conventional<br />

approach, and it has proven effective.<br />

Advancements in IR sensor technology<br />

have enabled increased array sizes and<br />

decreased pixel sizes to facilitate the routine<br />

production of large megapixel arrays<br />

(Figure 1). These are now attaining the<br />

technology readiness levels (TRL) necessary<br />

to be deployed in space surveillance satellites.<br />

Space surveillance systems demand<br />

64 x 64<br />

256 x 256<br />

128 x 128<br />

Digital Output<br />

8192 x 8192<br />

8µm<br />

2052 x 2052<br />

InSb/HgCdTe<br />

1344 x 1344<br />

InSb<br />

640 x 480<br />

(InSb&HCT)<br />

1024 x 1024<br />

4096 x 4096<br />

8µm<br />

1980 1990 2000 2005<br />

6 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

highly operable FPAs with low noise, in<br />

either traditional scanning or novel large<br />

format staring arrays, to rapidly survey<br />

large areas.<br />

RVS has demonstrated impressive array<br />

operabilities for large format FPA in formats<br />

up to 4 megapixel (2K x 2K) arrays<br />

with either 15 or 20 µm pixels for short<br />

wavelength and middle wavelength<br />

infrared (MWIR) detectors. MWIR response<br />

has been obtained using either InSb or<br />

HgCdTe photovoltaic detectors. These<br />

detectors exhibit excellent spectral<br />

response characteristics, including both<br />

high and uniform quantum efficiency over<br />

the spectral bands of interest. Advantages<br />

of HgCdTe typically include higher temperature<br />

operation compared to InSb, as well<br />

as the critical inherent tunable spectral<br />

response of HgCdTe, which can be readily<br />

adjusted during semiconductor growth for<br />

short, middle, or long wavelength IR<br />

response. The ROIC requires high data<br />

rates to output the data from more than<br />

four million pixels in each frame at sufficient<br />

frame rates to provide the<br />

necessary coverage.<br />

The FPA module assembly consists of the<br />

ROIC/detector hybrid mated to an adjoining<br />

motherboard with an on-board temperature<br />

sensor and two attached cables, all<br />

mounted on a supporting pedestal. An<br />

example of a space surveillance HgCdTe<br />

MWIR 2Kx2K FPA module assembly is<br />

shown in Figure 2. Primary figures of merit<br />

for IR FPA include both response and signalto-noise<br />

ratio (SNR). A common measure of<br />

2560 x 512<br />

25µm<br />

4096 x 4096<br />

20µm<br />

High-Definition Infrared FPAs<br />

the SNR is the noise equivalent irradiance<br />

(the minimum irradiance necessary to produce<br />

unity SNR). The FPA module in Figure 2<br />

has achieved high operability at temperatures<br />

of 110K with 99.8 percent response<br />

operability (operable pixels exhibit response<br />

within 25 percent of the array mean) and<br />

99.3 percent NEI operability (operable pixels<br />

exhibiting NEI within twice the array mean).<br />

This level of performance is more than sufficient<br />

for ONIR surveillance system needs.<br />

This FPA requires motherboard electronics<br />

on two sides only, allowing it to be close<br />

butted to additional arrays on two sides.<br />

This two-side buttable capability allows up<br />

to four FPAs to be tiled together providing<br />

an effective 16-megapixel (4Kx4K) FPA with<br />

larger sensor field of view coverage. Tiling<br />

multiple IR FPA together to generate a single<br />

large format array is an option RVS has<br />

used successfully in the past for groundbased<br />

astronomy applications, with a 4x4<br />

mosaic of 2Kx2K SWIR FPA modules creating<br />

an effective 64-megapixel FPA (Figure 3).<br />

This same tiling technique can be applied to<br />

the FPA module in Figure 2, or with recent<br />

technological advances, the manufacture of<br />

individual larger format arrays can be used<br />

to provide full continuous Earth coverage for<br />

missile surveillance systems.<br />

Recently, RVS, working jointly with <strong>Raytheon</strong><br />

Space and Airborne Systems independent<br />

research and development (IR&D) funding,<br />

has scaled the MWIR 2Kx2K readout integrated<br />

circuit for space surveillance up to<br />

both 2Kx4K and 4Kx4K formats to meet<br />

future system needs. Ongoing develop-<br />

Figure 1. Progression of ROIC format at RVS over time Figure 2. 2Kx2K, 20µm pitch MWIR FPA module assembly

Figure 3. 64-megapixel FPA composed of<br />

sixteen SWIR 2Kx2K FPA modules<br />

ment of the technology to fabricate these<br />

increased format array sizes has focused<br />

on large area uniformity in diverse fields,<br />

including semiconductor growth, wafer and<br />

die polishing for flatness, and high-force<br />

hybridization. A single 4Kx4K ROIC die is<br />

greater than 8 cm on a side. The flatness<br />

requirements are equivalent to having a circu-<br />

ENGINEERING PROFILE<br />

lar lake one mile in diameter with no ripples<br />

across the entire lake greater than three inches<br />

high. Dealing with this type of flatness over<br />

huge thermal ranges requires in-depth understanding<br />

of all the thermal expansion properties<br />

of the materials used. Testing has its own<br />

unique concerns for handling the massive<br />

data throughput capability. To simply output<br />

data from a 16-megapixel array at 30 Hz<br />

requires 0.5 Gbps data rates. This necessitates<br />

low inductance and capacitance wiring<br />

schemes, as well as high-speed computers<br />

with vast amounts of memory capable of<br />

storing and manipulating large arrays of data.<br />

Each of these areas in fabrication and test<br />

of large format IR FPA has now improved to<br />

the point where the manufacture of 4Kx4K<br />

arrays is possible with minimal risk. A single<br />

eight-inch ROIC wafer from 2007 <strong>Raytheon</strong><br />

IR&D is shown in Figure 4 containing 2Kx2K,<br />

2Kx4K, and 4Kx4K (4-, 8-, and 16-megapixel)<br />

die. Scaling up to the 16-megapixel FPA<br />

provides larger sensor FOV and improved<br />

Dr. Angelo Scotty Gilmore<br />

Principal Infrared System Engineer<br />

<strong>Raytheon</strong> Network Centric Systems<br />

Angelo Gilmore is a principal infrared system engineer<br />

in <strong>Raytheon</strong> Vision Systems (RVS). Current programs<br />

he works on include Alternative InfraRed Satellite<br />

System — a potential vehicle for ONIR to replace<br />

SBIRS HIGH. He was the program manager for this<br />

program for the last year. He also works on independent<br />

research and development efforts (IR&D) to<br />

improve the very long wavelength infrared focal plane<br />

array capabilities at RVS.<br />

Intrigued by physics at a young age, Gilmore recalled,<br />

“I was always interested in how things work, and my<br />

father suggested I study physics to further my understanding<br />

of everyday observations.” Gilmore said. “I was<br />

fascinated by the studies, and in graduate school began<br />

researching alternative energy solutions using solar<br />

power from CdTe photovoltaic detectors.”<br />

According to Gilmore, <strong>Raytheon</strong> Vision Systems’<br />

infrared group has a large focus on HgCdTe photovoltaic<br />

detectors, and he sees this as a natural step from his<br />

previous experience. As an engineer, he found that his<br />

skills carried over into management, and he began leading<br />

IR&D efforts and small developmental programs.<br />

Feature<br />

Figure 4. Eight-inch SB395 ROIC wafer<br />

with 4Kx4K, 2Kx4K and 2Kx2K die<br />

full Earth coverage of the ballistic missile<br />

theater. Individual larger arrays are advantageous<br />

over tiling multiple smaller FPAs, and<br />

result in 100 percent coverage without the<br />

additional effort required to account for the<br />

gaps between tiled arrays.<br />

Continued on page 8<br />

Gilmore believes the biggest challenges facing his current<br />

programs are the compressed timelines required to<br />

transfer new technologies into viable system solutions.<br />

To help meet that challenge, he said, “<strong>Raytheon</strong> needs<br />

continuing focus on the transition from development to<br />

production in order to reduce that cycle time and more<br />

rapidly field new technologies.”<br />

Growing up on a ranch, Gilmore developed the solid<br />

work ethic reflected in his philosophy that employees<br />

should “treat everyone as a customer, and give them the<br />

best value you can for their money, work and time.”<br />

Gilmore also believes his competitive nature has its<br />

roots in his position as the youngest of four children.<br />

“The combination of my work ethic and competitive<br />

nature has helped me excel throughout my education,<br />

and now in my career at <strong>Raytheon</strong>.”<br />

Five years after joining <strong>Raytheon</strong>, Gilmore remains<br />

excited about his work. “Designing and developing<br />

cutting-edge technologies that will make a difference<br />

to our country’s success continually excites me,” he<br />

said, noting, “Mission Assurance is not just a catch<br />

phrase in the field, and the products we make help<br />

our soldiers succeed.”<br />

RAYTHEON TECHNOLOGY TODAY <strong>2008</strong> ISSUE 1 7

Feature<br />

Continued from page 7<br />

Current <strong>Raytheon</strong> IR&D has funded the<br />

prove-in of all the key fabrication steps<br />

required for this burgeoning technology.<br />

Highlights of these recent IR&D efforts<br />

include the design and fabrication of IR<br />

FPA-specific 4Kx4K ROICs; dramatic<br />

improvements to six-inch wafer, molecular<br />

beam epitaxy grown, HgCdTe detector uniformity;<br />

and the successful generation of a<br />

mock-up 4Kx4K array, to prove in the large<br />

format hybridization process. Routine fabrication<br />

of silicon ROIC wafers at RVS has<br />

ensured the handling procedures are in<br />

place for processing wafer up to eight inches<br />

in diameter. All this work leaves only the<br />

final step of fabrication and test of an IR<br />

FPA module in the 4Kx4K array format,<br />

ENGINEERING PROFILE<br />

8 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

planned in <strong>2008</strong>. To the author’s knowledge,<br />

this will be the largest individual IR<br />

FPA fabricated to date. Each of these key<br />

efforts acts to reduce the manufacturing<br />

risk and improve the producibility of large<br />

format infrared FPA for space surveillance.<br />

In the future, large format staring arrays<br />

providing wide FOV coverage will replace<br />

complex scanning arrays in satellite surveillance<br />

systems. These staring arrays will<br />

eliminate the system-level moving components<br />

such as gimbals and pointing mirrors<br />

required for conventional scanning arrays.<br />

Staring arrays will prove advantageous in<br />

terms of the primary considerations for<br />

satellite systems, including size, weight,<br />

power and reliability. The incorporation of<br />

staring IR FPAs will simplify the satellite<br />

David M. Filgas<br />

Engineering Fellow<br />

<strong>Raytheon</strong> Space and Airborne Systems<br />

David Filgas is an engineering fellow at Space and<br />

Airborne Systems. Current programs he works on<br />

include K2, NSEP, SALTI, and IRAD projects related to<br />

development of laser systems for a variety of applications.<br />

Filgas has studied lasers since college. While working for<br />

an electrical engineering degree, he undertook a junioryear<br />

internship with a large laser company, and then as a<br />

senior, became involved with a laser startup company. He<br />

has worked in the laser field ever since. “I fell in love with<br />

lasers,” he said. “Looking back now, I have to chuckle when<br />

my parents remind me that my first word was ‘light.’”<br />

His prior career experiences helped Filgas build a foundation<br />

for his success after he joined <strong>Raytheon</strong> five years<br />

ago. After finishing a master’s degree, he worked for a<br />

large technology company, but left after a year “to escape<br />

the big-company bureaucracy.”<br />

He then went to work for a small startup company developing<br />

the highest power solid-state industrial laser in the<br />

world at that time. “I loved being on the technological<br />

cutting edge and the experience of working in a small<br />

company,” he said. “In a startup company, you have to<br />

wear a lot of hats.” In addition to being the chief laser scientist,<br />

he designed system components using CAD, programmed<br />

control systems, built production lasers,<br />

installed and serviced lasers in the field, conducted sales<br />

visits, and performed laser application studies. “I think<br />

High-Definition Infrared FPAs<br />

sensor system through fewer moving components<br />

leading to drastic reductions in the<br />

system weight. Reducing the number of<br />

moving components will also make it easier<br />

to satisfy the overall system reliability<br />

requirements. The enhancements in<br />

satellite surveillance made possible by large<br />

format staring arrays include 100 percent<br />

continuous full Earth coverage at higher<br />

frame rates than prior satellite systems.<br />

Future generations of satellite surveillance<br />

sensors will take advantage of the fundamental<br />

advancements provided by<br />

<strong>Raytheon</strong>’s large format staring IR FPAs<br />

to improve the nation’s missile defense<br />

network capabilities.<br />

Dr. Angelo Scotty Gilmore<br />

angelo_s_gilmore@raytheon.com<br />

Contributors: Stefan Baur, James Bangs<br />

the broad range of experiences I had working in a small<br />

company taught me to consider many larger system<br />

<strong>issue</strong>s during the design process.”<br />

For Filgas, one of the most rewarding aspects of his<br />

work is being on the leading edge of technology. “There’s<br />

a real satisfaction in doing things that have never been<br />

done before. We’re fortunate to have jobs where we can<br />

actually turn our inventions and designs into reality.”<br />

Offering others advice for success at <strong>Raytheon</strong>, Filgas<br />

said, “I believe we can all benefit from staying involved<br />

with multiple projects. It helps avoid getting burned out<br />

on a particular program, and there are always benefits<br />

from cross-pollinating the experiences of one program<br />

with those of another.”<br />

The challenges Filgas sees in current programs hark back<br />

to his large-company experiences. “Doing fast-paced<br />

development work in a large organization like <strong>Raytheon</strong><br />

is difficult. Developmental programs could really benefit<br />

from much more streamlined processes than we’re currently<br />

using,” he said, citing supply-chain delays as an<br />

example. In addition to their schedule impacts, delays<br />

impact our budgets because charge numbers tend to<br />

dwindle away while we wait for parts.”<br />

Filgas believes that streamlining processes is essential for<br />

<strong>Raytheon</strong>’s mission. “If we don’t develop state-of-the-art<br />

systems for our forces in a timely fashion, someone else<br />

will — and it might not be one of our allies. It being a<br />

large potential growth area for <strong>Raytheon</strong>, I believe that<br />

the laser technologies we’re developing can save lives.”

To maintain an advantage in today’s<br />

battlespace, our forces require the<br />

ability to engage targets at longer<br />

ranges and see them with higher resolution.<br />

Active electro-optical (EO) systems<br />

address this need, providing important mission<br />

capabilities such as ranging, tracking,<br />

marking, designating, 3-D imaging (ladar),<br />

chemical and biological agent detection,<br />

and laser defense using high-energy lasers<br />

(HELs). Compared to passive EO systems<br />

(FLIR or camera) or active radio frequency<br />

(RF) systems (radar), active EO systems allow<br />

us to increase both range and resolution<br />

and also to perform new types of missions.<br />

A critical component of any active EO<br />

system is the laser used to illuminate the<br />

target. To offer our customers the highest<br />

performance systems, we must utilize<br />

advanced lasers meeting ever more<br />

challenging requirements in the areas of<br />

laser power, beam quality, efficiency, size<br />

and weight.<br />

Lasers are inherently inefficient, converting<br />

only a portion of the electrical input power<br />

into useful laser output power. The size,<br />

weight and input power of a laser system<br />

are largely driven by two factors: 1) the<br />

average output power of the laser and 2)<br />

its efficiency. In the design of our active EO<br />

systems, we typically optimize the system<br />

design to minimize the required average<br />

power from the laser and then optimize the<br />

laser design for high efficiency. All lasers<br />

require a “gain medium,” a material that<br />

can emit a laser beam, and a “pump<br />

source,” a means of exciting atoms in the<br />

gain medium so that they emit light.<br />

Historically, most military laser systems have<br />

used arclamps to excite the laser gain medium<br />

with resulting efficiencies of just a few<br />

percent. During the past decade, efficiencies<br />

of 20 percent or more have been<br />

achieved by diode-pumped solid-state lasers<br />

due to development of high-power laser<br />

diodes as a more efficient means of exiting<br />

the gain medium, as well as advances in<br />

the gain medium configurations utilized.<br />

While laser diode pumping is a key factor in<br />

enabling high efficiency, scaling laser-output<br />

power while maintaining high beam quality<br />

necessitates improvements in the geometry<br />

of the gain medium itself. Due to the fact<br />

that lasers are not 100 percent efficient,<br />

significant amounts of waste heat are<br />

generated in the gain medium during laser<br />

operation. This waste heat can create<br />

distortions in the gain medium, adversely<br />

affecting important properties of the laser<br />

beam. <strong>Raytheon</strong> has long been at the<br />

forefront of laser technology development<br />

for military applications, and is currently<br />

focused on advanced laser architectures<br />

that leverage the benefits of laser diode<br />

pumping and address the shortcomings<br />

of conventional laser gain medium<br />

Feature<br />

Next-Generation Lasers<br />

for Advanced<br />

Active EO Systems<br />

architectures such<br />

as the venerable cylindrical<br />

rod and, more recently, bulk<br />

slab geometries. The optimal gain<br />

medium geometry for a given application<br />

varies, depending on the average power<br />

and laser waveform, but all of the<br />

advanced gain medium geometries<br />

employed by <strong>Raytheon</strong> seek to minimize<br />

the amount of waste heat and remove the<br />

waste heat from the gain medium in a<br />

manner that minimizes adverse effects on<br />

the quality of the laser beam. The goal of<br />

minimizing adverse thermal gradients within<br />

the gain medium has led <strong>Raytheon</strong> to<br />

focus on three primary gain medium<br />

geometries for advanced laser systems:<br />

microchip lasers, fiber lasers and planar<br />

waveguide lasers.<br />

Microchip lasers are very simple, robust<br />

devices for applications requiring up to<br />

~1W of average laser power. They can be<br />

operated in a pulsed mode with pulse energies<br />

up to ~1mJ and pulse widths as short<br />

as ~1 nanosecond, enabling peak powers<br />

up to 1MW. Fiber lasers and planar waveguide<br />

lasers both enable scaling of laser<br />

average power up to the kW level by using<br />

gain medium geometries with large surface-<br />

Continued on page 10<br />

RAYTHEON TECHNOLOGY TODAY <strong>2008</strong> ISSUE 1 9

Feature Next-Generation Lasers<br />

Continued from page 9<br />

area-to-volume ratios that provide efficient<br />

cooling of the gain medium and minimize<br />

adverse thermal effects. Both can also be<br />

efficiently pumped by laser diodes. In a<br />

fiber laser, the gain medium is configured<br />

as a long filament, while in a planar waveguide<br />

(PWG), the gain medium is configured<br />

as a thin sheet. Fiber lasers are well<br />

suited to applications with average powers<br />

up to 1kW when the pulse energy does not<br />

exceed a few mJ. Planar waveguide lasers<br />

are currently being developed by <strong>Raytheon</strong><br />

for applications with average powers ranging<br />

from 10kW. The PWG has the<br />

potential to scale in average power to the MW<br />

level and produce pulse energies up to >1 J.<br />

Fiber lasers evolved out of the telecom<br />

community beginning in the late 1980s,<br />

when they were invented to enable massive<br />

increases in data throughput by directly<br />

amplifying the packets of laser light that<br />

carry information in fibers around the planet<br />

and under the oceans. During the past<br />

15 years or so, the power capability of fiber<br />

lasers has increased five orders of magnitude,<br />

from 10s of mW to several kW.<br />

<strong>Raytheon</strong> is now actively exploring how<br />

these efficient, versatile laser sources can be<br />

inserted into advanced defense systems.<br />

Figure 1 shows a fiber-based master oscillator,<br />

power amplifier configuration. The fiber<br />

gain medium is formed into a 10 cm coil,<br />

Micro-laser<br />

Remote fiber pigtailed pump diodes<br />

Passively cooled fiber<br />

~ 10 cm coil<br />

10 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

and it is excited by several pump diodes.<br />

Note that the pump power is directly coupled<br />

into the gain fiber through conventional<br />

passive fibers, thereby avoiding any<br />

free-space optics in the pump coupling<br />

function. A micro-laser generates a weak<br />

signal containing the properties appropriate<br />

for the intended application: wavelength,<br />

spectral bandwidth, temporal profile, beam<br />

quality, etc.; the fiber amplifier adds the<br />

power. We see that, unlike most other<br />

types of lasers, there are essentially no freespace<br />

optics in the signal channel — just<br />

robust, flexible fibers — and there is no<br />

need for a rigid, thermally stable optical<br />

bench. The inset shows the cross-section of<br />

a state-of-the-art cladding-pumped fiber<br />

amplifier. The active core occupies just a<br />

fraction of the fiber, with most of the<br />

cross-sectional area being made available<br />

to receive the diode pump power. The fiber<br />

is made sufficiently long that nearly all of<br />

the pump power is ultimately absorbed by<br />

the core, despite the small relative size of<br />

the core. Typical dimensions are core<br />

diameter ~ 20 μm, and pump cladding<br />

diameter ~ 400 μm.<br />

In addition to the packaging features of<br />

fiber lasers, they are also among the most<br />

efficient lasers ever built. One major factor<br />

leading to the high efficiency has to do<br />

with the tiny core along the fiber axis that<br />

contains the laser ion (typically Yb or Er),<br />

the pump light and the signal light. Since<br />

the pump and signal are closely confined<br />

Cladding-pumped fiber amplifier<br />

Cross-section<br />

Robust single-mode<br />

output beam quality<br />

Figure 1. Schematic diagram showing a fiber-based master oscillator, power amplifier laser<br />

system. Inset shows the cross-section of a cladding-pumped fiber amplifier.<br />

Core<br />

Pump cladding<br />

Outer cladding<br />

(typ. polymer)<br />

within the fiber, and the interaction length<br />

can be made very long (many meters, if<br />

necessary), very efficient conversion can<br />

occur from the pump power to signal<br />

power. Commercial fiber lasers typically<br />

demonstrate more than 70 percent power<br />

conversion efficiency from the pump to<br />

signal. Another feature is that the tiny core<br />

size does not allow anything but the lowest-order<br />

transverse spatial profile, which<br />

rigorously forces the beam divergence of<br />

the output signal to the minimum value<br />

allowed by fundamental physical laws.<br />

These and other features are summarized<br />

in Table 1.<br />

Table 1. Features of Fiber Lasers<br />

High efficiency, due to the excellent<br />

spatial overlap of the pump and signal<br />

Rigorously single-mode outputs<br />

Favorable thermal geometry with a large<br />

surface-to-volume ratio<br />

Compact size and considerable<br />

packaging flexibility<br />

Recent technical breakthroughs<br />

allowing power scaling to > 1kW with<br />

a single fiber<br />

Evolving all-fiber architectures free of any<br />

free-space propagation of signal beams<br />

Common pump-diode technology developed<br />

for bulk crystalline solid-state lasers<br />

A foundation in the telecom culture,<br />

with mature materials and processes that<br />

offer robust components with long<br />

operational lifetimes<br />

Not listed in Table 1 is “high power.” This is<br />

because the same tiny core that makes fiber<br />

lasers efficient and ensures excellent beam<br />

quality also makes it difficult to produce<br />

high-peak or average powers without either<br />

degrading some other performance parameter<br />

of interest, or causing severe damage<br />

to the fiber medium. However, the laser<br />

community is actively working on innovative<br />

fiber laser designs that, hopefully, will<br />

retain all of the key performance features<br />

listed in Table 1, while allowing power scaling<br />

by several orders of magnitude.<br />

<strong>Raytheon</strong> is pursuing a proprietary<br />

approach to accomplishing these objectives,<br />

and we anticipate significant new power<br />

capabilities in the next few years.

Near-term <strong>Raytheon</strong> applications of fiber<br />

lasers have been in various versions of laser<br />

sensors, including a state-of-the-art coherent<br />

laser radar system. In the commercial<br />

world, fiber lasers are becoming the laser of<br />

choice in a number of laser processing<br />

applications, most significantly in the marking<br />

area where they essentially dominate all<br />

other options.<br />

Planar Waveguide Lasers (PWGs), are<br />

high aspect ratio sandwich-type structures<br />

consisting of a high-index active core surrounded<br />

by lower index claddings. A PWG<br />

is essentially a one-dimensional fiber in<br />

which the thin transverse axis is guided and<br />

the wide transverse axis is unguided. The<br />

core, typically 5 to 200 μm thick, may be<br />

single-mode or multimode and may be<br />

ENGINEERING PROFILE<br />

Figure 2. Planar waveguide gain medium showing pump insertion and output beam<br />

James Mason<br />

Senior Principal Fellow<br />

<strong>Raytheon</strong> Space and Airborne Systems<br />

When Jim Mason walked in the doors of Texas<br />

Instruments — later part of <strong>Raytheon</strong> — 42 years ago,<br />

he knew he found a home.<br />

Mason was given opportunities to work on challenging<br />

projects with the most advanced technologies; to work<br />

with brilliant and motivated people; to support the<br />

defense of our nation; and to get a paycheck on top of<br />

all of that. After 42 years, you can still see his excitement.<br />

“If you are excited about working with technology,<br />

<strong>Raytheon</strong> is a great place to work!” he declared.<br />

For the last 10 years Mason has worked on millimeter<br />

wave (MMW) active electronically scanned arrays<br />

(AESA) and MMW technology at Ka-band and W-band<br />

frequencies. As part of this effort, Mason invented and<br />

developed the low-cost MMW AESA concept. “This<br />

radically different and eloquently simple concept is a<br />

solution that is obvious to everybody,” Mason said,<br />

“once they see it.” The low-cost AESA concept reduced<br />

the per-channel cost by 10 times. This technology has<br />

now been applied to the multibillion dollar, multifunction<br />

RF System program.<br />

AESA design technology covers a broad range of technology<br />

disciplines, including RF, digital, power, monolithic<br />

microwave integrated circuits, software, thermal,<br />

materials and processes. The very high packaging densities<br />

of this equipment makes it a particularly difficult<br />

design challenge. Everything is interrelated and interconnected.<br />

“It reminds me of the PBS TV show called<br />

Feature<br />

Continued on page 12<br />

Connections,” Mason said. “It takes a person with a<br />

broad experience base to span this technology breadth<br />

and provide the leadership to connect the dots.”<br />

The most rewarding aspect of his job, Mason said, is the<br />

challenge. “There’s a fortune cookie that says, ‘My greatest<br />

joy in life is accomplishing what others say is impossible.’<br />

This is the challenge that I live for,” Mason said.<br />

“Leading a team of less experienced design engineers<br />

and showing them how to ask the right questions,<br />

makes it even more rewarding. You can see the excitement<br />

of the team build and we get closer and closer to a<br />

solution. When this magic moment occurs, the dynamics<br />

of the team are completely transformed.”<br />

Mason is a strong believer in visualization, and it’s one<br />

of the primary tools he uses when he invents something<br />

new. “It’s a powerful technique that can be applied to all<br />

aspects of a program, as well as your life. If you can see<br />

it you can make it happen. It takes practice and a lot of<br />

scientific background knowledge, but if you can develop<br />

this ability, you can change the world.” It helps,<br />

Mason said, to spend time with children. “Not only is it<br />

fun, but they will teach you how to think like a child.<br />

That’s what you need to be an inventor.”<br />

Reflecting on what aspect of his job keeps him up at<br />

night, Mason relates a “conversation” that he might have<br />

with his subconscious. “You know that problem that<br />

you asked me to work on several days ago? Well I’ve got<br />

the answer. Hope you are ready to get started, because<br />

I can’t sleep.” He commits many of his most difficult<br />

problems to his subconscious, and his mind, he said,<br />

“Let’s me know when it’s ready.”<br />

RAYTHEON TECHNOLOGY TODAY <strong>2008</strong> ISSUE 1 11

Feature Next-Generation Lasers<br />

Continued from page 11<br />

core- or cladding-pumped. The guiding<br />

structure allows high pump absorption efficiency.<br />

The high aspect ratio offers a large<br />

surface-area-to-volume ratio for efficient<br />

cooling and a high power loading limit.<br />

With an aspect ratio of 100:1 or higher, a<br />

100kW-class PWG will require only 30 to<br />

40cm of length. The guided propagation of<br />

the signal beam in the thin core of a PWG<br />

cancels thermal lensing, permitting a wide<br />

operating power range with low optical<br />

distortion. The high intensity in a PWG<br />

(~1MW/cm 2 ) provides very efficient power<br />

extraction (fiber lasers run ~100MW/cm 2 ).<br />

If designed with a low numerical aperture,<br />

PWGs can provide very high gain with low<br />

amplified spontaneous emission.<br />

<strong>Raytheon</strong> has been the leader in laser<br />

amplifier power scaling, previously setting<br />

world records for the highest output power<br />

from a single rod, 2.6kW, and the highest<br />

output power from a single zigzag slab,<br />

8kW. The planar waveguide architecture is<br />

a natural evolution from zigzag slabs as the<br />

aspect ratio is increased. Advances in slab<br />

fabrication capability have enabled the creation<br />

of planar waveguides with aspect<br />

ratios of 100:1 and higher in the sizes<br />

required for weapon-class lasers. <strong>Raytheon</strong><br />

presented data on a record-setting highpower<br />

Yb:YAG planar waveguide amplifier<br />

at SSDLTR 2006. This device demonstrated<br />

single-pass small signal gains up to 1,200<br />

(240W output with a 200mW input beam)<br />

and 16.1kW output power in a single-pass<br />

MOPA with G=160 (100W input beam).<br />

Electrical to optical efficiency at 16kW output<br />

power was 20 percent. The results were<br />

in excellent agreement with <strong>Raytheon</strong>’s<br />

laser kinetics models. <strong>Raytheon</strong>’s models<br />

predict no major technical obstacles to<br />

power scaling even up to the MW level.<br />

Slab fabrication capabilities currently support<br />

fabrication of 100kW-class PWG<br />

devices. Further power scaling will require<br />

additional slab fabrication process development.<br />

With its world-record demonstration,<br />

<strong>Raytheon</strong> has proven the applicability of the<br />

planar waveguide laser architecture for use<br />

12 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Figure 3. 16kW planar waveguide MOPA configuration hardware under test<br />

in compact, efficient, weapon-class,<br />

solid-state lasers.<br />

Future Trends<br />

Emerging requirements for efficient,<br />

compact lasers that operate in the desirable<br />

1,500nm wavelength window (also referred<br />

to as “eye-safe” wavelength regime) have<br />

spawned efforts to develop lasers based on<br />

the resonantly pumped Er ion. In addition<br />

to operating in this desirable wavelength<br />

band, resonantly pumped Er lasers offer<br />

the potential of extremely high efficiency<br />

and — perhaps more importantly — low<br />

thermal waste heat generation due to the<br />

extremely small quantum defect made possible<br />

by the Er ion energy level energetics<br />

and dynamics (illustrated in Figure 4).<br />

2 F5/2<br />

Pump<br />

941 nm<br />

~9% Waste Heat<br />

2 F7/2<br />

Yb:YAG<br />

10902<br />

10624 cm<br />

10327<br />

-1<br />

Laser<br />

Transition<br />

1029 nm<br />

785<br />

612<br />

565<br />

0<br />

Figure 4. Energy level structure for Yb:YAG and Er:YAG<br />

cm-1<br />

<strong>Raytheon</strong> has demonstrated 57 percent<br />

slope efficiency in ErYAG (shown in Figure<br />

5) and others have recently achieved >81<br />

percent efficiencies from the same material.<br />

More recently, <strong>Raytheon</strong> has demonstrated<br />

ultra-low quantum defect operation<br />

(

Output Power [W]<br />

15<br />

10<br />

5<br />

0<br />

0 10 20 30 40 50<br />

Input Power [W]<br />

1645nm Er:YAG laser pumped at 1534nm<br />

CW Operation: 32% slope efficiency with<br />

respect to incident power (57% with<br />

respect to absorbed power)<br />

Figure 5. Resonantly pumped ErYAG laser<br />

results showing high efficiencies<br />

transmitter/system — especially when<br />

implemented in conjunction with the PWG<br />

gain architecture/geometry.<br />

Summary<br />

Advanced active EO systems will be<br />

critical to providing a competitive advantage<br />

to our forces for the foreseeable<br />

future. To maintain its position as a leading<br />

provider of these systems, <strong>Raytheon</strong> is<br />

actively maintaining a leadership position<br />

in the development of the next-generation<br />

lasers that power these active EO systems.<br />

Development of advanced laser architectures,<br />

such as fiber and planar waveguide<br />

lasers, along with advances in laser diode<br />

technology and gain medium materials,<br />

will fuel <strong>Raytheon</strong>’s growth in this expanding<br />

market segment.<br />

David Filgas<br />

dmfilgas@raytheon.com<br />

Co-authors: Dr. David Rockwell and<br />

Dr. Kalin Spariosu<br />

Prior to the discovery of the laser in<br />

1960, optical range measurements<br />

depended on the use of incoherent<br />

spark sources that suffered from large pulse<br />

widths and high-beam divergence. The<br />

laser’s narrow, high-energy pulses and highly<br />

collimated monochromatic beam made<br />

for an ideal source and revolutionized<br />

rangefinder accuracy and functionality. It<br />

was soon realized that these narrowlinewidth<br />

sources would make heterodyne<br />

detection possible in the infrared (IR) and<br />

optical spectral range.<br />

Laser radar (or ladar — laser detection and<br />

ranging) is an extension of conventional<br />

microwave radar techniques to much shorter<br />

wavelengths (by a factor of 100,000).<br />

Like microwave radar, ladar can simultaneously<br />

measure range, velocity, reflectivity,<br />

and azimuth and elevation angles. Ladar is<br />

well suited for precise measurements useful<br />

in target classification and recognition, but<br />

ill suited for wide-area search because of<br />

the time and energy required.<br />

Laser radars, with their optical wavelengths<br />

and active sensing, behave like forwardlooking<br />

infrared sensors in terms of angular<br />

resolution, and like microwave radars in<br />

terms of range and velocity measuring<br />

capability. However, coherent effects and<br />

extreme wavelength differences give rise<br />

to phenomena not seen in these more<br />

traditional sensors.<br />

For example, coherence of the laser transmitter<br />

causes speckle in the return from<br />

optically rough target surfaces. The apparent<br />

brightness of individual scene pixels<br />

may fluctuate wildly, giving visually poor<br />

intensity imagery unless considerable scene<br />

averaging is applied, which requires more<br />

time on target and more consumed energy.<br />

Often, ladar images are better displayed as<br />

range rather than intensity images.<br />

Feature<br />

<strong>Raytheon</strong> Achieves Advanced Radar<br />

Functionality at Optical Wavelengths<br />

via Coherent Ladar<br />

The extremely short wavelengths typical of<br />

ladars move the noise floors well into the<br />

quantum dominated regime. Thermal noise<br />

is the driving limit in sensitivity in radars,<br />

however, in ladars the quantized photon<br />

energy in the signal and background light<br />

drive the noise floor sensitivity. As the<br />

wavelengths approach visible light, the<br />

signal itself becomes noise-like and the<br />

detection threshold becomes roughly one<br />

photon. In addition, the short wavelengths<br />

give rise to huge Doppler shifts that may<br />

require processing bandwidths far greater<br />

than needed in conventional radar.<br />

Coherent Ladar Capabilities at <strong>Raytheon</strong><br />

Coherent ladar became viable in the early<br />

1980s with the development of frequency<br />

stable CO2 laser transmitters. <strong>Raytheon</strong><br />

(then Hughes Aircraft) was in the forefront<br />

of the technology development, flying the<br />

first frequency modulated (FM) ladars in<br />

1981–86. Radar waveforms such as Linear<br />

FM Chirps were used. In the late 1980s,<br />

diode-pumped solid-state lasers replaced<br />

the CO2 gas lasers as the preferred transmitters<br />

for ladar, due to their simpler and<br />

more robust designs.<br />

Inverse Synthetic Aperture Ladar<br />

During the mid-1990s, <strong>Raytheon</strong> developed<br />

and demonstrated one of the first flyable<br />

coherent ladar systems to measure space<br />

object microdynamics for discrimination<br />

between precision decoys and RVs for the<br />

Exo-atmospheric Kill Vehicle (EKV). The<br />

Advanced Discriminating Ladar Transceiver<br />

(ADLT) sensor used a short wavelength,<br />

coherent mode-locked, solid-state transceiver<br />

and inverse synthetic aperture ladar processing<br />

to provide range-resolved Doppler<br />

imagery of the target. The laser transmitter<br />

used a fiber-optic laser waveform generator,<br />

which produced the coherent, high-bandwidth<br />

waveform and amplified this signal<br />

within a multi-stage diode-pumped, solid-state<br />

Continued on page 14<br />

RAYTHEON TECHNOLOGY TODAY <strong>2008</strong> ISSUE 1 13

Feature<br />

Continued from page 13<br />

amplifier with extremely high efficiency and<br />

high gain. The challenges that were overcome<br />

during the demonstration phase of<br />

the ADLT program included development of<br />

a fiber-based waveform generator, widebandwidth<br />

signal processing (~1 GHz), and<br />

a high laser amplifier gain (~3,000) requiring<br />

a new laser material (Nd:YVO 4 ). The<br />

success of the ADLT demonstration proved<br />

that coherent ladar has a much higher payoff<br />

than simpler direct detection systems, by<br />

allowing a multitude of waveforms to<br />

extract subtle discriminating target features.<br />

Synthetic Aperture Ladar<br />

In January 2003, <strong>Raytheon</strong> was awarded<br />

DARPA’s Synthetic Aperture Ladar for<br />

Tactical Imaging (SALTI) Program. The program<br />

culminated on Feb. 17, 2006, with<br />

production of the world’s first synthetic<br />

aperture ladar image from an airborne platform.<br />

This success dramatically advanced<br />

state-of-the-art ladar research by transitioning<br />

ladar technology from the lab to actual<br />

flight demonstrations.<br />

SALTI is an imaging synthetic aperture ladar<br />

that operates at optical wavelengths.<br />

Traditional radar components, such as<br />

exciters, antennas and waveguides, have all<br />

been replaced by their optical equivalents:<br />

14 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

lenses, mirrors, and beam splitters to enable<br />

control of optical waveforms. Optical ladars<br />

exploit platform motion to synthesize a synthetic<br />

aperture in exactly the same manner as<br />

RF radars; significant differences include dwelltime<br />

and beam-footprint on the ground.<br />

The result is a narrow field-of-view imaging<br />

sensor capable of producing ultra-high resolution<br />

2-D and 3-D images of the target.<br />

SALTI’s success is built on several years of<br />

intense work overcoming many difficult<br />

problems confronting optical ladars: atmospherics,<br />

vibration and motion compensation,<br />

Doppler processing and laser phase<br />

noise. The random nature of the atmosphere<br />

introduces phase-noise into signals,<br />

resulting in degraded pulse compression.<br />

Slow-time image compression requires<br />

Doppler knowledge beyond that obtainable<br />

via inertial navigation systems and intertial<br />

measurement unit instrumentation; new<br />

motion compensation techniques had to be<br />

invented. Modern radars employ state-of-theart,<br />

sub-Hz clock oscillators. In comparison,<br />

the best 1.55 μm laser sources have kHz-level<br />

linewidths — again, new solutions had to<br />

be invented to surmount these problems.<br />

After flying 30-plus successful missions over<br />

land and water, SALTI has demonstrated the<br />

imaging capabilities achievable through<br />

optical SAR. In conjunction with modern<br />

Vibration Ladar Sensor maps ground vibration response to detect buried objects.<br />

Coherent Ladar<br />

radars, optical SAR offers very powerful<br />

capabilities to augment persistent track and<br />

assured ID mission requirements. With the<br />

upcoming SALTI Phase IV & V programs,<br />

<strong>Raytheon</strong> Space and Airborne Systems<br />

(SAS) is preparing to transition the SALTI<br />

technology toward a deliverable long-range<br />

sensor system for our customers.<br />

Vibration Ladar<br />

Using the ladar technology base developed<br />

under the SALTI imaging ladar program,<br />

<strong>Raytheon</strong> SAS has embarked into the vibrometric<br />

sensor market.<br />

Our goal is to develop an instrument capable<br />

of watching the surface of the Earth<br />

vibrate, similar to high-speed photography<br />

of a drum head, or the resultant waves of a<br />

water drop rippling across the surface of a<br />

mill pond. Specialized signal processing will<br />

enable the warfighter to isolate and detect<br />

vibrations from objects buried in the Earth.<br />

Vibrometric sensing contains a number of<br />

unique and interesting scientific challenges<br />

to overcome. First and foremost is the <strong>issue</strong><br />

of platform motion: How can signal processing<br />

detect faint vibrations on the<br />

ground’s surface while driving over a rocky,<br />

gravel road that induces massive random<br />

vibrations into the gimbaled optical sensor?<br />

<strong>Raytheon</strong> researchers working on SALTI had<br />

begun to investigate this question, focusing<br />

on the goal of augmenting SALTI’s already<br />

impressive imaging capabilities with vibrometry.<br />

Our research team designed and built<br />

a table-top laser Doppler vibrometer and<br />

began testing platform motion detection<br />

and compensation algorithms. A successful<br />

Independent Research and Development<br />

(IR&D) project in fiscal year 2007 led to<br />

patentable intellectual property and patent<br />

applications are underway.<br />

Ongoing and Future IR&D Efforts:<br />

Receivers<br />

<strong>Raytheon</strong> SAS ladar researchers quickly realized<br />

that ladar sensors generate raw data<br />

streams comparable to modern active electronically<br />

scanned array radars. Consequently,<br />

ladar and radar architects and signal processing<br />

specialists collaborated, resulting in a

significant transfer of knowledge. Specifics<br />

include radar pulse compression, phase compensation<br />

(“pre-warp”), Hilbert transforms,<br />

and Chirp-Z transforms, just to name a few.<br />

Doppler centroiding is one of the most serious<br />

<strong>issue</strong>s confronting ladars operating in<br />

the near-infrared eyesafe wavelength band<br />

(1.55 μm). This effect arises from the<br />

Doppler relationship between platform<br />

velocity and optical wavelength. Thus,<br />

ladars demand very stringent timing<br />

requirements between wideband sensor<br />

data and narrowband line-of-sight (LOS)<br />

servo-control mechanisms. Traditional<br />

passive IR LOS mechanisms think in two<br />

dimensions, known as angle–angle space.<br />

In comparison, ladar LOS mechanisms must<br />

ENGINEERING PROFILE<br />

think in three dimensions: angle–angle and<br />

range. As a result, ladar receivers are evolving<br />

rapidly, incorporating commonly used<br />

real-time radar processing techniques,<br />

including in-phase and quadrature processing,<br />

digital filtering and decimation.<br />

These demands have led to the concept of<br />

a fully integrated ladar LOS servo controller,<br />

exciter and receiver, which is similar in concept<br />

to active electronically scanned array<br />

(AESA) radars but with appropriate modifications<br />

for ladar. Currently, ladar and radar<br />

technologists across <strong>Raytheon</strong> are sharing<br />

information on architectures, wideband<br />

data formats, data transmission and data<br />

storage techniques. As ladar receivers<br />

continue to evolve and incorporate radar<br />

Jéan-Paul Bulot<br />

Principal Multi-Disciplined Engineer<br />

<strong>Raytheon</strong> Space and Airborne Systems<br />

Jéan-Paul Bulot is an architect and research scientist<br />

working on several coherent ladar programs led by<br />

Space and Airborne Systems’ Advanced Concepts and<br />

<strong>Technology</strong>: SALTI, SAVi and NSEP. He is also the principal<br />

investigator and a part-time member of multiple<br />

internal research and development teams working on<br />

ultra-high bandwidth coherent waveforms, advanced<br />

ladar speckle noise reduction techniques, laser doppler<br />

vibrometry and vibrometric algorithms.<br />

“My job is to stretch the boundary of what’s possible, to<br />

illuminate the path of new scientific discoveries<br />

enabling my customer goals,” according to Bulot.<br />

Bulot believes his drive to become an engineer began<br />

early. “There’s this famous family photo of me spinning<br />

a soup can at the age of three,” he recalled. “By sixteen I<br />

knew I was going to be an engineer of some sort.”<br />

His career at <strong>Raytheon</strong> began in 2000, when Maurice<br />

Halmos, senior ladar scientist, and Lou Klaras, senior<br />

laser electronics engineer, were looking for creative<br />

minds to tackle difficult multi-disciplinary problems in<br />

ladar. A good friend and fellow Georgia Tech engineer<br />

already working at <strong>Raytheon</strong> sent Bulot’s resume to<br />

Klaras and, according to Bulot, “It’s been a nonstop<br />

rollercoaster ever since.”<br />

Bulot cites many reasons for the success he has found in<br />

his career. “I grew up without TV in a family that<br />

encouraged independence, creativity, self-reliance and<br />

Feature<br />

technology lessons learned, <strong>Raytheon</strong> SAS<br />

is well positioned to provide this blending<br />

of RF and photonics technologies into an<br />

integrated active sensor system capable of<br />

significant stand-off ranges with remarkable<br />

synthetic aperture image clarity. The<br />

enhanced sensing capability afforded by<br />

<strong>Raytheon</strong>’s coherent ladar systems will allow<br />

the sensing platforms to perform their<br />

critical target detection, identification and<br />

handoff missions while remaining out of<br />

harm’s way.<br />

Dr. Maurice J Halmos<br />

mjhalmos@raytheon.com<br />

Co-authors: Jean-Paul Bulot and<br />

Dr. Matthew J. Klotz<br />

the idea of being able to self-educate,” he said. “I am<br />

particularly grateful that my parents instilled the idea<br />

that there is always positive learning to be discovered,<br />

even in failures.”<br />

“My engineering is akin to my big-wave surfing: I seek<br />

the path of balance in a rapidly and dynamically changing<br />

environment. Failure is my friend and feedback<br />

mechanism that tells me if my intuition is correct. I<br />

trust my team — I champion their successes. Where I<br />

perceive shortcomings, I lend a hand, and if I don’t<br />

know the answer I find someone who does.”<br />

This collaborative approach is seen in Bulot’s commitment<br />

to teaching and mentoring junior engineers, a<br />

commitment he sees as mutually beneficial. “Explaining<br />

an idea empowers the student to grow in skill and<br />

progress forward in life and career, while offering the<br />

teacher a fresh viewpoint and opportunity to further<br />

probe and improve the true understanding of how<br />

something works.”<br />

His work at <strong>Raytheon</strong> allows Bulot to continually learn<br />

and grow by interacting with a diverse group of<br />

employees committed to success. “I enjoy working with<br />

individuals who exhibit excellence in all manner of<br />

their professional and personal lives; it’s fascinating and<br />

inspiring to have the opportunity to discuss a broad<br />

spectrum of ideas and I appreciate differing points of<br />

view. I believe life offers the opportunity to be both a<br />

student and a teacher everyday; as the famous woodworker<br />

George Nakashima once said, ‘work can be a<br />

form of yoga for the mind.’”<br />

RAYTHEON TECHNOLOGY TODAY <strong>2008</strong> ISSUE 1 15

Feature<br />

Radio Frequency Sensors<br />

Small, Low-Power Radars Satisfy Big Needs<br />

When we think of <strong>Raytheon</strong> and radars, we usually think of large missile defense radars like the Sea-Based X-band Radar, early<br />

warning radars like the PAVE PAWS, or fighter aircraft radars for the U.S. Navy’s F/A-18. However, the advancement of solidstate<br />

radio frequency (RF) active circuit technology and packaging during the past several years has enabled the proliferation of<br />

more affordable active phased array antennas to many more applications. In this <strong>issue</strong> you will read about small radars used to protect military<br />

aircraft and their crew from intruders after they land in remote areas, and an exciting new system on the horizon with the potential to<br />

provide significantly improved warning for severe weather on a very local scale.<br />

When one thinks of RF and networks, it is usually in the context of communications. Radars, however, may also be used in networks so<br />

that they operate autonomously or together to do their job. Think of having the ability to simultaneously view a football game from several<br />

angles, much like what happens inside the control-room truck of a television crew covering the event. The director has the complex task<br />

of scanning the various camera options as the play unfolds and deciding which camera to select for what gets aired. A network of radars<br />

essentially operates similarly. Each radar may observe, from different vantage points, the same phenomena, and when the information is<br />

re-constructed and processed we see a lot of details about what we are observing. In the medical world, CT scans (computed tomography)<br />

work similarly, using X-rays to form a 3-D image of the body. In this case, we use RF and the antennas are fixed while the weather is moving;<br />

whereas, in CT scans, we are stationary while the X-ray machine moves (well sort of, we actually move as well, so that many slices<br />

may be taken as the X-ray machine moves around us in a circle). This technique allows us to observe more details of the weather as it<br />

develops and ultimately improve accuracy and warning times for severe weather such as tornadoes.<br />

Landing military aircraft in areas of the world where our soldiers are in harm’s way is very dangerous to the soldiers and the aircraft and its<br />

contents. A new system has been devised using millimeter wave radars that allow our warfighters to deploy sensors around the perimeter<br />

of the aircraft to provide warning against intruders. This frees up the soldiers to perform tasks relevant to the aircraft’s contents, and it<br />

requires less manpower for standing watch.<br />

Mike Sarcione<br />

michael_g_sarcione@raytheon.com<br />

16 <strong>2008</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY

Feature<br />

Active Panel Array <strong>Technology</strong><br />

Enables Affordable Weather Radar<br />

<strong>Today</strong>’s weather forecasting and<br />

warning infrastructure uses data<br />

from high-power radars that have<br />

helped meteorologists improve forecasts<br />

significantly in the past 20-plus years.<br />

Despite having substantial capability to<br />

measure wind and rainfall and to diagnose<br />

storms, these long-range radars have limited<br />

ability to observe the lowest and most<br />

critical part of the atmosphere owing to the<br />

Earth’s curvature. This prevents the radars<br />

from observing the behavior of tornadoes<br />

and other hazards at or near ground level.<br />

As a result, one in five tornadoes goes<br />

undetected by current technology, and<br />

80 percent of all tornado warnings turn<br />

out to be false alarms.<br />

<strong>Raytheon</strong> Integrated Defense Systems (IDS),<br />

in partnership with a team of academic 1 ,<br />

government and industrial collaborators,<br />

has formed a National Science Foundation<br />

Engineering Research Center (ERC) called<br />

the Center for Collaborative Adaptive<br />

Sensing of the Atmosphere (CASA) to<br />

address this problem. CASA is researching<br />

a new weather hazard forecasting and<br />

warning technology based on low-cost,<br />

dense networks of radars that operate at<br />

short range, communicate with one<br />

another, and adjust their sensing strategies<br />

in direct response to the evolving weather<br />

and to changing end-user needs. In contrast<br />

to today’s large weather radars with<br />

10-meter-diameter antennas, the antennas<br />

in CASA networks are expected to be onemeter<br />

in diameter with electronics that are<br />

about the size of a personal computer. This<br />

small size allows these radars to be placed<br />

on existing cellular towers and rooftops,<br />