Raytheon Technology Today 2011 Issue 1

Raytheon Technology Today 2011 Issue 1

Raytheon Technology Today 2011 Issue 1

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technology</strong><br />

<strong>Today</strong><br />

HigHligHting RaytHeon’s tecHnology<br />

<strong>Raytheon</strong>’s Integrated Energy Solutions<br />

Applying technologies critical to national security<br />

<strong>2011</strong> ISSUE 1

A Message From Mark E. Russell<br />

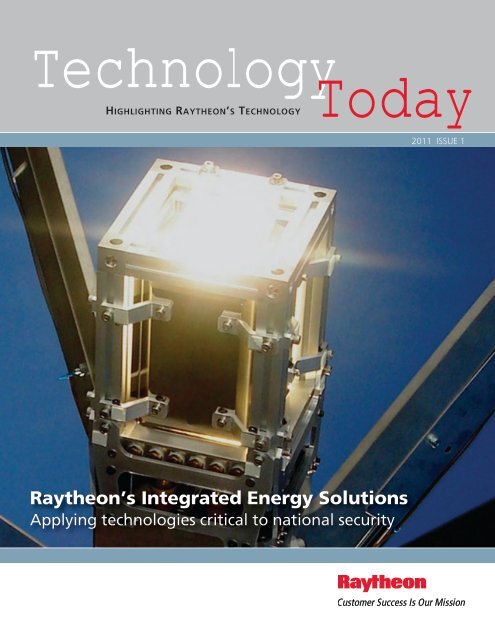

On the cover: <strong>Raytheon</strong>, together with United<br />

Innovations and the University of Arizona,<br />

is developing a high efficiency solar energy<br />

system. The heart of the system is a novel<br />

photon-recycling photovoltaic cavity converter<br />

(PVCC). It works in conjunction with a parabolic<br />

dish reflector that concentrates sunlight<br />

through the PVCC onto an internal array of<br />

photovoltaic cells to produce electrical energy.<br />

2 <strong>2011</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Vice President of Engineering, <strong>Technology</strong> and Mission Assurance<br />

Just as minimizing energy use and cost-effectively meeting energy needs are top-of-mind<br />

for all of us at <strong>Raytheon</strong>, so too are these major concerns for <strong>Raytheon</strong>’s defense and<br />

national security customers. Collectively we face the growing challenges related to<br />

energy and fossil fuel usage. <strong>Raytheon</strong>, known for technological innovation, is focused<br />

on helping to better meet these energy needs and create solutions that support our<br />

customers’ missions.<br />

This Energy issue of <strong>Technology</strong> <strong>Today</strong> focuses on <strong>Raytheon</strong>’s innovative approaches to<br />

satisfying the energy needs of its systems and its customers by leveraging and adapting<br />

advanced energy technologies. Assuring reliable energy sources, adjusting to unpredictable<br />

fuel pricing, and responding to mission needs are important variables in designing<br />

defense systems.<br />

<strong>Raytheon</strong> is at the forefront of providing the domain knowledge, technologies and<br />

solutions to meet energy challenges. We incorporate alternative energy sources such as<br />

solar, fuel cells and advanced batteries in our power management solutions. We are<br />

investigating power cells and storage technologies ranging from a few milliwatts to many<br />

megawatts. We understand what it means to efficiently manage and conserve energy in<br />

domains spanning air, land, sea, space and cyberspace.<br />

In this issue’s Leaders Corner, Tom Kennedy, president of <strong>Raytheon</strong> Integrated Defense<br />

Systems, discusses his vision for IDS and how he plans to meet the challenges that lie<br />

ahead — from changes in the external business environment to leveraging deep technical<br />

talent to addressing the energy needs of today.<br />

In the Meet a New <strong>Raytheon</strong> Leader section, we introduce Luis Izquierdo, vice president,<br />

corporate Operations. Luis is responsible for developing and executing <strong>Raytheon</strong>’s<br />

enterprise operations vision and strategy. He leads strategic initiatives for manufacturing<br />

and manufacturing business systems, and co-leads corporate initiatives related to energy<br />

and environmental sustainability and real estate utilization. Luis discusses how we are<br />

making an impact on energy efficiency by reducing <strong>Raytheon</strong>’s load demand. <strong>Raytheon</strong><br />

has achieved the ENERGY STAR® Sustained Excellence Award from the U.S. Dept. of<br />

Energy for several years.<br />

Best regards,<br />

Mark E. Russell

View <strong>Technology</strong> <strong>Today</strong> online at:<br />

www.raytheon.com/technology_today/current INSIDE THIS ISSUE<br />

<strong>Technology</strong> <strong>Today</strong> is published<br />

by the Office of Engineering,<br />

<strong>Technology</strong> and Mission Assurance.<br />

Vice President<br />

Mark E. Russell<br />

Chief <strong>Technology</strong> Officer<br />

Bill Kiczuk<br />

Managing Editor<br />

Cliff Drubin<br />

Senior Editors<br />

Donna Acott<br />

Tom Georgon<br />

Eve Hofert<br />

Feature Editor<br />

Lindley Specht<br />

Art Director<br />

Debra Graham<br />

Photography<br />

Don Bernstein<br />

Rob Carlson<br />

Website Design<br />

Nick Miller<br />

Publication Distribution<br />

Dolores Priest<br />

Contributors<br />

Sarah Castle<br />

Kate Emerson<br />

Kenneth Kung<br />

Samantha Sullivan<br />

Frances Vandal<br />

Feature: <strong>Raytheon</strong>'s Integrated Energy Solutions<br />

Overview: Applying Technologies Critical to National Security 4<br />

Building Tomorrow’s Energy Surety With <strong>Today</strong>’s Technologies 7<br />

Advanced Chemical Battery Technologies: The Lithium Revolution 9<br />

Power Sources That Last a Century 12<br />

Creating Compact, Reliable and Clean Power With Fuel Cell <strong>Technology</strong> 15<br />

The Battlefield Game Changer: Portable and Wearable Soldier Power 17<br />

Solar Power: Applying <strong>Raytheon</strong>‘s Defense Technologies 18<br />

External Combustion Engines for Military Applications 21<br />

The ReGenerator: Alternative Energy for Expeditionary Missions 23<br />

Intelligent Power and Energy Management 25<br />

The Role of Energy Storage in Intelligent Energy Systems 26<br />

Cyber Risk Management in Electric Utility Smart Grids 30<br />

Cybersecurity for Microgrids 32<br />

Standardizing the Smart Grid 34<br />

<strong>Raytheon</strong> Leaders<br />

Leaders Corner: Q&A With Tom Kennedy 36<br />

Meet a New <strong>Raytheon</strong> Leader: Luis Izquierdo 38<br />

EYE on <strong>Technology</strong><br />

Advanced Vehicle Airframe Innovations Cut Missile Cost and Schedule 40<br />

Dynamic Ontology Creation Techniques: Weapon Smuggling Example 42<br />

Ka-band Cooperative Target ID for the Current Force 43<br />

Special Interest<br />

RF MEMS Development at <strong>Raytheon</strong> 45<br />

Carbon-Based Electronic Devices Open a New Window to Electronics 47<br />

People<br />

Profiling <strong>Raytheon</strong> Certified Architects 48<br />

Resources<br />

IPDS 3.4 for Engineers: The Right Way to Start a Program 49<br />

Events<br />

Fellows Meeting: Disruptive Technologies 50<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

10<br />

Power W/mm<br />

-4 10-3 10-2 10-1 130 nm CMOS<br />

1 10<br />

Editor’s note: Correction: <strong>Technology</strong> <strong>Today</strong>,<br />

2010 <strong>Issue</strong> 2, “Next Generation RF Systems,”<br />

2010 Mission Systems Integration <strong>Technology</strong> Network Symposium 51<br />

page 44. The reference to the FCC frequency<br />

allocation chart should have been to the United<br />

States National Table of Frequency Allocations.<br />

Figure 1 was taken from the United States Frequency<br />

Allocations: The Radio Spectrum, October 2003,<br />

National Telecommunications and Information<br />

Administration, Department of Commerce, Office<br />

Patents 53<br />

of Spectrum Management. RAYTHEON TECHNOLOGY TODAY <strong>2011</strong> ISSUE 1 3<br />

Fmax, Ft (GHz)<br />

InP HEMT<br />

Carbon-Based Electronics<br />

10 mW, 80% PAE, 20 dB Gain<br />

InGaAs PHEMT<br />

NextGen GaN<br />

GaN HEMT

Feature<br />

<strong>Raytheon</strong> Energy<br />

Solutions Overview<br />

Applying Technologies<br />

Critical to<br />

National Security<br />

4 <strong>2011</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Energy is becoming increasingly critical to national security. It is a major concern<br />

and cost consideration for current and future defense operations. The 2010<br />

Quadrennial Defense Review calls for crafting a strategic approach to energy and<br />

for operational energy considerations to be incorporated into force planning, requirements<br />

development and acquisition processes.<br />

Known for its technological innovation and total mission solutions, <strong>Raytheon</strong> is<br />

addressing energy applications from an overall system perspective by employing three<br />

complementary approaches, illustrated in Figure 1:<br />

1. Development and incorporation of advanced energy sources.<br />

2. Management and security of energy grids and infrastructures.<br />

3. Conservation of existing energy supplies, exemplified by <strong>Raytheon</strong>’s<br />

sustainability initiatives.<br />

<strong>Raytheon</strong> produces a large number of systems and products with diverse power and<br />

energy demands. Power demands range from less than 1 watt, for low-power,<br />

man-portable systems and unattended sensors, up to many megawatts for large radar<br />

installations and critical infrastructure needs. Operational environment and logistical<br />

constraints are also considered when evaluating alternative sources such as solar and<br />

wind power. For example, operations in a remote desert location may be better supported<br />

by incorporating solar energy and energy storage to minimize dependence on<br />

diesel generators and their corresponding fuel usage. However, incorporating new<br />

technologies should not inadvertently introduce vulnerabilities in the overall system<br />

architecture. This is one of the basic tenets of good systems engineering at <strong>Raytheon</strong>.<br />

In addition, it is important to properly assess the financial impact of these alternative<br />

energy implementations through a detailed return on investment analysis that examines<br />

total operational costs.<br />

In this issue of <strong>Technology</strong> <strong>Today</strong>, you will read about how <strong>Raytheon</strong> partners with<br />

developers and institutions on leading-edge, energy-related technology to provide the<br />

best system solutions for our customers’ unique applications.<br />

Systems Analysis and Architecture<br />

Beginning with a fundamental understanding of the mission objectives and power requirements,<br />

a comprehensive solution requires expertise in energy generation, storage<br />

and distribution, architecture, modeling and simulation, command and control, information<br />

management, sensing, cyberdefense, critical infrastructure protection, software,<br />

and power electronics integration. The next article, “Building Tomorrow’s Energy Surety<br />

With <strong>Today</strong>’s Technologies,” discusses <strong>Raytheon</strong>’s systems engineering approach to addressing<br />

our customers’ energy needs. The article describes how <strong>Raytheon</strong>, as an energy<br />

surety integrator, utilizes our resources in these areas to develop energy solutions that<br />

address the three primary stages in a system’s energy life cycle: concept, implementation<br />

and maintenance. This sets the stage for a series of articles highlighting <strong>Raytheon</strong>’s<br />

use of developing source technologies, our energy systems management solutions and<br />

our conservation initiatives.<br />

Applications<br />

<strong>Raytheon</strong>, as a technology company and as a systems integrator, recognizes that<br />

addressing the energy needs of our customers is key to providing total life-cycle solutions.<br />

In this issue, you will read about technologies such as advanced batteries for<br />

lightweight mobile applications, atomic batteries for persistent sensors, and fuel cells<br />

for man-portable, facility and fixed-base power applications. Renewable solar sources<br />

and energy management systems are being developed to support the energy needs of<br />

domestic communities, fixed bases and mobile tactical units. Another development is

Applications<br />

• Infrastructures<br />

• Bases<br />

• Airborne<br />

• Maritime<br />

• Ground<br />

• Wearable<br />

providing long-duration energy for the autonomous<br />

operation of underwater vehicles.<br />

With growth in domestic power needs and<br />

the complexity of interconnected power<br />

grids, integrated energy surety solutions<br />

have entered the forefront as the means<br />

for identifying and mitigating the risks and<br />

impacts of failure or compromise within<br />

the U.S. energy infrastructure. <strong>Raytheon</strong> is<br />

applying our considerable systems engineering<br />

resources to address power generation,<br />

distribution and storage strategies, and<br />

cybersecurity measures. Finally, as responsible<br />

citizens, we have a strong culture of<br />

energy awareness in everything we do, as<br />

evidenced by an established track record of<br />

conservation within our facilities.<br />

Source Technologies<br />

There are several existing and emerging<br />

electrical power generation technologies<br />

that play an important role in meeting the<br />

needs of our customers.<br />

The generalized Ragone chart in Figure 2<br />

is used to compare the performance of<br />

various energy sources. On the chart, the<br />

values of energy density (Wh/kg) are plotted<br />

against power density (W/kg). The vertical<br />

axis represents how much energy is available,<br />

while the horizontal axis represents<br />

how quickly that energy can be delivered<br />

to a load. The chart shows various energy<br />

sources — from low-power betavoltaics to<br />

Integrated Energy Solution<br />

System Analysis and Architecture Development<br />

Sources<br />

• Batteries<br />

• Fuel Cells<br />

• Solar<br />

• Wind<br />

• Generators<br />

• Others<br />

Approaches<br />

Management<br />

• Generation<br />

• Storage<br />

• Security<br />

• Distribution<br />

• Reconfigurability<br />

• Reliability<br />

• Recoverability<br />

• Safety<br />

Conservation<br />

• Consumption<br />

• Sustainability<br />

• Renewability<br />

Figure 1. <strong>Raytheon</strong> employs integrated systems resources to achieve comprehensive energy<br />

solutions for its customers.<br />

higher power lithium batteries, fuel cells<br />

and combustion engines.<br />

Many of <strong>Raytheon</strong>’s products require the<br />

use of electrical sources with moderate<br />

power and energy density. This need is<br />

typically met with conventional chemical<br />

batteries. In “Advanced Chemical Battery<br />

Technologies: The Lithium Revolution,” we<br />

start with a general discussion of chemical<br />

batteries, and then focus on advancements<br />

in lithium ion battery technology, which<br />

have evolved to dominate other common<br />

battery technologies for many of today’s<br />

applications. Work is ongoing to further increase<br />

lithium battery performance through<br />

improvements in three areas: chemistry,<br />

electrodes and electrolytes.<br />

Other applications benefit from very long<br />

life (high energy density), but require only a<br />

small amount of power. These applications<br />

are typically persistent unattended sensors<br />

for monitoring and tagging. The article<br />

titled “Power Sources That Last a Century,”<br />

about betavoltaics (atomic energy sources),<br />

addresses this class of applications, which<br />

will enable tiny smart sensors that never need<br />

their batteries recharged or replaced.<br />

For those applications requiring a clean and<br />

quiet power source — and where there is<br />

access to fuel for extended operation — the<br />

fuel cell is a viable technology. “Creating<br />

Compact, Reliable and Clean Power With<br />

Feature<br />

Fuel Cell <strong>Technology</strong>” discusses the various<br />

types of fuel cells with the capability to<br />

cover a very large power range. We highlight<br />

an application where this technology<br />

has the potential to replace conventional<br />

batteries that power equipment for manportable<br />

operations, significantly reducing<br />

the weight and volume of power sources<br />

that must be carried by soldiers on missions<br />

that range from days to weeks.<br />

Development of renewable solar energy<br />

sources is being undertaken at our sun-rich<br />

facility in Tucson, Ariz. We are participating<br />

in this collaborative research effort with<br />

Science Foundation Arizona, the University<br />

of Arizona, United Innovations and the<br />

California Energy Commission. This work is<br />

based on the photovoltaic cavity converter.<br />

The novel “photon-recycling” technology<br />

described in “Solar Power: Applying<br />

<strong>Raytheon</strong>'s Defense Technologies” helps<br />

to increase the efficiency of current solar<br />

cells by capturing more of the incident<br />

solar energy. The goal is to develop a costcompetitive<br />

solar power solution to replace<br />

conventional power sources for many<br />

military and commercial applications. A<br />

photo of the team’s proof of concept demonstration<br />

hardware appears on the cover<br />

of this issue.<br />

The last article on power sources highlights<br />

our involvement with Cyclone Power<br />

10,000<br />

Energy Density (Wh/kg)<br />

1,000<br />

100<br />

10<br />

1<br />

0.1<br />

Fuel Cell<br />

Lead/Acid<br />

Battery<br />

Betavoltiac<br />

Continued on page 6<br />

Combustion<br />

Li-ion Battery<br />

1 10 100 1,000 10,000<br />

Power Density (W/kg)<br />

Figure 2. Ragone chart comparing the<br />

performance of several source technologies<br />

discussed in this issue<br />

RAYTHEON TECHNOLOGY TODAY <strong>2011</strong> ISSUE 1 5

ENGINEERING PROFILE<br />

Lindley Specht<br />

Senior Principal<br />

Engineering<br />

Fellow, IDS<br />

Lindley Specht<br />

has focused<br />

his career on<br />

discovering<br />

opportunities<br />

and innovating<br />

to help solve<br />

interesting<br />

customer problems.<br />

A 30-year<br />

<strong>Raytheon</strong><br />

veteran, Specht continues to share his<br />

knowledge and expertise with all <strong>Raytheon</strong><br />

businesses.<br />

“I have a relatively broad background<br />

that ranges from electrical engineering to<br />

chemistry, and continues to grow while I<br />

am at <strong>Raytheon</strong>,” Specht said. In his current<br />

assignment, Specht is responsible for<br />

the development of new technologies and<br />

capabilities for the warfighter. He is also the<br />

electro-optics and lasers technology champion<br />

for the company.<br />

Specht received <strong>Raytheon</strong>’s award for<br />

Excellence in <strong>Technology</strong> as well as the<br />

Thomas L. Phillips award for Excellence<br />

in <strong>Technology</strong>. He was a participant in the<br />

National Academy of Engineering second<br />

annual symposium on Frontiers in Science,<br />

and he was a member of the technical advisory<br />

committee for the University of Illinois<br />

Center for Compound Semiconductors. In<br />

addition, he was on the technical advisory<br />

committee for the Fundamentals of Infrared<br />

Detection Multidisciplinary University<br />

Research Initiative, sponsored by the Army<br />

Research Office.<br />

He holds a bachelor’s degree in chemistry<br />

with very high honors from the University<br />

of Florida, Gainesville, Fla. He also holds a<br />

master’s degree in electrical engineering, a<br />

doctorate in electrical engineering, and has<br />

completed all the requirements for a doctorate<br />

in physical chemistry, all from the<br />

University of Illinois at Urbana-Champaign,<br />

Urbana, Ill.<br />

Specht is a member of the Institute of<br />

Electrical and Electronics Engineers and the<br />

American Chemical Society. He is also a<br />

qualified <strong>Raytheon</strong> Six Sigma Specialist.<br />

6 <strong>2011</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Feature<br />

Continued from page 5<br />

Technologies, a company that has developed<br />

an innovative engine that converts<br />

heat from external combustion to electricity.<br />

<strong>Raytheon</strong> is integrating this technology as a<br />

replacement for batteries in long-endurance,<br />

long-range underwater vehicle applications.<br />

Energy Management<br />

We begin this series of articles with a system<br />

that illustrates the principles of energy<br />

management on a small scale. <strong>Raytheon</strong>’s<br />

ReGenerator is a self-contained hybrid power<br />

system that generates, stores and manages<br />

clean renewable energy, such as solar and<br />

wind power, designed for tactical use in remote<br />

locations. In fact, the ReGenerator has<br />

been deployed with the U.S. Marines in the<br />

Southwest United States, North Africa and<br />

Afghanistan. The article shows how the use<br />

of alternative energy along with intelligent<br />

energy command and control (IEC2) may<br />

considerably reduce a combat unit’s dependence<br />

on fossil fuels. This not only represents<br />

a cost savings, but it also reduces risk to<br />

warfighters by reducing the logistics footprint<br />

while providing reliable energy where and<br />

when it’s needed. The accompanying article<br />

discusses <strong>Raytheon</strong>’s intelligent power and<br />

energy management (IPEM) technology and<br />

explains how we employ it in development of<br />

our energy systems, such as the ReGenerator,<br />

to optimize efficiency and availability.<br />

A discussion of energy management must<br />

include energy storage. “The Role of Energy<br />

Storage in Intelligent Energy Systems” explains<br />

why energy storage is an important<br />

element of any energy system architecture,<br />

outlines general requirements, and identifies<br />

several technologies of interest along with<br />

their applications.<br />

The next two articles focus on the security<br />

risks associated with complex power grids.<br />

They discuss the complexities and challenges<br />

for managing risks in evolving smart<br />

grid concepts. “Cyber Risk Management<br />

in Electric Utility Smart Grids” discusses<br />

<strong>Raytheon</strong>’s collaboration with the University<br />

of Arizona, Tucson Electric Power, and several<br />

small-business partners to meet recently<br />

mandated regulations and guidelines for<br />

smart grid cybersecurity, architecture and<br />

Energy Overview<br />

infrastructure protection. “Cybersecurity for<br />

Microgrids” discusses our process and suite<br />

of modeling and evaluation tools used to assess<br />

the security of energy networks and to<br />

develop appropriate mitigation strategies.<br />

The last article in this series, “Standardizing<br />

the Smart Grid,” discusses <strong>Raytheon</strong>’s presence<br />

in the international energy standards<br />

community and our activities related to<br />

developing smart grid requirements and<br />

guidelines. The two key areas of standardization<br />

are interoperability and cybersecurity.<br />

<strong>Raytheon</strong> is represented on the Smart<br />

Grid Interoperability Panel sponsored by<br />

the National Institutes of Standards and<br />

<strong>Technology</strong> and the related series of task<br />

forces established by the Institute of Electrical<br />

and Electronic Engineers (IEEE) to address<br />

power systems, information technology and<br />

communications technology standards.<br />

Conservation<br />

In the “Leaders Corner,” <strong>Raytheon</strong>’s<br />

Integrated Defense Systems President Tom<br />

Kennedy provides examples of how our<br />

technology is being applied to reducing<br />

customers’ energy costs and how we are<br />

reducing our own energy footprint through<br />

our “Energy Citizen” program and “green”<br />

certified facilities.<br />

In “Meet a New <strong>Raytheon</strong> Leader,”<br />

<strong>Raytheon</strong>’s energy conservation and<br />

management measures are addressed by<br />

Luis Izquierdo, <strong>Raytheon</strong>’s vice president<br />

for corporate Operations in Engineering,<br />

<strong>Technology</strong> and Mission Assurance. In this<br />

Q&A, Izquierdo talks about his role and how<br />

it relates to energy conservation and management,<br />

<strong>Raytheon</strong>’s energy goals, and the<br />

key elements of <strong>Raytheon</strong>’s energy program.<br />

Summary<br />

We hope this issue provides you with a<br />

good perspective of the degree of focus<br />

and breadth of development that <strong>Raytheon</strong><br />

is bringing to bear on the many energyrelated<br />

challenges. Energy is critical to our<br />

national security and <strong>Raytheon</strong>, as a systems<br />

and technology company, is using its resources<br />

to provide comprehensive solutions<br />

to meet our customers’ energy needs. •<br />

Lindley Specht

Building Tomorrow’s Energy Surety<br />

With <strong>Today</strong>’s Technologies<br />

Energy surety is an approach to an<br />

“ideal” energy system that, when fulfilled,<br />

enables the system to function<br />

properly while allowing it to resist stresses<br />

that could result in unacceptable losses. The<br />

attributes of the energy surety model include<br />

safety, security, reliability, recoverability and<br />

sustainability.<br />

Numerous existing and emerging electrical<br />

power generation and energy storage technologies<br />

may be employed to address the needs<br />

and objectives of U.S. Department of<br />

Defense (DoD) and other domestic and international<br />

customers. Maintaining energy surety<br />

throughout a system’s life cycle requires the<br />

identification, analysis and integration of the<br />

right energy technologies, while considering<br />

specific applications and environments.<br />

<strong>Raytheon</strong> accomplishes this by leveraging its<br />

expertise and resources in system architecture,<br />

design and integration; command and control;<br />

communications; cybersecurity; critical<br />

infrastructure protection; weather prediction;<br />

and modeling and simulation (M&S).<br />

Full Life-cycle Approach<br />

The system solution is developed and matured<br />

throughout the three primary stages<br />

Topology/<br />

weather analysis<br />

Vulnerability<br />

analysis<br />

Concept Stage<br />

• Requirements<br />

derivation<br />

• Tech budgets<br />

• Gov’t mandates<br />

Cost benefit analysis<br />

<strong>Technology</strong> assessment<br />

Configuration<br />

trades<br />

in the energy solutions life cycle — concept,<br />

implementation and maintenance — as<br />

illustrated in Figure 1.<br />

During the concept stage, understanding<br />

the requirements, performing analysis of<br />

alternatives (AoA), cost benefit trades, and<br />

vulnerability analyses result in cost-effective<br />

solutions that meet user needs and are<br />

resilient to enemy attack. Early planning<br />

addresses the strategic concerns related to<br />

the architecture and deployment of a new<br />

initiative or mission and considers policy<br />

constraints, resource availability, personnel<br />

safety, target environment topology and<br />

weather characteristics, vulnerability and<br />

cost. AoA supports the planning process<br />

through rigorous trade-offs of operational<br />

approaches, technology configurations,<br />

cost-schedule-technology risks, and threats.<br />

Finally, architecture definition, modeling,<br />

simulation and systems analysis provide the<br />

foundation for design and implementation<br />

efforts and provide predictions of how —<br />

and how well — the system will operate<br />

once it is implemented. Some of these early<br />

analyses address the approach, effectiveness<br />

and costs of maintenance to ensure that the<br />

architecture and operational approach can<br />

Figure 1. The comprehensive system solution is matured throughout the energy solutions life cycle.<br />

EPA<br />

Deploy/install Design<br />

Feature<br />

be adequately supported and upgraded.<br />

This early total system analysis and architecture<br />

definition yields dividends during the<br />

implementation and maintenance stages by<br />

reducing the costs of operation, maintenance<br />

and upgrades.<br />

The implementation stage continues with<br />

detailed planning and design trade-offs that<br />

focus on installation performance, testability<br />

and supportability. Specific system and<br />

technology choices are made and a detailed<br />

deployment cost and schedule plan is created.<br />

All stakeholders are involved, and service-level<br />

agreement contracts are created and signed.<br />

System engineering, power systems design,<br />

supply chain and contracts management<br />

are critical during this and the maintenance<br />

stage. Proper analysis and selection in this<br />

phase reduces operational costs and improves<br />

system availability, enhancing energy surety<br />

and reducing the required frequency and cost<br />

of future upgrades.<br />

In the maintenance stage, the choices made<br />

during the concept and implementation<br />

stages are evaluated and evolved to support<br />

normal and peak operations. Power<br />

Implementation Stage Maintenance Stage<br />

Solution<br />

laydown<br />

Tech maturity<br />

and obsolescence<br />

Integrator Concept Integrator Baseline Integrator<br />

Contracts Procurement<br />

Cost and<br />

schedule<br />

Stakeholder coordination<br />

Maintenance<br />

Continued on page 8<br />

Evaluate &<br />

Improve Plan<br />

Growth and upgrades<br />

<strong>Technology</strong><br />

road map<br />

M&S/data from estimates and “as likes” Mature models through data gathering Cost benefit for planned upgrades<br />

$<br />

Implement<br />

RAYTHEON TECHNOLOGY TODAY <strong>2011</strong> ISSUE 1 7

Feature<br />

Continued from page 7<br />

generation, power transmission, energy<br />

storage and load balance technologies<br />

are assessed and refreshed as needed.<br />

Optimization of human and system resources<br />

required to maintain the power system also<br />

occurs during this stage. The plan, implement<br />

and improve cycle runs continuously,<br />

drawing on the architecture, design, modeling<br />

and analysis skill sets.<br />

The attributes of energy surety are optimized<br />

through the application of <strong>Raytheon</strong>’s system<br />

engineering methods and resources addressing<br />

the full life cycle of the energy system.<br />

Enterprise Architecture<br />

The development and analysis of a comprehensive<br />

energy enterprise architecture<br />

is required for complex systems and is<br />

necessary before the total system can be<br />

understood and optimized. <strong>Raytheon</strong> employs<br />

the industry-standard Unified Profile for<br />

DoD Architecture Framework/U.K. Ministry<br />

of Defence Architecture Framework. This<br />

architecture captures all of the energy surety<br />

attributes and characteristics related to<br />

availability, performance, testability, interoperability,<br />

maintainability and scalability. One<br />

of the essential methods is model-based engineering<br />

(MBE) and the analysis capabilities<br />

it provides.<br />

Model-Based Engineering<br />

Model-based systems engineering is the formalized<br />

application of modeling to support<br />

system requirements, design, analysis, verification<br />

and validation activities beginning<br />

Energy<br />

Solution Gaps<br />

Intelligent Energy<br />

Management<br />

Interoperability<br />

Cyberprotection<br />

Physical Security<br />

Forecasting and<br />

Planning<br />

Comprehensive<br />

Solution Provider<br />

<strong>Raytheon</strong><br />

Strengths<br />

Command and<br />

Control<br />

Communications<br />

Cybersecurity<br />

Critical Infrastructure<br />

Protection<br />

Environmental Data and<br />

Modeling & Simulation<br />

Systems of Systems<br />

Integration<br />

Figure 2. <strong>Raytheon</strong>’s core competencies<br />

address energy surety solution gaps.<br />

8 <strong>2011</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

in the conceptual design phase and continuing<br />

throughout development and later<br />

life-cycle phases. <strong>Raytheon</strong> employs proven<br />

MBE practices to evaluate functional and<br />

non-functional system characteristics and<br />

perform engineering trade-offs of the energy<br />

solutions, considering the entire life<br />

cycle. Modeling and simulation are used to<br />

evaluate the scalability and cost-benefit implications<br />

of alternative architectures, designs<br />

and deployment strategies.<br />

For example, <strong>Raytheon</strong>’s MBE architecture<br />

analysis of one of the U.S. Army’s training<br />

bases demonstrated significant cost and<br />

time savings by employing a mixed profile of<br />

renewable and legacy energy generation resources,<br />

while deploying more efficient<br />

energy utilization strategies.<br />

For this analysis, several modeling, simulation<br />

and analysis tools were used to assess<br />

the viability of a wide range of energy surety<br />

capabilities and technologies.<br />

• The National Renewable Energy Laboratories’<br />

HOMER (Hybrid Optimization Model for<br />

Electric Renewables) and ViPOR (Village<br />

Power Optimization Model for Renewables)<br />

tools were used to support the planning<br />

during the concept stage. The HOMER<br />

tool provided a low-fidelity modeling environment<br />

to trade cost, performance, functionality<br />

and risk factors associated with<br />

alternative energy deployment strategies.<br />

The ViPOR tool supported power bus and<br />

distribution line lay-down trade-offs.<br />

• Power transmission modeling tools such as<br />

PowerWorld Simulator were useful during<br />

the implementation stage to conduct<br />

trade studies on various power source and<br />

load balance alternatives.<br />

• General-purpose physics modeling and<br />

discrete event simulation models using<br />

tools such as Simulink ® and eXtend<br />

were useful for end-to-end system and<br />

device-specific performance trade-offs.<br />

A useful outgrowth of this modeling and<br />

simulation effort was the ability to employ<br />

both discrete and continuous modeling<br />

techniques in an integrated, end-to-end<br />

performance assessment, linked to live<br />

energy-generation and storage resources.<br />

Energy Surety<br />

Energy Security<br />

Defensive mechanisms that respond to a<br />

wide range of security threats and reduce<br />

vulnerabilities address an important attribute<br />

of energy surety. These mechanisms draw<br />

on <strong>Raytheon</strong>’s core competencies in cybersecurity,<br />

critical infrastructure protection,<br />

command and control, situational awareness,<br />

environmental data modeling and<br />

analytics, and secure communications.<br />

We have expanded our command and control<br />

situational awareness functionality to<br />

include energy-related resources (generation,<br />

storage and loads). These monitoring functions<br />

now provide the historical, current and<br />

predictive operational state of mission-critical<br />

energy subsystems. Secure, reliable wired<br />

and wireless communications technologies<br />

are being effectively applied to develop<br />

secure SCADA (supervisory control and data<br />

acquisition) capabilities that address the<br />

high risk of cyberattacks against the energy<br />

infrastructure.<br />

Physical security risks associated with the<br />

energy infrastructure are cost effectively<br />

addressed as part of a comprehensive critical<br />

infrastructure protection (CIP)-based suite of<br />

sensing, defense and deterrence capabilities<br />

demonstrated and matured in <strong>Raytheon</strong>’s<br />

existing CIP solutions.<br />

Forecasting and Planning<br />

<strong>Raytheon</strong> addresses the challenges of energy<br />

demand forecasting and planning by<br />

employing weather, social and technology<br />

modeling techniques to analyze trends<br />

and to project probabilities of occurrence<br />

of a wide range of factors that influence a<br />

system’s energy profile. <strong>Raytheon</strong>’s environmental<br />

weather modeling capabilities, linked<br />

with our partnerships in academia, government<br />

and industry, build a strong foundation<br />

for providing these capabilities.<br />

Closing the Gaps<br />

As shown in Figure 2, <strong>Raytheon</strong>’s strengths<br />

align with many of our customers’ energy<br />

solution gaps. The application of a total<br />

system and full life-cycle approach, along<br />

with appropriate expertise, enhances energy<br />

surety. The energy system is better managed,<br />

improving efficiency and reducing costs.<br />

Better defenses are provided to counter<br />

physical and cyber threats. •<br />

Ron Williamson and Bob Gerard

Advanced<br />

Chemical<br />

Battery<br />

Technologies:<br />

The Lithium<br />

Revolution<br />

The ability to provide<br />

reliable, long-lasting<br />

power to portable and<br />

compact systems is a<br />

key performance<br />

characteristic for a<br />

variety of government<br />

and defense products,<br />

ranging from radios to<br />

unmanned systems.<br />

Feature<br />

Many of us are aware of a number of technologies that have followed some variant of<br />

“Moore’s Law” for growth in long-term performance, but advances in battery technology<br />

have been more modest. The increased presence of power-hungry portable devices<br />

(e.g., smart phones, personal digital assistants and their military counterparts) as well as the push<br />

to clean hybrid or all-electric vehicles has intensified the focus on — and public and private sector<br />

investment in — battery chemistry and development. This article highlights recent developments in<br />

lithium battery technologies that may advance the current state of the art and meet the increasing<br />

energy needs of our customers.<br />

Battery Fundamentals<br />

A battery is a device that converts stored chemical energy, in the form of metals and electrolytes,<br />

into electric current through internal reactions at the battery’s positive and negative terminals.<br />

Performance of any battery is dependent on three technology areas: the chemistry that generates<br />

the electrons, the electrodes that provide half of the reaction and collect and distribute the electrons,<br />

and the electrolytes that provide the remaining chemistry and the internal pathway for the<br />

electron flow.<br />

Electrical current begins to flow when a load is applied connecting the two battery terminals.<br />

Without the load providing the path from the negative to the positive terminal, the chemical reaction<br />

does not take place and the battery remains charged. A single unit of a battery, commonly<br />

called a cell, will have a characteristic voltage range between charged and discharged states based<br />

on the electrochemical properties of the materials used and the specific reactions that occur in the<br />

electrolytic solution between the two terminals.<br />

There are basically two types of batteries. A primary battery is one where the energy is exhausted<br />

after the active materials are consumed (e.g., carbon-zinc, silver oxide and alkaline). A secondary<br />

battery is one where the active materials can be regenerated by charging (e.g., lead acid, lithium ion,<br />

nickel cadmium or NiCd, nickel metal hydride or NiMH).<br />

The specific materials used within a battery control its voltage; each different reaction has a characteristic<br />

voltage value. Take a car battery as an example. A single cell of a typical automotive<br />

lead-acid battery has a negative plate made of lead (Pb) and a positive plate made of lead dioxide<br />

(PbO2 ), both of which are placed into a strong electrolyte solution of sulfuric acid (H2SO4 ) and<br />

water (H2O). When placed in aqueous solution, the sulfuric acid separates into a hydrogen ion (H + )<br />

–<br />

and a hydrogen sulfate ion (HSO4 ). During battery discharge, a reaction takes place at the negative<br />

terminal, where the lead combines with the hydrogen sulfate ion to create lead sulfate (PbSO4 ),<br />

a hydrogen ion and two electrons (e – ) that drive the load (starting the engine). At the positive<br />

– + terminal during discharge, lead dioxide (PbO2 ), hydrogen sulfate ions (HSO4 ), hydrogen ions (H )<br />

plus the returning electrons from the negative terminal create lead sulfate on the lead dioxide<br />

–<br />

plate and water. As the battery discharges, both plates build up lead sulfate, and the HSO4 concentration<br />

decreases in the electrolyte solution. This reaction generates a characteristic voltage of<br />

-0.356 volts at the negative plate and +1.685 volts at the positive plate, or about 2 volts per cell,<br />

so by combining six cells in series, a standard 12-volt battery is formed. To recharge, current is applied<br />

to the battery from the alternator with the<br />

Secondary Battery Example<br />

Automotive Lead-Acid<br />

Negative terminal (Pb):<br />

discharge �<br />

– Pb + HSO4 � PbSO4 + H + + 2e – (-0.356 V)<br />

� charge<br />

Positive terminal (PbO2 ):<br />

discharge �<br />

– + – PbO2 + HSO4 + 3H + 2e � PbSO4 + 2H2O (1.685 V)<br />

� charge<br />

Figure 1. The process within a common<br />

automotive lead-acid battery is a familiar<br />

example that illustrates the basic operation of<br />

all chemical batteries.<br />

additional electrons reacting to regenerate lead,<br />

lead dioxide, and hydrogen sulfate ions. Figure 1<br />

summarizes these chemical processes.<br />

Advances in Battery <strong>Technology</strong><br />

Figure 2 identifies several milestones in the<br />

evolution of battery technology. The introduction<br />

of lithium-based batteries in past decades was<br />

revolutionary in that battery performance rapidly<br />

improved after years of attaining only small<br />

incremental gains over the universal lead-acid<br />

technology.<br />

Why lithium? Conventional, commercially available<br />

battery technologies typically have energy<br />

densities on the order of tens of watt-hours per<br />

Continued on page 10<br />

RAYTHEON TECHNOLOGY TODAY <strong>2011</strong> ISSUE 1 9

ENGINEERING PROFILE<br />

Tony Marinilli<br />

Chief Hardware<br />

Engineer, ET&MA<br />

With more than<br />

32 years at<br />

<strong>Raytheon</strong>, Tony<br />

Marinilli’s considerable<br />

experience<br />

suits his current<br />

position as chief<br />

hardware engineer<br />

for <strong>Raytheon</strong><br />

Engineering,<br />

<strong>Technology</strong> and Mission Assurance.<br />

As a member of the corporate Engineering team,<br />

Marinilli provides technical leadership and<br />

supports the development of innovative solutions<br />

that ensure mission success. He supports<br />

hardware development by driving performance,<br />

processes, innovation and the implementation<br />

of disruptive, leading-edge technologies.<br />

Before his current position, Marinilli was a principal<br />

engineering fellow for <strong>Raytheon</strong> Integrated<br />

Defense Systems and a senior manager and<br />

engineering fellow within the Northeast region’s<br />

Radar Design and Electronics Laboratory.<br />

He was also responsible for radar technology<br />

and strategic planning and acted as principal<br />

engineer and engineering section manager for<br />

the microwave systems department within the<br />

Missile and Radar Systems Laboratory.<br />

Among his many accomplishments, Marinilli<br />

has published 13 papers in the areas of missile<br />

seekers, photonic technology, satellite communications<br />

and solid-state transmitters. He has<br />

contributed to the design and development of<br />

low-noise, microwave-power amplifiers while<br />

utilizing microwave integrated circuits and<br />

microwave monolithic integrated circuits for<br />

advanced radar systems.<br />

Marinilli attributes his success to his inquisitive<br />

nature, saying, “I have always been curious and<br />

persistent. I’m not discouraged by failure, and<br />

I enjoy making linkages between obscure and<br />

unrelated facts.”<br />

In addition to his career, Marinilli is actively<br />

involved in promoting initiatives among institutions<br />

of higher education that help increase the<br />

number of students preparing for and entering<br />

careers that employ engineering, science,<br />

technology and mathematics.<br />

10 <strong>2011</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Feature<br />

Continued from page 9<br />

kilogram. This is dictated by the chemistry<br />

used as well as the ionic transport media —<br />

the electrolytes. Lithium is a highly reactive<br />

element with the additional advantage that<br />

its ionic size (atomic number 3) is relatively<br />

small compared with other elements; this<br />

facilitates ionic transport. In order to utilize<br />

the stored chemical energy in an element<br />

or compound, the reaction with oxygen<br />

or other reactants needs to be controlled,<br />

and paths of electrons and ions need to be<br />

separated. Consequently, reaction rates are<br />

limited by ionic conductivity through the<br />

electrolyte. In lead-acid automotive batteries<br />

the ionic species is lead traveling through a<br />

sulfuric acid electrolyte. Since the liquid<br />

allows fast ionic conduction, these batteries<br />

can produce great power for, as an example,<br />

starting the engine. The downside, however,<br />

is that the chemicals are quickly depleted<br />

and the reaction slows. Therefore, the stored<br />

energy tends to be low, and the battery<br />

needs to be recharged to reverse the reaction<br />

and restore the level of stored energy.<br />

With an atomic number of 3, lithium is the<br />

lightest of all metals. The electrodes of a<br />

lithium-ion battery are made of a lithium<br />

compound, (e.g., lithium phosphate) and<br />

carbon, so they are generally much lighter<br />

than other types of rechargeable batteries<br />

of the same size. Lithium is also a highly reactive<br />

element (located on the far left of the<br />

periodic table of elements), meaning that<br />

a lot of energy can be stored in its atomic<br />

bonds, resulting in a very high energy density.<br />

A typical lithium-ion battery can store<br />

200 watt-hours of energy in 1 kilogram of<br />

Rechargeable<br />

Nickel-Metal Hydride Cell<br />

~80 Wh/kg<br />

Rechargeable<br />

Nickel-Cadmium Cell<br />

~50 Wh/kg<br />

Rechargeable<br />

Lead-Acid Battery<br />

~30 Wh/kg<br />

Advanced Batteries<br />

battery versus the automotive lead-acid<br />

battery, which can store about 30 watthours<br />

per kilogram.<br />

Lithium-based batteries’ higher energy<br />

density brings with it greater challenges<br />

to contain and control the chemical reaction.<br />

The first lithium battery experiments<br />

conducted in Japan and the U.S. were<br />

failures due to the explosive nature of<br />

the compounds used. The end result is a<br />

compromise that sacrifices performance<br />

for safety, an approach that utilizes lithium<br />

not in its elemental form, but in compound<br />

form. In this way, the explosive nature of<br />

pure lithium can be controlled, but at the<br />

expense of reduced energy storage.<br />

Application in Hybrid Power Systems<br />

While they find common application in<br />

portable devices, lithium batteries play an<br />

important role as energy storage devices<br />

in hybrid power systems being developed<br />

at <strong>Raytheon</strong>. <strong>Raytheon</strong> designed, and is<br />

now testing, hybrid power systems using<br />

advanced technology lithium-ion battery energy<br />

storage with solar, wind and generator<br />

inputs to provide power for forward-operating<br />

equipment in support of the warfighter.<br />

These systems are designed to provide<br />

power surety as well as significant reduction<br />

in fuel usage, resulting in fewer fuel sorties,<br />

thus lowering the casualty rate, reducing<br />

maintenance, and lowering total cost of<br />

ownership. Environmentally ruggedized<br />

batteries based on lithium with long-life,<br />

deep-discharge capability, high-efficiency,<br />

and high power and energy densities are<br />

instrumental in realizing the advantages inherent<br />

within these hybrid power systems.<br />

1859 1960 1980 1990 2000 2010 2020<br />

Optimized Li-ion Cells<br />

– Nano-Surface Electrodes<br />

– Composite Electrodes<br />

~1,000 Wh/kg<br />

Lithium-Thionyl-CI Battery<br />

~350 Wh/kg<br />

Lithium-S02 Battery<br />

~250 Wh/kg<br />

The Lithium Revolution<br />

1990 and Beyond<br />

Figure 2. Battery <strong>Technology</strong> Evolution. Lithium-based batteries offer significant<br />

improvement in energy density over other known chemistries.

Courtesy of Polyplus Corporation, Berkeley, Calif., with permission of<br />

Dr.Steven J. Visco, chief technical officer, Polyplus Battery Company.<br />

The Future<br />

Lithium-ion batteries have made tremendous<br />

inroads in the commercial market, and<br />

their use in providing the driving power in<br />

automotive applications has now become<br />

possible. Boston Power’s lithium-ion batteries<br />

are a good example. Their rechargeable<br />

batteries, based on a proprietary lithium<br />

compound, produce energy densities of<br />

about 180 Wh/kg, and power densities of<br />

about 440 W/kg. These batteries are commercially<br />

available and well suited for long<br />

missions. Another promising lithium-ion<br />

variant is offered by A123 for the automotive<br />

market. These batteries are based on<br />

lithium iron phosphate nanotechnology,<br />

which creates an extremely large surface<br />

area on the electrodes for the chemical<br />

reaction to take place, and results in high<br />

power densities up to 2,000 W/kg. The large<br />

surface area provides for quick discharge to<br />

accelerate a vehicle and fast recharging.<br />

Several companies continue development of<br />

a pure lithium-based battery. Success in this<br />

will open up many applications, and it will<br />

be a breakthrough in the automotive world.<br />

Feature<br />

Chemistry<br />

• Complex chemical systems based on lithium<br />

compounds (e.g., lithium thionyl chloride or<br />

lithium manganate).<br />

• Energy density typically 350 Wh/kg.<br />

Future<br />

• Lithium-air and lithium-water cells offer<br />

simpler chemistry.<br />

• 1,200 Wh/kg demonstrated (Polyplus).<br />

Electrodes<br />

• Conventional graphite and lithium compounds used.<br />

• Surface area limits reaction rate and current flow.<br />

Future<br />

• Nano and bio-inspired technologies offer<br />

extremely high surface area materials.<br />

Courtesy of Prof. Daniel E. Morse, Institute for Collaborative Biotechnologies, California NanoSystems Institute, and the Materials Research Laboratory, University<br />

of California, Santa Barbara, from “Materials for New Generation High-Performance Lithium Ion Batteries.”<br />

Courtesy of Dr. Mason K. Harrup, “Advanced Membranes Produce Longer<br />

Lasting and Safer Batteries,” Idaho National Laboratory.<br />

Electrolytes<br />

• Liquids and gels used for high ionic conductivity<br />

and reactivity.<br />

• Downside: fast charge or discharge can lead to<br />

excessive heating and explosions.<br />

• Power densities ~100 to 250 W/kg.<br />

Future<br />

• Solid state electrolytes, ceramic or polymers.<br />

Figure 3. Lithium battery development to achieve large energy and power densities seeks to<br />

optimize performance within three technology areas.<br />

One company that has not given up on pure<br />

lithium is California-based Polyplus. It has<br />

developed a method to contain pure lithium<br />

in a solid electrolytic capsule that controls<br />

the violent reaction of lithium and oxygen.<br />

An experimental cell from Polyplus recently<br />

set a new record in energy density of 1,200<br />

Wh/kg. The company’s next challenge is to<br />

increase the power density of their system.<br />

The quest for more powerful and energetic<br />

batteries continues, and the available<br />

energy of lithium is still not fully tapped<br />

(lithium has an energy density potential<br />

of ~12,000 Wh/kg, close to gasoline at<br />

~13,300 Wh/kg). Consequently, another<br />

performance leap is anticipated for the<br />

near future. Figure 3 highlights ongoing<br />

developments in the three technology areas<br />

of chemistry, electrodes and electrolytes.<br />

Successful development and merging of<br />

these technologies could achieve an energy<br />

density of ~3,000 Wh/kg and a power<br />

density of ~2,000 W/kg. •<br />

Tony Marinilli, Peter Morico, Bart VanRees<br />

Contributor: Steve Klepper<br />

ENGINEERING PROFILE<br />

Peter Morico<br />

Engineering Fellow,<br />

IDS<br />

As the Power<br />

Cell Enterprise<br />

Campaign (PCEC)<br />

lead, Peter Morico<br />

is identifying and<br />

promoting powerrelated<br />

technology<br />

to bring about<br />

discriminating<br />

advantages<br />

to <strong>Raytheon</strong> products and pursuits. The<br />

PCEC enables technologies to grow product<br />

lines, and offers substantial benefits to our<br />

customers.<br />

Morico’s interest in power design developed<br />

early. At 13, he obtained his advanced-class<br />

amateur radio license. By 15, he had erected a<br />

40-foot tower complete with a four-element<br />

Yagi antenna. He also designed and built a<br />

2 kV power supply as well as a 1 kW linear<br />

amplifier using parts scavenged from old<br />

television sets and surplus military electronics.<br />

Morico began his professional career<br />

at Hughes Space and Communications,<br />

designing hybrid microcircuits and power<br />

supplies for military satellites. His passion for<br />

power design moved him from California to<br />

Massachusetts to design the first generation of<br />

kinetic hit-to-kill infrared seeker electronics.<br />

An 11-year <strong>Raytheon</strong> veteran, Morico has<br />

led power conversion design teams for<br />

several major surface radar programs.<br />

Speaking about the value of experience,<br />

he said, “With more than 30 years in the<br />

defense and aerospace industry, it is clear to<br />

me that the body of knowledge of what does<br />

not work far exceeds that of what worked the<br />

first time. This is where experience is vitally<br />

important, because no one is teaching what<br />

doesn’t work.”<br />

Morico has led a number of internal research<br />

and design projects and serves on the board<br />

of directors of the Massachusetts Hydrogen<br />

Coalition. He is frequently called on to solve<br />

difficult technical problems and conducts<br />

customer, academia and industry briefings.<br />

RAYTHEON TECHNOLOGY TODAY <strong>2011</strong> ISSUE 1 11

Feature<br />

Electronic devices that never<br />

need to have their power source<br />

replaced and can function<br />

unattended for 100 years.<br />

Science fiction? No, science fact.<br />

<strong>Raytheon</strong>’s customers need compact,<br />

reliable and long-lived, high<br />

energy density power supplies for<br />

applications such as sustainable low-power<br />

electro-mechanical devices. One such application<br />

is unattended embedded stress<br />

monitoring devices using microelectromechanical<br />

systems (MEMS) that are located in<br />

inaccessible areas such as aircraft structures,<br />

bridges and buildings. These applications<br />

all beg for a robust, viable, cost-effective<br />

power supply that can satisfy the long-<br />

duration needs and sustainable power<br />

required for predicting the onset of a<br />

structural failure, and then conveying this<br />

information to allow for pre-emptive action<br />

and avoid catastrophe.<br />

These isolated sensors are only practical if<br />

they are small, long-lived and unaffected<br />

by harsh environmental conditions. Typical<br />

chemical-based batteries may last a couple<br />

of years, whereas autonomous sensors require<br />

miniature power sources with much<br />

longer lifetimes. For sensor networks in<br />

harsh, inaccessible environments, battery<br />

replacement can be a practical impossibility<br />

or prohibitively expensive. There is also a<br />

need for MEMS technology that can overtly<br />

or covertly sense mechanical motion,<br />

temperature changes, chemicals and<br />

biological species. This requires long-term<br />

sources of compact energy. Applications<br />

include radio frequency identification (RFID)<br />

tags, autonomous sensors, and long-lived,<br />

12 <strong>2011</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Power Sources<br />

That Last a Century<br />

miniature, wireless transmitters. The discriminator<br />

in all of these technologies is<br />

long-term, reliable, high-energy density that<br />

is addressed using devices that contain embedded<br />

betavoltaic power sources, referred<br />

to, in general terms, as “atomic batteries.”<br />

Atomic Battery Physics<br />

Atomic batteries are power sources utilizing<br />

the emissive properties of a certain class<br />

of radioactive isotopes. These unstable<br />

isotopes are mostly man-made in nuclear<br />

reactors. They are a form of naturally<br />

occurring elements, where the normal distribution<br />

of protons and neutrons in the<br />

nucleus is disturbed, rendering it unstable.<br />

Over time it is destined to return to a stable<br />

state through an internal restructuring<br />

called transmutation. A consequence of<br />

transmutation is the emission of some<br />

nuclear constituents that convert the<br />

material into a different element. These constituents<br />

primarily include highly energetic<br />

particles such as alpha particles (helium<br />

nuclei) and beta particles (electrons).<br />

Upon impact with matter, these constituents<br />

deposit their energy through ionization<br />

in a predictable manner, creating tracks<br />

of secondary charged particles, such as<br />

electrons and ions similar to electron-hole<br />

pairs in semiconductors. Eventually, the<br />

particles are captured by the encountered<br />

material when their kinetic energy dwindles<br />

down to zero. In all cases, the total energy<br />

content of each of these particles, initially<br />

in the form of energetic charged particles,<br />

eventually emerges as deposited energy in<br />

the form of heat. Some atomic battery technologies<br />

are based on capturing the copious<br />

amounts of charged particles created during<br />

ionization, while others utilize the resulting<br />

generated heat.<br />

Radioisotope Thermoelectric Generator<br />

Several applications have exploited the<br />

heat generation aspects of atomic batteries.<br />

One is the radioisotope thermoelectric<br />

generator (RTG), which has been used in<br />

numerous NASA deep-space missions that<br />

cannot implement photocells as power<br />

sources; e.g., missions to the outer regions<br />

of the solar system, where power generation<br />

by sunlight is ineffectual. The basis for<br />

these types of power generators consists<br />

of hundreds of Curies of the alpha particleemitting<br />

isotope Pu-238 embedded in<br />

ceramics. This produces energy by heating<br />

the ceramic mass through alpha particle<br />

energy absorption, with subsequent thermoelectric<br />

conversion to useful electricity.<br />

These RTGs have no moving parts and have<br />

been the major source of power in at least<br />

41 NASA missions on satellites expected to<br />

operate for more than 20 years. Another<br />

lower power application of this type of<br />

technology is found in pacemakers (see<br />

Figure 1). This application uses about three<br />

Curies of Pu-238. Weighing only about<br />

three ounces, the pacemaker produces<br />

approximately 1 milliwatt of power while<br />

contributing a generally acceptable typical<br />

radiation dose of 100 millirems per year<br />

Figure 1. Pacemaker RTGs – Technologies<br />

based on “atomic batteries” are not new<br />

and have been used in various applications<br />

for many years.

to the patient. Although in use for a number<br />

of years, this application was replaced<br />

several years ago when improvements in<br />

pacemaker technology reduced energy<br />

requirements to the point where lithium<br />

battery technology became viable.<br />

Betavoltaics<br />

Betavoltaics, another form of atomic battery,<br />

are the little brothers to RTGs; the<br />

difference is that this energy source is not<br />

based on the heat generated, but on its<br />

ability to generate sufficient quantities<br />

of material-ionizing beta particles. While<br />

betavoltaics are similar in concept to photovoltaic<br />

cells, there is a notable difference.<br />

Where photovoltaic cells harvest energy<br />

from interacting photons, betavoltaics function<br />

by capturing and converting the kinetic<br />

energy of energetic electrons, emitted from<br />

decaying radioactive isotopes, into large<br />

amounts of secondary electrons.<br />

Betavoltaics-powered devices may be<br />

engineered to be extremely robust. Since<br />

the source of power is electrons emitted<br />

from the isolated atomic nucleus, electron<br />

emission rates are immune from effects of<br />

stressful, harsh environmental conditions.<br />

Since this technology is based on feature<br />

sizes on the scale of an atom, betavoltaics<br />

show potential improvement in both<br />

energy density and total energy content,<br />

compared with conventional power sources<br />

such as AA batteries. This large energy<br />

density is attributed to the huge number<br />

of radioisotope atoms contained in a small<br />

amount of material (recall Avogadro’s number),<br />

and each atom is primed to unload its<br />

Type<br />

Lithium AA<br />

Battery<br />

Betavoltaic<br />

1 cm 2<br />

Power<br />

(mW)<br />

~1<br />

(1.5 V)<br />

~0.3<br />

(2 V)<br />

Total<br />

Energy<br />

(mWh)<br />

energy-generating beta particle emission at<br />

a rate that is only dependent, in a statistical<br />

manner, upon the particular isotope’s<br />

half life. This advantage in energy density is<br />

indicated in Table 1, which shows a relative<br />

comparison of capabilities for a notional<br />

betavoltaic battery design with those of a<br />

typical lithium AA battery.<br />

Two betavoltaic manifestations are<br />

possible: the so-called direct conversion<br />

category, where secondary electron-hole<br />

pairs are generated in P-N semiconductor<br />

diodes, or the vibrating cantilever concept<br />

that converts mechanical energy to electrical<br />

energy using a piezoelectric-driven, energyscavenging<br />

mechanical converter. Miniature,<br />

low-powered technology devices, based<br />

on either of these two general operational<br />

classes, hold the potential for the development<br />

and integration of tiny smart sensors<br />

that will never need their power supplies<br />

replaced. Specific designs based on<br />

atomic batteries are customized for their<br />

intended applications; some of the basics<br />

that help dictate the design are briefly<br />

discussed below.<br />

Direct Conversion Betavoltaics<br />

One unique rendering of betavoltaics is<br />

the direct conversion approach based on<br />

a P-N semiconductor diode such as gallium<br />

nitride (GaN) placed in direct contact<br />

with a source of beta particles. Figure 2<br />

is a notional design for the P-N junction<br />

method. In the figure, the source adjacent<br />

to the semiconductor is a thin plated film<br />

layer of a beta particle-emitting isotope. A<br />

typical useful source for these applications<br />

Volume<br />

(cm 3 )<br />

Weight<br />

(g)<br />

Total<br />

Energy<br />

Density<br />

(mWh/g)<br />

4,350 7.9 14.5 300<br />

10,512 0.025 0.08 131,400<br />

Table 1. Comparison of a lithium AA battery with conceptual betavoltaic power source.<br />

Source: M.V.S Chandrashekhar, et al., “Design and Fabrication of a 4H SiC Betavoltaic Cell,”<br />

Cornell University.<br />

I GEN<br />

+<br />

−<br />

Feature<br />

Incident beta radiation<br />

p-semiconductor<br />

n-semiconductor<br />

Built-in<br />

electric<br />

field<br />

Figure 2. Schematic betavoltaics P-N junction<br />

power source. One betavoltaic conceptual<br />

design configuration is based on “direct<br />

conversion” that derives small currents from<br />

electron-hole pairs produced by impinging<br />

beta rays in P-N junction depletion zones.<br />

is a 5-micron layer of the pure beta particleemitting<br />

isotope Ni-63, providing an activity<br />

of roughly 0.25 milliCuries, that emit beta<br />

particles over a wide range of energies, with<br />

an average energy of 17 kiloelectronvolts<br />

(keV) and peaking at 67 keV. On average,<br />

half of all emitted beta particles are transported<br />

toward the semiconductor P-layer<br />

where, upon interacting with the material,<br />

some beta particles are backscattered from<br />

the interface and do not penetrate into the<br />

semiconductor.<br />

Those beta particles that make it into the<br />

semiconductor begin losing energy quickly,<br />

primarily through ionization, generating<br />

electron-hole pairs that are captured once<br />

all their energy is dissipated. Beta-particle<br />

path lengths depend on initial beta-particle<br />

energy and the material through which it<br />

is transported; in general, they are in the<br />

range of a few tens of micrometers. For this<br />

energy transfer to be effective as a power<br />

source, beta particles should be able to<br />

reach deep enough into the semiconductor<br />

to deposit most of their energy, through<br />

ionization, in the P-N junction depletion<br />

region. Those electron-hole pairs generated<br />

in the depletion region — where the<br />

number of pairs depends on material band<br />

gap and beta energy — are swept across<br />

the junction by the generated electric field<br />

and are converted into useful electricity to<br />

power an attached load (Figure 2).<br />

Continued on page 14<br />

RAYTHEON TECHNOLOGY TODAY <strong>2011</strong> ISSUE 1 13

Feature<br />

Continued from page 13<br />

These types of betavoltaics generally<br />

develop power levels that can approach<br />

1 milliwatt. Radiation-tolerant, wide band<br />

gap semiconductors are ideal candidates for<br />

direct-conversion betavoltaics. Several semiconductors<br />

have been identified as ideally<br />

suited for these applications. They include<br />

GaN, aluminum gallium nitride, silicon<br />

carbide and diamond. Since electrons are<br />

rapidly absorbed as they emerge from the<br />

radioactive plated surface, the useful isotope<br />

plating thickness is limited to a few<br />

micrometers at best. Therefore, methods<br />

to scale up the output of these devices depend<br />

primarily on increasing direct contact<br />

surface area. Honsberg, et al., described<br />

a conceptualized approach to address this<br />

issue. It consists of mating GaN layers on<br />

each side of thin Ni-63 wafers in order to<br />

maximize output power. Using this GaN-<br />

isotope sandwich design to capture a large<br />

fraction of emitted beta particles, the<br />

ability to develop a 2.3 volt open circuit<br />

voltage with a short circuit current of<br />

1.1 microamperes was reported. 1 <strong>Raytheon</strong><br />

currently produces GaN devices for highpower<br />

microwave applications and also has<br />

an established and demonstrated capability<br />

for growing thin-film chemical vapor<br />

deposition diamond. With this established<br />

presence in developing materials that are<br />

highly desirable for betavoltaics-based<br />

power sources, <strong>Raytheon</strong> is in a good<br />

position to drive this technology forward.<br />

In light of the limited range of low-energy<br />

beta particles considered here, beta sources<br />

for direct conversion devices are considered<br />

to be relatively safe since they are literally<br />

stopped by the outermost dead skin layer.<br />

There are a number of radiologically-safe<br />

pure beta emitting isotopes with half-lives<br />

ranging from 2.6 to 100.3 years and with<br />

energy densities as high as 10 11 kilojoules<br />

per cubic meter (kJ/m 3 ). In comparison,<br />

diesel fuel has an energy density of approximately<br />

4x10 7 kJ/m 3 , illustrating that<br />

betavoltaic sources can have very high energy<br />

densities and, consequently, long lives.<br />

The choice of the appropriate isotope<br />

is dictated primarily by operational<br />

14 <strong>2011</strong> ISSUE 1 RAYTHEON TECHNOLOGY TODAY<br />

Radioactive<br />

Source<br />

Half-life<br />

(year)<br />

Specific<br />

Activity<br />

(GBq/g)<br />

considerations, where the isotope is selected<br />

based in part by matching its half-life to<br />

the application’s expected operational life.<br />

Use of a pure beta emitter is also preferred,<br />

since generating other decay products can<br />

lead to a significant dose to the operator<br />

and possible damage to the direct conversion<br />

device semiconductor when long<br />

term exposures are required. In general, a<br />

long half-life pure beta isotope provides<br />

prolonged battery life at the expense of<br />

generating low power, while a short halflife<br />

isotope provides higher power at a more<br />

limited sustainable life span. Table 2 shows<br />

some candidate beta-emitting isotopes and<br />

their relevant properties.<br />

Self-Reciprocating Cantilever<br />

Another unique betavoltaic application is<br />

based on a vibrating piezoelectric cantilever<br />

concept, the self-reciprocating cantilever.<br />

This functions initially as a charge-to-motion<br />

Maximum<br />

Decay Energy<br />

Average<br />

Decay Energy<br />