4 - ARMO GLOBAL

4 - ARMO GLOBAL

4 - ARMO GLOBAL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

global rotomoulding community newsletter • www.armo-global.org<br />

April 2010 • en<br />

4<br />

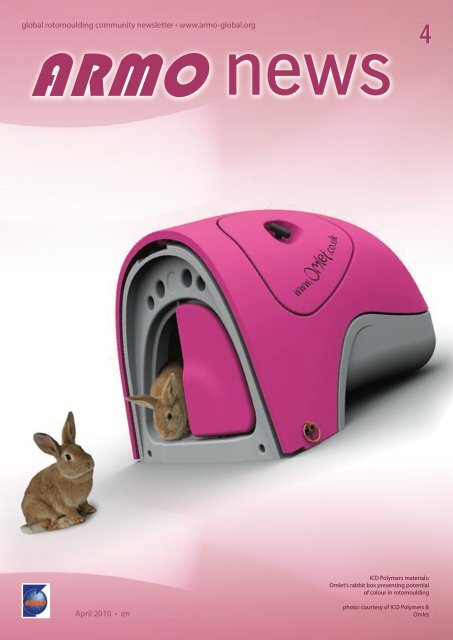

ICO Polymers materials:<br />

Omlet’s rabbit box presenting potential<br />

of colour in rotomoulding<br />

photo: courtesy of ICO Polymers &<br />

Omlet

Dear Readers,<br />

Welcome to this year’s second issue of <strong>ARMO</strong><br />

NEWS. The issue is sponsored by Orenda<br />

Automation Technologies Inc.<br />

In this issue, I intend to bring you even further into the<br />

global, international world of <strong>ARMO</strong>, so that you can learn<br />

more about the organisations it brings together, the people<br />

involved in the activities of <strong>ARMO</strong>, the type of work they do,<br />

as well as the final outcomes of their activities.<br />

In the first part of this newsletter, as usual, I share with<br />

you the news from the world of rotomoulding and the<br />

updated calendar of events organised by individual <strong>ARMO</strong><br />

associations. The New President of the Association of<br />

Rotational Moulders of Southern Africa (ARMSA), in his<br />

opening address presents the people from the organising<br />

committee of ARMSA and the most immediate plans for his<br />

organisation. Make sure you check out Mr. Clive Robertson’s<br />

remarkable, truly “rotomoulding” resume.<br />

France’s first Plastic EcoDesign<br />

Center in Lyon organizes its<br />

Open Doors Day<br />

Officially the Center was set up in November 2009. It was<br />

created to promote research and development, organize<br />

trainings and also give advice to companies of the Plastic<br />

& Composite processing industry. In 2010 the Plastic<br />

EcoDesign Center was enlarged by more than 400 m2 of<br />

exhibition surface. On the 4-th of May 2010 the Center<br />

organizes its “Open Doors Day” in Lyon. The French Member<br />

of the <strong>ARMO</strong> – AFR will be involved. The organization<br />

will present the materials and the samples of the rotational<br />

moulding technology.<br />

4<br />

photo: courtesy of ICO Polymers<br />

Moving on, the highlight of this issue is the article by Mr.<br />

Ian Hansen on the new specification of the funnel, officially<br />

named by the Board of <strong>ARMO</strong> as the “<strong>ARMO</strong> funnel”. <strong>ARMO</strong><br />

has no doubt that the standardisation of the funnel will<br />

improve the quality of the rotational moulding technology.<br />

In turn, the “Supplier’s Corner” presents an interesting<br />

article on the psychology of colour, written by Mr. John<br />

Steel of Ico Polymers, featuring extraordinary photographs.<br />

Further pages present descriptions of industry events<br />

to be held soon by the member-organisations of<br />

<strong>ARMO</strong>, including the series of events held by the French<br />

organisation AFR at the first facility of its kind in France, the<br />

modern Plastic EcoDesign Center in Lyon. You are welcome<br />

to participate!<br />

Wishing you a pleasant read, I encourage you to<br />

send me your reflections and comments,<br />

Anna Walorek-Iwanowska<br />

<strong>ARMO</strong> Secretariat Manager

<strong>ARMO</strong> calendar - upcoming events<br />

NAME DATE PLACE CONTACT<br />

AFR<br />

Centre Plastique Ecodesign<br />

BPF seminar :<br />

»Design Innovation in<br />

Rotational Moulding”<br />

AFR designers and<br />

rotomoulding meeting<br />

Quality in Rotomoulding.<br />

Advanced training course for<br />

intermediate technicians<br />

03.05.2010<br />

Inaguration<br />

03.06.2010<br />

Workshop with<br />

designers<br />

19.05.2010<br />

ARMA Rotomould 2010 20-23.06.2010<br />

StAR Regional Meeting - OEM<br />

Focus<br />

StAR Regional Meeting - OEM<br />

Focus<br />

Rotation 2010 Conference 9-10.09.2010<br />

Lyon/France<br />

Telford/United<br />

Kingdom<br />

03.06.2010 Lyon/France<br />

18.06.2010 Alessandria /Italy<br />

June, 2010 Mumbai<br />

August, 2010 Chennai<br />

Queenstown/New<br />

Zealand<br />

Euphoria Golf<br />

Estate and Hydro<br />

Naboomspruit, South<br />

Africa<br />

AFR Conference Annuel 22-23.09.2010 Lyon/France<br />

Fall Training course for<br />

Rotomoulding technicians<br />

ARM International Annual<br />

Meeting Theme: “The Global<br />

State of Rotomoulding”<br />

September, 2010 Italy<br />

CEE ARM/ARM CE October, 2010<br />

StAR Regional Meeting OEM<br />

Focus<br />

StAR Annual International<br />

Conference<br />

4th Nordic ARM conference<br />

02-05.10.2010 Montreal/Canada<br />

November, 2010 Delhi<br />

23-25.01.2011 Mumbai<br />

First quarter of<br />

2011<br />

Slubice/Frankfurt<br />

Oder<br />

Poland/Germany<br />

Denmark<br />

Anne De Lansalut,<br />

Email: a.delansalut@allize-plasturgie.<br />

com<br />

Doreen Greenaway<br />

BPF Events Team<br />

Direct Tel: +44 (0) 20 7457 5047<br />

events@bpf.co.uk<br />

Anne De Lansalut,<br />

Email: a.delansalut@allize-plasturgie.<br />

com<br />

Matteo Martinenghi – Secretariat<br />

info@aisr.it<br />

Michelle Lorenzo<br />

mlorenzo@rotationalmoulding.com<br />

www.rotationalmoulding.com<br />

S.B. Zaman<br />

arnacz@sify.com<br />

S.B. Zaman<br />

arnacz@sify.com<br />

Anle van Niekerk<br />

Tel. +27 82 782 0413<br />

Email: anle@accelerate.co.za<br />

Anne De Lansalut,<br />

Email: a.delansalut@allize-plasturgie.<br />

com<br />

Matteo Martinenghi – Secretariat<br />

info@aisr.it<br />

Adam Webb<br />

ARM International Board<br />

http://www.armmeetings.org/<br />

www.ceerotomoulding.org<br />

www.rotational-moulding.de.<br />

S.B. Zaman<br />

arnacz@sify.com<br />

S.B. Zaman<br />

arnacz@sify.com<br />

Ronny Ervik<br />

ronny@opd.no<br />

www.armo-global.org | info@armo-global.org

Association of Rotational Moulders<br />

Southern Africa (ARMSA)<br />

Please find below a welcome letter written by Clive Robertsons<br />

– the new ARMSA Chairman. Clive is introducing ARMSA<br />

new team.<br />

We are pleased to notify you all that a new ARMSA<br />

Committee was elected at our AGM on Thursday 18th<br />

March 2009. The new committee consists of the following:<br />

Chairman:<br />

Mr. Clive Robertson - cRc Rotoconsult<br />

Vice Chairman:<br />

Piet van Niekerk - Accelerate Design<br />

Secretary/Treasurer:<br />

Miss Anle van Niekerk - Accelerate Design<br />

Committee Members:<br />

Mr Wayne Wiid - Pioneer Plastics<br />

Mr Gary Bolt - Atlas Plastics<br />

Mr Piet van Niekerk - Accelerate Design<br />

Mr Nick Aggett - Sasol Polymers<br />

Mr Rod Cairns - Jo Jo Tanks<br />

Mr Graham Randall - Lomotek Polymers<br />

Mrs Loodjie van Dyk - Sinvac Plastics<br />

4<br />

Brief Summary of Clive Robertson:<br />

I would like to introduce our new team and we sincerely<br />

hope that with time we will get to meet all of you. I have<br />

already met a lot of you but have to admit that I may have<br />

difficulty putting the name to the face next time round. I<br />

hope to get to meet all the rest during my tenure.<br />

We bid our warmest farewell to our Past Chairman Gary<br />

Lategan and Secretary Petro Geldenhys who in their own<br />

rights became Icons of the South African Rotomoulding<br />

Industry. We will miss both but know we can always draw<br />

on them for their experience and advise. Thanks to Gary<br />

and Petro for your commitment and dedication to ARMSA,<br />

<strong>ARMO</strong> and the around the world.<br />

We will need a bit of time to reorganize ourselves and<br />

get our communication channels sorted out but in the<br />

meanwhile we are alive and well down at the tip of Africa.<br />

Please take note of the new contact details and we will<br />

revert with any further information as we get organized.<br />

I certainly hope we can strengthen our communications and<br />

share our experiences for the benefit of the Rotomoulding<br />

Industry. Our 1st task is to finalize our up and coming Rotation<br />

2010 Conference scheduled for 9th and 10th September. We<br />

will keep you informed regarding format etc and I dare say<br />

try and convince some of you to join us as either speakers<br />

or delegates - we enjoy showing off our country and our<br />

hospitality - we even have good wine and beer!<br />

We would like to reaffirm our commitment to <strong>ARMO</strong><br />

and we would like to see improved interaction and<br />

communications moving forward.<br />

We are looking forward to working with all of you in the<br />

future!<br />

Best Regards<br />

Clive Robertson<br />

Clive is a ‘Farmer turned Plastician’! Educated in Plastics Technology at Pretoria Technicon and<br />

around the world with various Institutions, Industrial Marketing Rand Afrikaans University. With<br />

32 years experience in the Plastics Industry serving in the Injection Moulding Industry; as Training<br />

Manager for The Plastics Federation of SA; Technical Service and Sales of Engineering Plastics ,<br />

Technical Services Manager for Sasol Polymers PP Division , 1st Official Agent for Borealis in SA ,<br />

Affirm Marketing manufacture and supply of Colour Compounded Rotomoulding Powder and<br />

recently Market Development Director and Shareholder Lomotek Polymers.<br />

Introduced the 1st competitive Rotomoulding Powder to South Africa in 1994 from<br />

Borealis; Introduced the 1st locally Colour Compounded and Pulverised Rotomoulding<br />

Powder to SA in 1998 with Affirm Marketing. An Honoury Life Member of ARMSA and<br />

Fellow of the Plastics Institute of SA.<br />

Clive enjoys rugby and is an ardent parent supporter of his sons Schools 1st Rugby<br />

Team and supports The Sharks in the Super 14 Rugby. Other than that the<br />

Rotomoulding Industry - is said to have Roto Powder running in his veins.

Central & Eastern European Association<br />

of Rotational Moulders (CEE ARM)<br />

Association Francophone<br />

du Rotomoulage (AFR)<br />

Meeting of experts from the industrial design<br />

and rotational moulding industries<br />

On 3 June 2010, in Lyon (France) the Francophone Association<br />

of Rotational Moulding (AFR) is holding a meeting for the two<br />

complementary communities: industrial design specialists<br />

and rotomoulding experts. The aim of this undertaking is to<br />

promote networking, exchange views on the advantages<br />

and limitations of rotomoulding technologies and consider<br />

cooperation opportunities for new projects.<br />

The meeting is held at the Plastic Ecodesign Center (*),<br />

which opens its doors on 4 May 2010 and the AFR is<br />

involved, presenting rotomoulding at « Materiautech ». It<br />

presents a wide range of material samples, a clear proof<br />

that there are other options than just polyethylene.<br />

BPF offers rotomoulding seminar at PDM10<br />

The Rotational Moulding Group of the British Plastics<br />

Federation will host an innovation seminar on 19 May at<br />

the PDM exhibition, Telford. Manufacturers, designers and<br />

suppliers to the industry will address issues including:<br />

�<br />

�<br />

�<br />

�<br />

Association of Rotational Moulding<br />

Central Europe (ARM CE)<br />

ARM CE & CEE ARM co-prepare their Annual<br />

Meeting on the Polish – German border<br />

For the first time in the <strong>ARMO</strong> history two regional<br />

associations of the rotational moulding from Germany and<br />

Poland organize the Congress together.<br />

On the 31 of March 2010 the representatives of both<br />

organizations met on the Polish – German Border to set<br />

up the initial program of this joint project. ARM CE was<br />

represented by Oliver Wandres/MAUS, Ortwig Vogel/SAVO<br />

Cost competitiveness<br />

Surface finish and mould textures<br />

Moulding graphics<br />

Cutting edge design case study<br />

and Karsten Krohne/HAKO. And the CEE ARM was represented<br />

by: Austin Campbell/CAPS and Anna Walorek-Iwanowska<br />

The joint project will take place in the last quarter of 2010,<br />

in the buildings of the Viadrina International University,<br />

located on the Polish and German sides of the border.<br />

The conference will have a very rich program of lectures,<br />

a unique border character and plenty of the additional<br />

attractions we will inform you about soon. All those<br />

interested in the Annual Meeting participation, please<br />

contact us at: info@ceerotomoulding.org.<br />

On and September 010 : Rotomoulding<br />

Technology Days<br />

Also held at the Plastic Ecodesign Center, technology<br />

days usually attract 60 to 80 rotational moulding experts:<br />

a wide range of topics will be discussed, based on the<br />

suggestions of industry representatives and therefore<br />

addressing their expectations.<br />

The anticipated topics include: application of<br />

biomaterials, energy efficiency of appliances, thickness<br />

optimisation, benchmarking of various technologies<br />

(rotomoulding / blow moulding / thermoforming), plasma<br />

processing, electromagnetic sealing and many other<br />

topics, as they emerge.<br />

British Plastics Federation<br />

Rotational Moulding Group (BPF)<br />

�<br />

�<br />

Use of recyclate<br />

Continuous improvement.<br />

The seminar will be followed by the BPF Rotational Moulding<br />

group meeting commencing from 2.30pm onwards.<br />

Further details and booking (free of charge) are available<br />

from Doreen Greenaway on tel: 0207 457 5047; email<br />

dgreenaway@bpf.co.uk., website: http://www.bpf.co.uk/<br />

Events/Rotational_Moulding_Seminar_2010.aspx<br />

www.armo-global.org | info@armo-global.org

Association of Rotational Moulders Australasia<br />

(ARMA)<br />

Welcome To Rotomould 010<br />

The rotational moulding industry is on its way to<br />

Queenstown and we would like you to join us. It can be a<br />

challenge to come up with an innovative and memorable<br />

technical and social program each year but once again we<br />

believe we have outdone previous events and Rotomould<br />

2010 is not to be missed.<br />

2010 program includes 13 Presentations from working<br />

rotational moulders willing to share their knowledge &<br />

experience!<br />

Rotomould 2010 will focus on a strong technical program<br />

that will integrate not only a range of presentations from<br />

within the industry but also will incorporate speakers that<br />

will assist you in the running of your business.<br />

Rotational Moulding Senior Manager’s Forum<br />

‘Innovate or Perish’<br />

A special event reserved for Senior Manager’s only, designed<br />

for maximum results in minimal time and not to be missed if<br />

you have to guide your organisation through the next twelve<br />

months in the rotational moulding industry!<br />

We look forward to seeing you again for lots of fun, hard work<br />

and new opportunities. On behalf of the ARMA Board of<br />

Directors, I look forward to welcoming you to Rotomold 2010<br />

Association of Rotational Moulders Australasia<br />

Established in 1978 ARM Australasia is the premier<br />

organisation for rotational moulders throughout Australia,<br />

New Zealand and South East Asia.<br />

ARMA’S Objectives are to Provide a Forum for Members to<br />

Network, Contribute to the Overall Stability of the Industry,<br />

Promote Research & Development, Promote Fair Trading<br />

Practices & Liaise with Other Organisations World Wide.<br />

ARMA is a founding member of the <strong>ARMO</strong> group and<br />

believes strongly in the benefits for rotomoulders to work<br />

globally with each other to enhance their profitability.<br />

ARMA’s website www.rotationalmoulding.com is a<br />

primary benefit for both members and the industry. It<br />

promotes rotational moulding and links to all other<br />

<strong>ARMO</strong> partners. Ian Hansen, the current ARMA President<br />

has served on the Board of Directors for several years as<br />

Treasurer, Vice President and President. During his term<br />

of service, Ian has concentrated his efforts on developing<br />

better resources for moulders around materials and he<br />

has been integral to the development of the Available<br />

Materials Guide, the In House Testing Guide for<br />

Rotomoulders currently being finalised and as a leader in<br />

the new global standard for dry flow funnels.<br />

4<br />

Queenstown Travel Information<br />

ARMA recommends that you book your flights early and<br />

arrive a day or two prior to the event to ensure that you are<br />

at the conference in case of bad weather. For international<br />

travellers it is advisable to stay overnight in Christchurch or<br />

Auckland prior to your departure.<br />

Getting There<br />

Queenstown is well served by major airlines. ARMA<br />

recommends that you arrive in Queenstown on Saturday<br />

19th June as there are not many options to arrive on<br />

Sunday unless you are flying domestically. There are also<br />

quite a few return flights available on Thursday the 24th<br />

June. Qantas, Jetstar and Air New Zealand offer the greatest<br />

range of flights to Queenstown.<br />

A magical season of snow- capped mountain and blue<br />

skies, the majestic surrounds and vibrant town centre<br />

makes Queenstown the perfect winter destination.<br />

Queenstown is the most popular New Zealand destination<br />

for international visitors. Dwarfed by mountains but with<br />

a huge, friendly heart, Queenstown is a cosmopolitan<br />

resort town with an adventurous pedigree. Tucked into the<br />

picturesque Queenstown Bay, its natural physical attractions<br />

and man-made developments create endless opportunities<br />

for fun and relaxation. Queenstown has something for all<br />

ages, all budgets and for all adrenalin levels.<br />

Winter in Queenstown<br />

The entire region is alive with the buzz of skiers and<br />

snowboarders, most activity operations are in full swing and<br />

open fires offer warmth and comfort whenever the sun is up<br />

or down. Winter temperatures seldom hit higher than 7 or 8<br />

degrees Celsius and can fall well below zero degree Celsius.<br />

Winter weather in the Southern Lakes is generally stable<br />

apart from the occasional storms that bring large dumps so<br />

snow, and snowfields seldom close due to bad weather.<br />

Conference contact<br />

For assistance with your registration and accommodation<br />

as well as anything else you may require please contact<br />

ARMA on the below details:<br />

Michelle Lorenzo<br />

Association of Rotational Moulders Australasia<br />

PO Box 826, Ipswich Qld 4305<br />

Telephone: + 61(0) 7 3812 1450<br />

Mobile: +61(0) 404 265 887<br />

Facsimile: +61(0)7 3009 0600<br />

Email: mlorenzo@rotationalmoulding.com

Powder testing – new global funnel specification<br />

Powder dry flow properties are important during rotational<br />

moulding. They determine how well the powder tumbles in<br />

the mould, which affects heat transfer in the powder bed and<br />

distribution over the mould surface. Flow depends mainly on<br />

particle size and shape. Processing the resin into powder can<br />

affect dry flow results and <strong>ARMO</strong> encourages all moulders to<br />

invest in this basic equipment to help grow their understanding<br />

of the materials they use.<br />

ARMA has been working on the adoption of a global<br />

standard since 2007, with substantial early work on the funnel<br />

specification being undertaken by ARMI. ARMA and ARMI<br />

worked co-operatively on finalising the global specifications.<br />

At the 2008 <strong>ARMO</strong> Belfast Board Meeting an ‘in principle’<br />

agreement was made by the leaders of the global associations<br />

to adopt this new funnel.<br />

In 2009 ARMA made the new specification Dry Flow funnel<br />

available for purchase to the industry, worldwide. At the recent<br />

<strong>ARMO</strong> Board Meeting during the 2010 Conference in Goa, <strong>ARMO</strong><br />

reconfirmed the adoption of the new global specification for the<br />

dry flow test funnel.<br />

In April 2010 ARMI held a web based seminar to communicate<br />

to their membership the formal adoption of the <strong>ARMO</strong> funnel by<br />

ARMI. This has proven to be an excellent method to get the news<br />

out to their membership, and allow direct interaction between<br />

ARMI and their members on what has changed, why it has<br />

changed, and the global nature of the specification.<br />

<strong>ARMO</strong> believes that standardisation of test equipment and test<br />

methods will realise quality improvements for the industry. The<br />

funnel is one of the first global agreements on test equipment<br />

by <strong>ARMO</strong>. This is a tangible benefit of the key global rotational<br />

moulding associations working together and improving the<br />

industry worldwide.<br />

Two of the key specifications for the new funnel are :<br />

1) Exit hole is 10.0mm, with tolerance of +/-0.01mm.<br />

2) Internal surface finish is now specified.<br />

The previous funnel had been identified as having deficiencies<br />

for many years. The specification was very broad, allowing<br />

different producers of powder to measure the same powder with<br />

substantially different results. This made comparisons between<br />

powder manufacturers and moulders almost impossible.<br />

The <strong>ARMO</strong> dry flow test funnel, which has recently been reviewed<br />

and agreed internationally is available for purchase from ARM<br />

Australasia or you can download the specifications and manufacture<br />

your own. The new funnel has an agreed nominal exit hole size of<br />

10mm. The previous funnels used within the industry could have<br />

different nominal exit holes, and even though made according to<br />

the standard, often resulted in a large variation between results<br />

from different funnels. The new funnel specification requires much<br />

tighter tolerances for the area of the exit hole .<br />

ARMA was the first association to offer funnels that meet the<br />

new specification. ARMA also offer robust stands, with density<br />

Association of Rotational Moulders Australasia (ARMA)<br />

cups that have been specifically<br />

designed to ensure they are strong<br />

enough to operate in a rotational<br />

moulding factory environment.<br />

ARMA advises that the interest from<br />

moulders and powder suppliers has<br />

been positive, with a lot of funnels<br />

already being purchased around<br />

the world. In addition to rotational<br />

moulding companies themselves,<br />

several material suppliers, additive<br />

and masterbatch developers and<br />

pulverizer manufacturers are already<br />

using the new funnels for testing.<br />

Ian Hansen<br />

Opinions on the <strong>ARMO</strong> dry<br />

flow funnel<br />

The <strong>ARMO</strong> Dry Flow Funnel is<br />

the quickest and easiest way to<br />

confirm properly ground powder.<br />

It’s a great tool to quantify any<br />

variations in powder.<br />

Ebby Jacob, Gough Plastics<br />

The new Dry Flow Funnel has proven<br />

to accurately test powder quality<br />

without worrying that the results are<br />

affected by differences in equipment.<br />

The benefits have been proven, and we<br />

will be obtaining another 2 funnels for our<br />

remaining factories.<br />

Ian Hansen, Bushmans Group<br />

After testing samples in both our old test units and<br />

the funnels which had been manufactured to the<br />

new global standard we went from a difference<br />

of up to ten seconds between results obtained<br />

on the old units to a point where results are<br />

now quite similar across the equipment used<br />

in our different plants<br />

Susanne Furche, Price Plastics<br />

The heavy duty Bulk Density measurement<br />

cup and funnel Set, allows us to complete<br />

dry flow and a bulk density checks at the<br />

same time without worrying about wear<br />

and tear on the equipment.<br />

Richard Dixon, Teampoly<br />

www.armo-global.org | info@armo-global.org

Association of Rotational Molders International<br />

(ARMI)<br />

The Association of Rotational Molders<br />

International is a non-profit association whose mission<br />

states: “We provide tools that will make good rotomolders<br />

and their suppliers great.”<br />

To learn more about ARM International, please visit<br />

the website at www.rotomolding.org or contact the<br />

association at 630-942-6589 or info@rotomolding.org<br />

Materials Committee issues new Dry Flow Funnel<br />

Test Standard<br />

On April 6, 2010, Jon Ratzlaff of Chevron Phillips Chemical<br />

Company and Ron Cooke of ExxonMobil Chemical Company<br />

introduced the new Dry Flow Funnel Test Standard during<br />

a one-hour webinar. The new Standard is the result of many<br />

years work from the Materials Committee, former Polyolefin<br />

Committee, ARM International Technical Director Roy Crawford<br />

and Association of Rotational Moulders Australasia (ARMA).<br />

The Standard was developed as a result of a concern that<br />

the tolerances documented in ASTM Standards D1895-<br />

96 were too broad for rotomolding powders. The new<br />

standard includes specifications and tolerances for the<br />

funnel used to conduct the dry flow test.<br />

This test method is being submitted for global acceptance<br />

by all rotomolding associations.<br />

You can download a copy of the standard at www.<br />

rotomolding.org<br />

More than 40 people took part in the webinar<br />

introducing the new standard. If you would like to<br />

purchase access to an archive of the webinar (audio and<br />

video), please visit www.armmeetings.org<br />

Passports for Annual Meeting in Montreal<br />

All ARM International Members should be saving<br />

the date for the 2010 Annual Meeting to be held<br />

at the Hilton Montréal Bonaventure October 2 – 5.<br />

The theme of this year’s meeting is Thriving in the<br />

Global State of Rotomolding.<br />

Members who do not yet have a passport or need<br />

to get their passport renewed should do so now. In<br />

the United States, applying for a new passport will<br />

take up to six weeks without paying any fees for<br />

expedited service.<br />

U.S. travelers can also save $75 by purchasing<br />

a Passport Card instead of a book. You can find<br />

complete information on US passports at http://<br />

www.travel.state.gov/passport/<br />

4<br />

Spring Forum brings rotomolding decision<br />

makers together<br />

This year’s Spring Executive Forum was a great success, more<br />

than doubling the attendance numbers from last year, while<br />

maintaining a group of attendees made up of executives and<br />

decision-makers from the rotomolding industry.<br />

More than 97% of attendees told us the meeting met or<br />

exceeded their expectations.<br />

“The meeting was very good,” said Michael Wilson of Ashland<br />

Distribution Company. “The level of attendees was such that<br />

you were able to accomplish a lot during the brief show.”<br />

The meeting kicked off with an outdoor cocktail reception at<br />

the Hyatt Regency Grand Cypress. Attendees then had a group<br />

dinner at Texas de Brazil, a Brazilian Steakhouse that features<br />

sizzling cuts of meat served tableside and a gourmet salad bar<br />

with fresh vegetables, imported cheeses, sushi and more.<br />

ARM members told us that the dinner provided great<br />

networking opportunities and a wide choice of food and<br />

drink while also keeping costs down.<br />

The following day focused on education. CPA Ed McMillan<br />

presented “Fraud: How It Happens and How To Prevent<br />

It.” Ed profiled embezzlers, indentified warning signs,<br />

and discussed the importance of implementing internal<br />

controls. He also offered countless anecdotes about his<br />

work as a fraud investigator.<br />

Dru Laws of Rotonics Manufacturing Inc. led a discussion of<br />

Product Development Strategy. Dru presented a number<br />

of case studies, talked frankly about their successes and<br />

failures and shared his Should We v. Can We philosophy.<br />

Patrick Long, Formed Plastics, Inc. moderated a Safety<br />

discussion that included a detailed plan of his company’s safety<br />

policies. The entire group joined in to discuss what procedures<br />

have helped make their plants and employees safer.

Al Bates returned to the Spring Executive Forum after being<br />

a highlight of last year’s program. His presentation this year,<br />

“Pricing For Profit,” did not disappoint. One attendee called<br />

it the “best session” of the meeting and lauded Al as an<br />

“energized speaker.”<br />

David Tingue of Meese Orbitron Dunne said, “As a relative<br />

newcomer, I was pleased at how easy it was to meet<br />

new people. Fellow molders were very welcoming and<br />

surprisingly candid.”<br />

Educational sessions were followed by another group<br />

dinner. The next morning five groups of golfers played in a<br />

Shamble Tournament at the Villas at Grand Cypress.<br />

Dave Smith, Pat Long, George Kraemer<br />

take part in the safety discussion<br />

Corey Claussen Jim Hammond and Dave<br />

Smith talk during the cocktail reception<br />

Association of Rotational Molders International (ARMI)<br />

Dugan Bradfield of Brunk Corporation called the meeting<br />

“well worthwhile.” He said, “It was a time to reflect on<br />

administrative issues and comparisons not often found<br />

time for during ordinary business day.”<br />

Steven Copeland of Jerico Plastics said, “The topics covered<br />

were of interest to both business owners and managers.<br />

The no-frills format kept the cost in line and made for an<br />

efficient meeting. I would recommend the meeting, and<br />

look forward to the next meeting.”<br />

Dru Laws presented on product<br />

development strategy<br />

Bill Spenceley reminded attendees<br />

they would encounter many humble<br />

Canadians at the 2010 Fall Meeting<br />

Group dinner<br />

www.armo-global.org | info@armo-global.org

10<br />

Aziende Italiane Stampaggio Rotazionale<br />

(AISR)<br />

AISR Secretary summarizes its first quarter<br />

activities<br />

The Management Board at its meeting on 20 January<br />

2010 identified the activities which were planned at the<br />

assembly in Lodi.<br />

In the second half of February, both associated and nonassociated<br />

companies were sent the programme of the<br />

first training: „Training for Rotational Moulding Managers”,<br />

including the registration form. The meeting, designed<br />

for shift managers, presented the main stages of the<br />

rotational technology, while the practical approach to the<br />

issues tackled helped every participant learn about the<br />

basic manufacturing problems faced by the companies<br />

operating in this sector on a daily basis.<br />

The training took place on Friday 12 March at ROTOTECH,<br />

in San Gillio (Turin), and took up half a day. The registration<br />

fee was 200 EUR for non-associated companies and 140<br />

EUR for associated companies.<br />

Future actions<br />

Another AISR initiative will be anticipated, under the name<br />

“Quality in rotomoulding”.<br />

This training will take up a whole day and is directed<br />

to owners as well as production and quality managers/<br />

directors. The anticipated training date is 18 June and the<br />

location is the head office of Proplast in Alessandria.<br />

In the second half of the year (in September and<br />

November) Marketing and Technical Workshops will be<br />

held, with the aim of reviving the analysis of supply and<br />

demand for machines and moulds: What do suppliers offer<br />

and what do moulding operators expect?<br />

4<br />

AISR web page launch<br />

A reminder to all – our new web page is coming soon at<br />

www.aisr.it. Companies will be able to publish and update<br />

their reports; pertinent information should be sent to<br />

the Secretary’s Office, which will handle the publication<br />

in compliance with the Web Page Regulations, which are<br />

currently being developed. All members should check<br />

whether their information is correct and report any<br />

discrepancies to the Secretary’s Office which will make the<br />

necessary corrections.<br />

Statistics-related activities<br />

AISR is planning to initiate activities involving collecting<br />

and processing of statistical data. The detailed scope<br />

of these activities will soon be specified by the Board.<br />

Activities will comply with a few fundamental principles:<br />

�<br />

�<br />

�<br />

Detailed data submitted by the companies will not<br />

be made public in any way other than collectively.<br />

The Secretary’s Office shall guarantee complete<br />

confidentiality.<br />

Access to collective results will only be granted to the<br />

companies, which themselves provide data regarding<br />

their facilities, whereas the results will always comprise<br />

at least three figures, none of which may account for<br />

more than 80% of the total.<br />

Companies will submit their data on specific dates, on<br />

a continual basis, at intervals accepted by all parties.<br />

These activities shall not be mandatory, but AISR<br />

Secretary’s Office would like to encourage all the members<br />

to participate in data collection so as to achieve as<br />

representative a result as possible. Statistical surveys will<br />

subsequently be expanded to include marketing activities,<br />

including an estimation of data regarding companies which<br />

were not involved in data collection.

Society of Asian Rotomoulders<br />

(StAR)<br />

StAR’s 010 Education Programme Begins with<br />

Students Seminar and Plant Tour<br />

StAR’s new season of activities began with a Seminar for<br />

Students of DSK International School of Design, Pune. The<br />

Design School in Pune is the first Indian campus of the<br />

well known and very modern international DSK Design<br />

institution of France. The Seminar was held on the Plant<br />

premises of Infra Industries in Khopali, near Mumbai<br />

on Feb 20, ’10. The Seminar Programme of over 3 hours<br />

consisted of a presentation by StAR Founding Chairman<br />

Ravi Mehra, interactions with the keen students almost<br />

half of whom were foreigners mostly from France, and<br />

concluded with a conducted tour of the rotomoulding<br />

plant for the students. The topic of the presentation by Ravi<br />

Mehra was What is Rotational Moulding & its advantages;<br />

Process, Materials, & Moulds; with comprehensive coverage<br />

of Products, Markets & Applications.<br />

Also present at the Seminar was the new StAR President<br />

Mukesh Ambani who is also Chairman & MD of Infra<br />

Industries; Satish Gokhale, Director Design Directions<br />

Pune who jointly heads the StAR Education Committee; G<br />

Zaslavsky Head of Product Design Studies at DSK, Pune;<br />

and Thomas Dal Head of Transportation Design Studies at<br />

DSK, Pune.<br />

The Presentation at the Seminar explored the many aspects<br />

of rotational moulding from the Design perspective.<br />

Judging by the questions and interactions which followed,<br />

the presentation seemed to have created a lot of interest<br />

in the budding designers of tomorrow. They found quite<br />

amazing the immense design possibilities which are<br />

inherent in the process.<br />

The Seminar and Plant Tour holds great significance for<br />

StAR’s Education Programme as DSK Pune is all set to<br />

include rotomoulding in its curriculum. The Pune school<br />

is already working on a couple of assignments to design<br />

rotomoulding products. A “ Chair “ for rotomoulding is also<br />

among its immediate plans. With the StAR Students Design<br />

Competition for the year soon to be announced this seems<br />

to have been the opportune moment for the students to<br />

become well aware of rotomoulding and StAR. The Seminar<br />

will also serve as a good building block for the StAR<br />

Education Programme which is targeting some important<br />

technology campuses of the country.<br />

Along with the Education committee, the other StAR<br />

Committees are gearing up for action too. The StAR<br />

Technical Committee has already begun work on a new<br />

project to draft Underground Tank Standards for the<br />

Indian industry which will be at par with the existing<br />

international standards.<br />

Ravi Mehra making the<br />

seminar presentation<br />

Interactions with the keen audience<br />

List of StAR Committees<br />

StAR Committee Heads<br />

Membership &<br />

Marketing<br />

Technical<br />

Education<br />

Regional Meets<br />

M.Ambani, Infra<br />

R.P.Shukla, MPlast<br />

L.K.Singh, Fixopan<br />

A.Baheti, Pure Ganga<br />

S.Dave, Promens<br />

B.Costabir, GMI Zarhak<br />

L.K.Singh, Fixopan<br />

S.Dave, Promens<br />

S.Gokhale,Design<br />

Direction<br />

M.Ambani, Infra<br />

R.P.Shukla, MPlast<br />

A.Baheti, Pure Ganga<br />

www.armo-global.org | info@armo-global.org 11

12<br />

Using colour to your advantage!<br />

John Steele, ICO Europe<br />

How can the correct colour<br />

choice help sell my products<br />

or make my customers’ products<br />

sell better? What influences people’s<br />

decision on colour?<br />

At ICO we make a lot coloured powders,<br />

last year in Europe alone we supplied in<br />

the region of 35000 tonnes.<br />

We decided to investigate by looking<br />

at some applications and talking<br />

to a specialist in colour<br />

psychology!<br />

Introducing the Psychology of colour<br />

When we choose to use colour we will get a complex<br />

“reaction” to that colour from everyone who sees it. Often<br />

in industry (rather than in the mass consumer market for<br />

example) we might think that perhaps the attractiveness<br />

and colour of our products is of lesser importance. Colour<br />

psychology is a specialty of Angela Wright. Here is an<br />

excerpt from fascinating work taken from her website<br />

www.colour-affects.co.uk by way of illustration:<br />

“The key factor that Angela Wright recognised in studying<br />

colour psychology was that, equally, there are no wrong<br />

colours; It is the combination of colours that triggers the<br />

response; you could have a grey sky on a summer day,<br />

but our reaction to that grey with the beautiful colours<br />

of the summer landscape would be different from the<br />

combination of a grey sky with a predominantly snow<br />

white scene. We do not respond to just one colour, but to<br />

colours in combination. Even the winter landscape contains<br />

many colours<br />

Case study: mail order CD project.<br />

“Our clients had already begun promotion of a new opera<br />

CD when Colour Affects first met them; their in-house<br />

designers had chosen the colours for the promotional leaflet.<br />

The client asked us to adjust the colours of the leaflet, in line<br />

with the principles of colour harmony/colour psychology<br />

contained in the Colour Affects System. We were not asked<br />

to create a palette from scratch. The client printed 50% of<br />

the leaflets in the original colours and 50% in the colours of<br />

4<br />

the adjusted palette; in every other respect, the two leaflets<br />

were identical. The two mail outs were as similar as possible.<br />

The promotional leaflets in the new colours produced sales<br />

of over 500,000 more CDs than the leaflets in the original<br />

colours specified by the in-house design team.”<br />

Angela gives some more examples on her website of how<br />

colour is energy and the fact that it has a physical effect on<br />

us has been proved time and again in experiments - most<br />

notably when blind people were asked to identify colours<br />

with their fingertips and were all able to do so easily.<br />

The shorter the wavelength, the stronger the underlying<br />

physical effect.<br />

She relates that colour is Nature’s own powerful signalling<br />

system - the universal, non-verbal language. Scientifically, it is<br />

the first thing we register when we are assessing anything: a

very simple and obvious example of that is our reaction to a<br />

fly in our home: if it is black or navy blue, we will probably find<br />

it a minor irritation, but if it has yellow stripes our reaction<br />

will be different - most of us will recoil. The same instinct tells<br />

us when food is unsafe to eat and throughout the animal<br />

kingdom colour is widely used to signal sexual availability<br />

Coloured pet houses<br />

At the ARM show in Berlin in 2006 ICO introduced the<br />

amazing Omlet rotomoulded chicken house and the<br />

surprising range of colours they produced them in.<br />

Omlet is a web based product design and retail company<br />

run by four entrepreneurs who met at the Royal<br />

College of Art in London.<br />

We asked them to review how colour affects their business.<br />

Johannes Paul, their marketing manager explained to us<br />

how they worked with customers and colours:<br />

“In 2004 we introduced the first product in the traditional<br />

colour of green which blends nicely into the garden<br />

environment and has become our “stock in trade” biggest<br />

seller. Following that we decided to offer customers a choice<br />

of colours, we did this in order to help differentiate the<br />

product away from “commodity” green garden products<br />

such as Composters. We added Red and Yellow colours<br />

then, listening to what customers were asking for, we<br />

cautiously introduced the world’s first pink chicken house!!<br />

We discovered that pink appealed to people buying presents<br />

especially for children and it became a hit with more than<br />

15% of our sales in pink that year. Recently we surveyed 200<br />

of our customers and found another pink surprise. Chickens<br />

who lived in the pink (definitely) laid more eggs!<br />

Using colour to your advantage!<br />

We can say that colour has revolutionized our product<br />

range and certainly made a huge impact on sales. Since<br />

PINK we have produced Lilac, Orange, Purple and Blue. You<br />

can also say that we use the introduction of colour as way<br />

of refreshing our product range”.<br />

A real rotomoulding example of the effective use of two<br />

colours in place of one is the LINPAC bin.<br />

Designer, David Bray provided some of the historical<br />

development of litter bins at LINPAC Environmental in the<br />

UK. A design of bin that was popular in the 90s was a single<br />

skin litter bin with a hexagonal top locked onto the base.<br />

This is shown in yellow colour in the photo. He recently<br />

designed a new double walled “Twinbin” product which was<br />

much better looking than the old bin and had increased<br />

functionality and visual appeal. They now often use two tone<br />

colours in many of their bin designs and see a sharp rise in<br />

the popularity of their bins some of which he thinks can be<br />

attributed to the colour choice.<br />

Useful references and more information<br />

ICO Polymers Europe<br />

jsteele@icopolymers.com,<br />

www.icopolymers.com<br />

Colour Affects Consultancy<br />

www.colour-affects.co.uk<br />

LINPAC Environmental<br />

http://www.linpac-environmental.co.uk/index.html<br />

Omlet (Chicken houses)<br />

www.omlet.co.uk/homepage/<br />

www.armo-global.org | info@armo-global.org 13

O rend a A uto m atio n T ec hno lo g ies Inc ., 1 6 5 S te e lc ase Ro ad E ast, M arkh am , O n tario , L 3 R1 G 1 , C an ad a<br />

���� ������������� � ���� ������������� � ������������������ ��������� � ���������������� ���������<br />

H 1 D 2 5 0<br />

� S h arp e n Pu lv e rizin g D isc s<br />

� � �� � ����<br />

A LL Pulverizer m akes and m o d els:<br />

W e o ffer Full S ervic es & Parts fo r<br />

H 1 D 5 0 0<br />

� C o u n tle ss S atisfie d C u sto m e rs<br />

� A c c id e n t F re e<br />

� 2 0 Y e ars E xp e rie n c e<br />

� F u lly A u to m atic<br />

� L e ss E xp e n siv e to Ru n<br />

� O rig in al S in g le M ill D e sig n M an u fac tu re r<br />

� E asy to U se<br />

Orenda Automation Technologies Inc.,<br />

The Reliable Workhorse of the Industry