MiniMagster 1502, 1502s - Lincoln Electric - documentations

MiniMagster 1502, 1502s - Lincoln Electric - documentations

MiniMagster 1502, 1502s - Lincoln Electric - documentations

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

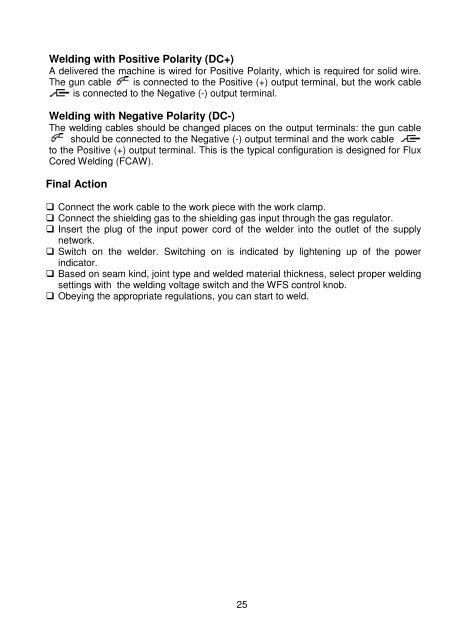

Welding with Positive Polarity (DC+)A delivered the machine is wired for Positive Polarity, which is required for solid wire.The gun cable is connected to the Positive (+) output terminal, but the work cableis connected to the Negative (-) output terminal.Welding with Negative Polarity (DC-)The welding cables should be changed places on the output terminals: the gun cableshould be connected to the Negative (-) output terminal and the work cableto the Positive (+) output terminal. This is the typical configuration is designed for FluxCored Welding (FCAW).Final Action Connect the work cable to the work piece with the work clamp. Connect the shielding gas to the shielding gas input through the gas regulator. Insert the plug of the input power cord of the welder into the outlet of the supplynetwork. Switch on the welder. Switching on is indicated by lightening up of the powerindicator. Based on seam kind, joint type and welded material thickness, select proper weldingsettings with the welding voltage switch and the WFS control knob. Obeying the appropriate regulations, you can start to weld.25