Strategic Approaches to Process Optimization and Scale-up - Almac

Strategic Approaches to Process Optimization and Scale-up - Almac

Strategic Approaches to Process Optimization and Scale-up - Almac

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

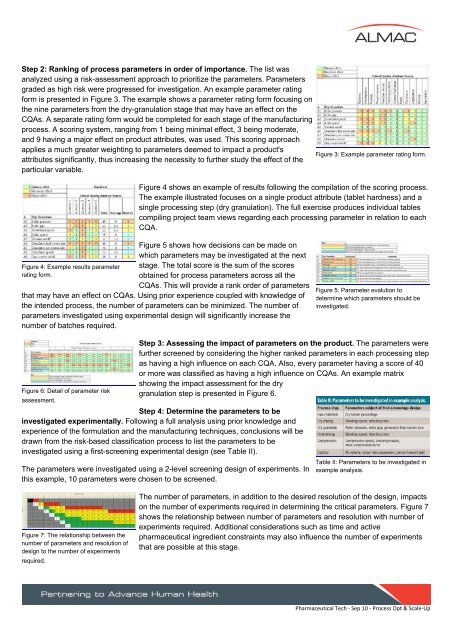

Step 2: Ranking of process parameters in order of importance. The list wasanalyzed using a risk-assessment approach <strong>to</strong> prioritize the parameters. Parametersgraded as high risk were progressed for investigation. An example parameter ratingform is presented in Figure 3. The example shows a parameter rating form focusing onthe nine parameters from the dry-granulation stage that may have an effect on theCQAs. A separate rating form would be completed for each stage of the manufacturingprocess. A scoring system, ranging from 1 being minimal effect, 3 being moderate,<strong>and</strong> 9 having a major effect on product attributes, was used. This scoring approachapplies a much greater weighting <strong>to</strong> parameters deemed <strong>to</strong> impact a product'sattributes significantly, thus increasing the necessity <strong>to</strong> further study the effect of theparticular variable.Figure 4: Example results parameterrating form.Figure 4 shows an example of results following the compilation of the scoring process.The example illustrated focuses on a single product attribute (tablet hardness) <strong>and</strong> asingle processing step (dry granulation). The full exercise produces individual tablescompiling project team views regarding each processing parameter in relation <strong>to</strong> eachCQA.Figure 5 shows how decisions can be made onwhich parameters may be investigated at the nextstage. The <strong>to</strong>tal score is the sum of the scoresobtained for process parameters across all theCQAs. This will provide a rank order of parametersthat may have an effect on CQAs. Using prior experience co<strong>up</strong>led with knowledge ofthe intended process, the number of parameters can be minimized. The number ofparameters investigated using experimental design will significantly increase thenumber of batches required.Figure 6: Detail of parameter riskassessment.Step 3: Assessing the impact of parameters on the product. The parameters werefurther screened by considering the higher ranked parameters in each processing stepas having a high influence on each CQA. Also, every parameter having a score of 40or more was classified as having a high influence on CQAs. An example matrixshowing the impact assessment for the drygranulation step is presented in Figure 6.Step 4: Determine the parameters <strong>to</strong> beinvestigated experimentally. Following a full analysis using prior knowledge <strong>and</strong>experience of the formulation <strong>and</strong> the manufacturing techniques, conclusions will bedrawn from the risk-based classification process <strong>to</strong> list the parameters <strong>to</strong> beinvestigated using a first-screening experimental design (see Table II).The parameters were investigated using a 2-level screening design of experiments. Inthis example, 10 parameters were chosen <strong>to</strong> be screened.Figure 3: Example parameter rating form.Figure 5: Parameter evalution <strong>to</strong>determine which parameters should beinvestigated.Table II: Parameters <strong>to</strong> be investigated inexample analysis.Figure 7: The relationship between thenumber of parameters <strong>and</strong> resolution ofdesign <strong>to</strong> the number of experimentsrequired.The number of parameters, in addition <strong>to</strong> the desired resolution of the design, impactson the number of experiments required in determining the critical parameters. Figure 7shows the relationship between number of parameters <strong>and</strong> resolution with number ofexperiments required. Additional considerations such as time <strong>and</strong> activepharmaceutical ingredient constraints may also influence the number of experimentsthat are possible at this stage.Pharmaceutical Tech ‐ Sep 10 ‐ <strong>Process</strong> Opt & <strong>Scale</strong>‐Up