Climatuff Compressor.. - HVAC.Amickracing

Climatuff Compressor.. - HVAC.Amickracing

Climatuff Compressor.. - HVAC.Amickracing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

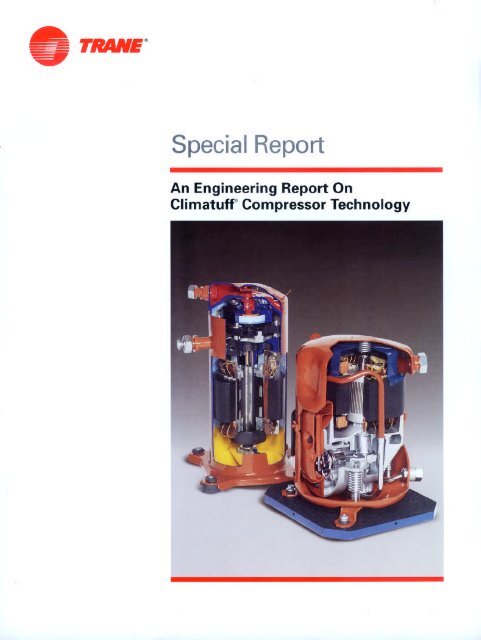

Special Repoticrlymeering Repour VIIClimatuW <strong>Compressor</strong> Technology

<strong>Climatuff</strong>”Technology<strong>Compressor</strong>IndexI Introduction ToClimatuW <strong>Compressor</strong>s 3II Reciprocating Technology StoryIntroduction 4How ReciprocatingCompression Works 4Reciprocating Valve/Piston Story 5How Acousti-CoolProcess Works 6Crankcase Pressure Recovery 6<strong>Compressor</strong> Stress Capability 7Shell Design/LiquidTolerance Capabilities ,,,.,,,,.,.,,., 8Crankshaft/Oil PumpDesign/Flow 9Cutaway with Parts Labeled 10Ill Scroll TechnologyStoryIntroduction 11Scroll Compression 11How Does the Scroll Work 12Scroll Gas Flow Pattern 12Scroll Conformance 13Radial and AxialConformance 13Benefits/Starting 13<strong>Compressor</strong> Stress Capability ,.,. 14Additional Design Features ,,,,.,,. 15Cutaway with Parts Labeled 16IV SharedFeaturesProtection Devices:Thermal Stresses 17Electrical Stresses IIV SystemChemical Stresses 18Service Benefits (Rotolocks,Lifting Lug, Test Kitsi 18TestingReliability Testing 19<strong>Climatuff</strong>’ Heritage 20Climatuw Application Testsand Criteria 20VI Manufacturing and TestingAssembly Line Qualification 21Outdoor Unit ProductionTesting 22VII Climatufl s <strong>Compressor</strong>Summary 23

Section I - IntroductionTo <strong>Climatuff</strong>” <strong>Compressor</strong>sSpecial Report IntroductionAnd BackgroundTrane, a world-leading <strong>HVAC</strong> company,mow manufactures 4 of the 5 leadingco~npressor technologies. Centrifugala?d screw compressors from 35 to1300 tons are manufactured by theWorldwide Applied Systems Group.Reciprocating and scroll compressorsfrom 1 to 15 tons are manufactured bythe Unitary Products Group and theWorldwide Applied Systems Group.Tram Is A Pioneer In The Four<strong>Compressor</strong> Technologies.. In 1938. the industry’s first hermeticcentrifugal refrigeration machinewas introduced by Trane. TheTurbovac is the forerunner totoday’s CenTraVac, Trane’s highlysuccessful refrigeration unit andthe industry standard for largecommercial air conditioningsystems.. In 1987. Trane introduced a newgeneration water chiller whichfeatured the most advanced largetonnage compression technology -a helical rotor or screw compressorTrane’s screw compressor with5 and 7 lobe rotor combinationsresulted in the highest screw compressorefficiencies in the industry.Reciprocating compressor technologyhas a dual heritage. For thecommercial sizes, Trane beganmanufacturing its own compressorsin 1950. For residential compressors,the heritage goes backto the 1930’s to the first hermeticcompressor. This provided thetechnology basis for the world’sfirst reliable heat pump compressor,the Climatuf?* which debutedin 1964. Both compressors haverepeatedly underpow several redesignsmaintaimng their pre-eminentreputation in the industry.Trane reciprocating compressorshave established several industry“firsts:” the first hermetic 30 toncompressor, the first reliable heatpump compressor, and the firstsuccessful 3 and 5 ton variablespeed compressor. These are someexamples of Trane’s commitmentto compressor innovation.Scroll compressor technology isthe latest area where Trane hasmade significant contributions.After 14 years of research andtesting, Trane introduced the3-D” scroll compressor in 1988,the industry’s first scroll designedspecifically for the commercialair conditioning market.And in 1998, after proving scrolltechnology in the demanding commericalmarket, Trane now Introducesthe Climatufi”’ residentialscroll compressor. This scroll compressorfollows in the ClimaKM ,...reclprocatlng compressor traamonltiliring similar design and testinglhilosophies to provide maximum-;eliability and durability, industryleading efficiency, and low noiselevels.<strong>Compressor</strong> technology is an integralfactor in Trane’s success. Trane under~stands compressor technologies;Trane advances compressortechnologies;and Trane introduces compressortechnologies into the products whenthe time is right.

Section II -ReciprocatingTechnologyReciprocatingIntroductionTrane’s ClimatuP reciprocating compressorwas the world’s first successful heatpump compressor. From its inception, the ClimatufP philosophy revolved aroundtwo fundamental principles.1. The compressor must be able to protect itself in all systems with minimumreliance on system controls.2. <strong>Compressor</strong> reliability and durability is to be proven in the laboratory not at thecustomer’s site.These two philosophies have been continually improved and today’s ClimatufPreciprocating compressor remains a world leader.How Reciprocating Compression Works:On the upstroke, the suction valve closes preventing reirigeranlfrom leavrng the cylinder. When cyiinderpressure exceedsdischarge pressure, the large round discharge valve lifts completelyoff ifs seal ailowing gas fo efficiently exit the cylinder lfthere isliquid present, Vow dynamics resulting from taperedsurfaces andvalve proximity will allow the liquid to be purged from the cylinderwithout damaging The wives. Besides being gas flow efficient,CiimafufY’s valving is enguxered to tolerate some liquid slugging.Valve design is critical to liquid refrigerant tolerance. On milddays, liquid refrigerant can accumulate in the suction line andwill flood into the compressor on start-up. Because of this, thevalves must be able to tolerate some slugging. ClimatufP’svalve assembly has been designed to allow liquid refrigerantto be expelled from the cylinder without damaging the valves.All ClimatufP reciprocating compressors have the dischargeline routed through the compressor sump. With the cornpressor running, the hot discharge line will vaporize liquidrefrigerant in the sump separating it from the oil. In the offcycle, Trane uses crankcase heat on all compressors (exceptlow efficiency cooling units where refrigerant quantity issmalll to vaporize liquid refrigerant and maintain desiredoil temperature.ClimatufP reciprocating compressors have an average of25 percent more volume inside the shell than other compressors.This gives it additional safety margin against sluggingwhich can be caused by overcharging or low indoor airflow.With a large shell design, ClimatufP compressorseliminate the need for suction line accumulatorson residential systems.

Section II -ReciprocatingTechnologyThe Ciimaruff”’ compressor’s piston fearures a specially designedsculptured head thatprovides minimum clearance volume in thecylinder on the full upstroke of the piston. Low clearance volumeyields higher voiumetnc efficficrency The sculptured piston headalso eases iiqwd refr~geranl slresses in extreme conditions.C,,mat”“~ compressors: ihe p,*ron and vaive assembly haYebeen mounted in pia*tic and cut in half to show the Ciearance“OiUnE me clearance befwee” the piston and “alYeassembly in the full up**roke position is just a fewthousandths of an inch. ihrs leads to high volumetriceificiencies and high EER ra0ngs.

Section II -ReciprocatingTechnologyHow Acousti-CoolWorksRefrigerant is returned to the compressorthroughthe high level suction inlet.As gas is drawn into the compressor,it is approximately 100 degrees coolerthan the motor windings. The gas entersthe motor/cap and flows across thetop of the motor. The gas continuesthrough the top of the suction tube andenters the cylinder with no more super-hen the suction valve closes, the inmingflow of gas is stopped until thenext intake stroke. This abrupt stop createsa pressure pulse that travels backwardalong the inlet path at the speed ofsound. The pulse of refrigerant vaporhits the top ofthe motor, muffling noiseas it cools the windings.The lowersuper-heat means highercompressor efficiencies IEER). Whilebeing cooled, the motor/cap are performingthe duty of a suction gas muffler.Since potential sound energy isbeing absorbed simultaneously withreturn gas motor cooling, the processis called Acousti-Cool.Acousti-Cool is engineered motor&mperaturemanagement. Managed motorcooling allows the compressor to runcooler than other hermetic compressors.Motor cooling leads to longer motor lifeand lower operating costs.CrankcaseRecoveryPressureThe <strong>Climatuff</strong>” reciprocating compressorutilizes an enclosed crankcase. Enclwing the crankcase protects the criticalconrodlcrankshattjournal bearings bylimiting the amount of liquid refrigerantand particulate in the bearing area. Theoil sump is separated from the spinningcrankshaft providing an undisturbed oilSUPPlY.During the downstroke (expansion)pressure in the crankcase is increasedproviding a small amount of refrigerantfor injecting into the oil. This producesa small layer of oil foam that minimizessound transmission. Crankcase pressuredeveloped during the downstrokeis recovered in the upstroke lcompressionlcontributing to high efficiencies.

Section II -ReciprocatingTechnologyAn aiiL9iuminum frame, mo*oihousing,piston and connecrrng rod help to reducetherma, strews and help the compressor torun co&r by dissipating heat away fromihe bear,ng *“ifaces.<strong>Compressor</strong>CapabilityStressThe ClimatufP compressor utilizesaluminum pistons and connectingrods. The lightweight aluminum providesfor easy starts and relieves stresson the crankshaft. Trane uses an industry-uniquepearlitic cast-iron cylinderliner for durability. Forsuperiorsealing at all heat pump operatingranges, Trane uses a cast-iron comepression ring.The Climatu~* compressor’s allaluminumframe and motor housingdissipates heat away from bearing surfaces.This reduces thermal stress andallows the compressor to run coolerthm cast-iron frame compressors. Theframe’s light weight reduces stress onthe mounting springs. The frame is designedwith a very large intake area tominimize the dynamic pressure drop ofsuction gas. Suction gas flow to thevalve is virtually unrestricted.MechanicalStressesUnder certain operating conditions,there will be some liquid refrigerantflooding back to the compressor. Thiscan lead to liquid slugging. While noreciprocating compressor is designedto pump liquid refrigerant, <strong>Climatuff</strong>’has superior tolerance to slugging.The valve is the most critical componentof the compressor. It experiences moremechanical, thermal. and pressurestresses than any other component ofthecompressor. Trane manufacturesall their valves to extremely tight designspecifications. Valves spring open andshut 57 times a second. up to 800 milliontimes a year on heat pumps. SinceClimatufP compressors are designedfor heat pump applications, a valvematerial that is practically indestructibleis required.The discharge valve and suction valveare made of special Swedish-type valvesteel. The steel has a unique microstrwture that has a high carbon content anda very low content of nonmetallic inclwsions such as sulfides and silicates. Thismakes the valve highly impact and distortionresistant. The valve is resistantto metal fatigue and is not affected byexcessive heat.The Ciimatuff compressor’s dischargevaive rnfake side, shown above.The Climafuff” compressor’s rugged valveassembly is rhe mosl critical componentoi the compressor. Discharge side shownabove with an exploded view of the 24intake port*.The Ciimaruff” compressor’s valves aremade ofSwedish-type steel to handleextreme heat and the swess of openingand dosing 57 times a second.

Section II -ReciprocatingTechnologyThere are some distinct advantageso the Large Shell Design since it acts1s the accumulator thus minimizinghe potential oil traps, system leaks,jnd pressure drop of a separatexcumulator.Good lubrication is essential to longcompressor bearing life, and is oneof the keys to the ClimatufF compressor’sreliability. The Climatuf? compressor’scrankshafi doubles as a positive,nowdirectional, centrifugal oil pump.It provides a constant oil supply to thebearing surfaces when the pump is running.In addition, it helps vaporize liquidrefrigerant and cools the motor andbearings.On system start-up, oil may have drainedor been washed off bearing surfacesby refrigerant migration. If the systemis overcharged, the oil reservoir at thebottom of the sump could be floatedabove the oil pump opening by theheavier liquid refrigerant. All of thiscan result in dry bearings that can seizea compressor on stan-up. To counterthis, Trane tin plates its bearings toserve as a boundary lubricant untiloil flow is established.Another mechanical stress is absorptionof inertia energy during starting andstopping. Climatuf? compressorsutilize a patented dual spring mountingsystem to absorb this energy. Heavysnubber springs quietly isolate therunning compressor inside the shell.Stress is reduced on external connectionsbecause of minimized shell vibration.The result is long system life.

The <strong>Climatuff</strong>” <strong>Compressor</strong>’s Crankshaft/Centrifugal Oil Pump...Engineering Technology from Top to Bottom1. The oil passage slot in rhe bottom of the crankshaftpicks UD the oil and residual liouid refriaerantfrom rhecompressor sump. This mixtu& is lifttei by centrifugalforce up the oil passage.2. The hot surface of the crankshaft begins to vaporizethe hquld refrigerant that has been picked upwith the oil.Centrifugal force caused by the rotating crankshaft beginsto separate the oil from the refrigerant vapor. The heavieroil is slung to the outside of the oil passage where it willbe delivered to bearing surfaces through ports in thecrankshaft Refrigerant vaporwill continue to rise upthe oil passage.3. The gas vent passage is angled at the top portionof the crankshaft The center line is the point of zerospressure, and oil will not be able to cross this linebecause of centrifugal force. Only refrigerant vaporwill cross the center line and exit at the top port.A cut-apart crankshaft (top right1 showsthe offset andangled gas vent passage. The crankshaft has 15 criticaldimensions, and is machined and polished to bearingtolerances as close as .0001 inches. This is roughlyIBOth the thickness of a human hair,

Section II -ReciprocatingTechnology

Section III -Scroll TechnologyIntroductionThe scroll concept was originally patentedin the 1890’s. It has taken yearsto perfect the technology to meet therigorous ClimatufP standards.Trane ClimatufP compressor quality -that means it is built to meet our specifications.The new scroll technologymeets the <strong>Climatuff</strong>’ compressor’s qualifications,design criteria, reliabilitytest~ing, applications testing and productionassurance testing outlined in this report.This means proving our reliability anddurability in the lab, not in our customers’applications. The Trane ClimatufFcompressor philosophy of excellence iscontinued by this scroll design!ScrollCompressionThe ClimatuW scroll compressor repre~sents a different approach to compression.Rather than a fixed chamber thatuses a piston or roller to change volume,the scroll compressor utilizes a movingpocket which is produced by the orbitingmotion ofthe two involutes described inthe diagram on the next page.11

Section Ill -Scroll TechnologyWarmer, Medium Pressure -Interim GasThe open passage is sealed off as gas isdrawn into the spiral.

Section Ill -Scroll TechnologyScrollConformanceIn a manner similar to Trane’s ruggedand highly successful 3-D’ commercialscroll compressor (introduced in 1988).the Cllmatuff scroll compressorfeaturesan innovative method, referred toas “Conformance” for assuring a tightcompression pocket. The orbiting scrollIS self-adjusting. It moves radially inand outto preciselyfollowthe involutegeometry; the fixed scroll moves vertitallyto maintain optimum contact ofthe tips. This dual motion capability1s the key to achieving the full benefitsof the ClimatufP scroll.Benefits of the <strong>Climatuff</strong>”Scroll ConformanceThe benefits ofthe Trane ClimatufPscroll Conformance are maximizedefficiency, proven durability, lowvolt~age Startability and quiet operation.ClimatufPcompressor Conformanceincreases efficiency by continuouslycompressing the refrigerant gas in eachrotation with minimal leakage. Verylow leakage is achieved with minimalefficiency-robbing friction because ofthe tight manufacturing tolerance of<strong>Climatuff</strong>” compressors.The ClimatufP scroll radial Conformance Durability is improved becauseseals compression in much the same Conformance plays a key role in themanner as the reciprocating <strong>Climatuff</strong>i <strong>Climatuff</strong>’scroll’s capability to handlepiston ring does in the upward stroke. reasonable amounts of liquid floodingAn innovative bushing coupled withand system contamination. The flankscentrifugal force is utilized to guide the and tips will separate if liquid refrigerantorbiting scroll involute towards the fixed or debris is present allowing the panic”-scroll involute minimizing gas leakage late to pass through without harm to thebetween the involute walls.scroll involutes. Contaminants that areflushed through the scrolls are trappedThe <strong>Climatuff</strong>- scroll axial Conformance in the system filter driers.supplements the radial Conformanceby sealing the tips using the controlled <strong>Climatuff</strong>’ scroll Conformance allowspressure balance forces to minimize any the flanks and the tips to separate whengaps between involute tips and the mat- the compressor cycles off and unloadsing scroll floor. the gas from its high pressure state.This allows for easy low-voltagestart* every time. Therefore, hard startkits are not required in non-equalizingsystems.ConformanceH, PlDri,,,eQuiet operation is obtained fromthe smooth continuous compressionwith little vibration due to the orbitingmotion.The Conformance ofthe <strong>Climatuff</strong>scroll delivers the high quality standardsthat Trane and our customers demand.

Section III -Scroll Technology<strong>Compressor</strong>CapabilityStressThe ClimatufP scroll incorporates twopermanently lubricated, teflon impregnatedbearingsto insure bearing lifeeven if sump oil is temporarily washedaway from flooding, or during a longoff period “dry” startup. In addition, theClimatufP scroll uses a white mineraloil, similar to the Climatuf? reciprocatingfor excellent lubrication and longline oil return.Upper housing with TOD and Gas Bypass.The Thermal Operating Disc (TOD) is asupplemental device that protects scrolltips and motor windings from high ternperaturelpressuredamage.When discharge temperature exceeds300 degrees F, the TOD device flows hotgas through the bypass tube onto theIOL. The IOL safety device then cutspower to the motor avoiding damagefrom excessive discharge temperatures.A positive pressure oil pump (similarto ClimatufF reciprocating compressors)is used to quickly supply oil to bearingsand scroll tips to ensure long life andenhanced pressure sealing. Note oilpickup vanes in bottom of compressorcrankshafl.High Pressure Area shows Muffler, IPRand Temperature Deflector Plate.High/low pressure sides of the ClimatuFscroll are separated by a minimum surfacetomaximize efficiency. The smallhigh side volume of the upper cap actsas a muffler to reduce pulsations of gas.14

Section Ill -Scroll TechndoavAdditional Design FeaturesThe orbit coupling connects the twoorbiting scrolls and provides for smooth,quiet operation.q scroll is desiqned to beexceptionally quiet in operation. Continuousscroll compression reduces gaspulsations. Balanced rotorcounterweightsreduce vibration, and shutdownmechanisms eliminate shutdown noiseand vibration thus eliminating the needfor internal springs.imatuW scroll crankshaft’rotor assemiesuse counterweights to reduce vibrationsand associated bearing loads.An oil baffle is also used to separate oilfrom the rotating crankshaft and rotorto reduce 011 foaming for improved efficiencyand lubrication.IAbRubber vibration isolators are also usedto ensure no vibration is transmitted tothe systemA new method of wire connection is beingused on all ClimatufF scrolls. This“terminal plug” positively connects tothe terminal header without the use ofindividual spade connections. This ensurescorrect wiring, reduces loose connections(and associated overheating),and seals the terminal box against moistureand corrosion

Section Ill -Scroll TechnologyHigh Pressure Volume Discharge DeflectorCheck ValveSi-Metallic ITODIThermal DiscLower OrbitingScroll SetSuctionRot0 Lock\, Orbit CouplingPositiveShutdownDeviceRotorCounterweights- InternalOverloadCrankshaftI/Oil BaffleOil Pick-upIUnderneath/Rota LockFitting*(DiyhargelLower Bearing --------‘RoundSack Shot

Section IV -Shared FeaturesThermalStressesCl~matuff’ compressors have a uniquelyapplied protection system using twontegrated components: the internaloverload device VIOL) and the internalpressure relief valve (IPR). SinceCllmatuff compressors are used in bothheat pump and cooling units, Trane hasdesigned the protection system for thehigher temperatures and stresses ofheat pump operation. The protectionsystem application is designed to allowoperation during normal conditions andto prevent compressor damage duringabnormal conditions.The <strong>Climatuff</strong>’ compressor’s protectionsystem is tamper-proof because bothcomponents are located inside the compressorshell. The IOL is mounted directlyon the motor windings so it cansense motor temperature without thecooling effect of incoming gas or liquid.The IOL will trip and take the compres-sor off line on any combination of temperatureand current that exceeds motorwinding tolerances, even if neither thecurrent nortemperature alone are sufficientlyhigh enough themselves to tripthe IOL. This application gives it a highmargin of reliability.The IPR valve is mounted in closeproximity to the IOL. Should pressuredifferential between the discharge andsuction sides exceed 400-500 psi, thevalve will open and hot discharge gaswill be drawn acrossthe IOL. The hotgas plus the higher compressor currentwill cause the IOL to open, shuttingdown the compressor. With the IPRvalve, high pressure is instantly relievedin the compressor shell where no refrigerantloss is possible.In addition, the ClimatufV scroll supplementsthe IPR with axial and radialconformance and a TOD to eliminatehigh pressure stresses and protectagainst low suction-pressure oil returnproblems.Motor winding insulation erosion iscontrolled through two methods:1. Motor winding flex is minimizedby specifying an epoxy varnish systemwhich bonds the wires and bundlestogether.2. Abrasion resistance is achieved witha double coating of space age “imide”based overcoat.As good as the bonding system is,Trane motors are designed to pass atorturous surge test in which a 5800 voltspike is applied to the stator. Not onlydo obvious defects show up, but alsominor variations in winding insulationthickness are detected.ElectricalStressesWhen the compressor is operating, therecan be slight motion of the motor windyings created by magnetic flux betweenthe wires. This flexing causes rubbingbetween adjacent wires, which couldwear away the insulation. Bare wirescan create turn-to-turn shorts that leadto motorfailure. The magnetic forcesand flexing increase with current andare exceptionally severe during start-up17

Section IV -Shared FeaturesChemicalStressesCllmatuff’ compressors use a highly refInedwhite refrigerant oil with specialadditives for high and lowtemperaturestability and high pressure stability. Theoil has superior lubricity over a widerange oftemperatures. The solubility ofrefrigerant in this white oil blend is lessthan with pale oils used by other manufacturers.Lower solubility minimizesviolent oil foaming on start-up. This reducesoil loss and provides rapid establishmentof oil flow to the bearings.Some of the pale refrigerant oils used inthe industry tend to “coke” (carbonize)on the valves at high temperatures. Thiscoking action leads to loss of efficiencyand capacity that the owner will see asclimbing utility bills. Coking can eventuallylead to compressor failure as thevalve cannot seat properly with thecarbon build-up. ClimatufP’s hightemperature oil additive helps preventcoking.ServiceabilityIn addition to being very efficient and reliable,ClimatufPcompressors havesome beneficial service aspects.All Climatu~compressorsfeaturehighly reliable Rotolock mechanicalfittings. Rotolock fittings provide foreasy service and replacement becausethere is no brazing or cutting required.They eliminate the safety hazards thatcan exist when unbrazing a compressorwith a torch. In addition to ease of con-nection and safety, Rotolockfittingsminimize contaminants such as copperchips, welding slag, and other foreignmaterials because there is no brazinginvolved.All <strong>Climatuff</strong>’ compressors feature alifting lug welded to the shell to makelifting easier. Trane compressor engineersoriginally developed a one timeacid test kit for checking unsafe systemacid levels. By testing an oil samplefrom the suction port of a failed compressor,the serviceman can tell if heneeds to install a suction line drier.Using the acid test kit the servicemanknows ifa suction he drier IS needed.18

Section V -System Testing<strong>Climatuff</strong>a <strong>Compressor</strong>Heritage: RelentlessTesting .. .We are different because of our ownin-house expertise of compressorapplications and reliability testing.We reliability-test compressors in theactual matched units prior to production.SEETTested!Sixteen weeks in SEEI=five years ofsriess in rhefield. in this unique test,sysrem quahfy and Peruforma”&’ are measuredand managed.In addition to using industry standardapplication guidelines, we develop ourown tests based on field experienceand in-house testing. This has led tocontinuous application and designchanges and improvementsforTrane<strong>Climatuff</strong>’ compressors.All <strong>Climatuff</strong>’compressors are designedto tolerate most extreme applications -from Canada to Florida to Arizona. Areliable compressor designed for ex-Verne heat pump application must beable to overcome higher operating temperatures,liquid refrigerant flooding, adverseelectrical stresses, and the stressof long operating hours. Climatuf? compressorsare designed to handle thosetough conditions. All these featuresbenefit the air conditioning design asTrane uses the same rugged heat pumpdesigned compressor in its air conditionersas well.-‘in Trane’s compres- Scroll 500/100 High Pressuresor life test facility “Snowball” has bee” undergorng Mechanica, Stress Testthis test since 1972. The purpose of the test is fo demonstratethe reliability of <strong>Climatuff</strong>” compressor’s undercondifions iike low indoor airflow orsystem overcharge.Every Ciimatuff” compressor returned fromthe field is cut apart and anaiyred ro ide”~trt) possible failure trends so appropriatecorrective action can be imokmented.

Section V -System TestingAll critical components go through threetiers of testing: as a component, as thecompressor, and as a “system.” Forquality assurance, Climatuf? is testedand re-tested in Trane’s unique SystemExtreme Environmental Test Center(SEET). A multi~million dollar facility,SEET allows engineers to measure andmanage a system’s quality and performancewith a sixteen week torturoustest period in which five years of fieldstress can be duplicated. After each testperiod, each unit is disassembled and itscompressor is cut apart and analyzed.Engineers examine for signs of stressand unusual wear. No manufacturer inthe industry goes to these lengths toensure compressor and system quality.In addition to SEET (System ExtremeEnvironmental Test) testing, other partsof the ClimatufP compressor QualificationStandards process include:<strong>Climatuff</strong>@ Application TestdCriterOil Management* Loss of charge testing in coolingand low ambient heating* Long line/rise field tests designatedMotor Protection* MotorilOL protection includeslocked rotor, maximum load trip,stuck start relay. IOL cycle life confirmation on“Monitor” Stand* Motor temperature “mapping”on SEET- System evaporator and condenserfan failure criteriaMechanicalDurability. A S-mode accelerated Life Testincluding start/stop, high load,floodback, high pressure ratioand defrost simulation* Life Test charge tolerance* Shipping vibration and drop testSound Acceptability. System/compressor/fan db ratingsand “panel” acceptance* Transient sounds-shutdown.startup, defrost* Discharge gas pulse measurementMiscellaneousTesting* Low voltage startability* <strong>Compressor</strong> driven tubingvibration* Field testing at employee homesand selected extreme locations.Rise Application -20

Section VI -Manufacturingand Testing<strong>Climatuff</strong>‘ compressor standardsInclude matching the correctcompressortothe right outdoor productThe <strong>Climatuff</strong>e tradition continues!OutdoorTestingProduction

Section VII - <strong>Climatuff</strong>”<strong>Compressor</strong> Summary<strong>Compressor</strong>s ResultsAnd ConclusionsTrane’s ClimatufF compressors areamong the world’s foremost designbecause of the <strong>Climatuff</strong>‘ philosophy.Our compressors are designed to usea minimum of system protection; to“stand alone.” This is easy to say butdifficult to achieve. It requires a thornough understanding of the system -the Trane Way of Life!It requires innovative compressordesign-a Trane strength. It requiresaccelerated stress testing to pre-determinefield reliability in the laboratoryaTrane strength. It requires uniquein-process testing in both compressorassembly and unit manufacturing toassure the design quality is achievedon every single unit/compressor built -a Trane Strength!ClimatuW motor and protection systems(shared by reciprocating and scroll)are designed to protect the compressorunder all adverse operating conditions.<strong>Climatuff</strong>~~compressor’s epoxyvarnish bonding system preventsmotor winding flexing and servesas a good electrical insulator. The“lmide”-based wire insulation isalso highly resistent to high temperatures,chemicals and abrasion.<strong>Climatuff</strong>’ compressor’s InternalOverload protects against high current,high and low voltage, low gasflow, loss of charge, high superheatand system electrical faults.<strong>Climatuff</strong>’ compressor’s InternalProtection Relief valve provideshigh pressure protection.ClimatuF compressors are designedto tolerate liquid refrigerant. TheClimatuW reciprocating compressorsutilize a large shell, a discharge linein the oil, a high suction inlet and themotor windings to minimize liquidrefrigerant in the cylinder. The fullysupported ring valves have high toleranceto liquid.The Climatuf? scroll compressor usesconformance which allows the scrolls toseparate and pass liquid through withoutdamage.Both ClimatufV compressors utilize thecrankshaft as a built-in oil pump. TheClimatuW scroll’s positive pressure oilpump is used to quickly supply oil tobearings and scroll tip to ensure longlife and enhance pressure sealing.The <strong>Climatuff</strong>’ reciprocating compressor’scrankshaft doubles as a positive,non-directional, centrifugal oil pumpproviding a constant oil supply to thebearings when the compressor is run-“IrIg.The ClimatuW compressor’s uniquewhite oil blend maintains lubricity andviscosity at extreme conditions and preventsviolent oil foaming on start-up.The Climatuf? compressor’s rotolockfittings provide the base of connections,eliminate unbraring hazards, and minimizecontaminants.Because of the <strong>Climatuff</strong>’ compressor’sreliability, Trane was the first manufacturerto offer a lO-year warranty on thecompressor as part of its XL 1200 seriesof air conditioners and heat pumps. Designedfor durability, manufactured toprecise specifications and tested to extremes,<strong>Climatuff</strong>” compressors set theindustry standard for reliability, andquality-the Trane Way of Life!