Redhill EMAS 2006 - Biffa

Redhill EMAS 2006 - Biffa

Redhill EMAS 2006 - Biffa

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SITE SCHEMATIC04The schematic diagram illustrates the site operations and typicalenvironmental controls which are in place at <strong>Redhill</strong> Landfill Site tominimise its impact upon the environment.1 MONITORING BOREHOLESThe site is surrounded by a series of gas andgroundwater boreholes; that go to a maximum depthof 78 metres below ground level; Water QualityMonitoring Samples of groundwater and surfacewater are taken regularly from 18 fixed points andanalysed for a variety of parameters; Landfill GasMonitoring Regular monitoring of 139 samplingpoints (perimeter boreholes) is carried out formethane; carbon dioxide and oxygen;2 BASAL ENGINEERINGThe basal formation is constructed to an agreedprofile using engineered clay and synthetic materials;permanent leak detection systems are in place tomonitor the performance and integrity of the sitelining system;3 LANDFILL GAS CONTROL SYSTEMSA physical barrier comprising a plastic geomembranecoupled with engineered clay liner prevents off-sitemigration of landfill gas;4 CONTROL AND RECEPTION OF WASTEPrior to acceptance; wastes are assessed and receiveapproval references; At the Weighbridge; computerrecords are generated and then the loads aredirected for further inspection prior to final deposit;5 SITE MANAGEMENT OFFICEThe offices are also the South East Regional centrefor <strong>Biffa</strong>'s Landfill activity;6 WHEEL CLEANERRequired to ensure both site and public highway iskept free of mud debris;7 VISUAL INTRUSIONSoil bunds and tree screens are positioned to helplimit the visual impact of the site; Progressive cappingand restoration follows quickly behind landfilloperations;8 POWER GENERATION PLANTOur power generation engines provide electricity tothe local distribution network and our quarrydewatering system and site domestic use;9 LANDFILL GAS FLARESurplus gas is diverted to a ground flare to minimisegreenhouse gas escape and the emission of odours;10 RESTORATIONThe site is being continually restored; a plasticgeomembrane is installed to prevent landfill gasemissions to atmosphere and water infiltration;11 GAS EXTRACTION SYSTEMSLandfill gas is extracted from wells within the wastemass and pumped to the power generation plant orflare;12 LEACHATE CONTROLLeachate levels are monitored and controlled byextraction from wells within the waste mass;13 LEACHATE TREATMENT PLANTThe plant is designed to reduce ammonia levels withinthe Leachate prior to its discharge to the sewernetwork;14 WORKING AREAThe waste is placed and compacted in layers;normally achieving a density of 1 tonne per cubicmetre; each layer is covered to prevent wind blownmaterial and control of pests;15 WASTE DEGRADATION AND STABILISATIONThe deposited waste breaks down over time toproduce landfill gas (a mixture of gases mainlycomprising of methane and carbon dioxide) andLeachate (contaminated water).1213

SITE ENGINEERING05During 2004 the first engineered phase of <strong>Redhill</strong> 2 was completed.The composite design gives assurance and confidence that the engineeringspecification can operate to the required standard and duration.ENGINEERING SPECIFICATION<strong>Redhill</strong> 2 is classified as asub aquifer site as theengineered base is belowthe local groundwatertable. The engineeringschematic shown oppositeprovides a detailed crosssectionof the constructiondesign, each elementcarefully calculated tomeet the rigours of landfilloperations. The design of<strong>Redhill</strong> 2 is based uponrisk assessment, whetherEngineering,Hydrogeological, Stabilityor Habitat, each combinesto provide a compositedesign specificationcapable of meetingexpectations anddurability.12345678910The lower rock drains allow the free passage of groundwater below the basal profile, accumulating in thelower lagoon where three large pumps remove the water at over 1,000,000 gallons a day.Overlaying this is approximately 12 metres of consolidated infill material bringing the level up toformation datum.The formation profile is constructed to a gradient of 1:50 from South to North in order to promote themovement of leachate to a focal point whereby removal of the liquid may take place.Placed within the formation level, a second series of drains have been installed to allow the pumping andremoval of groundwater should the lower drains fail for any reason. Much smaller than the lower drains andincorporating polyethylene pipes to allow the insertion of pumping systems.Overlaying the formation level is a geotextile; this material is designed to protect the clay liner from intrusionby groundwater and promote the dispersal of the same away from the liner, into the sub-liner drains.A 1-metre thick clay layer is then placed over the geotextile, placed in discreet lifts and compacted and testedto a high specification.Placed on the basal profile are a series of sensors each able to detect minor breaches in the subsequent plasticliner. This arrangement is called a permanent leak detection system. Its purpose is to determine whether theengineering system is operating within the design parameters and monitor the overall performance of thespecification.A high-density polyethylene membrane (HDPE) is then placed over the entire engineered profile. Each seam iswelded and tested by various means to ensure its integrity and performance.To protect the HDPE membrane from damage caused by the landfill environment a geotextile protection layeris placed over the HDPE. Specification for this material is determined by replicating the pressure that thousandsof tonnes of waste would have if placed directly onto the plastic.Finally, a leachate drainage blanket is installed to a depth of 500mm over the base, consisting of clean nonangulargravel and accommodating a network of pipes, to allow the free passage of leachate to the lowestpoint of the waste cell and final removal from the cell.1415

THE ENVIRONMENTALMANAGEMENT SYSTEMCORPORATER ESPONSIBILITY POLICY06The formal implementation of our environmental systems ensures that issuesare dealt with effectively together with any wider environmental matters thatmay arise from the site. In addition, <strong>Biffa</strong> personnel are required to attendregular site meetings at which environmental issues are discussed, includingobjectives and targets.Our environmental credentials give confidence to thelocal community and regulating authorities that ouroperations and procedures are well-managed andmonitored for performance and improvement.There is a requirement within ISO14001 for anenvironmental policy statement. In the case of <strong>Biffa</strong>, thisneeds to reflect both site based and environmental issues.The <strong>Biffa</strong> policy recognises the importance we place onenvironmental issues and is brought to site level throughthe local environmental management systems beingimplemented at each landfill facility. In view of theimportance that <strong>Biffa</strong> places upon such systems, the entireLandfill division was awarded the ISO 14001accreditation in March 2004.The implementation of our Environmental ManagementSystems (EMS) has identified those significantenvironmental issues relevant to the Southeast landfillregion and <strong>Redhill</strong> landfill site and focused managementattention to control and improve our environmentalperformance. The operational activities at <strong>Redhill</strong> wereanalysed using information gathered during the planningphase of the landfill development, data from sitemonitoring and potential environmental risks associatedto the site and its locality. The operational activities aretabulated overleaf.The potential effects of these activities were assessed fora number of receptors, such as potential impacts uponland, surface water or air quality. This system takes intoaccount the frequency, potential severity and anymitigating control measures to establish a significantrating.These impacts are documented in the EnvironmentalAspects Register and are used to set environmentaltargets and objectives.The Aspects Register is reviewed on an annual basis. Thesite is audited internally every six months for complianceagainst pertinent legislation, PPC Permit and corporateenvironmental requirements. Following the Divisionaladoption of the ISO 14001systems, our Aspects Register,was revised to reflect that of the division. Due to theconsistency of the potential effects from each landfill site,a generic register is produced at regional level.<strong>Biffa</strong> is a leading integrated waste managementcompany with operations in the UK. We acknowledgeour responsibility to safeguard and positively contributeto the environment and communities within which weoperate.Our PrinciplesEveryone is responsible for their impacts upon ourenvironment. We believe in employee empowerment, theprevention of pollution and compliance with relevantlegislation and approved codes of practice. We will abideby our Code of Business Principles and Conduct. We willseek to ensure that all our activities are operated safelyand in line with our separate Health and Safety Policy.Our approach is based on the following values:• We will operate to the highest ethical and professionalstandards through fostering a style of managementbased on honesty, trust and integrity;• Respecting our employees whilst fostering a workingenvironment that will encourage employees tooperate to their full potential;• We have a responsibility to safeguard the communitiesand environment that come into contact with ouroperations;• We regularly monitor, audit and review our ownperformance to ensure continuous improvement;• We involve our employees on environmental issuesand raise awareness of their responsibilities under thelaw and this policy;• We will target our efforts to reduce our significantnegative environmental aspects by operatingcomprehensive Environmental and Compliance Systems.To ensure this policy is achieved, <strong>Biffa</strong> has anEnvironment, Quality, Health and Safety (EQHS)Directorate that is headed by a Board Director, with thenecessary responsibility, authority and resources toimplement the EQHS Management System.Our ContributionWe seek to minimise the impact of our operations andsociety's waste through the way we conduct our business,by promoting sustainable waste management practicesand by integrating the concept of sustainabledevelopment into our business activities.Reducing our ImpactsWe recognise that our large fleet of vehicles and thedistances they travel have a significant impact upon theenvironment. We therefore seek to use cleaner fuel andto minimise our consumption of the fuel we use to carryout our business.A by-product of the disposal to landfill of society's wasteis the generation of methane and carbon dioxide, whichare recognised greenhouse gases. Our contribution tomitigating the effects of Global Warming will be toincrease the proportion of landfill gas captured andthereby reduce greenhouse gas emissions.ProtectingWe believe staff awareness and robust managementsystems are key to our protection of the environment.EnhancingWe recognise that to be a truly responsible organisation,<strong>Biffa</strong> must contribute positively to society and theenvironment within which we operate.EmpowermentA positively motivated work force is essential to deliverour business goals, working in line with our Policy onPeople Values.Working with OthersWe recognise that to achieve our objectives and to makea positive contribution, we must work closely with thosewho contribute to; are affected by; or who influence ourown and society's activities.StakeholdersGovernment Policy influences both society's and thewaste industry's response to waste management. Webelieve it is therefore important to promoteunderstanding and stimulate debate at the highest levels.CommunitiesWe believe that openness and dialogue helps to promoteunderstanding and mutual respect between ourselves andthe communities in which we operate.Our Supply ChainWe acknowledge that our responsibility for our businessactivities extends through our supply chain, those fromwhich we purchase goods and services and to ourcustomers. We will therefore seek to encouragecommercial relationships with organisations that havestandards compatible with our own and strive to influenceour customers' behaviour.1617

SIGNIFICANTENVIRONMENTAL ASPECTSPERFORMANCE AGAINST OURTARGETS AND OBJECTIVES (2005/06)07Our environmental evaluations and analysis have shown the following issuesto be the most significant for <strong>Redhill</strong> landfill.OBJECTIVE 1To improve landfill gas capture efficiency.OBJECTIVE 2Improve community awareness.• The breakdown of wastes results in the production ofcontaminated water called leachate, which if itescapes it may affect groundwater or surface waterquality.• The breakdown of waste results in the generation oflandfill gas, of which methane, a greenhouse gas, is asignificant component. If landfill gas is not managed itcan lead to gas migration issues.• The landfilling of waste depletes the void available.• Energy is consumed during water and leachatemanagement and in the offices located on site.• The machinery used to landfill waste results in the useof non-renewable resources.• The landfilling of wastes can result in the generationof nuisance issues resulting in local air pollution if notmanaged.• The transport of waste and materials to and aroundthe site results in the use of non-renewable resourcesand vehicle emissions.• Waste is produced during plant and machinerycleaning and maintenance.• The handling of leachate can result in spray driftcausing odour and the possible dispersion ofcontaminants.• The impact of landfilling and operations could impactupon the biodiversity of the surrounding area.TargetMaintain gas capture efficiency The current gas captureefficiency at <strong>Redhill</strong> is 88.9% against the EA guidance of85%.Actions UndertakenThe installation of gas pin wells in cells 1 & 2 and alongexposed waste flanks and sensitive areas.Installation of gas extraction pipe work in the lowerwaste levels of Cell 3 (<strong>Redhill</strong> 2) not yet connected tosystem.TargetsTarget 1Produce a site newsletter.Actions UndertakenNewsletter has been produced biannually, withdistribution to local residents and authorities.Target 2Set up a visitor centre/education centre.<strong>Redhill</strong> shall act as an education and visitors centre for;schools, residents, businesses and other interested parties.Providing information and education on issues such as:recycling, waste management, diversification and otheralternative technologies.In order to address these identified significant aspects,each year we set ourselves objectives and targets. Theseobjectives are achieved through an action plan wheretime scales and responsible persons are clearly defined.A large number of significant aspects are addressed viaour adherence to established company procedures wheremaintenance of awareness and training of personnel arekey factors.The objectives mentioned above are typically set forthose aspects, which require additional work beyond ournormal practices. They tend to be focused on areas,which have, or are perceived to have, a direct impact onour local environment. Achievement of the action plans isan important facet of our continual advancement andstriving for better procedures and techniques.A summary of our achievements in 2005/06 is set outopposite. The environmental action plan and progressagainst the objectives are reviewed at the 2005/06Management Business review programme.All actions are the responsibility of the sitemanagement team.Actions UndertakenWe are in the process of developing our educationalfacilities, providing information boards at the view pointand improving access from our office across the restoredarea to the viewing platform. In addition we are activelyliaising with our contacts within the Local EducationAuthority.Target 3Increase the number of educational visits to <strong>Redhill</strong>Landfill Site.Actions Undertaken410 children from the local area have attended visits tothe site since the new year began as part of their Ready,Steady, Recycle project. A party has also visited us fromthe University of the Third Age.1819

PERFORMANCE AGAINST OURTARGETS AND OBJECTIVES (2005/06)OBJECTIVE 3OBJECTIVE 4OBJECTIVE 5Increase recycling/minimisation of wasteproduced on siteTargetsGenerate a register of all waste produced at the site byApril 2004.Increase recycling of site produced waste by 20% (fromprevious year).Actions UndertakenA waste register was compiled in March 2005.Each department or individuals working at <strong>Redhill</strong> Landfillsite office were requested to produce a summary ofwaste produced, categorised as waste paper, foodstuffsand ink cartridges. Approximately 75% of waste paper isrecycled the remaining 25% is unsuitable for recycling.Only a small amount of food waste is produced at site,which has now been added to the recently installedoffice ‘wormery’. Used ink cartridges are stored in theoffice reception and sent from site for recycling. The mainarea for improvement for office recycling lies in wastepaper reuse where possible before it is sent for recycling.Pest ControlTargetsTarget 1Introduce pest control management plan:Target 2Reduce pest related complaints: The implementation ofthe above measures (target 1) has seen pest relatedcomplaints drop to almost nil.Actions UndertakenPest control is an ongoing item and falls in to threemain areas.Bird Control: This is achieved by using birds of prey tocontrol the number of birds on site at anyone time and isa seven days a week year round activity.Fly control and Vermin: Spraying using environmentallyfriendly products takes place between April and Octoberand between the months of November and March asand when needed.Site specificTargetsTarget 1Introduce leachate management plan: The leachatemanagement plan shall include all relevant PPC permitconditions, BAT, Freds Head (internal best practiceguidance), and site-specific initiatives designed to improvethe holistic management of leachate on site.Target 2Commission leachate treatment plant by December 2005:The leachate treatment plant (LTP) contains two sequencebatch reactors, one for each of the permitted sites at<strong>Redhill</strong>. Each will operate independently of the other,<strong>Redhill</strong> 1 (South West area), will treat leachate to bedisposed from site into the local sewer network, <strong>Redhill</strong> 2,will treat leachate allowing either dispersal from site orrecirculation back into site pursuant to the bio flushingreactor principle.Implementation of the above action plan is theresponsibility of the Site Manager, Operations Managerand Environmental Control Assistant.Actions UndertakenDue to problems associated with the proposed route ofthe discharge pipeline a new route had to be found andplanning permission for this route has now been obtainedafter consultations with the Planning Authority, TheEnvironment Agency and other interested parties. Thisshould now enable us to have a fully compliant leachatemanagement plan in place and a treatment plant readyfor operation by the end of July <strong>2006</strong>.Targets and Objectives (<strong>2006</strong>/07)Objective Target Target DateImprove Gas Capture Efficiency • Maintain gas collection efficiency at 85% December <strong>2006</strong>Surface Water Management • Produce Surface Water Management Plan July 2007Electricity and Water Consumption • Review Current Usage for the Calendar Year 2005 March 2007• Produce Management Plan to reduce consumptionon a year on year basis going forward March 2007Odour Management • Produce Odour Management Plan March 2007• Zero OPRA/CCS Scores November 20072021

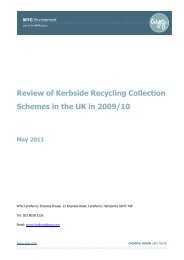

DISCUSSION OFENVIRONMENTAL ISSUES<strong>Redhill</strong> landfill site is governed by two PPC Permits and isessentially made up of two sites. The original site knownas <strong>Redhill</strong> 1 is a dilute and disperse site with minimalengineering whilst the new site is a fully contained site,with permanent leak detection monitoring, known as<strong>Redhill</strong> 2. <strong>Redhill</strong> 1 operates under PPC Permit BV2263whilst <strong>Redhill</strong> 2 operates under PPC Permit BU8126.It is a requirement of our PPC Permits that all potentialfugitive emissions from the site are regularly monitored toensure we are not polluting the environment. This sectionof the report presents a summation of our monitoringdata and compares our most recent results with previousdata. This allows us to gauge the sites performanceacross the years and structure any improvements thatmay have been overlooked.LeachateLeachate is the contaminated water, which is generatedwhen rainwater comes into contact with decomposingwastes. The <strong>Redhill</strong> 1 permit dictates that the height ofaccumulated leachate, known as leachate levels, at thebase of the site should be no more than two metres andin the <strong>Redhill</strong> 2 site no more than one metre. In order tokeep the level of leachate below these consented levels,a leachate management plan agreed with theEnvironment Agency is in place. Any leachate that isproduced is collected and pumped for re-circulation intofresh waste. This practice encourages the breakdown andstabilisation of the waste mass and the increased landfillgas produced is captured and utilised by the site.Both PPC Permits require <strong>Biffa</strong>, as the operator, to provethat leachate is not contaminating groundwater orsurrounding surface waters. In addition to our normalmonthly monitoring of specified determinants, each yearwe undertake extensive monitoring and analysis to searchfor particular contaminants within our leachate and alsowithin our groundwater.Our PPC permit contains a condition that allows fortreatment of leachate other than recirculation andirrigation on site. In order to meet this condition aleachate treatment plant has been constructed to theNorth West of the site, that is in close proximity to thepower generation compound. The main purpose of theplant is to reduce ammoniacal nitrogen (ammonia) to alevel below the discharge consent criteria. This is achievedby use of aerobic nitrifying bacteria, which convertammonia via nitrite into nitrate. The waste heat from thepower generation plant is used to increase the efficiencyof the process, hence the close proximity of the treatmentplant to the power generation compound.Both PPC permits require us to deal with the treatedleachate in different ways. The permit for <strong>Redhill</strong> 1requires the treated liquid to be removed from site bycontrolled disposal into the local sewerage network; whistthe permit for <strong>Redhill</strong> 2 allows treatment and recirculationwithin the waste mass before disposal from site.Following the redesign of <strong>Redhill</strong> 2 and implementation ofthe site permit, the proposal to operate a test cell(flushing bioreactor) was agreed with the EnvironmentAgency. The objective of the test cell was to determinethe optimum recirculation rate for improving the pace ofstabilisation of the waste and reduction of thecontaminant inventory of the liquid. The leachatetreatment plant needs to be fully commissioned beforethe leachate can be treated and removed.The concept requires leachate abstraction and treatmentto reduces the ammoniacal nitrogen prior to recirculationback into the waste mass. Continual saturation of thewaste accelerates the degradation process and thereforewaste mass stability. This means that gas is produced atan earlier stage and in greater quantity promoting earliersettlement within the landfill, thus reducing the longerterm liability of the site.GroundwaterThere are nineteen groundwater boreholes around thesite that are regularly monitored at two different levels tocomply with the additional requirements specified withinour PPC Permit. A further 18 boreholes were drilled in thesummer of 2005 and as yet they have no trigger levelallocated to them. They will be monitored in accordancewith the PPC requirements and discussed in the next<strong>EMAS</strong> statement.The main parameters that the PPC Permits require us tomonitor for on a regular basis are: - AmmoniacalNitrogen, Chloride, Nickel, Potassium, Cadmium,Mecoprop and Tributylin Tin Oxide. On pages 26 and 27are a series of graphs showing the quality results of thesamples taken during the last reporting period.Mecoprop - a selective, hormone-type phenoxyherbicide, has to be monitored annually and thereforethis data has not been presented graphically. The sampleresults indicate that three boreholes breached theirtrigger limits and this will continue to be monitored.Tributylin Tin Oxide/Tributyltin compounds are asubgroup of the Trialkyl Organotin family of compounds,they are the main active ingredients in biocides used tocontrol a broad spectrum of organisms. These also haveto be monitored annually and the sample results haveshown that all monitoring points have remained compliantduring the last year.The results of our monitoring data continue to beevaluated and submitted to the Environment Agency on amonthly basis. Groundwater quality has remainedrelatively consistent throughout the last year,demonstrating that the groundwater quality around thesite has not deteriorated.It can be seen in the graphs (pages 26 and 27) that:• Borehole H98/GWB/23 has breached AmmoniacalNitrogen levels in this period. Since the installation of anew purging system these levels have reduced and willcontinue to be assessed.Although levels of Ammoniacal Nitrogen and othercontaminates are high along the Eastern boundary it isimportant to note that these boreholes are locactedupstream of our landfill site. Groundwater flow throughthe local area is from the East to the West and thereforewe are unable to manage these high levels as theborehole situated along this Eastern boundary aresituated prior to any influence from our site.The trend data over the last five years indicates that threeboreholes have shown significant breaches. BoreholeH90/8 and H98/GWA/64.0 have shown a trend inincreasing levels over the last two years. These boreholessit on the Eastern boundary and are both upstream ofany influence from the site. Borehole H90/1 Deepbreached Ammoniacal Nitrogen levels in 2003/04 buthas returned to compliance again in 2005/06.2223

LANDFILL GASSurface waterSurface water is managed on site by a series of ditcheschannelling the water. <strong>Redhill</strong> landfill site has twodischarge points; one is for surface water discharge, fromthe lagoon discharge point and any spillage from thewheel wash unit; and the other is for groundwater that iscontinually pumped from within the quarry, the quarrydischarge point.The quarry discharge has not breached any of its triggerlimits throughout the last period; this could be attributedto the de-silting program, which was completed in thesummer of 2005.The lagoon discharge point breached its suspended solidstrigger limit once in December 2005; this is probably dueto the intermittent flow from the lagoon. The lagoonsampling point is dry for most of the year; thereforethere is a limited amount of available analysis data. Theonset of winter and increased rainfall tends to loosen anyconsolidated material, which has settled in the dischargepipe. This lagoon has been de-silted which has alleviatedthe problem.All of the contaminants monitored have remained fairlyconstant throughout the last two years although someseasonal changes can be noted. The lagoon dischargepoint has a limited data set with the majority of resultsbeing taken in the winter.Landfill gas is a by-product of the natural degradationprocess of organic waste within landfill. Landfill gas ismade up of methane (CH 4 ) and carbon dioxide (C0 2 );both are significant greenhouse gases, which contributeto climate change. If these emissions were not strictlycontrolled through our operations, there would be asignificant increase emitted directly to the atmosphere.The landfill site perimeter is surrounded by monitoringgas boreholes designed to locate breaches of the gascontainment system and therefore migration. Theseboreholes are regularly monitored by our environmentalteam and reported to the Environment Agency. Boreholesare also drilled within the waste itself to extract the gasdirectly as it is produced.These boreholes are monitored and balanced to ensureoptimum gas capture for combustion in either gasengines or landfill flares. Gas odour is also monitored todetect any leaking pipe work.During the last reporting period 1,740 measurementswere taken of which 28 were in breach. A number of thebreaches are associated to the low trigger parameteroutlined for carbon dioxide which has a trigger level of1.5% by volume. Many of the gas boreholes breachedthis trigger by less than 0.3% which is insignificant.This figure may rise next year as some of the triggerlevels for the Eastern boundary of the site have not beenagreed by the Environment Agency as we are unable tocontrol gas migrating from sources beyond our control.In last years report we discussed the requirement ofdrilling new gas boreholes along the Northern boundaryof the site. These were originally scheduled to be drilledin Summer 2004 but due to technical difficulties and thearea being vulnerable to flooding the decision was takento postpone the works until Summer 2005, which is whenthe works were undertaken.2425

CHARTSQuarry Discharge Lagoon Discharge Averages 2005/06pHQuarry dischargepH Quarry DischargepHLagoon dischargepH Lagoon DischargeChlorideAverages for 2005/06Chloride Averages for 04.05 - 04.06NickelAverages for 2005/06Nikel Averages 04.05 - 04.06pH1614121086420Jun-05Jul-05Aug-05Sep-05Oct-05Nov-05DateDec-05Jan-06Feb-06Mar-06Apr-06May-06Upper PermittedTrigger LimitLower PermittedTrigger LimitpHpH1614121086420Jun-05Jul-05Aug-05Sep-05Oct-05Nov-05DateDec-05Jan-06Feb-06Mar-06Apr-06May-06Upper PermittedTrigger LimitLower PermittedTrigger LimitpHChloride Concentrations mg/l800.00700.00600.00500.00400.00300.00200.00100.000.00H90/1 DeepH90/3 DeepH90/1 ShallowH90/2 DeepH90/4 DeepH90/3 ShallowH90/4 ShallowH90/2 ShallowH96/5BH90/6 DeepH90/7H90/8H98/GWB/23H98/GWA/60H98/GWB/20H98/GWC/85H98/GWC/30AverageChloride mg/lTriggerLimit mg/lNikel Concentrations mg/l0.160.140.120.100.080.060.040.020.00H90/1 DeepH90/3 DeepH90/1 ShallowH90/2 DeepH90/4 DeepH90/3 ShallowH90/4 ShallowH90/2 ShallowH96/5BH90/6 DeepH90/7H90/8H98/GWB/23H98/GWA/60H98/GWB/20H98/GWC/85H98/GWC/30AverageNikel mg/lTriggerLimit mg/lBoreholeBoreholeSuspended SolidsQuarry dischargeSuspended Solids mg/l302520151050Suspended Solids Quarry DischargeJun-05Jul-05Aug-05Sep-05Oct-05Nov-05Dec-05Jan-06Feb-06ChlorideQuarry dischargeDateChloride Quarry DischargeMar-06Apr-06May-06PermittedTrigger LimitSuspendedSolids mg/lSuspended SolidsLagoon dischargeSuspended Solids mg/l100806040200Jun-05Jul-05Aug-05Suspended Solids Lagoon DischargeSep-05Oct-05Nov-05DateDec-05Jan-06ChlorideChloride Lagoon DischargeLagoon dischargeFeb-06Mar-06Apr-06May-06Trigger LimitSuspendedSolidsAmmoniacal NitrogenConcentrations mg/lAmmoniacal NitrogenAverages for 2005/064.504.003.503.002.502.001.501.000.500.00H90/1 DeepH90/3 DeepH90/1 ShallowH90/2 DeepAmmoniacal Nitrogen Average 04.05 - 04.06H90/4 DeepH90/3 ShallowH90/4 ShallowH90/2 ShallowH96/5BH90/6 DeepBoreholeH90/7H90/8H98/GWB/23H98/GWA/60H98/GWB/20H98/GWC/85H98/GWC/30AverageAmmoniacalNitrogen mg/lTriggerLimit mg/lCadmium Concentrations mg/lCadmiumAverages for 2005/060.035000.030000.025000.020000.015000.010000.005000.00000H90/1 DeepH90/3 DeepH90/1 ShallowH90/2 DeepH90/4 DeepCadmium Averages 04.05 - 04.06H90/3 ShallowH90/4 ShallowH90/2 ShallowH96/5BH90/6 DeepBoreholeH90/7H90/8H98/GWB/23H98/GWA/60H98/GWB/20H98/GWC/85H98/GWC/30AverageCadmiumLevels mg/lTriggerLimitChloride Concentrationsmg/l160140120100806040200Jun-05Jul-05Aug-05Sep-05Oct-05Oil and GreaseQuarry dischargeNov-05DateDec-05Jan-06Oil and Grease Quarry DischargeFeb-06Mar-06Apr-06May-06PermittedTrigger LimitChlorideConcentrationsmg/lChloride Concentrationsmg/l160140120100806040200Jun-05Jul-05Aug-05Sep-05Oct-05Oil and GreaseLagoon dischargeNov-05DateDec-05Jan-06Oil and Grease Lagoon DischargeFeb-06Mar-06Apr-06May-06Trigger LimitChloridePotassium Concentrations mg/lPotassiumAverages for 2005/0618.0016.0014.0012.0010.008.006.004.002.000.00Potassium Average 04.05 - 04.06H90/1 DeepH90/3 DeepH90/1 ShallowH90/2 DeepH90/4 DeepH90/3 ShallowH90/4 ShallowH90/2 ShallowH96/5BH90/6 DeepH90/7H90/8H98/GWB/23H98/GWA/60H98/GWB/20H98/GWC/85H98/GWC/30AveragePotassium Levels mg/lTriggerLimit mg/l2525BoreholeOil and Grease mg/l20151050Suspended Solids Quarry DischargeUpper PermittedTrigger LimitOil andGrease mg/lOil and Grease mg/l20151050Suspended Solids Quarry DischargeUpper PermittedTrigger LimitOil andGrease mg/lJun-05Jul-05Aug-05Sep-05Oct-05Nov-05Dec-05DateJan-06Feb-06Mar-06Apr-06May-06Jun-05Jul-05Aug-05Sep-05Oct-05Nov-05Dec-05DateJan-06Feb-06Mar-06Apr-06May-06Note: The data shown above is plotted against the hydrological risk assesment for the site.2627

METHANE UTILISATIONThe programme of extending the landfill gas collectionsystem has continued throughout the year. The system hasbeen installed to prevent potential landfill gas migrationfrom the site and also enables methane to be utilised forthe production of renewable electricity or burned byflaring. The ratio of methane utilised, flared or vented hasbeen calculated by utilising the Gas Sim Model (thepreferred Environment Agency tool).In June 2004 the percentage for overall gas capture ratefor the site had reached 71.6% of the total gasproduction from the location. The latest figures publishedin March <strong>2006</strong> show increases in gas capture of 17.3%bringing the overall gas capture for the site to 88.9%.The production of landfill gas is dependent on a numberof factors:• Area of landfill site that is active, restored and tonnageof waste deposited in each area;• Calorific value of waste deposited (i.e. its potential toproduce methane);• Tonnage of waste deposited each year.Methane production within the landfill peaks atapproximately 10 years and some areas of the siteproduce less methane than others, possibly due to alower calorific value of waste in that area, or as a resultof high inputs of non-biodegradable waste such as soils.The important point to note is that gas capture hasincreased overall and the amount of gas vented intoatmosphere has decreased significantly. Methane (CH 4 )and carbon dioxide (CO 2) are the two most significantgreenhouse gases and if left to vent to atmospherecontribute to global warming, but if captured, the landfillgas can be burned to produce valuable renewableenergy. The reduction in methane utilised in 2004/05compared to the previous year is either due to reliabilityof the gas engines, i.e. service down time, or depletingproduction in the gas field.The amount of gas flared has risen dramatically incomparison to previous years, this is a result of aproactive approach to gas control and the introduction ofcomprehensive extraction measures, in conjunction withour specialist Environmental Technology team who workclosely with site management. The table below alsohighlights the potential for additional gas generationengines operating on site. The value of producingrenewable energy from gas and reducing the UK’sreliance on electricity produced from fossil fuel is welldocumented and therefore a priority for the company.Our ability to generate and export further renewableelectricity has been boosted by a successful planningapplication to install a further three gas engines andthese are expected to come online during late <strong>2006</strong>/early 2007. Once operational the total available outputfrom the site will rise to six megawatts doubling ourcurrent export capacity.The three new engines will be dedicated to capturing gasfrom <strong>Redhill</strong> 2 and will be sited in a new gas compoundarea. This will enable a full redesign of our current flaringsystem to enable us to meet best practice. The new flareunits are able to burn gas at 1,200 degrees Celsius andhave combustion duration of 0.3 seconds, thus minimisingpotential pollutants to atmosphere.In the past we have explored alternative methods ofexporting power from site.We envisaged that this could be brought into effect byexporting power to other receptors, or indeed, by theexport of landfill gas, either by road tanker or pipeddirect to other power generation plants. We have lookedat many options in an effort to upgrade the presentsituation and with this in mind our colleagues in theEnvironmental Technology department are progressingwith the concept of creating a new connection into thenational grid, but to a receptor at the opposite end ofthe site, some 3-4 kilometres distant from the powerplant. There are many advantages to generating powerfrom landfill gas, as broadly speaking every 1,000 KWhof energy generated by landfill gas offsets 1,015 KWh ofenergy generated from fossil fuel power stations.At <strong>Redhill</strong> the site has been rewired to maximise the useof on-site generated power, within the confines andconstraints of the two Non Fossil Fuel Obligation (NFFO)contracts. By using site generated power and maximisinggenerator availability, the most efficient use of electricityoccurs, with distribution losses voided, which areestimated at 5.0%.Table OneTable TwoElectricity (MWh) 2005/06 - <strong>Redhill</strong> 1Electricity (MWh) 2005/06 - <strong>Redhill</strong> 2Exported 14941Exported 7275Imported 21Imported 53Supplied to site 0Supplied to site 7482829

NATURAL RESOURCESThe predominant raw non-renewable resources used on the site are:oil, water and electricity. Consumption figures for 2005/06 are:Oil: 287,380 litres Water: 2,557 m 3Water UsageWater meter readings have remained high during theperiod 2005–<strong>2006</strong>. This is again an increase on theprevious reporting period.There are two reasons for the increase in usage.Firstly the consequence of operating the Odour Controlsystem has undoubtedly lead to an increase in waterusage. This type of equipment is used to negate theeffects of odour permeating from the site and causing anuisance to our neighbours. Therefore, we must attemptto balance the operational demand on water usageagainst the potential for causing a nuisance to ourimmediate neighbours. The odour control equipment inplace at <strong>Redhill</strong> allows us the option of restricting the flowof the system. This is achieved by selecting which points ofthe compass are considered the most sensitive and settingthe system to operate automatically when the wind isleast favourable. We also have the option to operate thesystem on a pulse setting that remains effective butreduces the demand on water supply. We will continue tomonitor water usage and liaise with the supplierregarding the results.Secondly; changes to operational practices brought aboutby increasing legislation, have tended to have a negativeimpact upon water consumption.In the coming months we will be investigating greater useof the naturally occurring water sources on the site to seeif these can be utilised to lower imported waterconsumption.Gas Oil UsageGas oil usage is also on the rise and this can beattributed to changing operational practices, such as ourclients utilising bigger vehicles to bring waste on to thesite. This in turn means we need larger compactors andother plant to enable us to efficiently and safely dealwith these larger loads.The benefits of employing larger machines far outweighsthe extra fuel consumed, in terms of customer satisfaction,where operating standards have improved and not least,better waste compaction and therefore a saving inlandfill void space.Electricity UsageAs part of the redesign of the lower quarry access andpumping configuration, two electric pumps werecompletely decommissioned and following refurbishmentof the remainder only two are now required onpermanent duty. This leaves two on standby with adownward trend in electricity consumption.In the future there will be an increasing demand forelectricity as additional phases of <strong>Redhill</strong> 2 becomeoperational. We will however endeavour to utilise energyefficient measures to control future consumption ofelectricity.3031

BIODIVERSITY &RESTORATIONBiodiversity is described in the Government's UK Biodiversity Action Plan as“the variety of life forms that we see around us. It encompasses the wholerange of mammals, birds, reptiles, amphibians, fish, insects and otherinvertebrates, plants, fungi and micro-organisms”. During 2002, as an initialpilot, we assessed the biodiversity of <strong>Redhill</strong> landfill site. From this assessmentwe established a formal Biodiversity Action Plan (BAP) to manage thebiodiversity of the site.Over the past five years the majority of <strong>Redhill</strong> 1 hascome to completion and it’s attained final restorationprofiles. These areas have now entered into formalaftercare status.At <strong>Redhill</strong> the completed areas of the site are used forthe grazing of livestock and the collection of a crop ofhay in early summer. Tree planting is something that wetake very seriously, over the past five years in excess offive thousand trees have been planted at variouslocations throughout the site. Species of tree and shrubare selected to be sympathetic to the locality.The redesign of <strong>Redhill</strong> 2 following the approval ofplanning application in 1998 necessitated the creation ofa soil embankment around the Northern extent of thesite. Construction of the embankment took place withinthe flood plain area and therefore compensationmeasures were necessary. Two locations were identifiedas suitable and with sufficient area to compensate for theloss of flood plain. Firstly a small area immediately to theNorth of the embankment was chosen as compensationarea 1, followed by a larger off site area 2. The latter iswithin our ownership yet outside of our normal area ofoperations on a site used primarily for grazing livestock.The chosen areas were reduced in height by the removalof topsoil, which was placed in a temporary stockpile,allowing the lower subsoil to be relocated outside of theflood plain, and then the topsoil was replaced to create abowl effect for the collection and storage of water.The affected areas when completed were sown with agrass meadow seed type, again sympathetic to the area.Our new surface water lagoon continues to develop andattract wildlife, as the harsh contours of construction areeroded by the colonisation of aquatic plants andanimal life.Situated to the extreme North East of <strong>Redhill</strong> landfill is thesite orchard, here are grown many different varieties ofapples and some that originated locally in Surrey.Planting of the orchard was funded by <strong>Biffa</strong> but cared forby local volunteers, who diligently tend the trees year onyear and hopefully enjoy the fruits of their labours beforethe least scrupulous members of the community get tothe crop.3233

EXTERNAL RELATIONS08<strong>Redhill</strong> Landfill Site's local liaison group continues to meet on a regular basis.The meetings, which are open to all, provide a forum for the review ofoperations and a discussion of local issues. We hope that the meetings willcontinue to help develop positive links with the local community, where livelydebate about national and local waste issues can be made and help createan open platform for locals to communicate their concerns or fears aboutour activities.To continue this theme, we have produced a sitenewsletter which is printed every six months andcirculated to local residents and parish councils. The aim isto provide an informal link with the local community andprovide an up-to-date bulletin on site activities andgeneral matters. Not forgetting an invitation to localresidents to take the opportunity to visit the site.During 2005/06, we received three complaints; this figureis down on last year. This years issues have been: twoodour complaints and one report of a hawk killing a birdin a neighboring garden. Regarding odour problems,extensive monitoring and the introduction of newtechniques has facilitated our understanding of gasproduction and emissions. Exposed areas of waste arenow installed with gas scavenger collection pipes andwaste flanks are post drilled to a shallow depth so thatgas extraction pipes capture potentially fugitive emissions.We have also installed a new weather station that is setup to warn the site staff in the event that wind strengthand or the prevailing direction is towards an area ofpopulation. This will enable us to double check that thede-odorising system is in operation during any at riskperiods.The policy of progressively capping and restoringcompleted waste cells and applying positive gasextraction at the earliest opportunity is one of the bestmethods of dealing with the problem of landfill gasodour. De-odourising systems have a part to play in theoverall odour control scheme and at <strong>Redhill</strong> these type ofsystems are in use at the most sensitive points around thesite. We also conduct a thorough programme for thetreatment of flies, currently the operational cells aresprayed to control fly infestation on a twice weekly basisand more frequent during the summer months, thisactivity is carried out after the daily closure of the siteand within favourable weather conditions.When investigating the bird kill incident we checked theFalconers log and found that none of our birds werebeing flown off or near the property at the time of thereported incident. We can only surmise that the hawkcarrying out the attack was a wild bird not under ourcontrol.We also received a report from one of our neighbourswho expressed a concern as to the safety of a treebordering their property. As a result of this report wehave inspected all of the trees on the South Easternboundary of the site and have instigated a rollingprogramme of both inspection and care of all trees withinour site.All complaints received during the year were immediatelyinvestigated in accordance with company procedures andprotocols. Each complaint was dealt with sympatheticallyand measures taken to reduce the sites impact on thelocal community.In order to enable us to act swiftly to any concerns wehave introduced an e-mail address specifically dedicatedto concerns and complaints. The introduction of this willenable us to instantly react to issues such as odourcomplaints and other matters which demand immediateattention and rectification.Due to engineering works scheduled for the summer of <strong>2006</strong>we will be unable to hold a site open day. We howeverintend to hold one during 2007.The Marsh Project, which we have detailed in previousstatements continues to flourish under the watchful eye ofSurrey County Council environmental enhancement officer.The Landfill Tax funded <strong>Biffa</strong>ward scheme renovated theflood plain habitat area immediately to the North of the site.The project was undertaken in conjunction with aneighbouring mineral operator, Surrey County Council, theEnvironment Agency and the Wildlife Trust. The NationalCycle route crosses the Northern most extreme of the site.Completed last summer, this section of the cycle route makesthe connection between <strong>Redhill</strong> and Cormongers Lane to theEast.School and other visitsAs mentioned earlier in the report school trips are on theincrease and below are some comments made by LouiseMiller our educational contact, who co-ordinates theeducational visits to the site;“Over the last 4 years, <strong>Redhill</strong> landfill site has been aninvaluable partner in our project to support local schools inrecycling education. The children taking part in “Ready,Steady, Recycle” have the chance to do lots of activities to putacross waste minimisation messages, but the greatest impact isalways made by seeing the scale of the problem, first-hand.In the last year 410 pupils have visited as part of our project.However it's not just the pupils that get the recycling message.Several years after their visit, parents of the children who havevisited the site will be proud to tell me about the changes theyhave made to create less rubbish going to landfill.”Louise Miller, Education Manager, Gatton Park EducationOur external relations policy and in particular our policy ofopenly encouraging organised visits to the site resulted in agroup from the University of the Third Age visiting the site inApril <strong>2006</strong>. The chairperson of this organisation sent to us aletter of thanks that contained the following quote.“All too often we hear of people objecting to waste sites,without we now realise, knowing what they are talking about. Itwas so rewarding to see just how comprehensively the <strong>Biffa</strong>site at <strong>Redhill</strong> is planned and managed and I am sure that theinformation gained by us will be passed on endlessly.”Anne Workman. 05/04/06The letter from Louise Miller and the quote from AnneWorkman's letter of thanks are both testament andjustification of the external relations policy of <strong>Biffa</strong> <strong>Redhill</strong>.3435

09THE FUTUR EDuring the course of recent years the waste industry has undergoneand implemented profound changes to the way landfill sites areoperated and monitored.We are greatly influenced by legislation originating fromEurope, the EU Landfill Directive is designed to improvethe operational and technical standards of landfillingwaste, prevent or reduce, as far as possible negativeaffects on the environment. The first alteration to ouroperational practices occurred in July 2002, when the banon the disposal of certain waste to landfill, such as itemscontaining Ozone Depleting Substances (ODS), Corrosiveor Flammable materials commenced. Whole tyres arealso prohibited from landfill and shredded tyres will followsoon in <strong>2006</strong>.We are however, continuing negotiations with a locallandowner to develop a 'pre-treatment' plant onCopyhold works adjacent to the site. The development willconsist of a materials recovery facility whereby all itemsthat have a reusable value will be removed from thewaste and recycled for future use. The remaining materialthat has no further use would then be transported to theactive landfill for disposal.One source of energy not yet utilised is heat generatedby the gas engines. We have mentioned that this energysource will be used to provide heat within the leachatetreatment process, yet a surplus remains for use elsewhereshould the right application present itself. A number ofparties have shown interest but as yet this has not evolvedinto any active projects. With three further gas-generatingengines due to come on line by the end of <strong>2006</strong> we areactively seeking local bodies that can utilise the heat ourgas engines generate.3637

MANAGEMENT SYSTEMThe site has an Environmental Management System and its environmentalperformance is reported to the public in accordance with the EuropeanCommunity Eco-Management and Audit Scheme.For further information, please contact:Site Manager, <strong>Biffa</strong> Waste Services Ltd, <strong>Redhill</strong> Landfill, Cormongers Lane, <strong>Redhill</strong>, RH1 4ER.Telephone (0)1737 765 122Fax (0)1737 765 042Website: www.biffa.co.ukTHIS STATEMENT HAS BEEN PRODUCED IN ACCORDANCE WITH THE ENVIRONMENTAL ANALYSIS ANDDOCUMENTATION REQUIREMENTS OF THE EUROPEAN COMMUNITY ECO-MANAGEMENT AND AUDITSCHEMENext interim verification due November 2007VARIFICATION DECLARATION “SGS United Kingdom Limited (accreditation No, UK-V-0007), as appointed verifiers to<strong>Biffa</strong> Waste Services Ltd, further to consideration of the documentation, data and information resulting from thecompany's internal procedures examined during the verification process, it is evident that environmental policy,programme, management system review (or audit procedure) and environmental statement meet the requirements ofRegulation 761/01 (the <strong>EMAS</strong> Regulation).”Signed _______________________________________________________________________________________4th October <strong>2006</strong>VALIDATED INFORMATIONREG. N0. UK-S 0000019SGS United Kingdom LtdRossmore Business ParkEllesmere PortSouth WirralEnglandCH65 3EN38